Introduction

This comprehensive guide covers everything you need to know about poly tanks and their applications.

You'll discover:

- What poly tanks are

- The different types available

- How they're manufactured

- Their various uses

- And much more...

Chapter 1: Understanding Poly Tanks

Poly tanks are versatile plastic containers specifically designed for storing, transporting, and collecting water, liquids, and granular materials. Constructed from polyethylene or polypropylene, these lightweight and cost-effective tanks offer excellent handling capabilities, making them ideal for managing substantial material volumes.

Storage tanks have long been essential in industrial settings due to their strength and durability. The introduction of poly tanks revolutionized storage solutions by combining reliability with longevity. While metal tanks still serve specific purposes, poly tanks have become the preferred choice for modern storage requirements.

Despite their stability, poly tanks require proper foundation support. Suitable base materials include crushed gravel, sand, or wood chips to maintain tank positioning. With UV stabilizers to prevent sun damage, these tanks typically last up to 20 years with minimal maintenance. Many feature self-cleaning systems to remove accumulated debris.

Chapter 2: Poly Tank Varieties

Polyethylene storage tanks safely contain various liquids, categorized by material grade, application, orientation, and features. The two main classifications are potable water tanks (certified for drinking water) and non-potable tanks (for greywater, chemicals, and industrial fluids).

Vertical Poly Tanks

These space-saving upright tanks dominate the market with their superior strength. Commonly used for water storage, chemicals, and agricultural products, their cylindrical design evenly distributes hydrostatic pressure, enhancing durability.

Manufactured through rotational molding, these seamless tanks resist cracking, corrosion, and UV damage. Food-grade versions serve pharmaceutical and beverage industries. Customization options include various fittings, gauges, and insulation systems.

Compared to horizontal tanks, vertical models offer greater capacity and durability for irrigation, chemical storage, and fire protection systems. Specialized versions safely handle aggressive chemicals like sulfuric acid.

Horizontal Poly Tanks

Featuring low-profile designs with support legs, these portable tanks excel in mobile applications like agricultural spraying and fuel transport. Their stable construction minimizes liquid sloshing during transit.

Translucent walls with calibration markings enable easy level monitoring. Standard features include top access ports and bottom drains. Their compact shape suits space-constrained installations.

Applications range from liquid fertilizer handling to construction site water supply. Available in elliptical and DOT-compliant transport configurations.

Underground Poly Tanks

Designed for subsurface installation, these discreet tanks solve space limitations for rainwater collection and stormwater management. Some models exceed 20,000 gallons capacity.

Rotationally molded for watertight integrity, they resist soil chemicals and root intrusion. Proper installation requires gravel bedding and level foundations. Options include integrated pump chambers and multi-compartment designs.

Silo Poly Tanks

Conical-bottom tanks facilitate gravity-fed dispensing of dry materials. Essential for grain and feed handling, they require sturdy steel supports for heavy loads.

Elevated designs allow material discharge into processing equipment. Large top hatches enable rapid filling. Available accessories include level indicators and dust control systems.

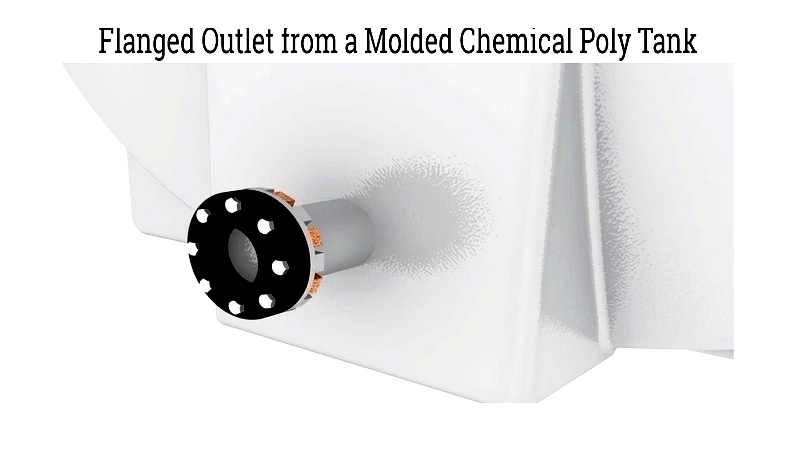

Chemical Poly Tanks

Engineered for hazardous material containment, these tanks use corrosion-resistant materials like XLPE. Double-wall designs provide secondary containment for regulatory compliance.

Maintenance involves regular inspections and specialized cleaning. Standard features include leak detection systems and secure venting.

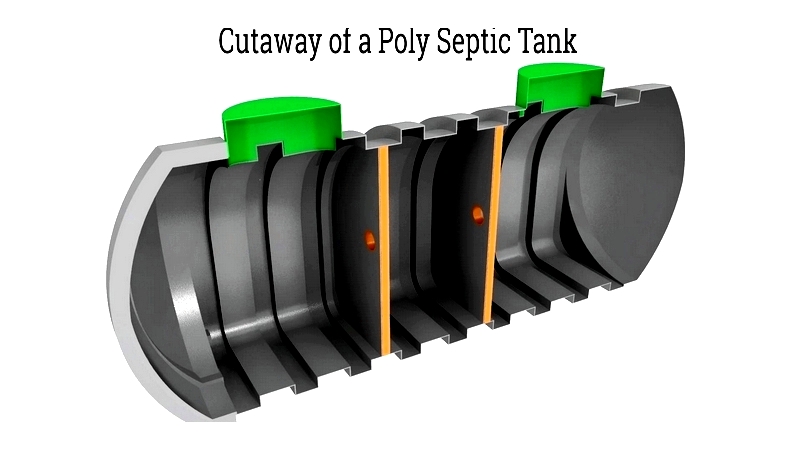

Poly Septic Tanks

These corrosion-resistant wastewater systems outperform concrete alternatives. Their lightweight construction simplifies installation in challenging locations.

