Introduction

This article provides an in-depth examination of Ultrasonic Flow Meters.

You will explore topics such as:

- What is an ultrasonic flow meter?

- How ultrasonic flow meters work

- Types of ultrasonic flow meters

- Applications of ultrasonic flow meters

- And much more...

Chapter One – What is an Ultrasonic Flow Meter?

An ultrasonic flow meter measures the flow rate of liquids or gases by sending ultrasonic waves through a pipe both with and against the flow direction. It calculates flow rate by analyzing the difference in wave travel times. The device includes two transmitters and two receivers, precisely positioned on opposite sides of the pipe at specific intervals to ensure measurement accuracy.

Known for exceptional precision (±1% accuracy), ultrasonic flow meters are essential for precise custody transfers. Their non-intrusive clamp-on design simplifies installation by attaching directly to the pipe exterior. Unlike traditional flow meters, ultrasonic versions have no moving parts, offering versatility and bidirectional flow measurement capability.

Chapter Two – How Do Ultrasonic Flow Meters Work?

The first ultrasonic flow meter was developed in 1959 by a Japanese inventor using Doppler technology to measure blood flow. By the 1960s, these devices were adapted for industrial use in measuring gas and liquid flow rates in pipelines. Today, they are vital tools for flow monitoring and control across industries including water treatment, oil and gas, chemical manufacturing, pharmaceuticals, HVAC, and food processing.

Ultrasonic flow meters measure liquid or gas volume/mass flow rates to ensure precise flow control. They are valued for their accuracy, reliability, and non-invasive measurement capability. These meters are crucial in industries like chemical processing, water distribution, and energy management where accurate flow data is essential for process optimization, efficiency improvement, and regulatory compliance. Their lack of moving parts or pipe penetration minimizes maintenance and ensures long-term reliability.

How an Ultrasonic Flow Meter Works

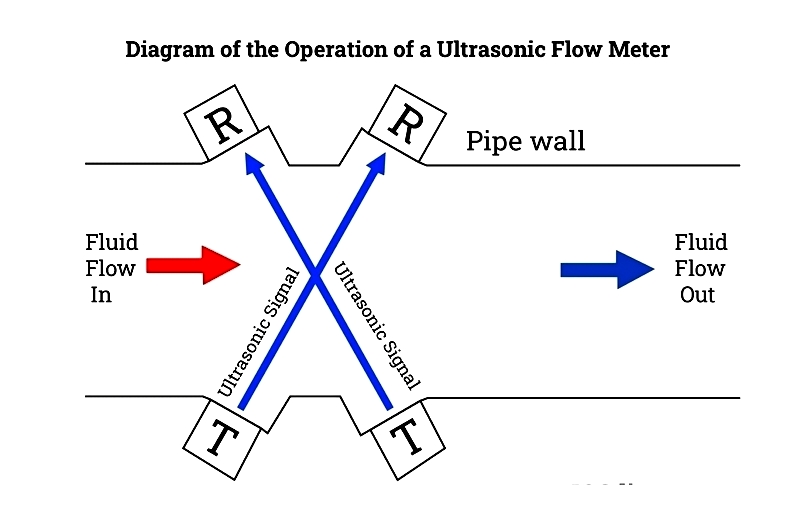

Ultrasonic flow meters use acoustic waves and two primary measurement methods: transit time and Doppler shift. These technologies enable high-accuracy flow measurement for both clean and dirty fluids. The transit time method sends sound waves diagonally across the flow, measuring travel time in both directions. The Doppler method projects waves along the flow path, measuring frequency shifts from suspended particles or bubbles.

The operating principle relies on how fluid flow rate affects ultrasonic wave pulse velocity. By analyzing these changes, the meter determines flow rates in pipes or channels, providing real-time data for process control and system diagnostics.

Construction Of An Ultrasonic Flow Meter

The transducer (core sensor) can be installed parallel to or at an angle on the pipe exterior, or inline within the flow stream. Ultrasonic flow meters typically use two transmitters to emit ultrasonic pulses and two receivers to capture signals. One transmitter sends waves with the flow (upstream), while the other sends waves against it (downstream). The signal strength difference between directions enables precise bidirectional flow calculations.

