Introduction

This article provides comprehensive information about softwall cleanrooms and their applications.

You will explore topics including:

- What is a Softwall Cleanroom

- Types of Softwall Cleanrooms

- Applications of Softwall Cleanrooms

- Softwall Cleanroom Designs

- And More...

Chapter One – What is a Softwall Cleanroom?

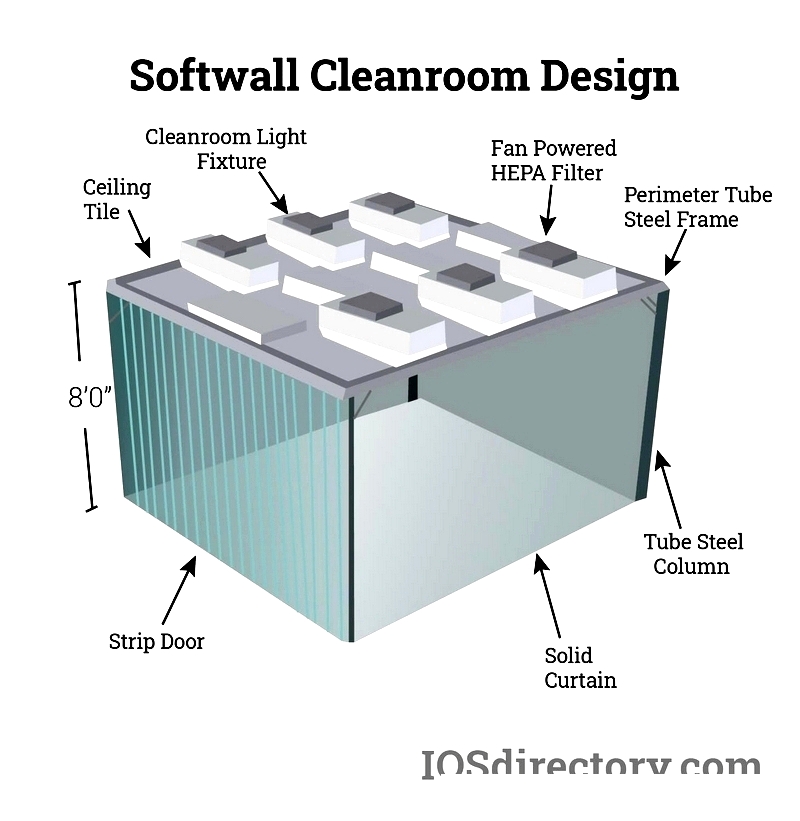

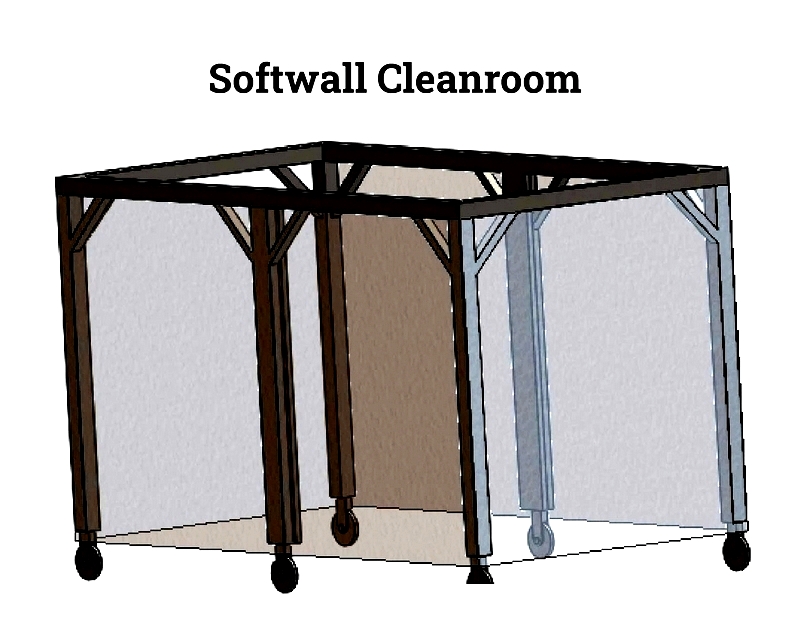

A softwall cleanroom, also known as a cleantent or portable cleanroom, is a modular structure with a prefabricated frame typically made of stainless steel or aluminum. Its design enables quick and easy assembly, depending on the cleanroom size. The walls consist of clear, flexible vinyl sheets that may be tinted, opaque, UV-filtering, ESD "Static Dissipative," or low-outgassing. The ceiling grid system, usually supported by the frame, includes ceiling tiles, light fixtures, and fan-powered HEPA filters similar to those in stick-built and modular hardwall cleanrooms.

