Introduction

This article provides an in-depth examination of head gaskets.

It covers various aspects including:

- Principles of Head Gaskets

- Types of Head Gaskets

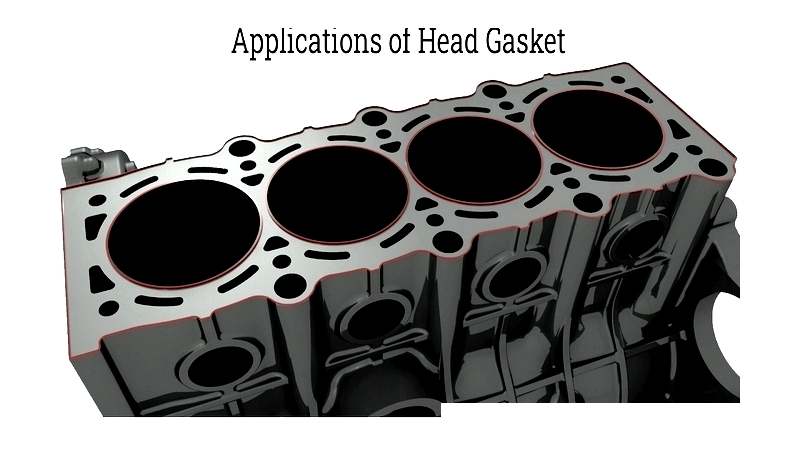

- Applications of Head Gaskets

- Head Gasket Maintenance

- And More...

Chapter 1: Understanding Head Gasket Fundamentals

This section explores the core functions of head gaskets, their working mechanisms, and manufacturing processes.

What is a Head Gasket?

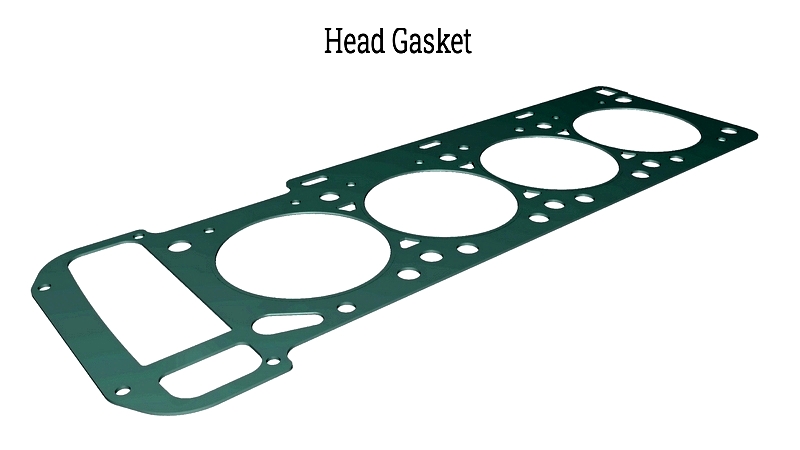

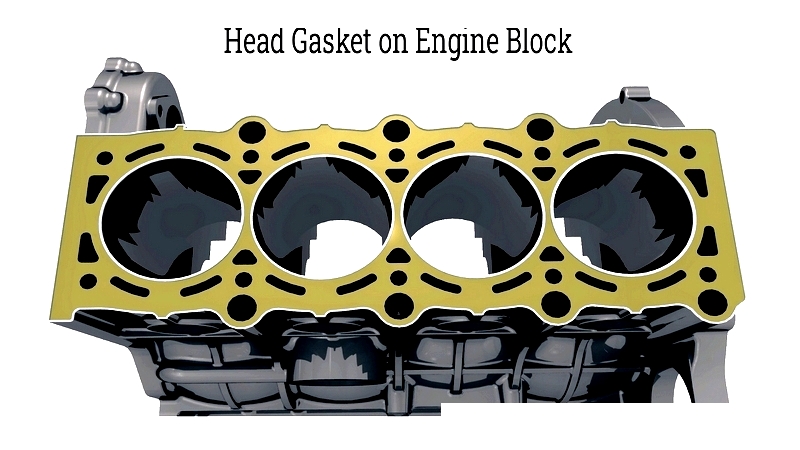

A head gasket is a crucial component in internal combustion engines, sealing the cylinder head to the engine block. It prevents combustion gas leaks and coolant mixing, which is essential for engine power generation. By containing gases in combustion chambers, it ensures proper exhaust system flow.

