Introduction

This article provides an in-depth exploration of EDM Machining.

It covers essential topics including:

- Operating Principle of EDM Machining

- Components of EDM Machining and their Functions

- Types of EDM Machines

- Applications of EDM Machining

- Advantages and Disadvantages of EDM Machining

- And Much More...

Chapter 1: Operating Principles of EDM Machining

This chapter explores the fundamental operating principles of EDM machining.

Defining EDM Machining

Electrical Discharge Machining (EDM) is a manufacturing process that removes material from a workpiece through rapid electrical discharges between electrodes in a dielectric fluid. This method is particularly effective for machining hard materials that are difficult to process with conventional techniques, as it relies on electrical rather than mechanical forces.

EDM's precision makes it ideal for creating complex shapes in hard metals like titanium. Both the workpiece and tool must be electrically conductive for the process to work effectively.

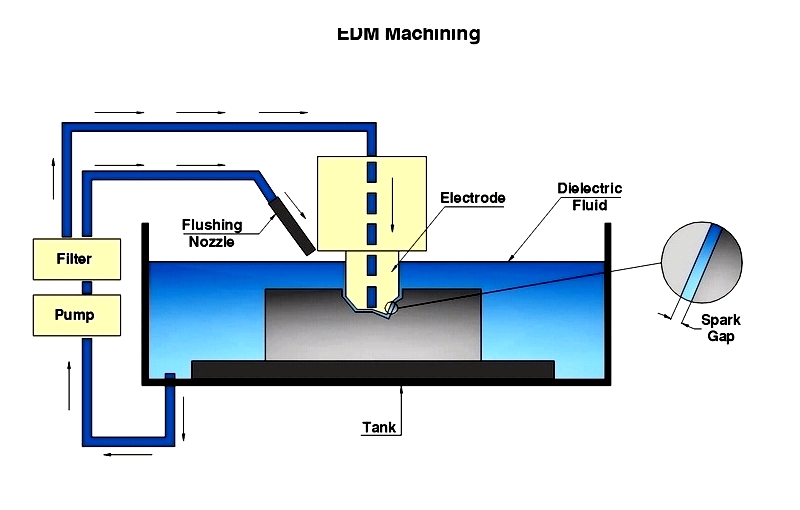

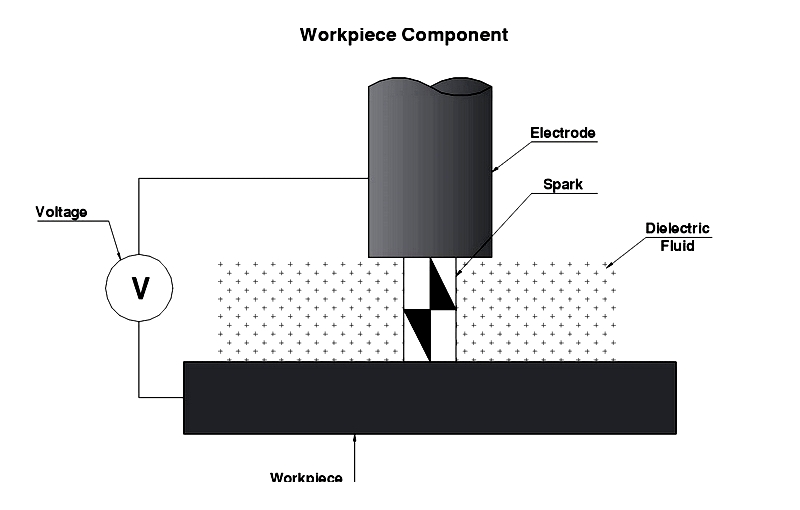

In EDM, the workpiece (anode) connects to the positive terminal of a DC power source, while the tool (cathode) connects to the negative terminal. Both remain submerged in dielectric fluid with a spark gap between them. Electrical discharges generate intense heat at the spark gap, melting and vaporizing portions of the workpiece through spark erosion.