Softwall cleanrooms typically range from 4 feet by 4 feet to 24 feet by 36 feet. Their flexible design allows for custom configurations and sizes to meet specific customer needs. Beyond standard sizes, these cleanrooms can be modified or expanded to accommodate unique requirements.

Why Use a Softwall Cleanroom

Softwall cleanrooms are more cost-effective than stick-built and prefabricated modular buildings, with faster delivery and installation. They generally require permits only for electrical and HVAC systems. Assembly can be completed by just two or three people. As prefabricated units, their assembly generates minimal noise and dust. Depending on the frame design, resizing or reconfiguring a softwall cleanroom is easily achieved by ordering additional components.

Chapter Two – Softwall Cleanroom Design Implementation

Softwall cleanrooms offer exceptional versatility due to their portability, compact size, and ability to fit into tight spaces. They can be disassembled when not in use and reassembled to meet changing production needs. Their practicality makes them suitable for both small manufacturers needing controlled environments and larger manufacturers requiring portable, contaminant-free spaces.

Most softwall cleanrooms feature hanging, overlapping flexible vinyl panels that extend three to six inches above the floor to facilitate air circulation from the filters. Some modular designs use vinyl materials securely attached to the steel frame on all sides, making them modular but not portable.

When designing a cleanroom, several factors must be considered, including its International Organization for Standardization (ISO) classification. For example, an ISO 8 cleanroom can be accessed without an airlock, while an ISO 5 cleanroom requires one or two airlocks. The HVAC system also plays a critical role in a softwall cleanroom's functionality.

Softwall Cleanroom Design Elements

Supporting frame

The supporting frame of a softwall cleanroom consists of powder-coated steel or aluminum uprights, cross sections, and ceiling frames. The frame supports the filtration system, air handling units, light fixtures, and ceiling tiles. Its dimensions are customized to customer needs. Steel tubular framing includes welded T bars to support the filters.

