Introduction

This article provides an in-depth discussion about collaborative robots.

It covers the following topics:

- Principles of Collaborative Robots

- Types of Collaborative Robots

- Applications and Benefits of Collaborative Robots

- And more...

Chapter 1: Understanding the Core Principles of Collaborative Robots

This chapter explores collaborative robots, focusing on key considerations when selecting the right cobot for specific applications.

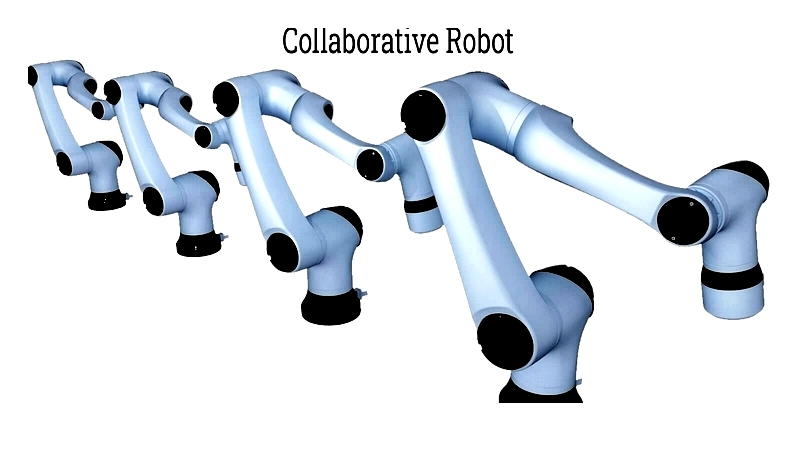

Defining Collaborative Robots

Collaborative robots, or cobots, represent a breakthrough in robotics by working alongside humans. Equipped with environmental sensors, they operate safely with human workers, entering protective mode when detecting disturbances or safety threats - a significant improvement over traditional robots lacking these safety features.

Automation Equipment

Cobots form a specialized category within automation equipment, which includes various machinery for automated production like automation cells, conveyors, industrial robots, and specialized equipment such as turn-over machines and lifters.

Tools for Collaborative Robots

Cobots use similar tools to traditional robots, adaptable to various positions and applications. Manufacturers are developing specialized cobot tools to enhance their capabilities, including:

- Vision systems

- End of Arm Tooling (EOAT)

- Grippers

- Software

- Range extenders

- Supply components

- Safety systems

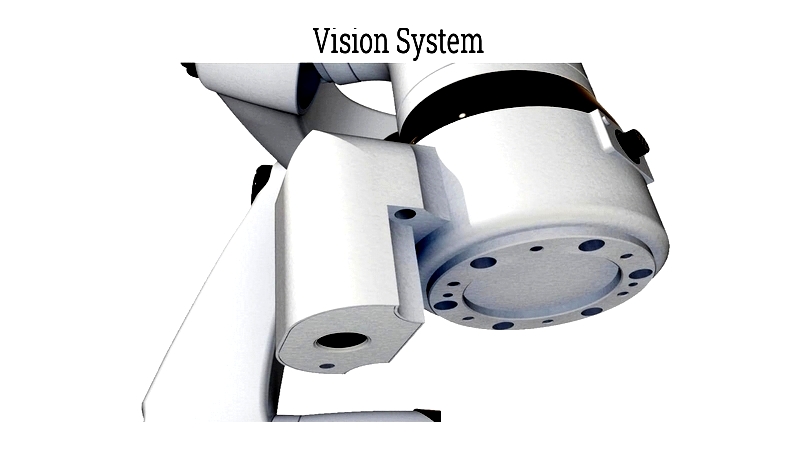

Cobot Vision Systems

Vision systems enable cobots to perceive and interpret their environment using 3D or 2D cameras. These systems allow object detection, pattern recognition, and barcode scanning, facilitating flexible product handling without requiring organized layouts. Enhanced by Artificial Intelligence, they support optical inspections like flaw detection.

Vision systems vary based on application needs, with options including:

2D Vision Systems

More affordable than 3D systems, 2D cameras measure width and length but not height.

3D Vision Systems

3D cameras measure width, height, and length, making them ideal for handling objects of varying elevations or stacked items in packing/palletizing operations.

