Introduction

This article provides an in-depth exploration of cold forging.

Key topics include:

- The fundamentals and mechanics of cold forging

- Advantages and limitations of cold forging

- Comparison between hot and cold forging

- Materials and machinery involved

- Industrial applications

- Additional relevant information

Need to evaluate Cold Forging suppliers?

Our team can assist your procurement research by connecting you with industry specialists.

Chapter One – What is Cold Forging and How Does It Work?

Cold forging is a metal shaping technique where bar stock is placed into a die and compressed into another enclosed die at room temperature or below the metal's austenite threshold.

This highly efficient method proves particularly cost-effective for mass-producing components. The process encompasses cold, warm, and hot forging variations, utilizing tools like hammers, dies, or presses to deform metal. Compared to machining and casting, cold forging yields superior strength and quality in finished products.

Distinct from warm or hot forging, cold forging forms metal at ambient temperature through localized compressive forces. Complex part designs may require multiple dies or repeated strikes to achieve the desired configuration.

Chapter Two – How Cold Forging Works

As a vital manufacturing technique in metal forming, cold forging delivers significant cost reductions and efficiency gains for mass production. This innovative approach substantially decreases labor requirements while eliminating numerous secondary machining operations, reducing waste and optimizing production flow. Modern cold forging methods enable manufacturers to achieve production rates often surpassing 1,000 units hourly, dramatically lowering per-unit costs for suppliers and OEMs. Through advanced cold heading and press technology, metal coils are automatically fed into precision forging machines, ensuring consistent output and quality control.

Components manufactured via cold forging demonstrate exceptional surface quality and dimensional precision, as shown in the accompanying image. With optimized grain structure and minimal material waste, these parts exhibit enhanced mechanical properties—including improved tensile strength, wear resistance, and durability—making them suitable for demanding applications in automotive, aerospace, electronics, and construction industries. The versatility of cold forging processes allows production of robust, corrosion-resistant fasteners, shafts, gears, and custom components that meet diverse industry specifications.

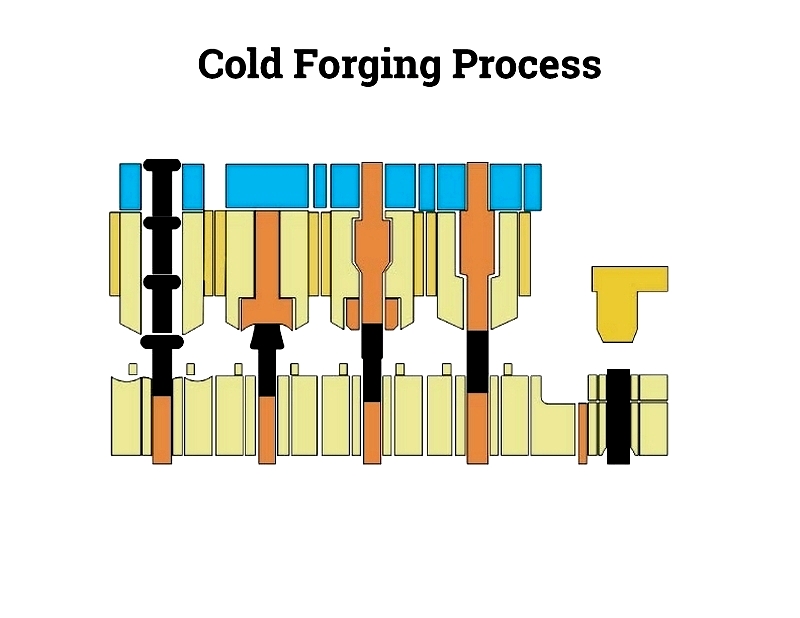

The Cold Forging Process

Step 1: Lubrication

Prior to forming, workpieces—typically steel or aluminum billets—receive an anti-sticking lubricant coating. This critical step prevents metal-die adhesion and minimizes tool wear during high-pressure deformation. Lubricants also promote smoother material flow and regulate frictional heat, which can reach 250°C-450°C while remaining below metal recrystallization points. Manufacturers employ various lubricant formulations, including specialized phosphate or polymer coatings designed for specific alloys. Some high-speed operations may utilize alternative die treatments to maximize productivity and tool longevity.

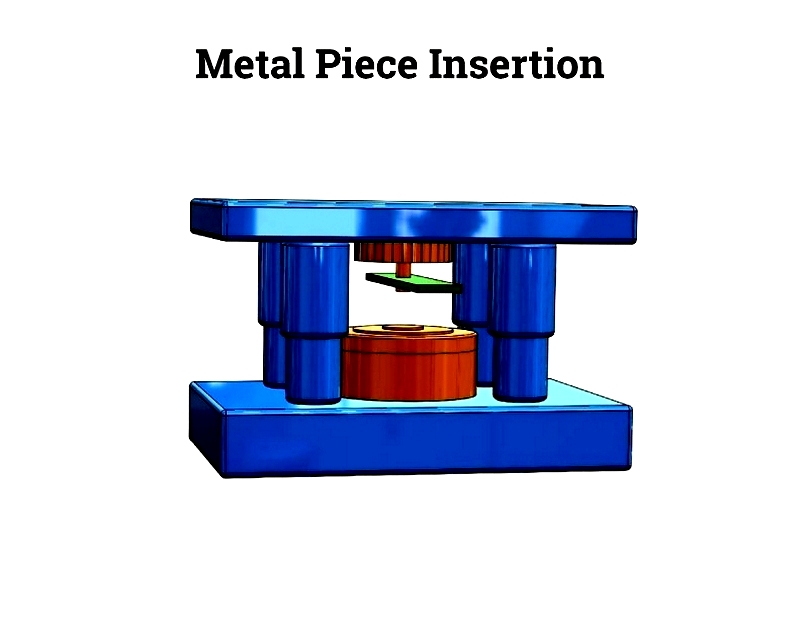

Step 2: Material Feeding

The selected metal coil—commonly cold-drawn steel, copper, brass, or aluminum alloy—is precisely positioned within the forging machine's die cavity. Most cold forging dies comprise multiple segments: a stationary lower die and movable upper die attached to a press ram. This configuration ensures accurate control over part dimensions and internal structure. Automated feeding systems maintain consistent material supply and alignment, crucial for maintaining production consistency and meeting tight turnaround requirements.