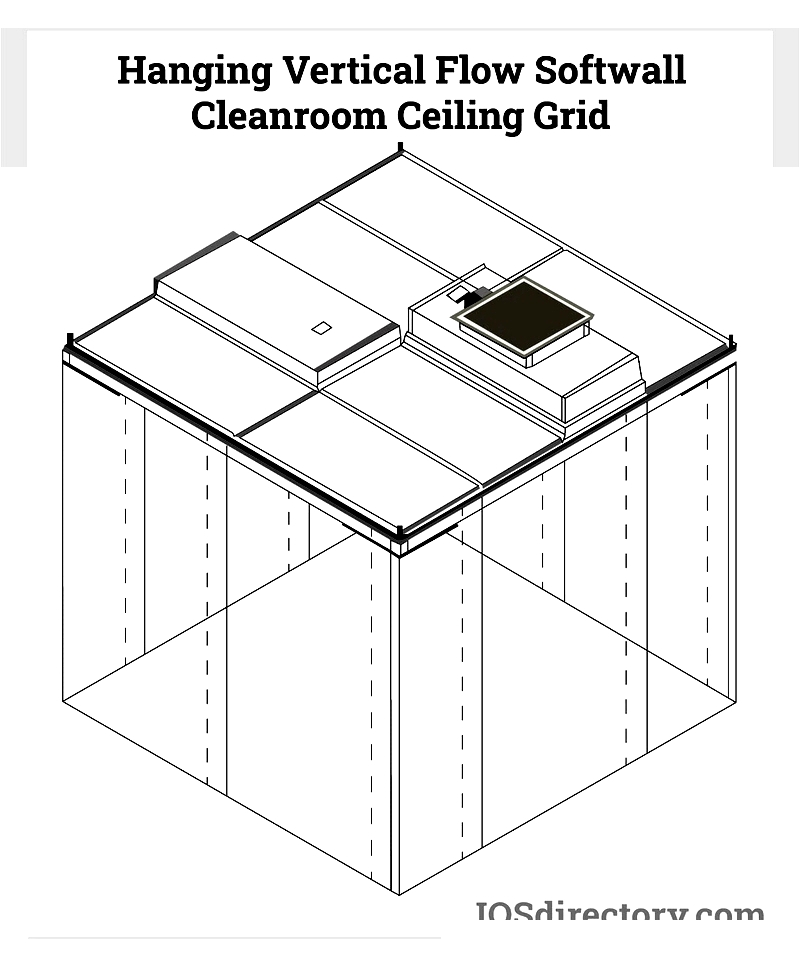

Cleanroom Ceiling

The ceiling of a softwall cleanroom features a grid system held together by lightweight connectors. There are two main types: self-supporting and suspended. Self-supporting grids are made from heavy-duty aluminum or steel, with post numbers varying based on ceiling height and weight. These grids are typically not walkable, though adjustments can be made for maintenance access.

Suspended ceiling grids are supported by turnbuckles and steel rods, providing additional support for the ceiling, lighting, and filters. These grids are also not designed to be walkable.

Softwall cleanroom ceiling heights range from seven to ten feet, with custom sizes available. A minimum two-inch clearance is required between filtration units and the facility ceiling, with filter units standing 16 inches tall.

Softwall Cleanroom Walls

Softwall cleanroom walls are made of clear, flame-resistant, low-outgassing vinyl strips. These lightweight panels are easy to install and clean. Available in various colors, they can be selected based on process requirements and UV sensitivity. Standard panels are 40 mil thick, while door panels are 80 mil thick. The panels overlap to create a barrier against external contaminants.

The 40 mil vinyl panels offer enhanced durability with double the material thickness, resisting tearing. They are secured to the frame using a grip track mounting system to prevent contamination.

Air Treatment System

The air treatment system is vital for a softwall cleanroom, relying on airflow patterns, air supply, HEPA filters, and room air pressure. The system's classification depends on the air change rate per hour (ACH), which determines the ISO classification. Air change rates vary from 10 to 250 times per hour, with higher rates corresponding to higher ISO classifications.

