Introduction

This article provides an in-depth exploration of stainless steel hinges.

You'll gain insights into various aspects including:

- What stainless steel hinges are

- The manufacturing process of stainless steel hinges

- Key components of stainless steel hinges

- Factors to consider when selecting stainless steel hinges

- Different types of stainless steel hinges

- Benefits of using stainless steel hinges

- Common applications for stainless steel hinges

- Maintenance practices for stainless steel hinges

- And much more...

Chapter 1: Understanding Stainless Steel Hinges and Their Manufacturing Process

What Defines Stainless Steel Hinges?

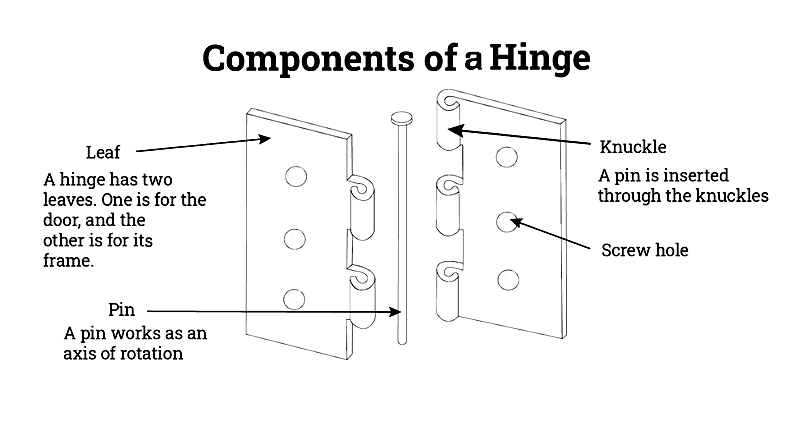

Stainless steel hinges connect two components while enabling relative movement between them. They come in various leaf configurations, including rectangular and other designs, depending on the specific hinge type. The leaves are joined by knuckles containing openings for screws or bolts to attach the hinge to a door. A pin inserted through the knuckles securely holds the leaves together.

Like hinges made from other materials, stainless steel versions are available in numerous styles and quantities. Their appeal lies in the shiny silver appearance combined with excellent rust and corrosion resistance. The material's strength and durability make it a preferred choice. Manufacturers favor stainless steel for creating durable, reliable hinges that deliver superior performance.

The precise pivot joint in stainless steel hinges allows rotation around a single axis, providing one degree of freedom (1-DOF). Some hinges are designed for more complex movements, enabling windows and doors to swing open before sliding out from recessed positions. These advanced movements require multiple pins and a four-bar linkage system.

How Stainless Steel Hinges Are Made

Stainless steel, an iron-based alloy, is enhanced with various elements to improve strength and appearance. Chromium primarily gives stainless steel its distinctive silver shine. Additional elements like nickel, silicon, manganese, nitrogen, and carbon are blended with chromium to create different stainless steel grades while enhancing properties.

The fundamental process for developing stainless steel grades is called tuning, which involves adjusting the alloy's chemical composition by removing unwanted elements and improving metal consistency.

After tuning, stainless steel is formed into slabs, rods, tubes, and billets. For hinge production, billets undergo hot-rolling above the steel's recrystallization temperature to create plates, strips, and sheets. Cold rolling below this temperature produces expansive stainless steel sheets with excellent surface finishes.

Before shipping to hinge manufacturers, stainless steel undergoes additional processes like annealing, descaling, cutting, and finishing to ensure quality. Properly prepared stainless steel sheets are then sent to manufacturers for hinge production.

Stainless Steel Stamping Process

Stainless steel sheets and coils serve as the base material for hinge production. A stamping press cuts or shapes thin stainless steel sheets to match hinge leaf dimensions. Stamping offers a cost-effective method for producing precise, efficient stainless steel hinges.

After stamping the leaves, a press punches holes in the hinge and forms the knuckles (also called loops or nodes) that surround the pin. Each leaf features knuckles that connect the leaves, allowing pin insertion. The leaves' sharp edges are smoothed before polishing and temporary pin assembly.

If plating is required, stainless steel hinges are polished and finished first. Temporary pins are then removed from semi-finished hinges to facilitate final assembly, which involves attaching hinge leaves and securing pin ends or headed pins.

Stainless Steel Casting Process

Casting involves molding metals within forms, followed by manual or mechanical polishing to achieve a smooth finish. This labor-intensive, time-consuming process results in higher costs.

Stainless Steel Extrusion Process

Extrusion creates hinges by applying pressure to a heated stainless steel billet as it passes through a die shaped like a hinge leaf. This produces thicker, more robust hinges than stamped versions, making them more expensive.

Stainless Steel Deformation Machining Process

Deformation machining involves bending, spinning, rolling, or forging stainless steel into hinge shapes. A turret punching machine applies pressure to transform the metal's dimensions through stretching and pulling. Excess material is removed via cutting, altering the hinge's configuration. The process may also include drilling, sawing, or shearing.

Manufacturers apply additional techniques and treatments to refine their products. For example, ball bearings may be installed between joints for smoother movement. Stainless steel hinges may feature pre-drilled holes or allow for customized installation based on application requirements.

Chapter 2: Components of Stainless Steel Hinges

Stainless steel hinges are essential components used in various door and panel applications, valued for their strength, corrosion resistance, and durability. These versatile hardware solutions play crucial roles in residential, commercial, and specialized industries like marine, automotive, and architecture. Despite material and manufacturing advancements, stainless steel hinges maintain core design elements that ensure reliable, smooth rotation between moving and stationary parts. Their robust performance in demanding environments and low maintenance requirements make them preferable to other hinge materials.

Components of Stainless Steel Hinges

Hinge Leaf

The hinge leaf is the flat plate extending from the hinge knuckle or barrel, designed for secure attachment to door frames or moving panels. Stainless steel hinge leaves come in various thicknesses and sizes to suit different applications, from heavy-duty industrial doors to cabinetry and marine enclosures. They often feature pre-drilled holes for easy installation using stainless steel screws or bolts, offering superior rust and chemical resistance for high-moisture or corrosive environments. The leaf's robust construction provides reliable load-bearing capacity, even under frequent or high-stress use.

Hinge Barrel or Knuckles

The hinge barrel, or knuckles, consists of interlocking cylindrical segments formed by precision bending of leaf edges. These weight-bearing components are engineered for maximum durability and resistance to wear. When a hinge pin is inserted, the knuckles connect securely while allowing leaf rotation around a central axis. Advanced manufacturing ensures consistent barrel clearances, reducing friction and preventing seizing for smooth, quiet operation—especially important in continuous hinges or ball bearing hinges for heavy doors.

Hinge Pin

The hinge pin is a specially designed rod that fits through the barrel, holding leaves together and serving as the pivot point. High-quality stainless steel pins offer strength, corrosion resistance, and secure fit to prevent removal or tampering—important for security doors and exterior hardware. Pins may be removable or non-removable, with ball-bearing versions used in high-traffic areas to reduce wear on heavy doors.

Stainless steel hinges feature precision-machined holes for mounting with screws or bolts, ensuring stable installation. Their revolute joint design allows controlled rotation around a single axis, essential for architectural, industrial, and commercial applications.

Considerations When Choosing Stainless Steel Hinges

- Select stainless steel hinges for environments requiring strength, abrasion resistance, and corrosion resistance—such as marine, pharmaceutical, or food processing settings.