Introduction

This article provides an in-depth exploration of nickel metal and its applications.

Topics covered include:

- Fundamentals of Nickel metal

- Varieties and Forms of Nickel metal

- Applications and Advantages of Nickel metal

- And More...

Chapter 1: Understanding the Fundamentals of Nickel metal

This section explores the core properties of nickel metal, detailing its production methods and diverse applications.

Defining Nickel metal

Nickel is a naturally occurring transition metal with a silvery-white appearance and slight golden hue. Known for its malleability, ductility, and excellent thermal and electrical conductivity, nickel has an atomic mass of 58.71 and is represented by the symbol Ni. It remains solid at room temperature, with a melting point of 1455°C and boiling point of 2730°C. Nickel's ferromagnetic properties, corrosion resistance, and hardness make it valuable for various industrial applications.

Nickel is extracted through metallurgical processes that isolate and purify the metal from its ore. The primary nickel ores are classified into two categories: laterites and magmatic sulfides.

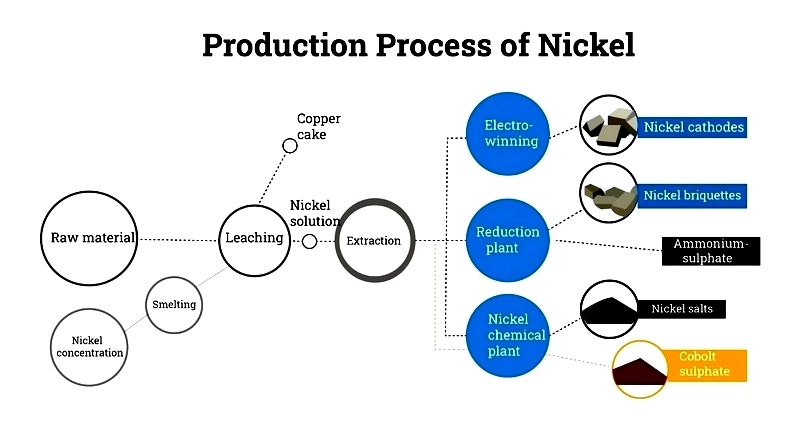

The Nickel Production Process

Nickel is primarily sourced from two types of ore deposits: laterites, which contain nickel-rich limonite and garnierite, and magmatic sulfides with pentlandite as the main ore mineral.

Nickel Extraction and Processing

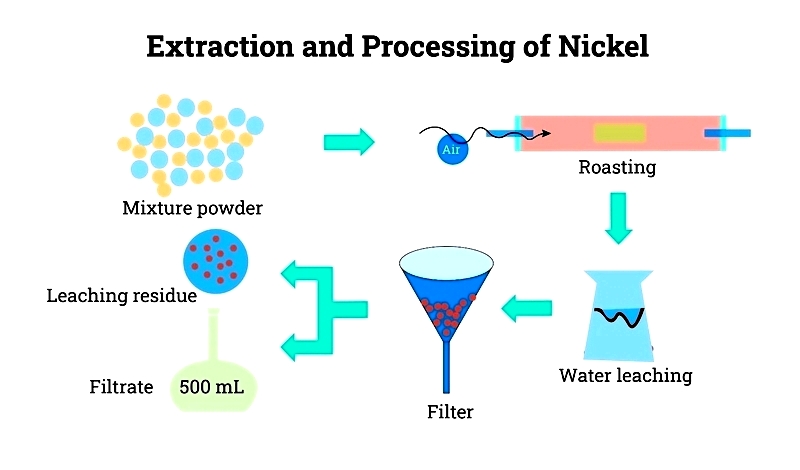

Nickel is extracted from ore using pyrometallurgical methods, which involve high-temperature chemical reactions. Laterite ores are typically mined through open-pit methods, while sulfide ores are extracted underground. Heavy machinery such as shovels and front-end loaders are used for laterite mining.

Sulfide Ore Nickel Extraction

After mining, sulfide ores are crushed and ground, with nickel separated from waste through flotation. This process attaches sulfide particles to air bubbles, which rise to the surface. The collected material typically contains 6-12% nickel.