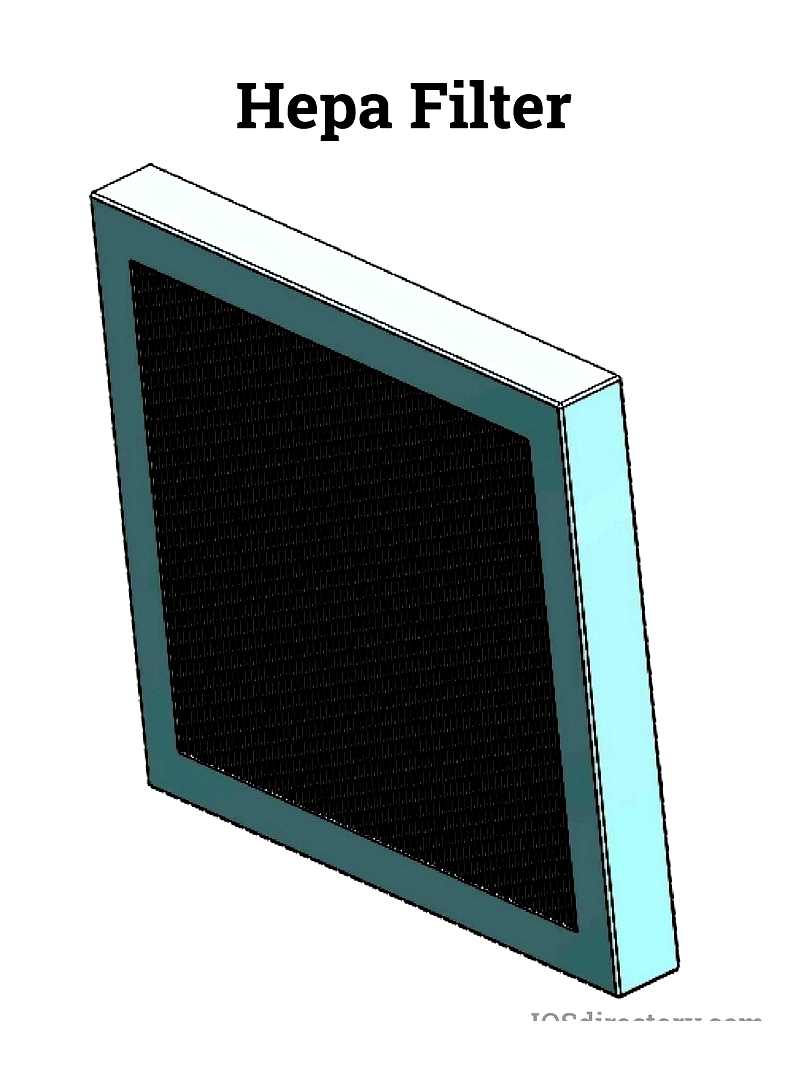

HEPA Filters

High-efficiency particulate air (HEPA) filters are the industry standard for cleanroom air treatment, removing 99.97% of particulate matter at 0.3 microns, including dust, pollen, bacteria, and other contaminants. They consist of randomly arranged fiberglass fibers of varying densities, with fiber diameter and thickness contributing to their efficiency.

HEPA filters' dense construction requires a powerful air circulation system to move air effectively.

HVAC System

The HVAC system for a softwall cleanroom manages temperature and humidity with capacities ranging from half-ton to two-ton. These systems use a multi-panel design for flexible ducting to accommodate varying needs. Condensers may be air or water-cooled, depending on requirements.

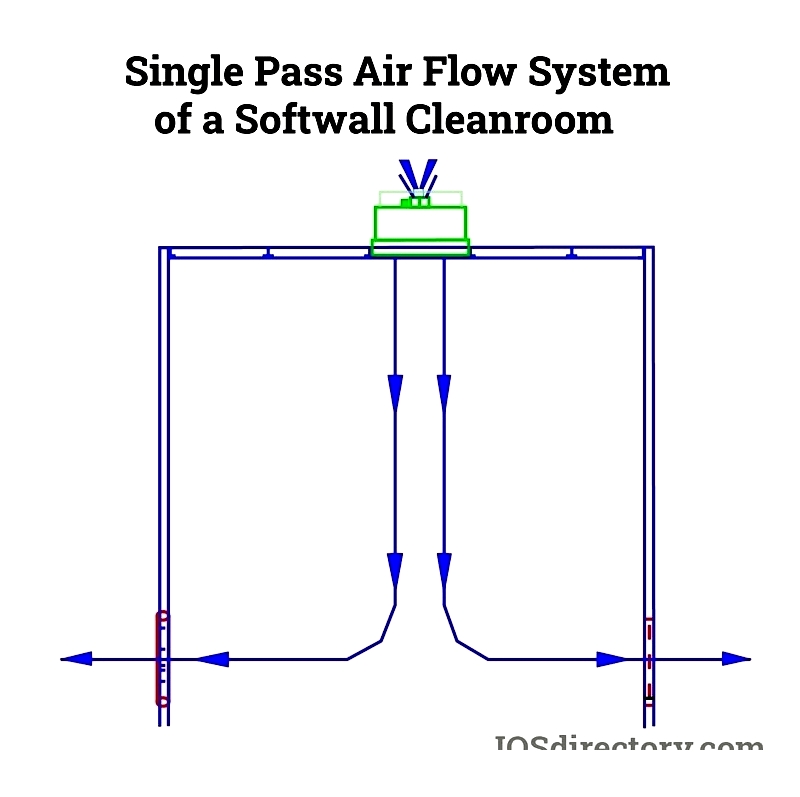

Air enters the HVAC system from outside the cleanroom, passes through prefilters, and exits through HEPA filters into the room. The air flows vertically downward toward the floor, exiting beneath the vinyl strip walls. In some cases, air conditioning may need to be routed from the building's HVAC system or another source.

Softwall cleanrooms use a single-pass HVAC airflow system, unlike solid wall cleanrooms which may use single-pass or recirculating systems.

Cleanroom Lighting

Lighting requirements depend on the processes performed in the cleanroom. Proper planning ensures adequate illumination without disrupting air movement and filtration. Common lighting types include recessed, surface mount, and teardrop, with teardrop lighting potentially affecting headroom.

Recessed Troffer

Recessed troffers fit into suspended drop ceilings, providing excellent illumination without disrupting airflow. They sit flush with the ceiling line, allowing ample plenum space. These are commonly used in high-classification softwall cleanrooms.

Surface Mounted

Surface-mounted lighting is typically used in lower-classification cleanrooms as it interferes with airflow. These lights mount directly on the ceiling without recessing, causing airflow disruption.