Typically made from multi-layer steel or composite materials, head gaskets withstand high temperatures and pressures during engine operation. Their primary role is to separate combustion gases from coolant and maintain engine compression for smooth performance.

Modern head gaskets use steel layers with elastomers for enhanced durability. These advanced designs offer greater reliability than older versions, reducing leakage risks and environmental concerns.

The gasket's sealing function maintains combustion chamber pressure, crucial for piston operation and engine performance. It also prevents oil and coolant mixing, which could reduce engine efficiency.

Head Gasket Functions

The following outlines key head gasket functions and their implementation.

Pressure Control

The head gasket manages extreme engine pressures and temperatures. It ensures proper coolant circulation in combustion chambers, vital for engine operation. High-quality materials and thorough research contribute to its effectiveness.

Heat Management

Exposed to intense heat, the gasket regulates oil and coolant flow. It prevents overheating by sealing coolant passages between cylinder head and engine block.

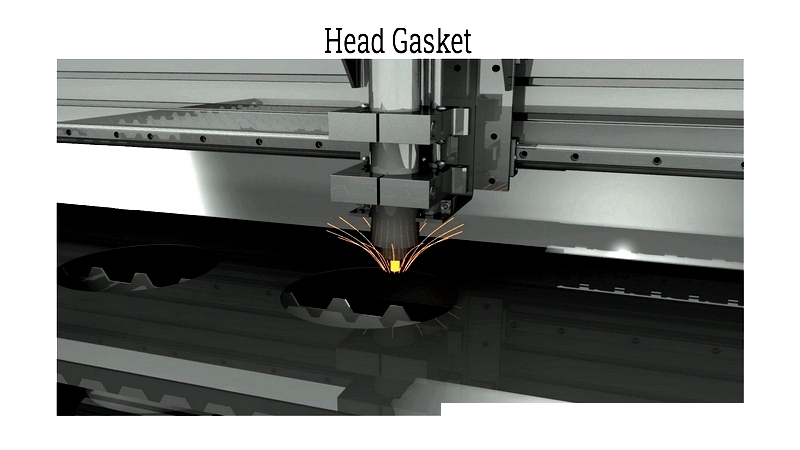

Manufacturing Process

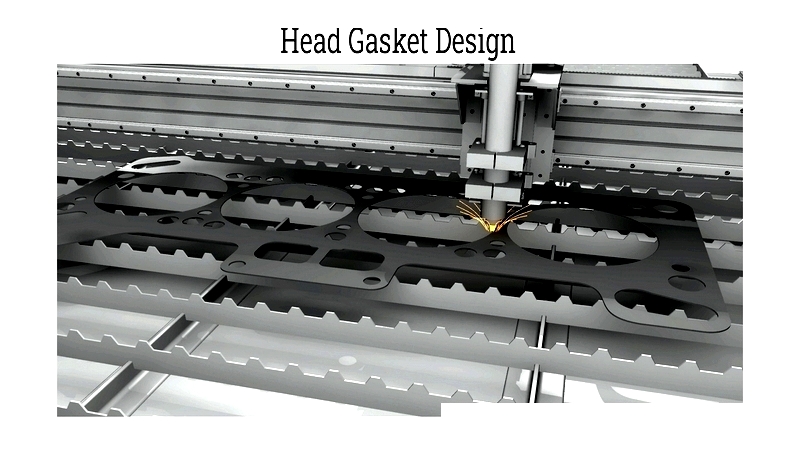

Traditional head gaskets combined asbestos fibers with synthetic rubber on metal sheets. Polymer-treated layers improved durability, supporting cooling and lubrication while sealing combustion chamber openings with metal rims.

Surface coatings enhanced seal efficiency but increased costs. Conventional methods faced durability challenges with soft materials, requiring precise sealing around combustion chambers.