Multi-chamber designs enhance treatment efficiency. Proper bedding prevents tank movement.

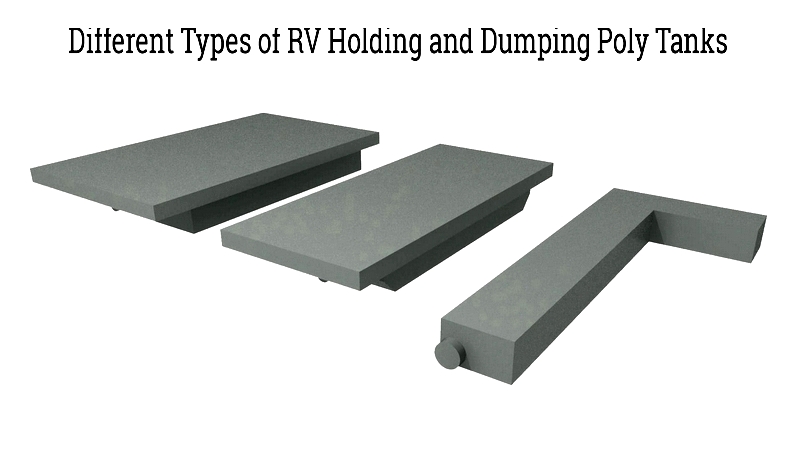

RV Poly Tanks

Specialized for mobile applications, these tanks meet potable water standards. Their seamless construction prevents leaks.

Compatible with RV plumbing systems, they're ideal for long trips. Various sizes accommodate different vehicle configurations.

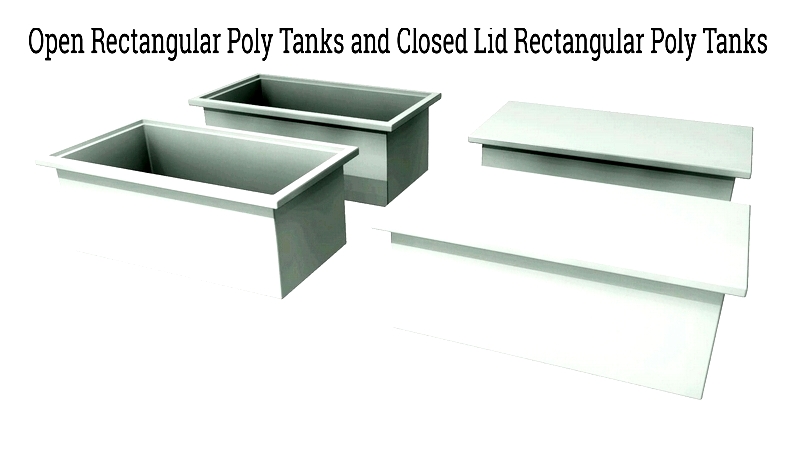

Rectangular Poly Tanks

These space-efficient tanks suit laboratories and industrial settings. Open-top versions facilitate mixing, while closed designs ensure contamination-free storage.

Stackable designs maximize vertical space. Various resin options accommodate different chemical compatibilities.

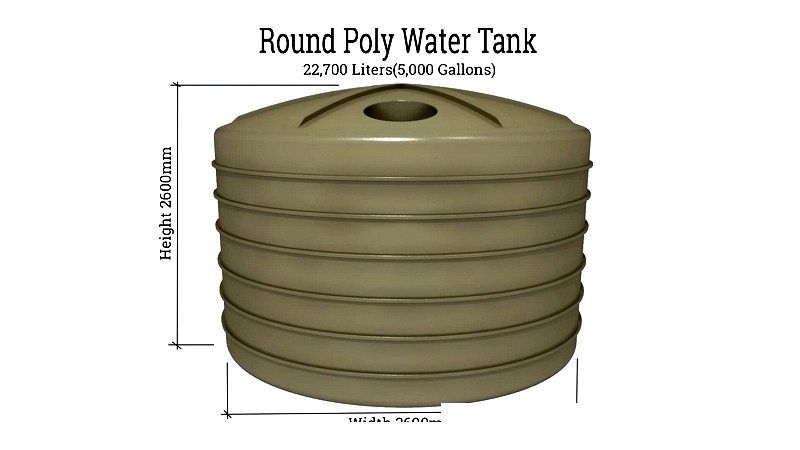

Poly Water Tanks

The backbone of water storage systems, these tanks serve residential to commercial needs. UV-resistant colors inhibit algae growth.

Wall thickness varies by application. Underground models prevent freezing with insulation.

Sizing Considerations

Selection depends on usage patterns and space availability. Large tanks reduce refill frequency while small units offer mobility.

Large Tank Benefits

- Economical bulk storage

- Simplified plumbing

- Space efficiency

Small Tank Advantages

- Lower initial cost

- Easy relocation

- Minimal spill risk

Custom fabrication meets specific application needs. Advanced materials enhance durability for specialized uses.

Chapter 3: Poly Tank Manufacturing

Poly tanks feature seamless walls for leak-proof performance. Their production requires specialized techniques suitable for large-capacity containers.

Primary methods include rotational and blow molding using durable polymers like HDPE. These materials ensure