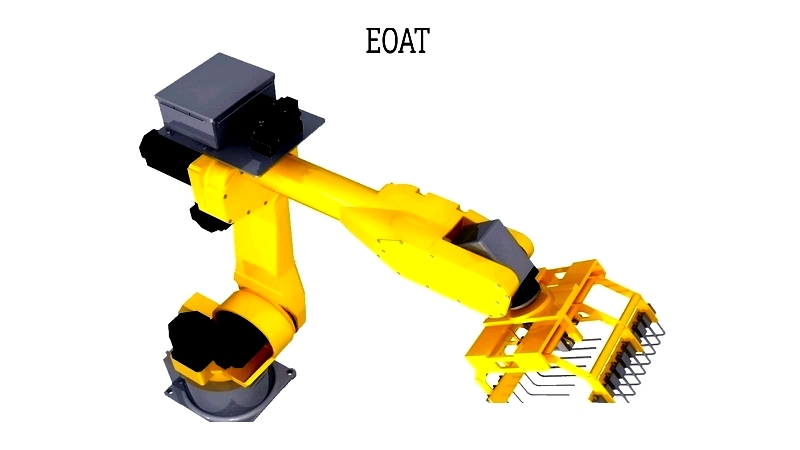

End of Arm Tooling (EOAT)

EOAT includes various attachable tools like sanders, screwdrivers, sensors, tool changers, glue dispensers, and welding equipment. Recent advancements have expanded cobot capabilities in production environments.

EOAT Varieties

EOAT tools continue evolving, enabling cobots to handle more applications. Examples include:

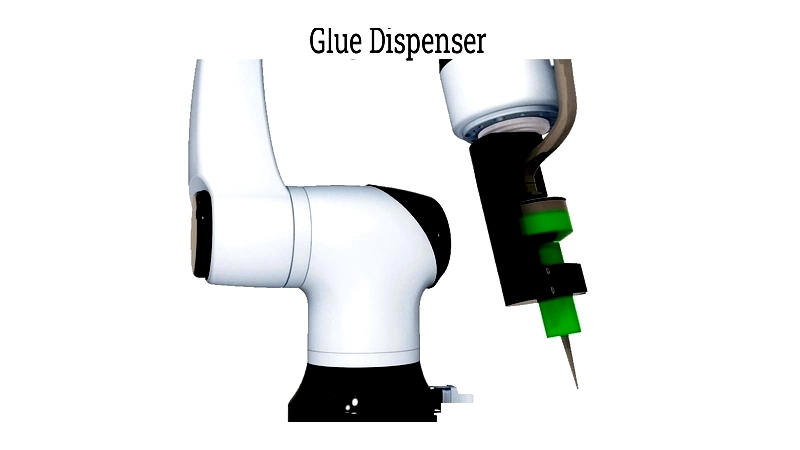

EOAT Glue Dispensers

These tools precisely apply glue along programmed paths, minimizing waste through controlled dispensing.

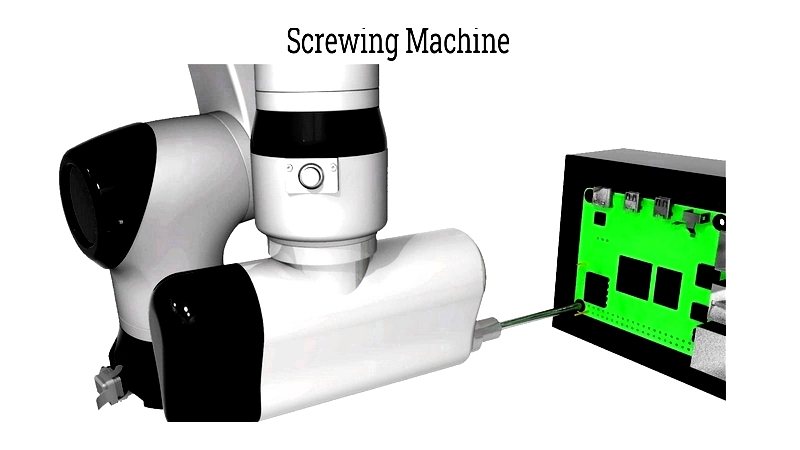

EOAT Screwing Machines

Automating repetitive fastening tasks, these tools work independently or alongside human operators.

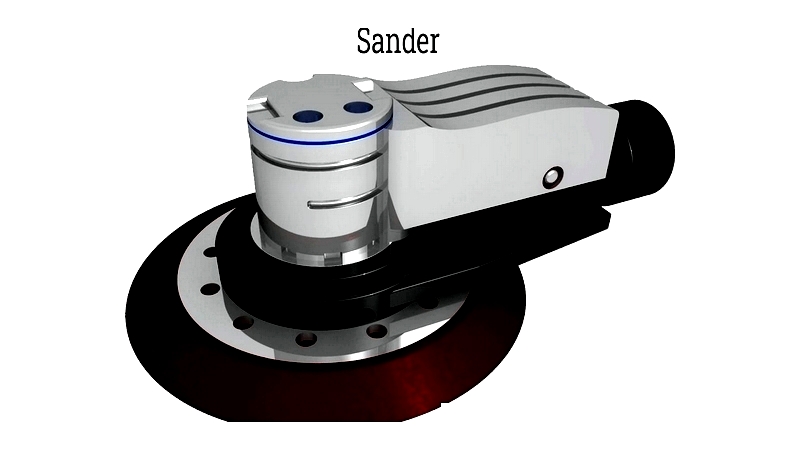

EOAT Sanders

Equipped with sensors for consistent pressure, these tools sand, polish, or deburr surfaces according to programmed paths.