Additional micro-sealing layers caused wear on metal rims during engine operation. Newer designs focus on improved performance and simpler production.

Recent advancements show better results. New saturating materials perform well at high temperatures, improving gasket stability and eliminating extra coatings.

Chemical reactions between impregnation materials and asbestos fibers enhance material properties.

Further testing revealed polymerization creates composite materials with excellent sealing, elasticity, and chemical resistance. This eliminates the need for micro-sealing coatings.

The improved process reduces material absorption during engine operation. Excess saturating agents are removed before polymerization for optimal sealing.

Preferred impregnating materials include poly-siloxanes with specific molecular weights. These materials effectively bond with asbestos fibers without requiring solvents.

Chapter 2: Leading Head Gasket Machine Manufacturers

Specialized machines are essential for head gasket production. They ensure precise sealing components for engines, supporting performance and leak prevention. Advanced equipment enables mass production while maintaining quality. Below are key manufacturers and their offerings:

FEL-PRO

FEL-PRO provides dedicated head gasket machines featuring precise material layering and cutting. Their technology supports multi-layer steel gaskets for modern engines.

Victor Reinz

Victor Reinz offers advanced production systems with laser cutting and automated assembly. Their solutions meet strict industry standards for various engine types.

MAHLE

MAHLE's manufacturing lines include CNC cutting and quality control systems. Their solutions cater to OEM and aftermarket needs with reliable sealing performance.

Cometic Gasket

Cometic provides precision equipment for high-performance gaskets. Their flexible production accommodates automotive and motorsport applications.

Elring

Elring's assembly machines ensure accurate alignment for multi-layer gaskets. Automated inspections support quality and traceability requirements.

When upgrading production capabilities, consider capacity, material compatibility, and quality systems. Advanced machinery improves productivity and product quality.

For current machine information, consult manufacturers or industry sources. Modern equipment is key for competitiveness in the automotive sector.

- Related Topics:

- Automated gasket production

- Quality assurance in manufacturing

- Material selection for gaskets

- Machine purchasing considerations

Chapter 3: Head Gasket Varieties

Head gaskets are vital engine seals between block and cylinder head. Proper selection maintains compression and prevents leaks. Four main types serve different engine requirements:

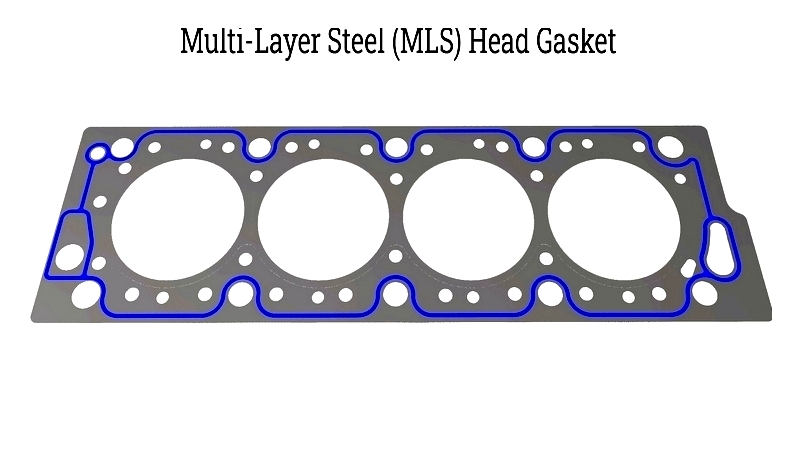

Multi-Layer Steel (MLS)

MLS gaskets are standard in modern vehicles, especially high-performance engines. Their steel layers with elastomer coatings provide durability under extreme conditions.

They seal high pressures effectively with specialized bead designs. MLS gaskets require smooth surfaces and precise installation.