The Working Principles of EDM Machining

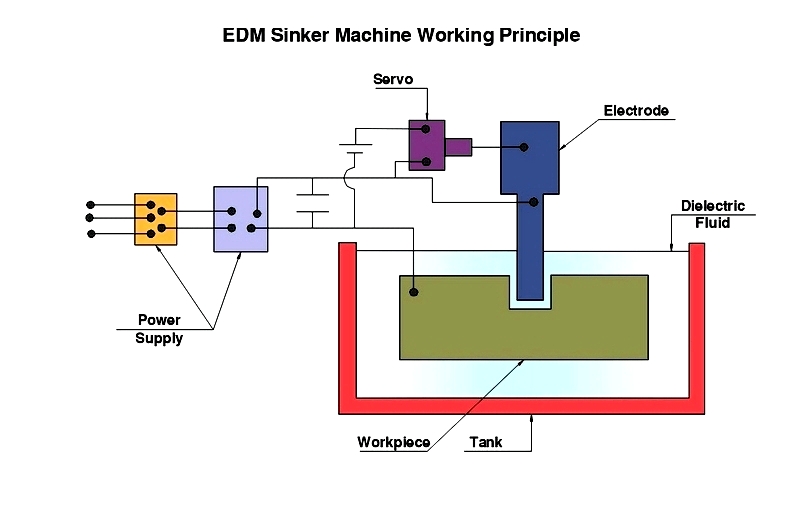

While the basic principles remain consistent, wire EDM and sinker EDM have distinct operational differences. Both methods use electrodes to shape the workpiece, but their current application varies significantly.

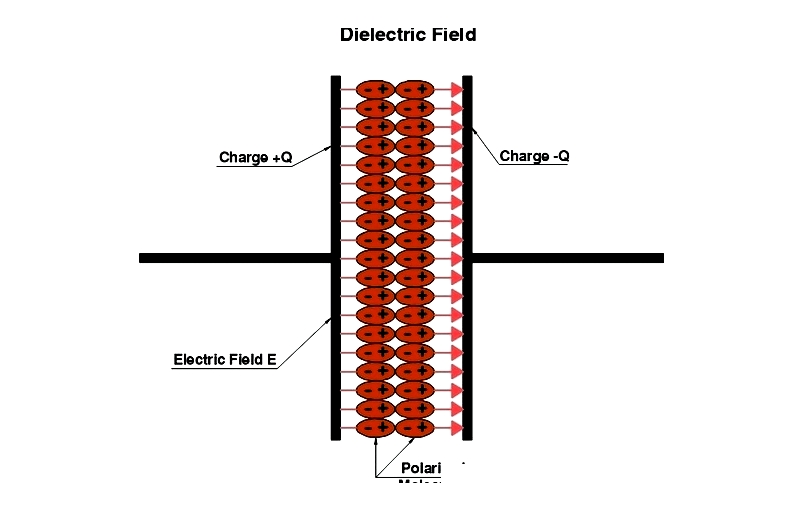

Sinker EDM creates an electrical potential difference between the conductive tool and workpiece, both submerged in dielectric fluid like hydrocarbon oil. The fluid maintains the spark gap, with the electric field depending on potential difference and gap width.

In sinker EDM, the tool connects to the negative terminal and the workpiece to the positive. The electric field causes electron emission from the tool. These electrons accelerate toward the workpiece, colliding with dielectric molecules and ionizing them.

This process creates a plasma channel with minimal resistance, allowing rapid electron and ion movement. The resulting collisions generate temperatures between 8,000°C and 12,000°C, melting the workpiece surface.

Wire EDM operates similarly to a band saw, using a conductive wire (typically copper or brass) to cut through the workpiece. The wire produces sparks in deionized water, which cools the material and removes debris.

The extreme heat removes material through vaporization, melting, or spark erosion. When the current stops, pressure waves expel molten material, creating craters at spark sites.

Material removal occurs through shock waves from collapsing plasma channels. Electrons create craters on the workpiece, while positive ions wear the tool. EDM requires substantial power, necessitating specialized generators.

Chapter 2: Components of EDM Machining and Their Functions

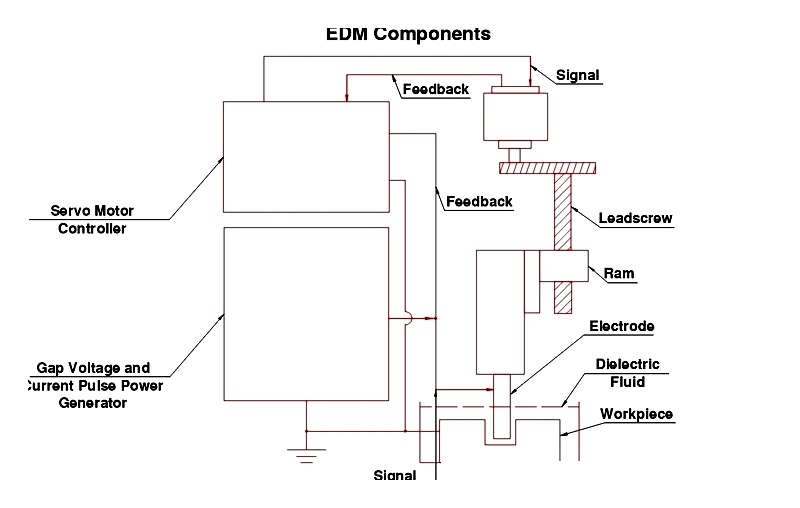

EDM uses controlled electrical discharges to machine conductive materials. The three main types - sinker, wire, and hole drilling EDM - share common components that utilize spark erosion technology. Understanding these components is crucial for precision engineering and achieving optimal surface quality.