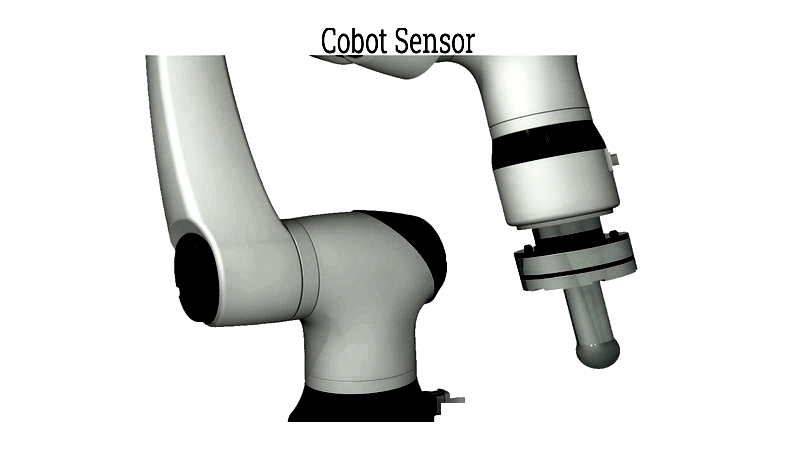

Cobot Sensors

Integrated sensors ensure safe human collaboration, with additional sensors available for tasks requiring extra precision.

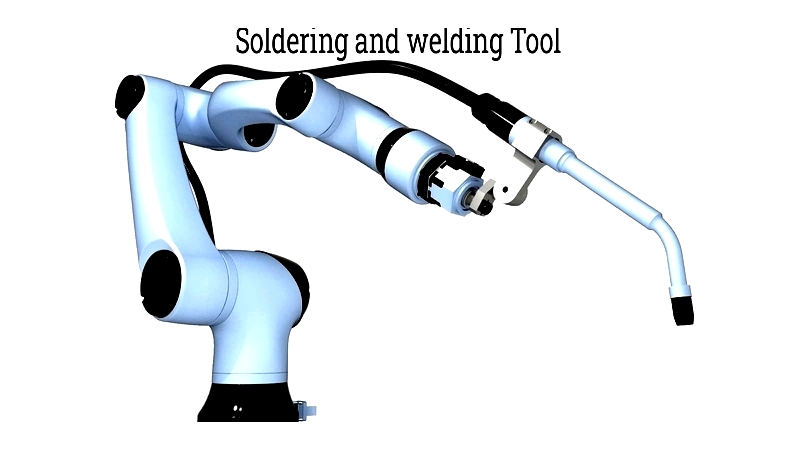

Cobot Soldering and Welding Tools

Cobots excel in high-precision soldering and welding when equipped with appropriate tools.

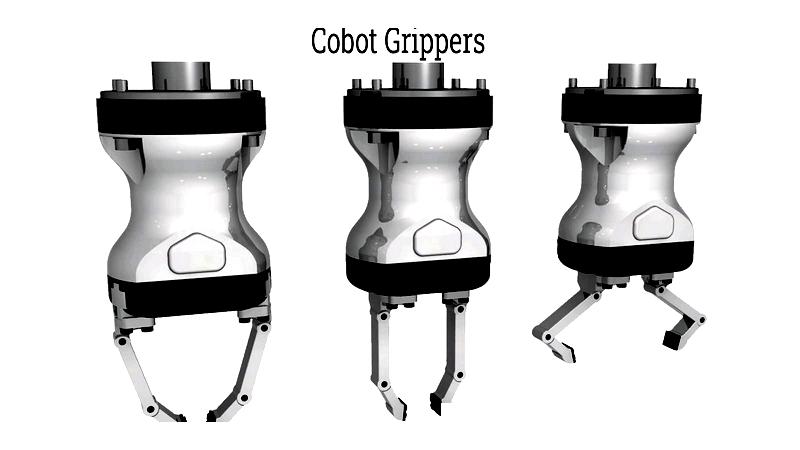

Cobot Grippers

Grippers enable cobots to manipulate objects, with types including vacuum, magnetic, and finger grippers designed for specific materials and tasks.

Gripper Types

Selection depends on material and task requirements:

Electric Grippers

Offer precise control for complex tasks.

Pneumatic Grippers

Cost-effective solution for simpler applications.

Finger Grippers

Provide secure handling for high-precision work.