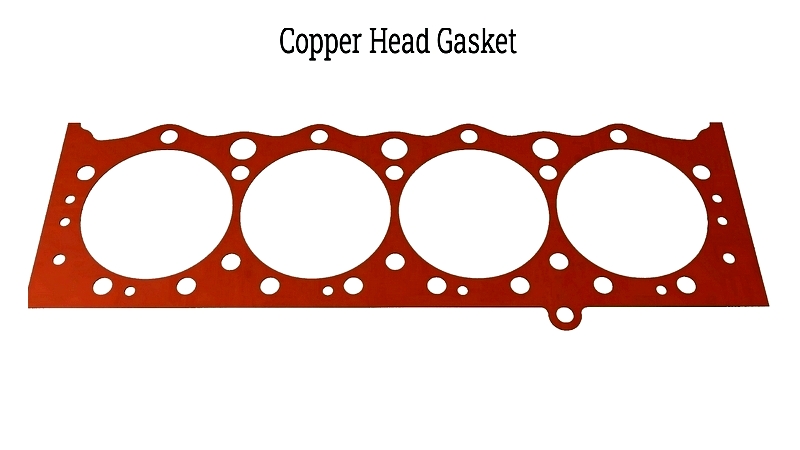

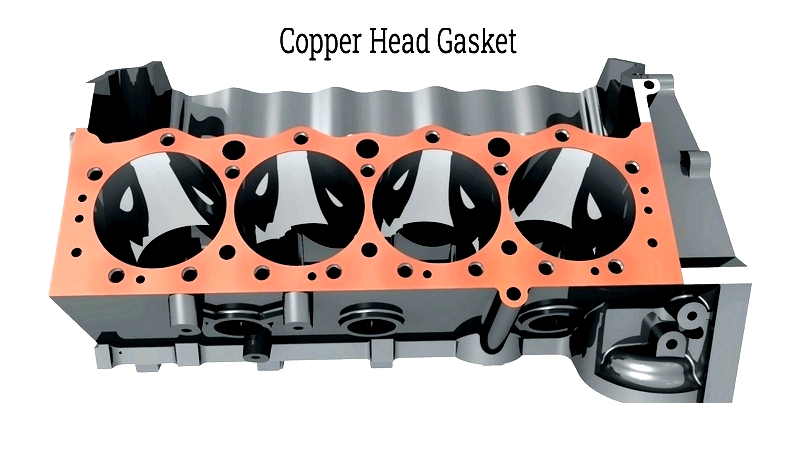

Copper

Copper gaskets suit racing and high-compression engines. Their strength prevents blowouts but requires specialized installation techniques.

O-ringing ensures proper sealing. Copper gaskets offer reusability and withstand extreme pressures, making them ideal for performance applications.

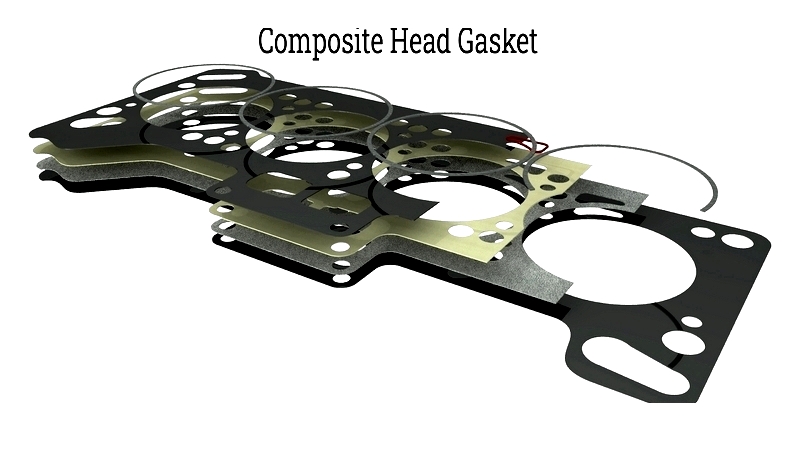

Composite

once common, composite gaskets now mainly serve older engines. Their graphite and fiber construction suits vintage restorations but lacks modern performance capabilities.

Elastomeric

Elastomeric gaskets combine steel cores with polymer beads for versatile sealing. They adapt to surface imperfections and resist harsh conditions.

These gaskets serve automotive, aerospace, and industrial applications with excellent