Introduction

This article provides comprehensive information about ball screws.

Continue reading to learn about:

- What are ball screws?

- Ball screw components

- Ball screw accuracy

- Different types of ball screws

- Comparing ball screws and lead screws

- Benefits of using ball screws

- And more...

Chapter 1: Understanding Ball Screws

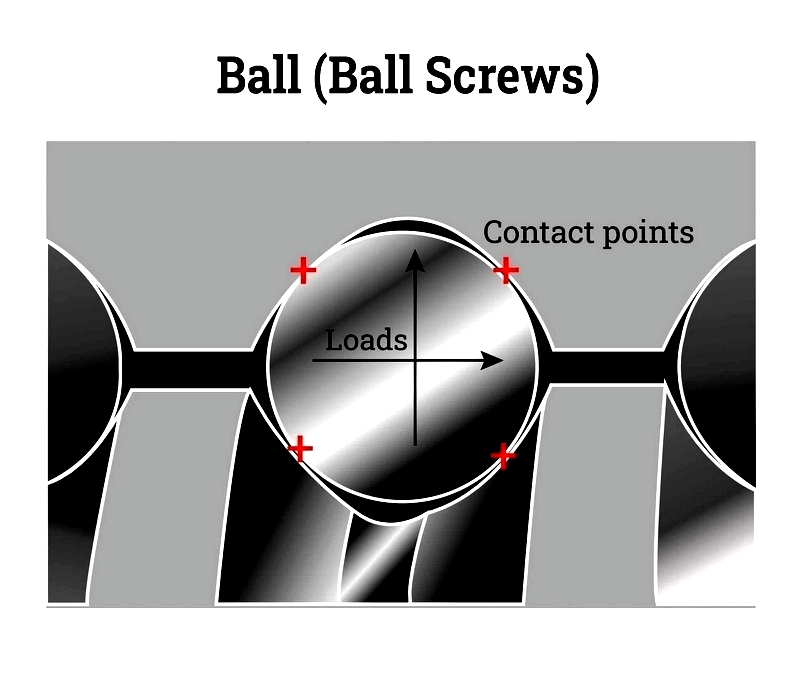

Ball screws are specialized mechanical linear actuators consisting of a screw shaft and a nut containing rolling balls. These balls move along matching helical grooves, converting rotational motion into precise linear motion. Ball nuts efficiently transfer force to stationary or moving loads with high accuracy and consistency.

By using rolling balls in helical channels, ball screws minimize mechanical contact within the assembly. This design replaces sliding friction with rolling friction, significantly reducing friction and improving power transmission efficiency. The performance of ball screws depends on their ability to smoothly convert rotational force into linear motion.

Ball screws feature more complex designs and are generally larger than other screw types. While they may cost more, their superior performance often justifies the investment.

Chapter 2: Ball Screw Components

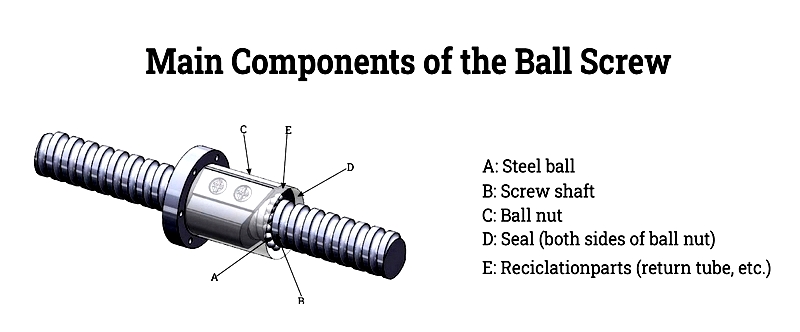

Ball screws are essential linear motion devices used in automation, robotics, and CNC machinery for converting rotation into precise linear movement with minimal friction. The main components include the screw shaft, ball nut, and ball bearings. Understanding these elements and their specifications is crucial for optimizing performance, efficiency, and longevity. Below we examine each component in detail.

Screw Shaft

The screw shaft is the central load-bearing component that receives rotational force from a motor or actuator. As it rotates, it converts this motion into controlled linear displacement, making it vital for high-precision applications.

The hardened cylindrical shaft features a continuous helical groove (ball groove) that serves as a raceway for the rolling balls. This groove forms the screw's thread and transmits force between the shaft and nut.

