Introduction

This article provides an in-depth exploration of centrifugal pumps.

It covers key topics including:

- Working Principle of Centrifugal Pumps

- Various Types of Centrifugal Pumps

- Applications and Advantages of Centrifugal Pumps

- Additional Relevant Information

Chapter 1: Fundamental Principles of Centrifugal Pump Operation

This section examines the core concepts of centrifugal pumps, including their design, construction, and operational mechanisms.

Understanding Centrifugal Pumps

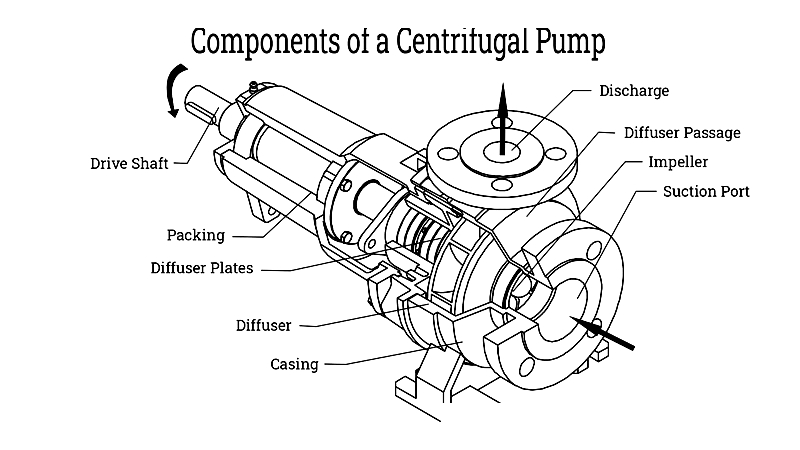

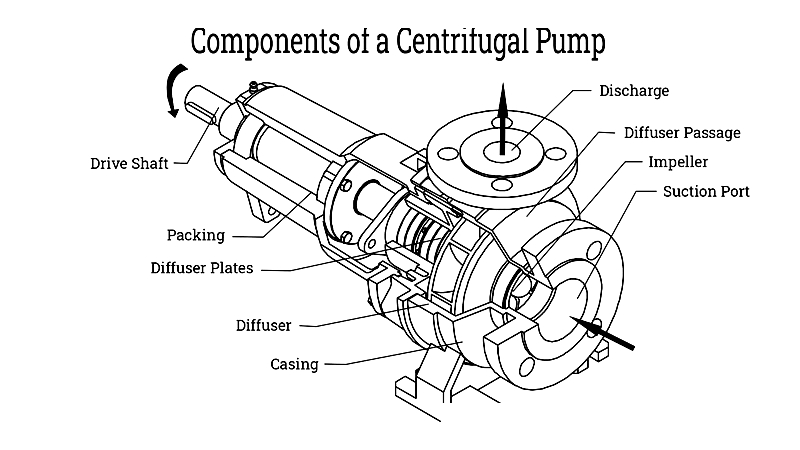

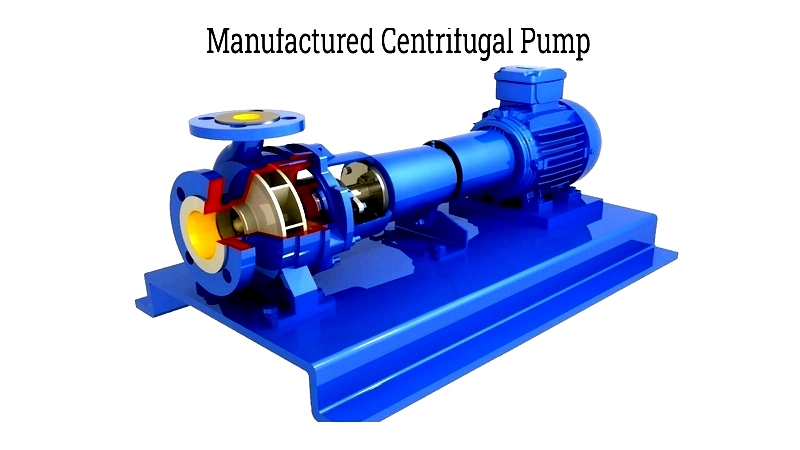

A centrifugal pump is a hydraulic device that transforms mechanical energy into hydraulic energy by applying centrifugal force to fluids. It operates by rotating an impeller to accelerate liquid, converting this velocity into continuous flow. The pump's efficiency relies on the coordinated operation of its mechanical components.

The mechanical assembly comprises a shaft supported by bearings, a sealing system to minimize leakage, structural elements that endure operational stresses, and wear surfaces facilitating maintenance and restoration.

Key Components of Centrifugal Pumps

Essential pump components include:

- Shaft

- Impeller

- Casing

- Suction Pipe

- Delivery Pipe

Pump Shaft

The central rotating element connects to both the impeller and prime mover, transmitting power while maintaining precise alignment through ball bearings.

Pump Impeller

Featuring backward-curved vanes mounted on the motor shaft, this rotating component accelerates fluid within a sealed housing.

Pump Casing

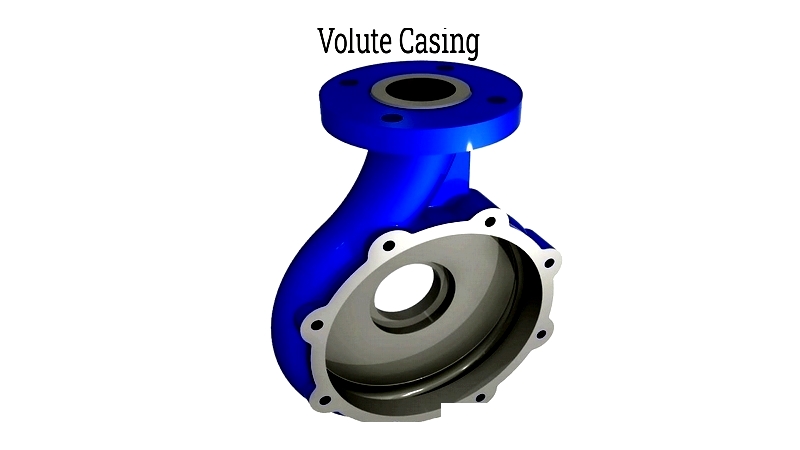

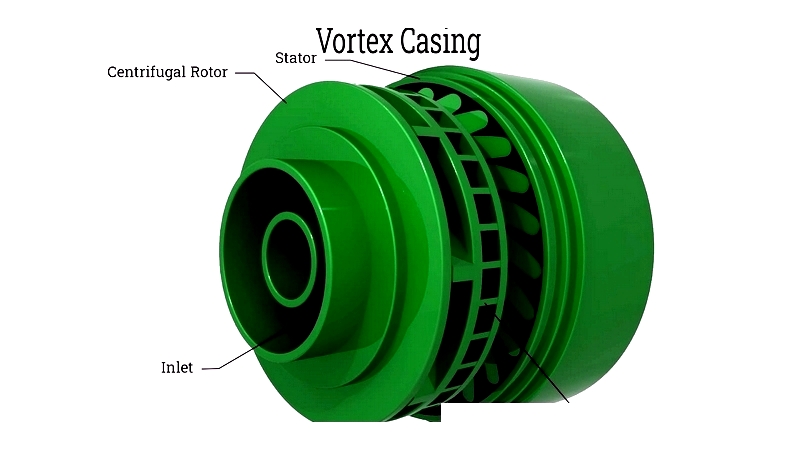

This enclosed chamber converts the impeller's velocity into pressure energy before fluid exits through the delivery pipe. Three primary casing types exist: volute, vortex, and guide blade designs.

Volute Casing

Characterized by a gradually expanding flow area, this design reduces fluid velocity while increasing pressure.

Vortex Casing

Incorporating a circular chamber between impeller and volute, this configuration enhances pressure conversion efficiency.

Guide Blade Casing

Equipped with strategically arranged vanes, this design minimizes turbulence while optimizing velocity-to-pressure conversion.

Suction System Components

The suction pipe connects the water source to the pump inlet, featuring a foot valve for unidirectional flow and a strainer to prevent debris entry.

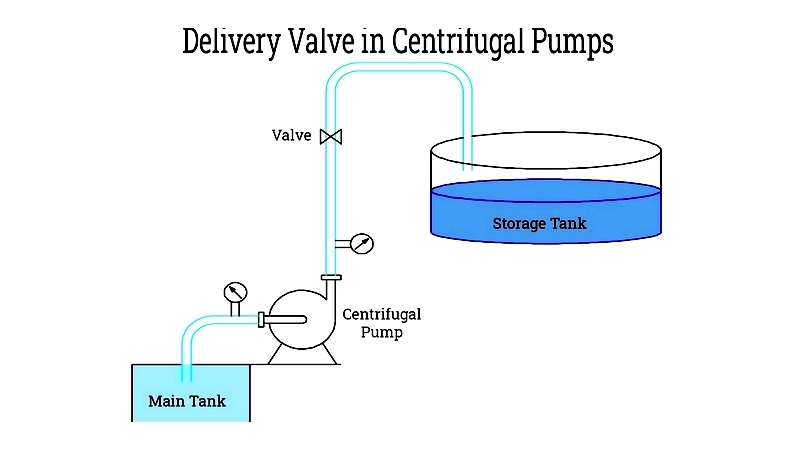

Delivery System

The delivery valve connects the pump outlet to the destination point, enabling fluid transport to required elevations.

Pump Manufacturing Considerations

Material selection balances factors like strength, corrosion resistance, machinability, and cost-effectiveness.

Common Pump Materials

Manufacturers utilize various materials including:

- Cast iron - Preferred for high-pressure applications due to strength and durability

- Stainless steel - Ideal for chemical processing with excellent corrosion resistance

- Cast steel - Suitable for high-pressure conditions with good mechanical properties

- Bronze - Used for sealing applications in pump bodies

- Specialty materials - Including composites for corrosive environments

Material Selection Criteria

Key considerations include:

- Chemical compatibility with processed fluids

- Explosion-proof requirements

- Sanitation needs for food/beverage applications

- Wear resistance for abrasive services

Chapter 2: Centrifugal Pump Varieties

Centrifugal pumps serve diverse industries including water treatment, chemical processing, and manufacturing. Proper pump selection ensures operational efficiency and reliability.

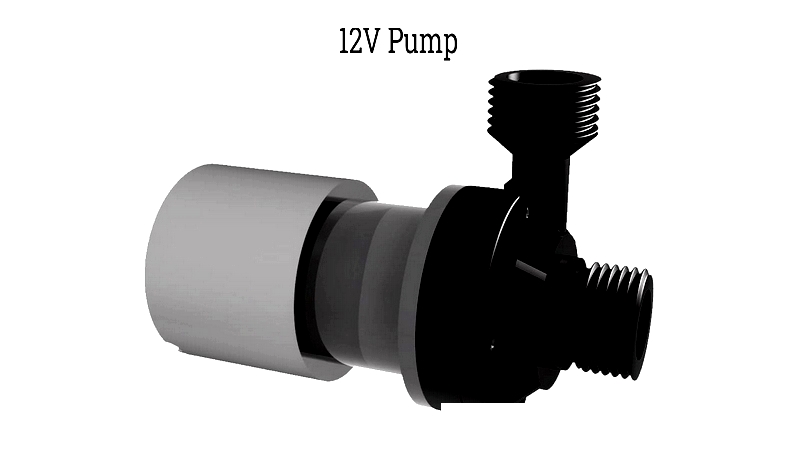

12V DC Pumps

Compact, portable units ideal for marine and emergency applications, featuring 330 GPH flow capacity and 40-foot lift capability.

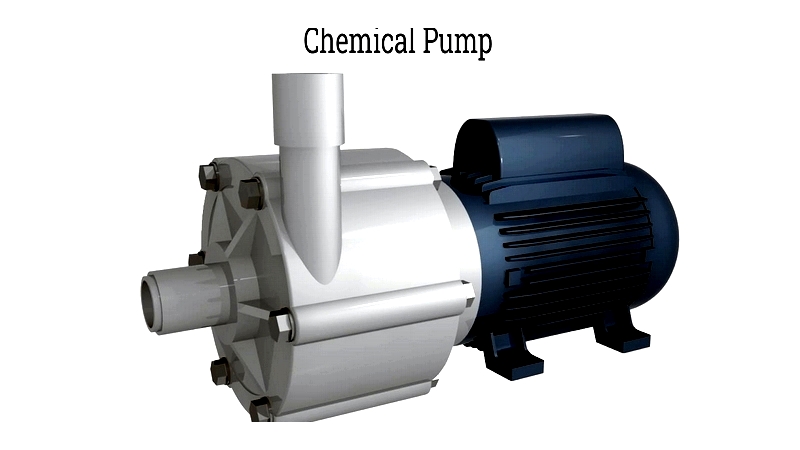

Chemical Handling Pumps

Specialized designs for corrosive/abrasive fluids, constructed with chemically resistant materials like Teflon and polypropylene.

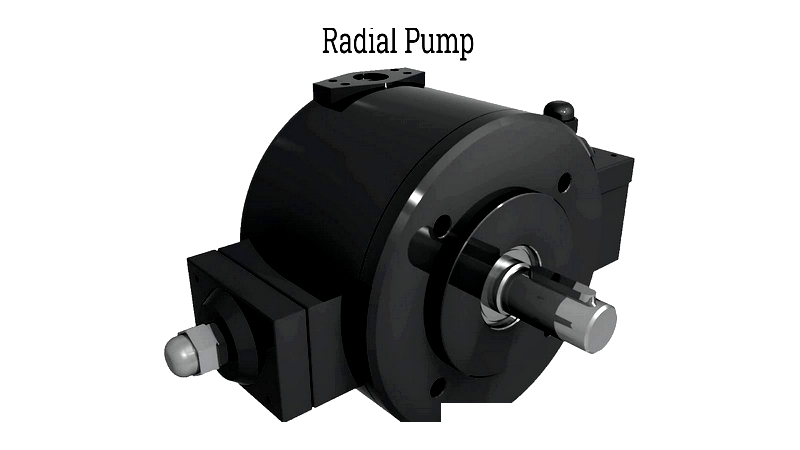

Radial Flow Pumps

Optimized for high-pressure, moderate-flow applications in oil/gas and power generation industries.