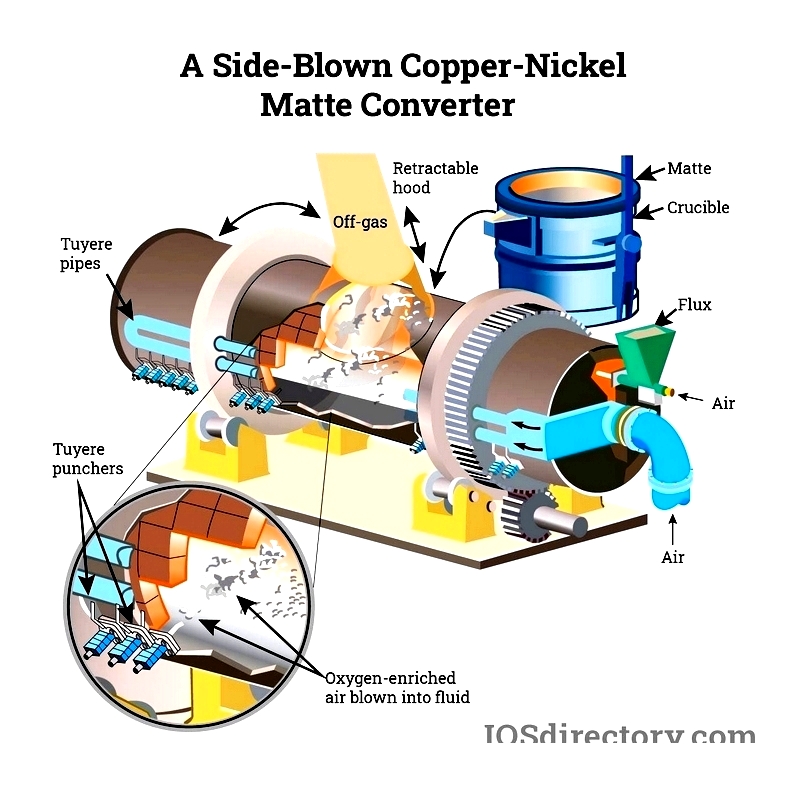

For ores with balanced copper and nickel content, a secondary flotation step produces separate nickel and copper concentrates. Nickel concentrates are then processed through smelting techniques, resulting in a nickel-iron sulfide called matte, with 25-45% nickel content.

Final refining occurs in rotating converters, where oxygen removes remaining iron and sulfide, yielding nickel matte with 70-75% nickel purity.

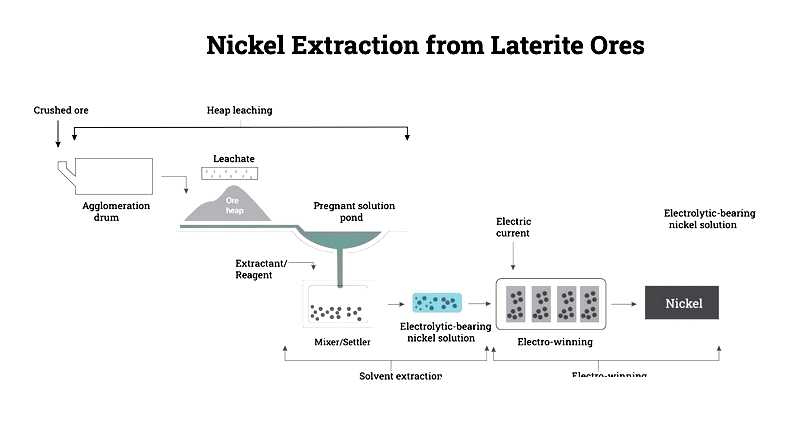

Nickel Extraction from Laterite Ores

Laterite ores require more energy for processing due to their high moisture content. Large kilns dry the ore before smelting in electric furnaces at temperatures between 1360°C and 1610°C.

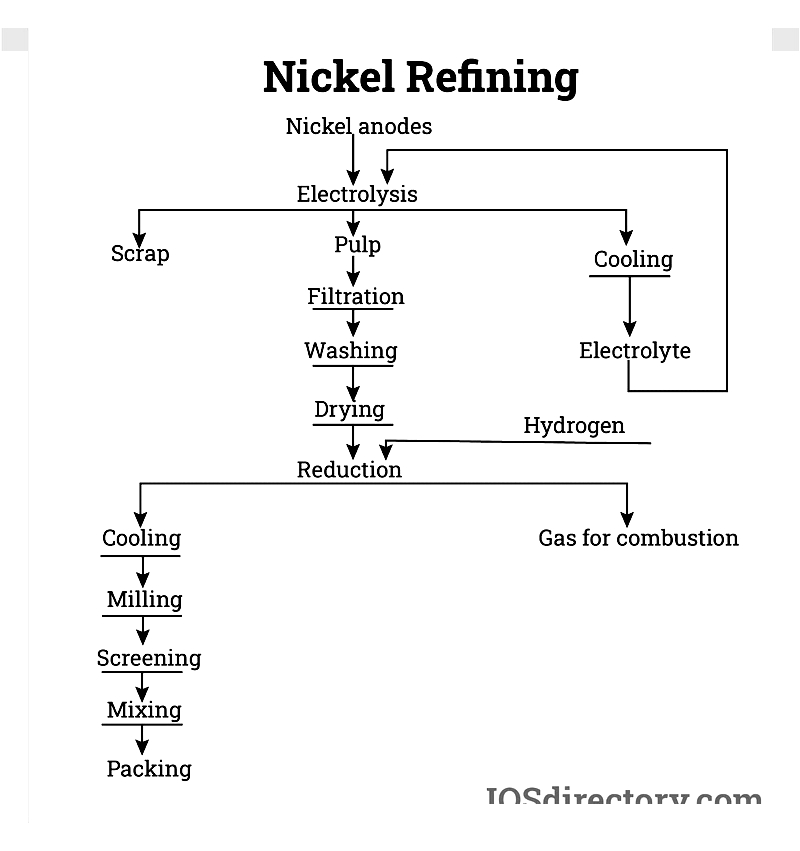

Nickel Refinement

After extraction, nickel matte undergoes refinement to achieve higher purity. Methods include ammonia pressure leaching and electrorefining, which can increase nickel purity up to 95%.

