Introduction

This article provides an in-depth exploration of optical comparators.

It covers various aspects including:

- What are Optical Comparators?

- Working Principles of Optical Comparators

- Selection Criteria for Optical Comparators

- Components of an Optical Comparator

- Different Types of Optical Comparators

- Applications, Benefits, and Limitations of Optical Comparators

- And more...

Chapter One: Understanding Optical Comparators

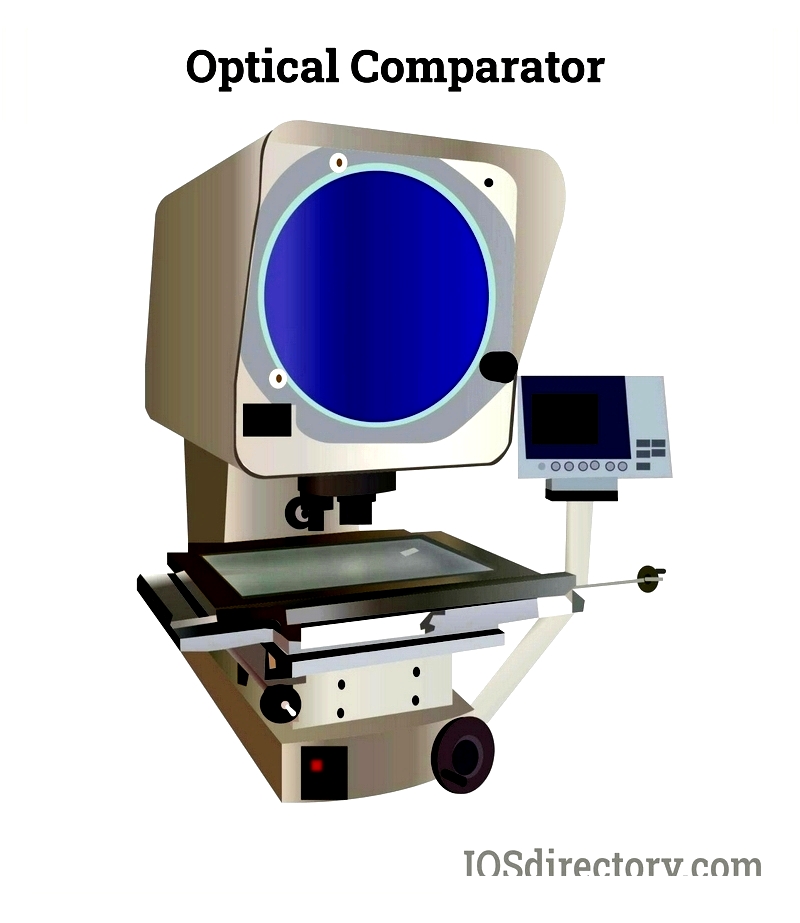

Optical comparators are precision measurement instruments that provide accurate and reliable data. These devices utilize video imaging, geometric dimensioning and tolerancing (GD&T), along with light, lenses, mirrors, and cameras to analyze part tolerances. For quality control teams, they are essential tools for evaluating production processes and ensuring product quality.

During workpiece analysis, the optical comparator projects an image onto a screen for comparison with established standards. This method enables examination of complex components like stampings, gears, cams, and threads against their models. Optical comparators are crucial in manufacturing precision machinery for industries such as aviation, aerospace, electronics, and instrumentation.

The comparator quickly identifies flaws like defects, scratches, indentations, and dimensional errors by comparing workpieces to standard specifications. Its precise calibration ensures accurate deviation detection.

Methods of Using Optical Comparators

The Traditional Comparator Approach

Since their introduction in the 1920s, comparator designs have remained largely unchanged. However, technological advancements, improved calibration methods, digital technology, and enhanced magnification have significantly increased their accuracy. Traditionally, workpieces are placed on an illuminated stage, with their shadows projected onto a screen using lenses and mirrors.