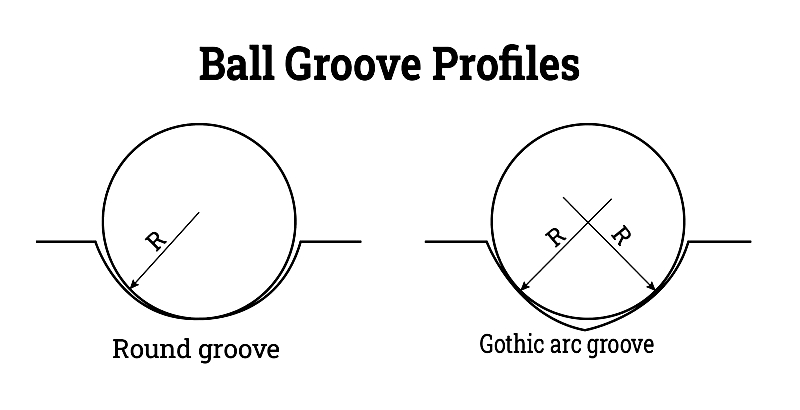

The ball groove profile, either semi-circular or gothic arch, affects load distribution, rigidity, and backlash. A semi-circular arc uses a single-radius curve, while a gothic arch has two intersecting curves for improved load capacity and accuracy.

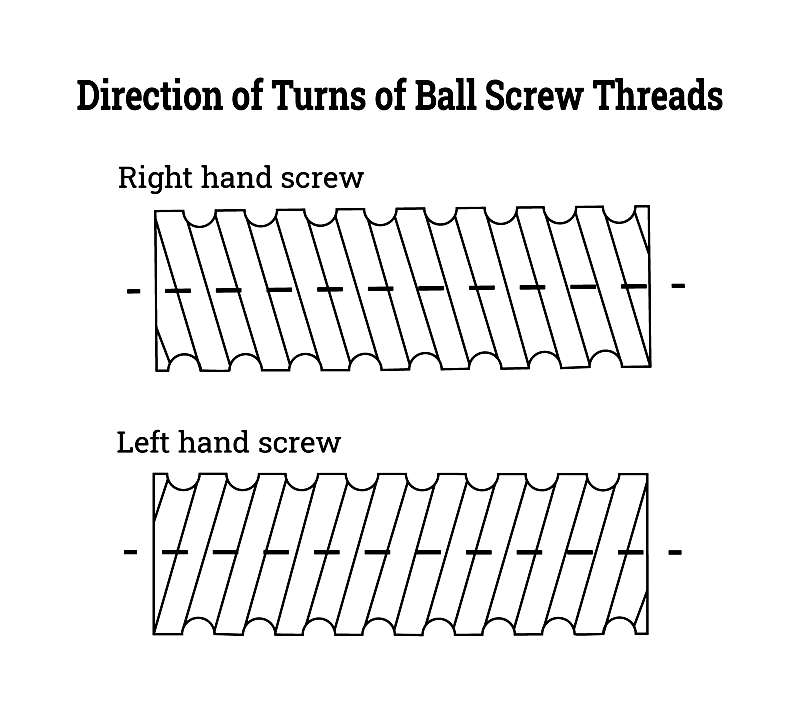

Ball screws are classified as right-hand (clockwise groove) or left-hand (counterclockwise groove). Proper identification is crucial for correct installation and machine design.

Key Screw Shaft Specifications:

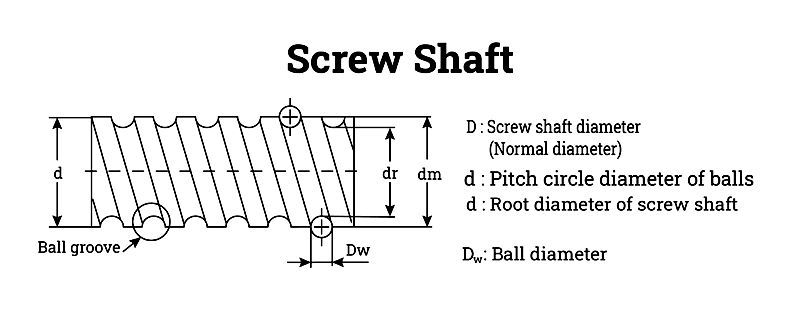

Nominal Diameter

The largest outside diameter of the screw shaft (excluding balls) determines load capacity and system fit. Larger diameters offer greater strength.