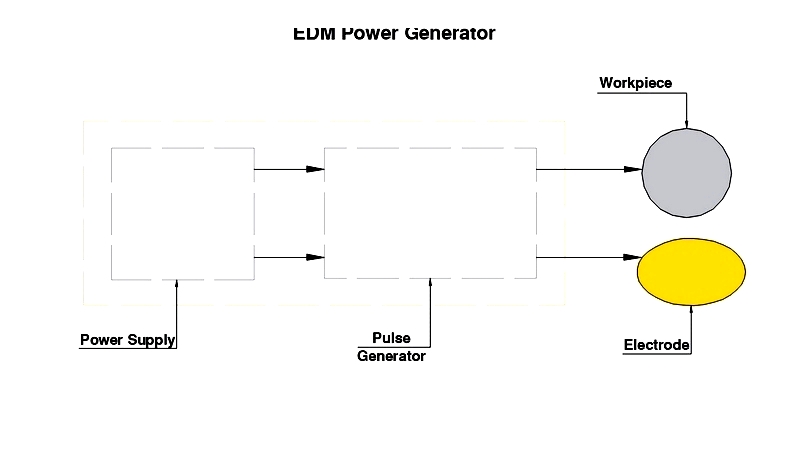

DC Power Generator

The DC power generator supplies energy for spark erosion, with the negative terminal connected to the tool and positive to the workpiece. Common generator types include:

- RC type relaxation generator

- Rotary impulse generator

- Electronic pulse generator

- Hybrid EDM generator

Workpiece Component

The workpiece, typically made of hard materials like tool steel or titanium, is securely fixtured in the dielectric container and connected to the positive terminal.

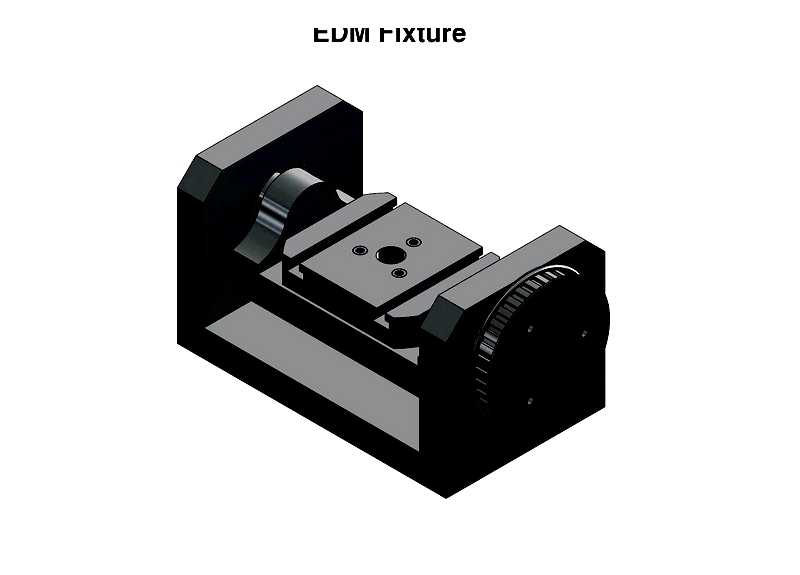

Fixture Component

The fixture maintains workpiece alignment and stability during machining, crucial for achieving precision tolerances.

