Introduction

This article provides comprehensive information about the blow molding process and its raw materials. Continue reading to learn more.

- Overview of blow molding

- History of blow molding

- The blow molding process

- And much more…

Chapter One – What is an overview of blow molding?

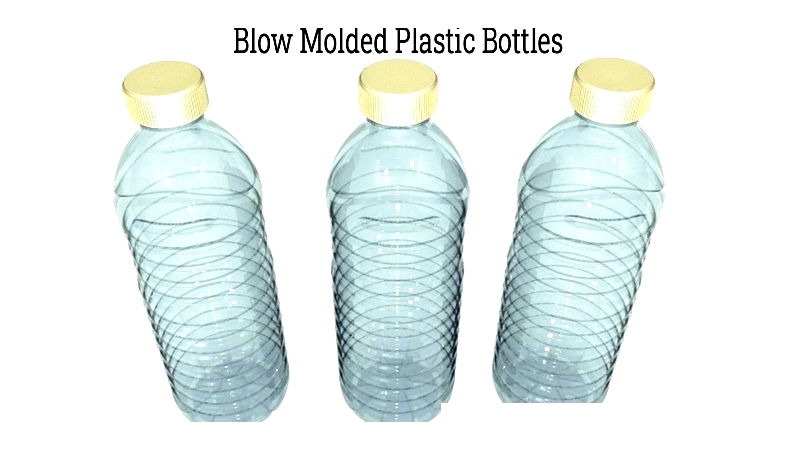

Blow molding is a manufacturing technique used to create hollow plastic products from thermoplastic materials. The process starts by heating a plastic tube called a parison or preform, which is then inflated inside a mold. The parison is placed between two mold halves that define the final product's shape. Compressed air expands the tube, forcing the plastic to stretch and conform to the mold's contours. After molding, the product is cooled, removed from the mold, trimmed, and prepared for any additional processing steps.

Blow molding is primarily used in bottling and packaging, accounting for nearly 49% of global market demand. Other major applications include construction, consumer goods, and transportation. In 2019, the global blow molding industry was valued at approximately $78 billion, with an expected annual growth rate of 2.8% from 2020 to 2027. Common materials used in blow molding include polyethylene (PE), polyethylene terephthalate (PET), and polypropylene (PP).

Chapter Two – What is the history of blow molding?

The origins of plastic blow molding can be traced to ancient glassblowing techniques, which laid the foundation for modern manufacturing processes. Both molten glass and thermoplastics can be shaped by introducing pressurized air, a principle central to today's blow molding industry. The earliest glass molding method, called free-blowing, dates to the 1st century BC and revolutionized glass container production by enabling complex hollow shapes. Around the 1st century AD, mold-blowing emerged, allowing artisans to create more uniform glass products. These early innovations paved the way for future advancements in molding technology.

After early work with glass, natural rubber became the first non-glass material used in blow molding. In the 1850s, Samuel Armstrong patented a process for molding hollow rubber products, setting a precedent for material exploration. The 20th century brought transformative changes to plastic manufacturing. A major breakthrough occurred in the 1930s when Plax Corporation introduced the first plastic blow molding machine using cellulose acetate, marking the beginning of commercial plastic blow molding.

A pivotal development came in 1939 when England's Imperial Chemical Industries (ICI) created low-density polyethylene (LDPE), a thermoplastic known for its flexibility and strength. LDPE's suitability for extrusion blow molding and widespread availability accelerated the adoption of blow molding in the plastics industry. By the 1950s, blow molding machines were widely used to manufacture hollow plastic containers, bottles, automotive components, and industrial packaging. This period saw the commercialization and rapid expansion of blow molded products, with high-density polyethylene (HDPE) and other polymers soon being used for more durable or specialized items.

Today, blow molding is a fundamental plastics processing method used globally to produce items like custom plastic bottles, food and beverage containers, industrial drums, automotive parts, medical device housings, and consumer packaging. The three main blow molding types—extrusion, injection, and stretch blow molding—address diverse industry needs. Modern advancements in computer-aided design, precision mold manufacturing, and sustainable bio-based resins have further transformed the field, enabling high-volume, cost-effective, and eco-friendly production.

Understanding blow molding's rich history helps manufacturers, engineers, product designers, and procurement specialists find reliable, efficient, and innovative solutions in plastic packaging and industrial manufacturing. Businesses seeking to optimize product development, reduce material costs, and achieve design flexibility can benefit from partnering with leading blow molding companies that offer cutting-edge technology and expertise.