Ball Circle Diameter

The diameter through ball centers affects torque transmission, smoothness, and system rigidity.

Root Diameter

The smallest core diameter between groove bottoms impacts tensile strength and buckling resistance in long-stroke applications.

These dimensions are essential for calculating load ratings, torque requirements, critical speed, and system compatibility.

Pitch

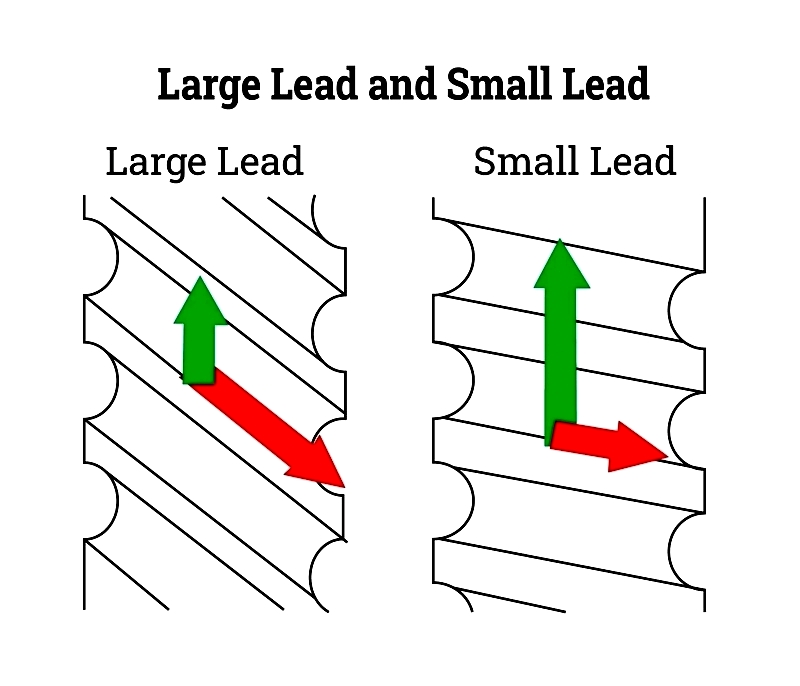

The axial distance between adjacent threads affects linear resolution and positioning precision per revolution.

Lead

The distance a nut travels per revolution influences speed, acceleration, and load capacity. Larger leads increase speed but reduce load capacity.

Higher leads mean fewer engaged balls, potentially lowering dynamic load ratings. Proper lead selection depends on application requirements.