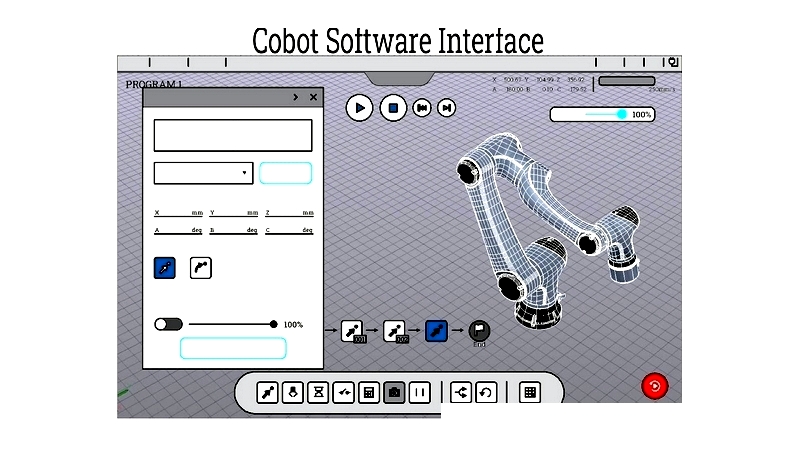

Cobot Software

Intuitive programming software enables quick cobot deployment and task adaptation, contrasting with traditional robots requiring extensive programming.

RoboDK

This user-friendly simulation tool supports offline programming for various applications without requiring coding expertise.

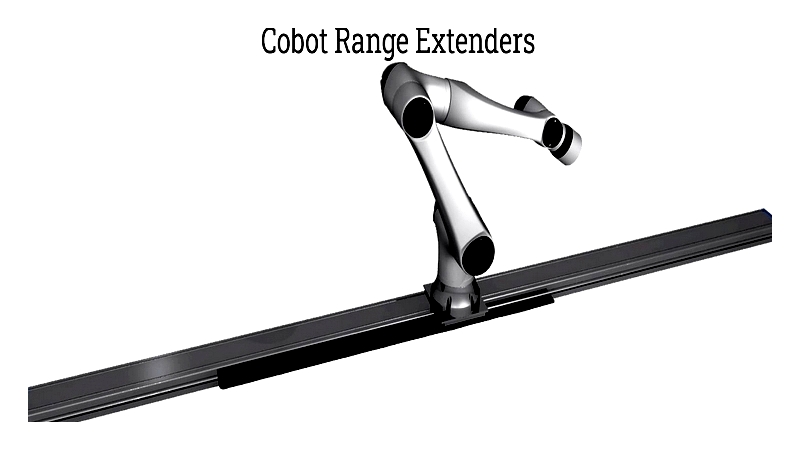

Cobot Range Extenders

These accessories expand cobot reach, enhancing automation capabilities in applications like palletizing.

Cobot Safety

Safety features include proximity sensors and barriers for safe human-robot interaction.

Cobot Supply Systems

These systems provide materials for cobot manipulation, such as screw-feeding systems for assembly processes.

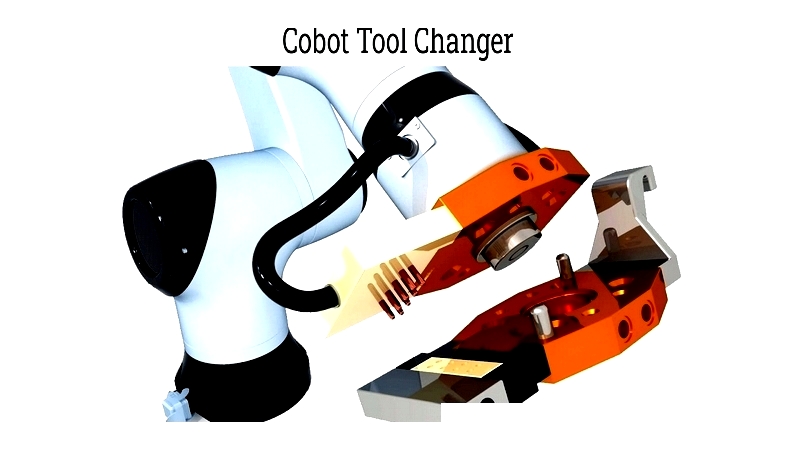

Cobot Tool Changers

Automatic changers enable cobots to switch between tools, increasing versatility and productivity.

Selecting a Collaborative Robot

Key considerations include:

Applications

Cobots excel in dull, dirty, dangerous, or physically demanding tasks like assembly, material handling, and packaging.

Systems Integrator

Professional integrators can facilitate smoother cobot implementation.

Risk Assessment

Essential for ensuring safe operation despite built-in safety features.

Implementation Questions

Key questions to address:

- What are the automation benefits?

- What are the investment and ROI expectations?

- How will employee roles change?

- What training is available?

- What post-installation support exists?