Doppler Principle

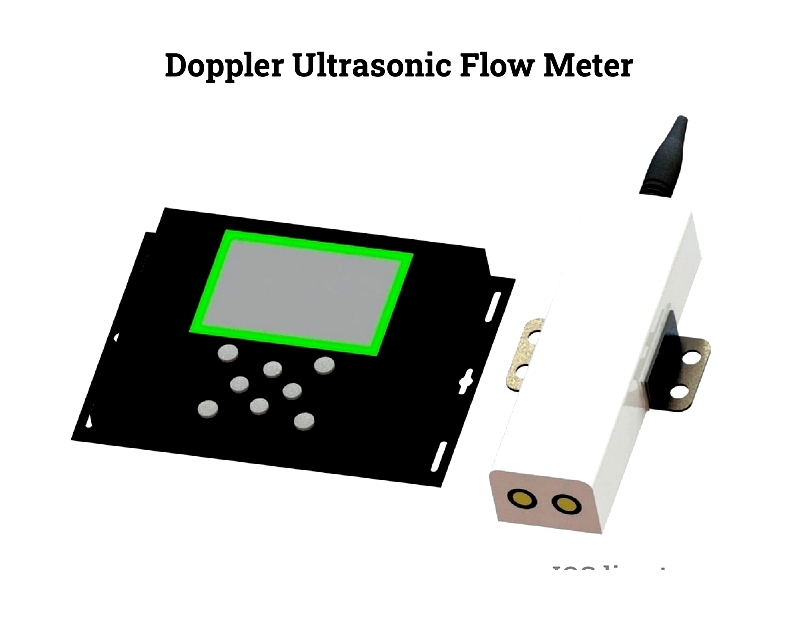

Doppler ultrasonic flow meters measure frequency shifts (Doppler effect) from sound waves scattered by suspended particles or bubbles in the fluid. This shift correlates to fluid velocity, enabling accurate measurement in challenging applications like sludge, slurries, and wastewater. These meters are ideal for "dirty" flows with particulates.

What Transit Time Measures

Transit time meters measure flow speed by calculating the time difference for ultrasonic pulses traveling with and against the flow. This data is converted to volumetric or mass flow rate, offering high precision for clean liquids. These meters can measure bidirectional flow, making them suitable for water distribution and energy management systems.

What Is Topology?

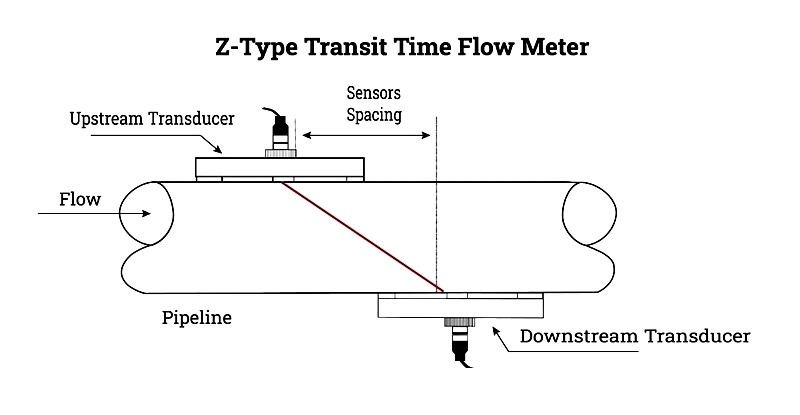

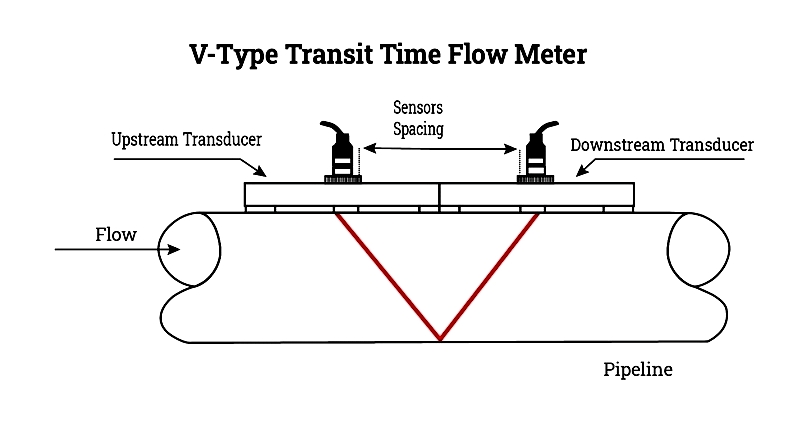

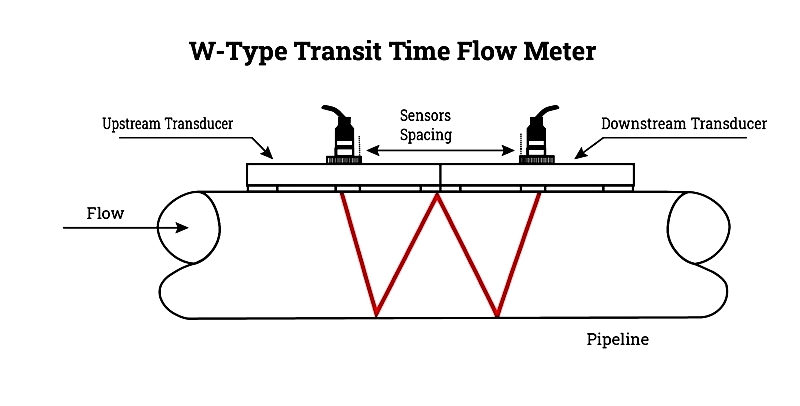

Topology refers to the geometrical path (Z, V, or W configuration) taken by ultrasonic pulses through the pipe. Each configuration affects measurement accuracy, installation flexibility, and suitability for different pipe sizes and materials.

Z Transit Time

Ultrasonic waves follow a Z-shaped path, commonly used for large pipes requiring high accuracy in industrial flow monitoring.

V Transit Time

Both receiver and transmitter are on the same pipe side, with waves reflecting off the far wall. Suitable for small to medium pipes, popular in HVAC and building automation.

W Transit Time

Waves bounce multiple times, increasing path length for enhanced accuracy in small pipes or high-precision applications.

Open Channel Ultrasonic Flow Meters

These non-contact meters use ultrasonic level sensors to measure water flow through weirs and open channels. They require precise channel geometry knowledge and perform best in sediment-free conditions for applications like wastewater treatment and irrigation.

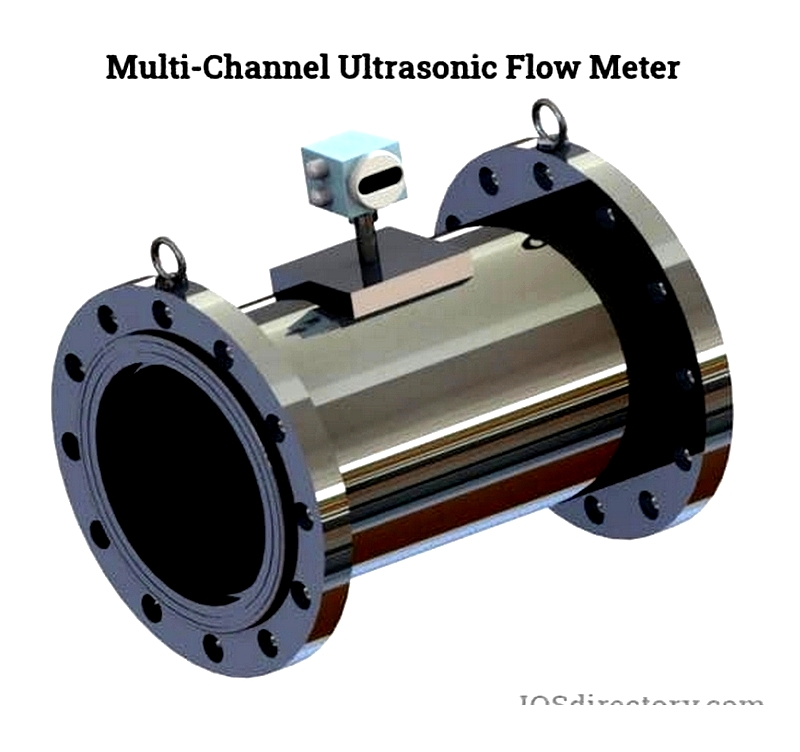

Using A Multi-Channel Ultrasonic Flow Meter

Multi-channel meters use multiple acoustic beams to measure flow at different pipe positions, improving accuracy in complex flow conditions. They're valuable for industrial automation and predictive maintenance.

Chapter Three – Types of Ultrasonic Flow Meters

Various flow meter types serve different industrial applications, from gas monitoring to water measurement. Ultrasonic meters stand out for their accuracy, reliability, and noninvasive operation. They differ by sensor configuration, attachment method, and compatibility with pipe materials and fluids.