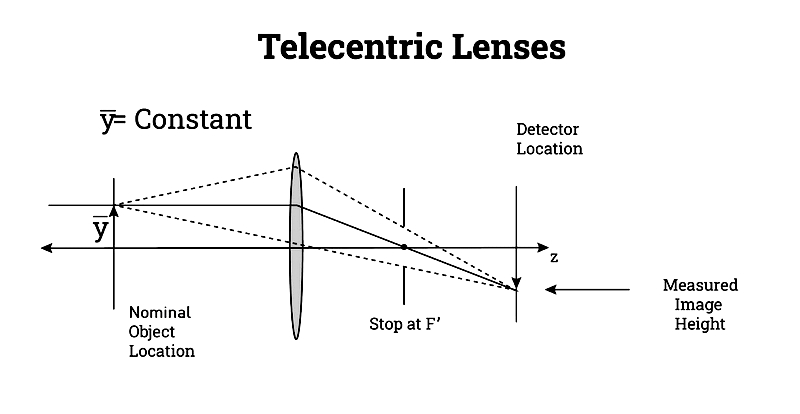

A telecentric optical system enlarges the projected image for precise magnification. This lens configuration maintains accurate scaling without distortion. The dimensional accuracy and surface details are then measured against standard parameters.

Optical comparators are primarily available in two styles: horizontal and vertical. Horizontal models provide side views, while vertical models offer overhead perspectives. Manufacturers have relied on both types for quality evaluation over the years.

While traditional optical comparators have been effective for decades, they face limitations in meeting modern manufacturing demands:

- Complexity - Modern components require multi-angle observation using 3D projection systems.

- Accuracy - Current manufacturing requires tighter tolerances than 2D projection systems can achieve.

- Efficiency - Conventional comparators can only measure one part at a time, making them inefficient for large-scale production.

- 2D Limitation - Traditional comparators are limited to 2D projections, which are inadequate for multiplanar components.

Optical System Varieties

Optical comparators utilize four main types of optical systems: simple optics, corrected optics, fully corrected optics, and telecentric optical systems.

- Simple Optics: This basic system includes a light source, magnification lens, mirror, and projection screen, producing an inverted and reversed image.

- Corrected Optics: An additional internal mirror improves the simple optics system, though the image remains inverted.

- Fully Corrected Optics: This system produces right-side-up, unreversed images, simplifying measurement translation.

- Telecentric Optical Systems: These systems enable accurate magnification projection across the entire stage, maintaining constant image size regardless of object distance.

Telecentric lenses align workpieces with screen grid overlays for precise distance measurements. Profile projectors may also use episcopic lighting for internal section illumination.

Manual methods are being replaced by advanced computer software. Three modern approaches include:

- Software evaluation: Digital video comparators use CAD overlays that automatically adjust with magnification changes.