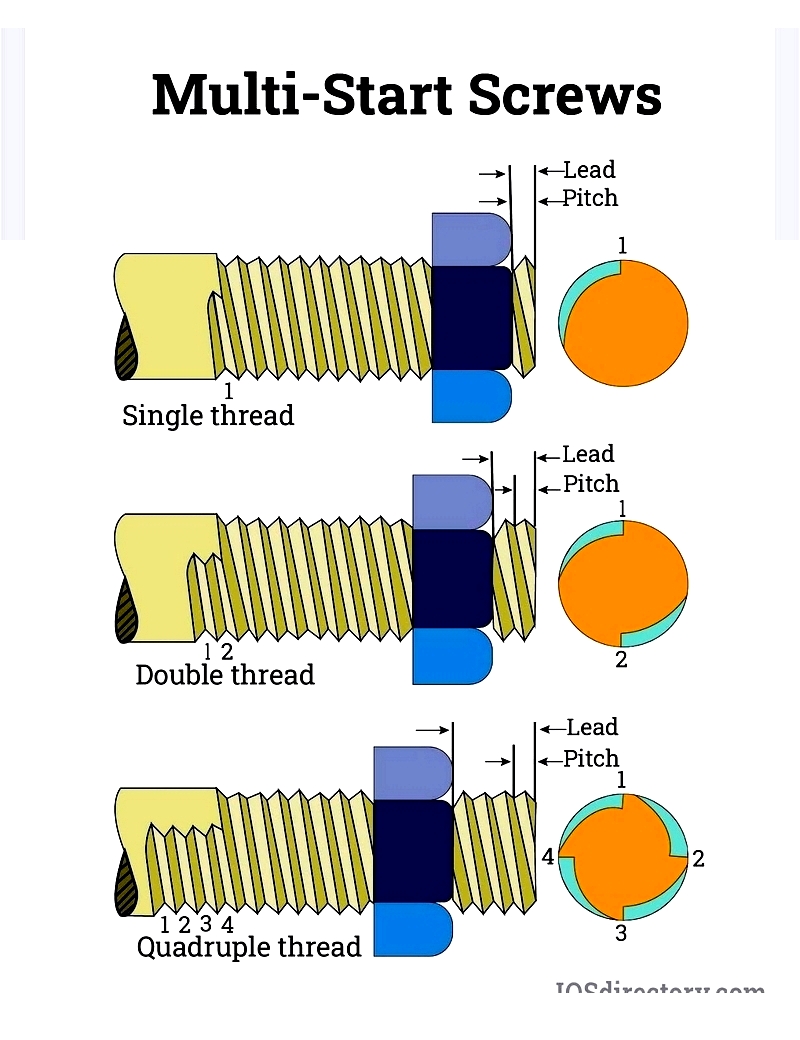

Start

The number of thread helixes determines total lead (start count × pitch). Multiple-start screws enable faster movement with fewer rotations.

For example, double-start screws have twice the lead of single-start, offering higher speeds. These are ideal for CNC machines and robotics requiring rapid movement without sacrificing accuracy.

Nut

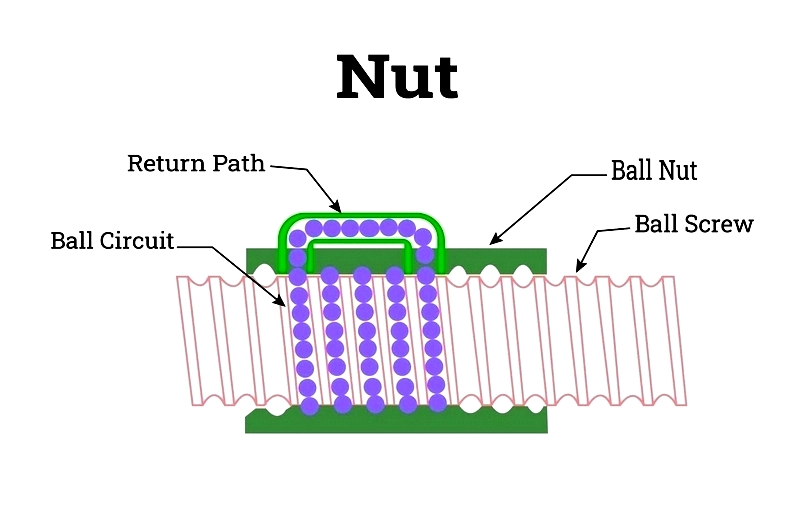

The precision-machined nut houses recirculating balls and their return mechanism. Its internal grooves match the screw shaft threads for efficient force transmission.

important Nut Specifications:

Circuit

The closed path balls follow during recirculation. Multi-circuit nuts distribute load more evenly for demanding applications.

Turn

The number of rotations balls complete before recirculating affects backlash, smoothness, and vibration reduction.

The ball recirculation system ensures continuous movement using deflectors, return tubes, or end caps to minimize noise and wear.

Ball Bearings

Precision-ground balls (usually hardened steel) roll with minimal friction between nut and shaft. Some high-performance screws use ceramic or stainless steel balls for special applications.

Balls roll between engineered raceways, with groove profile affecting load rating, stiffness, and backlash.

Gothic Arc Profile

Features two contact points per ball for higher rigidity and load capacity, ideal for precision CNC machines.

Semi-Circular Arc Profile

Provides single contact points for smoother movement but lower load capacity.

Both profiles use slightly larger radii than balls, creating controlled clearance. Preloading techniques eliminate excess movement for high-precision applications.

Seals protect internal components from contamination, preserving efficiency and extending service life. They're essential for industrial actuators and sensitive automation systems.

Selection considerations include: load capacity, accuracy class, speed requirements, lubrication, backlash tolerance, environment, and service life. Proper component combination ensures optimal performance.