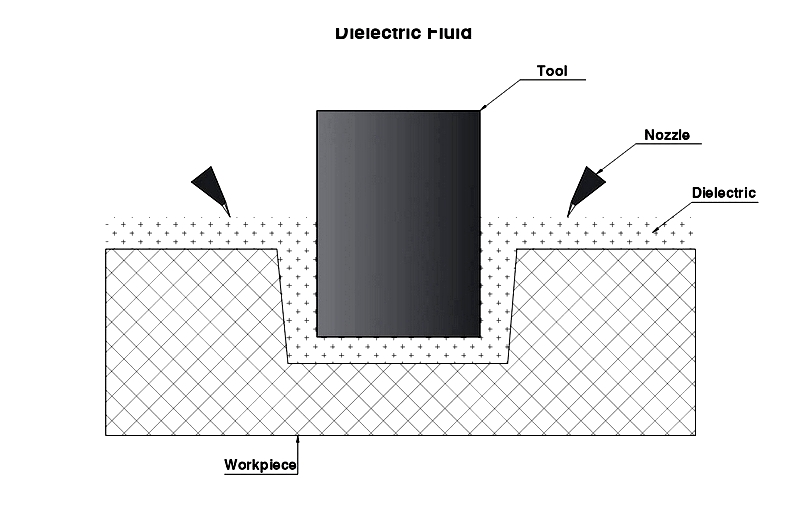

Dielectric Fluid

The dielectric fluid, typically hydrocarbon oil or deionized water, insulates the spark gap until breakdown occurs. It also cools the area and removes debris.

The Dielectric Medium

When the gap narrows to about 0.03 mm and voltage reaches 7V, the dielectric breaks down, allowing spark formation. The fluid quenches molten material and prevents secondary discharges.

Functions of the Dielectric Fluid

Key functions include:

- Maintaining electrical insulation

- Facilitating efficient sparking

- Quenching sparks

- Removing debris

- Cooling components

Desirable Properties

Ideal dielectric fluids have:

- High dielectric strength

- High flash points

- Low viscosity

- Chemical inertness

- Non-toxicity

Common Dielectric Fluids

Common choices include hydrocarbon oils and deionized water, selected based on application requirements.

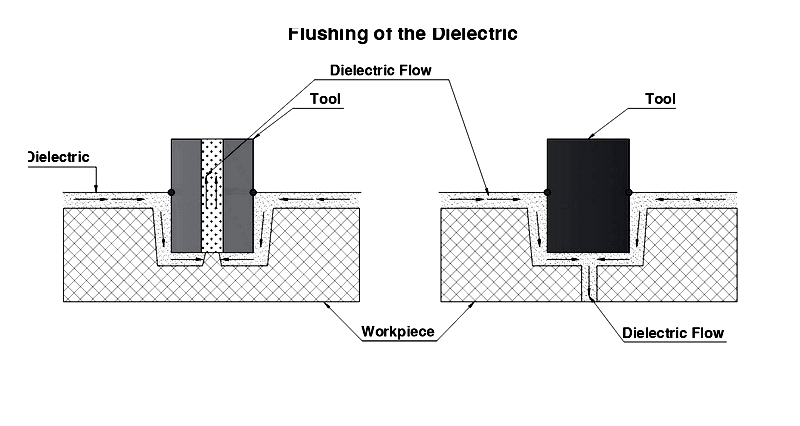

Flushing of Dielectric

Flushing circulates dielectric fluid to remove debris and maintain spark gap cleanliness. Effective flushing prevents defects and improves quality.

Common flushing methods:

Pressure Dielectric Flow

Forces fluid through tool holes, effective for deep cavities.

Reverse Dielectric Flow

Sends fluid upward to clear complex features.

Vacuum Dielectric

Draws fluid through central holes, ideal for precision drilling.

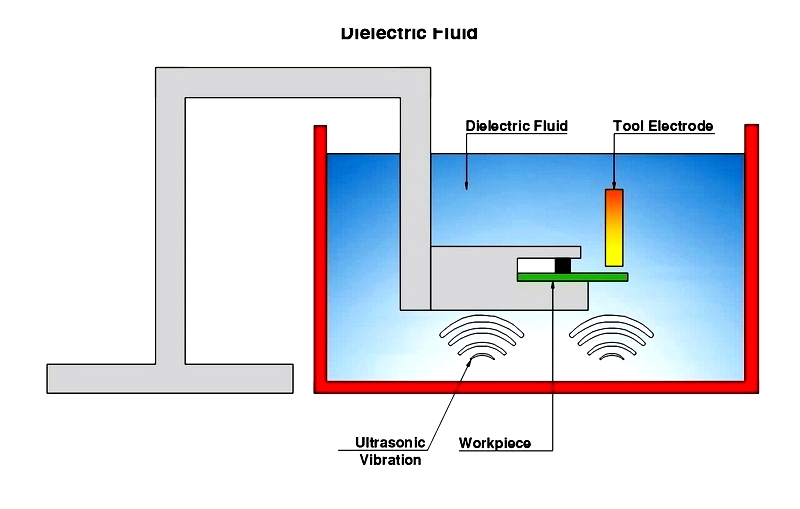

Vibration Flush Cut

Uses tool vibration when conventional flushing isn't possible.

Pump Component

Circulates dielectric fluid for consistent material removal and cooling.