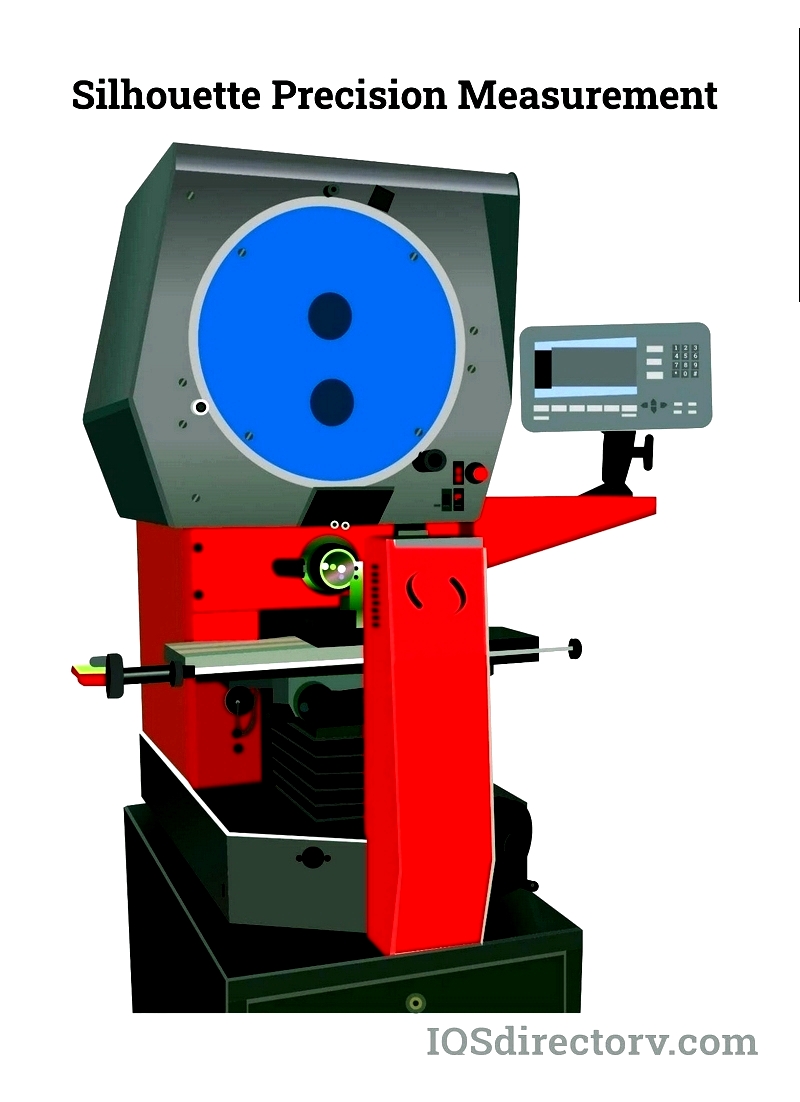

- Silhouette Size: This traditional method projects workpiece silhouettes for measurement, with digital readouts recording stage movements.

- Point Comparing: Similar to silhouette techniques, this method evaluates images against specified reference points.

Traditional optical comparators still primarily use silhouette methods, inspecting one piece at a time. Video comparators offer faster operation, precise data, and efficient large-part examination.

Traditional comparators experience image size variations due to optics and screen characteristics. Screens typically start at 12 inches, with larger screens requiring bigger enclosures to prevent distortion.

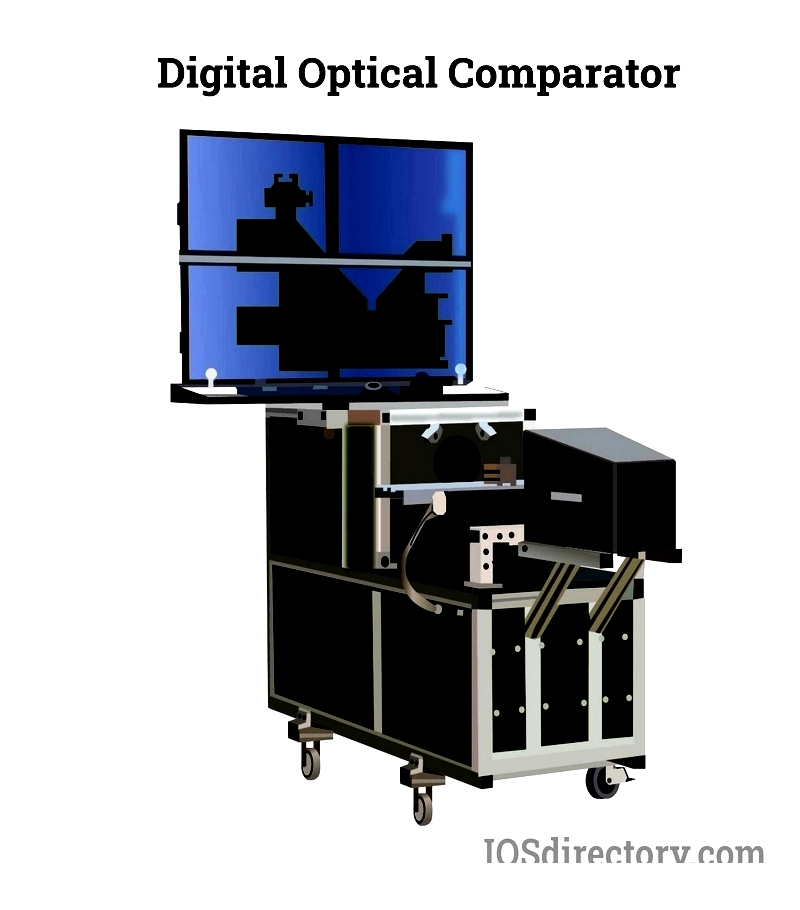

Digital video comparators project images onto computer displays for easy manipulation. Automated digital comparators use cameras to capture part images for electronic comparison with CAD references.