Ultrasonic Flow Meter Types

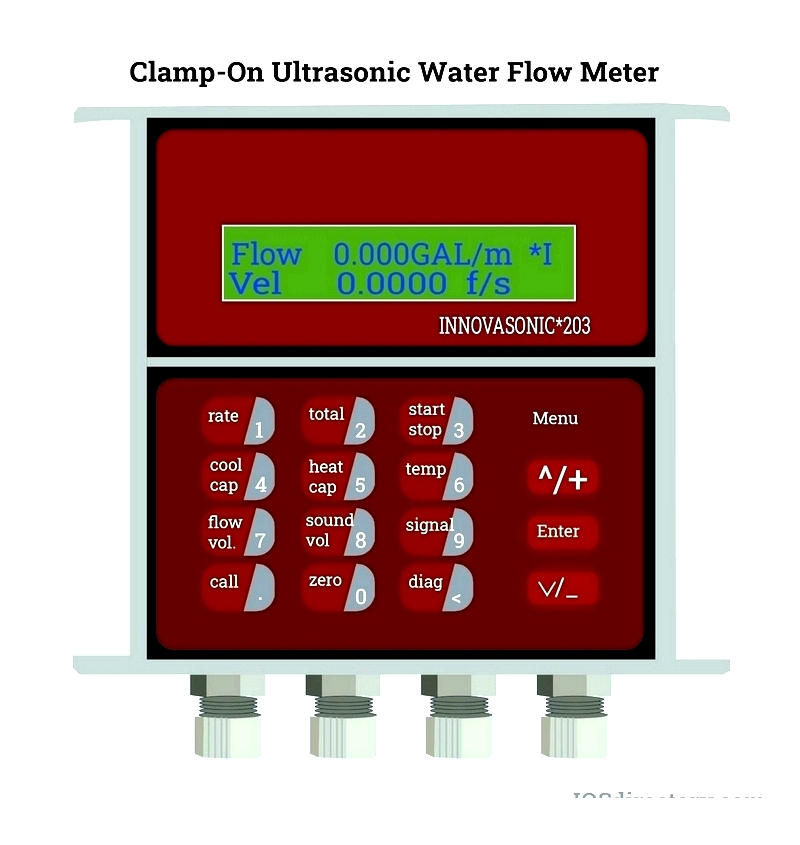

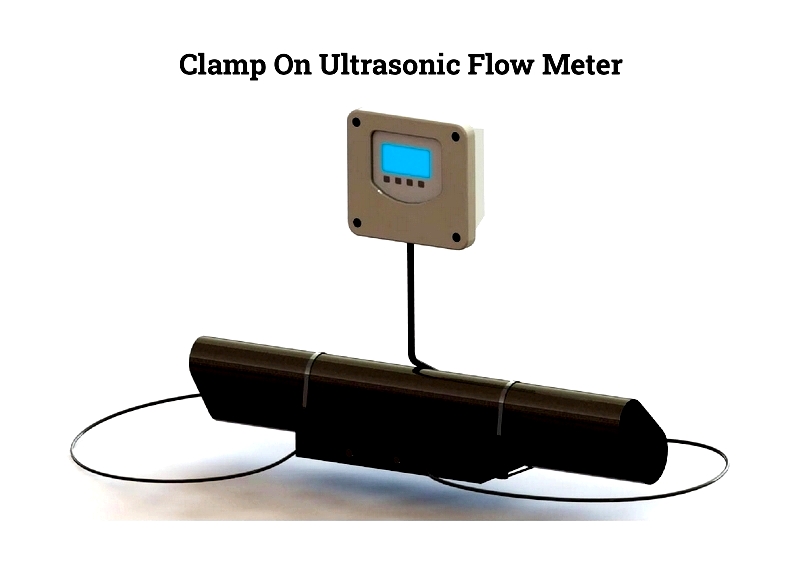

Clamp-On Ultrasonic Flow Meters

These non-invasive meters attach externally to pipes, ideal for temporary measurements or retrofits. Single-sensor models have both crystals in one body, while dual-sensor versions offer improved accuracy with separate transmitter and receiver units.

Hybrid Ultrasonic Flow Meters

Combining Doppler and transit time technologies, these versatile meters handle both clean and contaminated fluids, reducing the need for multiple instruments.