Nickel Shaping Processes

Refined nickel is shaped into various forms through methods like extrusion, cold drawing, and electroless plating.

Nickel Extrusion

This method involves melting nickel and forcing it through dies to create bars, rods, and tubes.

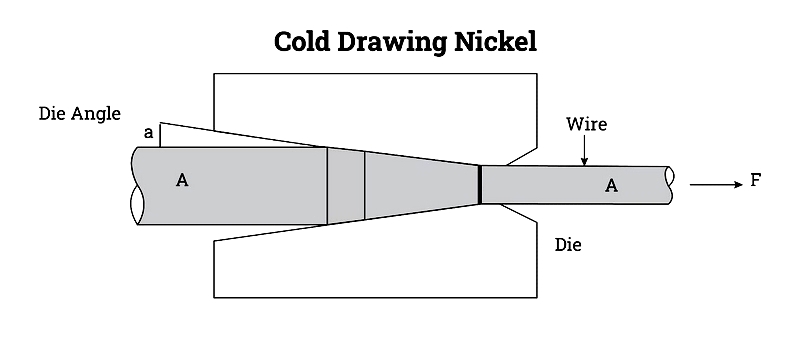

Cold Drawing

Nickel tubes or wires are pulled through progressively smaller dies without heat, reducing their diameter.

Electroless Nickel Plating

This chemical process deposits nickel ions uniformly without electricity, ideal for precise applications.

Key Considerations for Purchasing Nickel

When purchasing nickel, factors such as environmental conditions, stress requirements, intended use, and dimensional specifications should be evaluated. Selecting reliable suppliers is equally important to ensure quality, pricing, and support.

Chapter 2: Types and Forms of Nickel metal

Nickel's unique properties make it essential for various alloys used in industries like aerospace, marine, and chemical processing. Common nickel alloys include:

- Nickel-titanium alloys

- Nickel-chromium alloys

- Nickel-copper alloys

- Wrought nickel

Brushed Nickel

Brushed nickel features a textured finish that resists fingerprints and corrosion, making it ideal for fixtures and hardware.

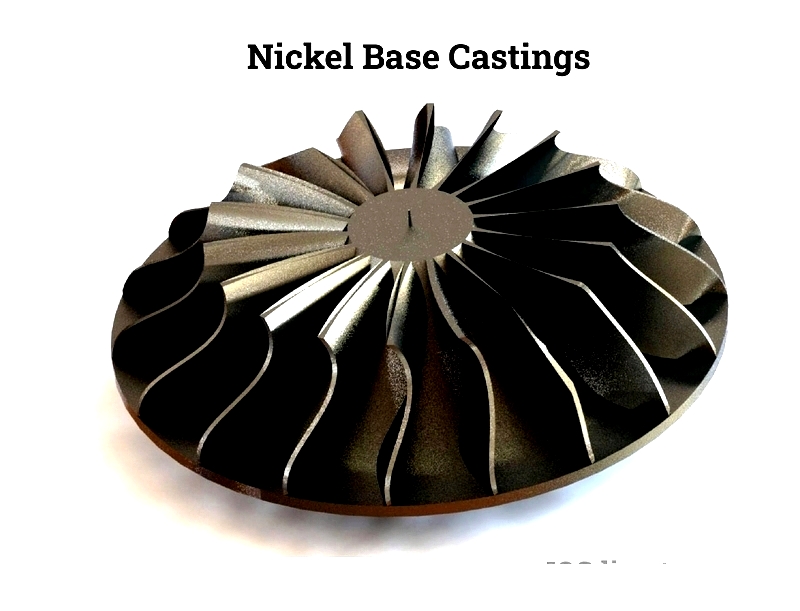

Casting Alloys

Nickel casting alloys like Inconel and Hastelloy are used for high-temperature applications in aerospace and chemical industries.

Cupro Nickel

Cupronickel, a copper-nickel alloy, excels in marine environments due to its corrosion resistance and durability.

Hastelloy

Hastelloy alloys offer exceptional resistance to corrosive chemicals, making them suitable for chemical processing equipment.

Inconel Alloy

Inconel alloys maintain strength at high temperatures, ideal for turbine engines and nuclear reactors.

Invar Alloy

Invar's low thermal expansion makes it perfect for precision instruments and aerospace applications.