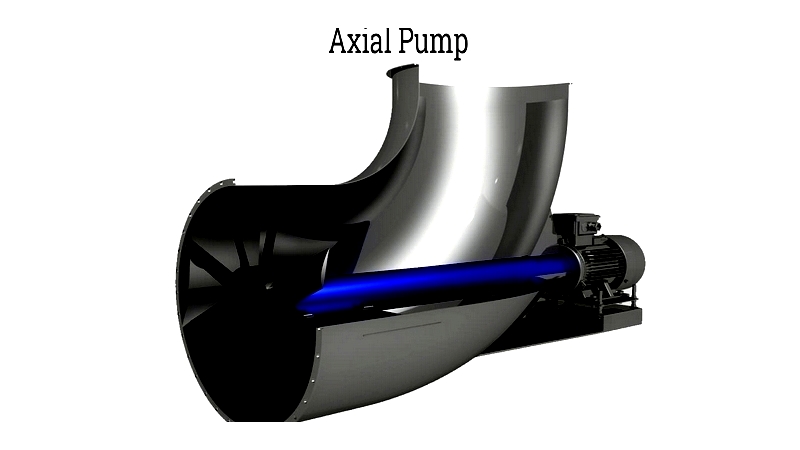

Axial Flow Pumps

High-volume, low-pressure units for irrigation and municipal water systems.

Mixed Flow Pumps

Hybrid designs balancing flow and pressure for versatile applications.

Single Suction Design

Standard configuration for moderate-flow applications with straightforward maintenance.

Double Suction Design

High-capacity configuration with balanced hydraulic performance for demanding services.

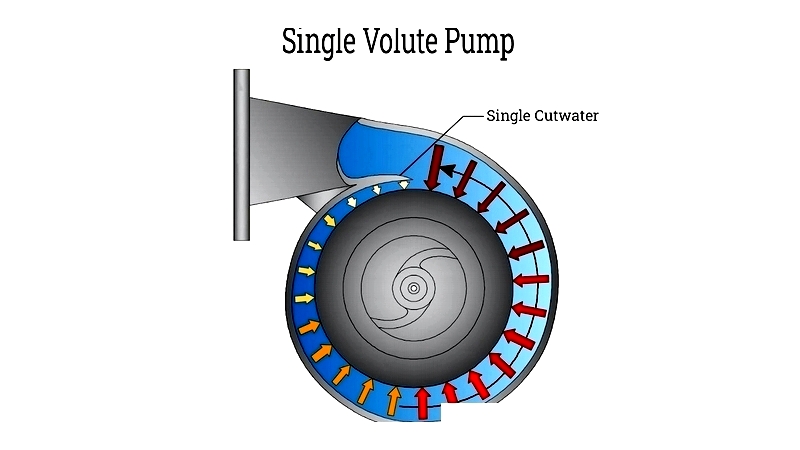

Single Volute Pumps

Cost-effective solution for uniform pressure delivery in refinery and chemical applications.

Trash Handling Pumps

Heavy-duty designs for slurry and wastewater with high solids content.

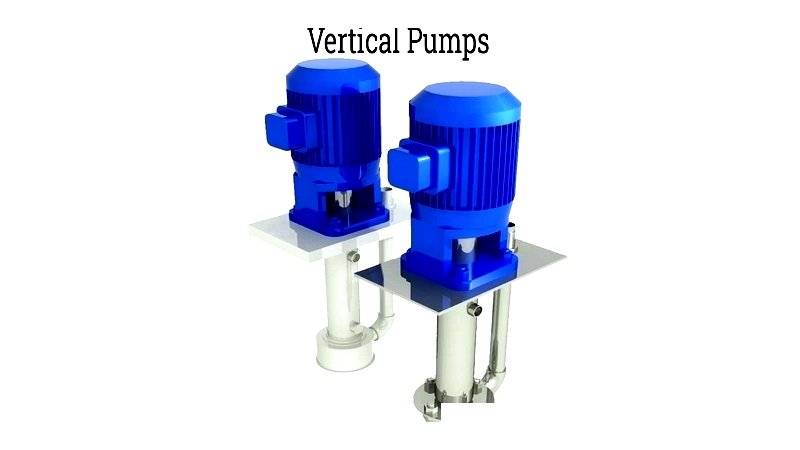

Vertical Turbine Pumps

Deep-well applications with multi-stage impeller configurations.