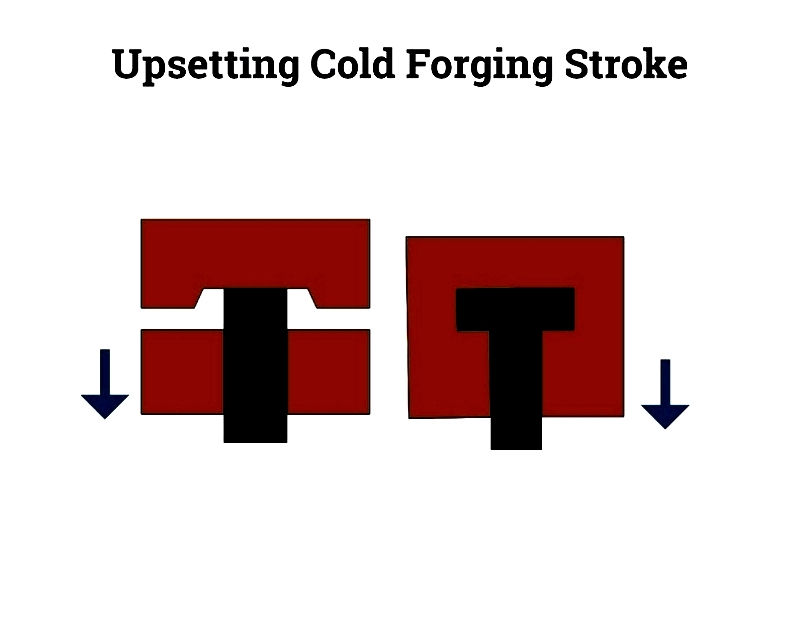

Step 3: Forming Stroke

The core of cold forging involves applying controlled compressive force through mechanical, hydraulic, or pneumatic mechanisms. Modern presses employ precision hammer mechanisms that deliver rapid, powerful strokes—typically within milliseconds. This high-speed deformation creates dense, uniform material structures while maintaining strict tolerances. Complex geometries may require progressive strokes or multi-stage forming to achieve intricate features without excessive flash. The stroke mechanism selection significantly impacts productivity, energy efficiency, and final part quality—key considerations when comparing manufacturing methods.

Step 4: Ejection

After forming, efficient part removal becomes essential for maintaining production flow. Contemporary facilities utilize automated systems—including conveyors, robotics, or pneumatic ejectors—to extract finished components without manual handling. This automation reduces errors, lowers costs, and facilitates integration with downstream quality control and packaging operations, ensuring compliance with international quality standards.

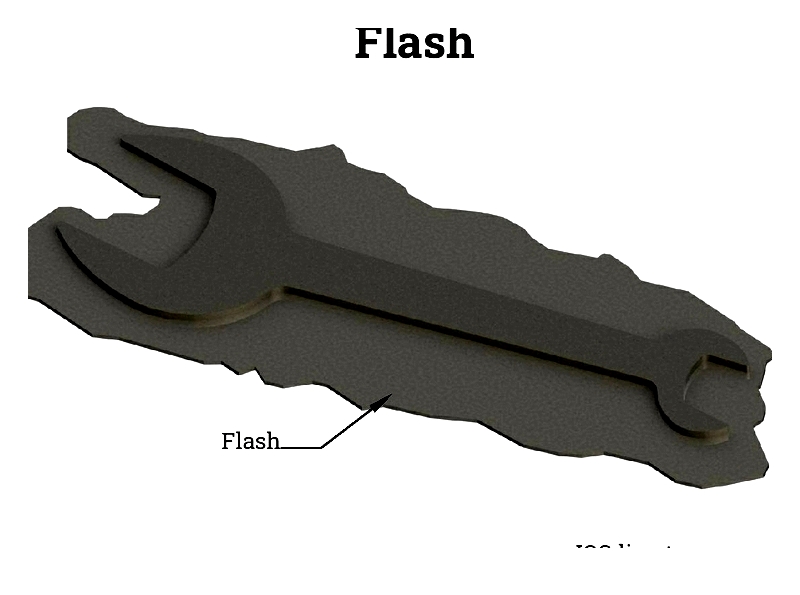

Step 5: Post-Processing

Final handling requirements vary by component complexity. Simple fasteners may only need flash trimming before finishing, while intricate parts might require additional forming, threading, or precision machining. Automated transfer systems move components between processing stations efficiently, while material handling equipment manages larger forgings. Manufacturers typically implement real-time inspection protocols using statistical process control and non-destructive testing to ensure defect-free production for critical applications.

When selecting cold forging services, buyers should evaluate technological capabilities, equipment range, material expertise, secondary processing options, and compliance with industry standards. Comparing cold forging with alternative manufacturing methods helps determine the optimal solution based on cost, performance, production speed, and customization needs. Reviewing samples, case studies, and supplier facilities further supports informed decision-making and supply chain reliability.