Selection Considerations for Optical Comparators

Readout and Software

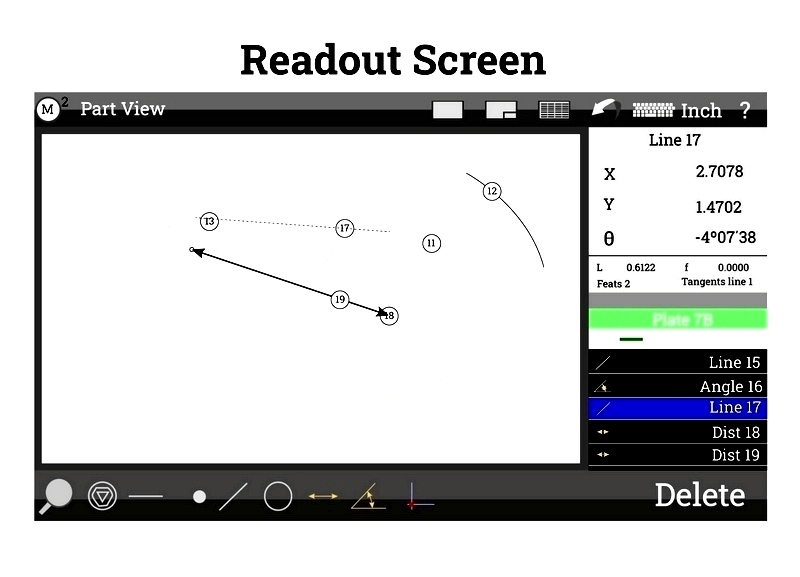

Basic measurements require XY digital readouts, while geometric tasks need more capable systems. CNC-capable readouts benefit repetitive measurements. Optical edge detection reduces operator subjectivity and improves accuracy.

Options and Tooling

Secure workpiece clamping is essential for consistent measurements. Modern fixtures like rotary fixtures and digital protractors enhance inspection versatility.

Screen Size

Screen sizes range from 12" to 32". Visible area is determined by dividing screen diameter by lens magnification. Engineers recommend staying within an inch of the screen's edge with overlays.

Lens Requirements

Operators can reliably discern 0.004" on comparator screens. Lens magnification resolution is crucial for tight tolerances. Standard projectors typically include one lens, with additional lenses available.

Light Path

Horizontal light paths suit threads, shafts, and machined parts, while vertical paths are better for flat components like gaskets and electronics.

Camera

Digital video comparators combine optical comparators with digital microscopes, offering high-resolution capabilities and user-friendly interfaces. They capture detailed images with superior clarity.

Technical Support

Choose manufacturers offering global online support to minimize downtime and quickly resolve issues.

Chapter Two: Components of Digital Video and Traditional Optical Comparators

Digital Video Comparator

Digital video comparators, or vision measurement systems, combine video imaging with computer software for high-precision measurements. These systems use CAD drawings for comparison and often incorporate laser measurement tools and specialized software. The integrated vision system connects to a computer for precise dimensional analysis, making them ideal for non-contact measurement and quality control.

Light Source

Workpieces are positioned on illuminated glass stages, typically with LED backlighting for uniform illumination. This transmitted light highlights profiles for clear imaging by high-resolution cameras.

LED Lights

Programmable LED ring lights enhance contrast and feature detection, supporting multi-angle illumination for accurate measurements.

Camera

Digital comparators use advanced industrial cameras, including:

- CCD Cameras: Produce sharp, low-noise images for accurate measurements.

- CMOS Cameras: