Introduction

This article provides an in-depth exploration of caster wheels.

Key topics covered include:

- How Caster Wheels Work

- Different Types of Caster Wheels

- Applications and Advantages of Caster Wheels

- And More...

Chapter 1: Understanding Caster Wheel Principles

This chapter examines the fundamentals of caster wheels, including their basic concept, manufacturing process, and operation.

What Are Caster Wheels?

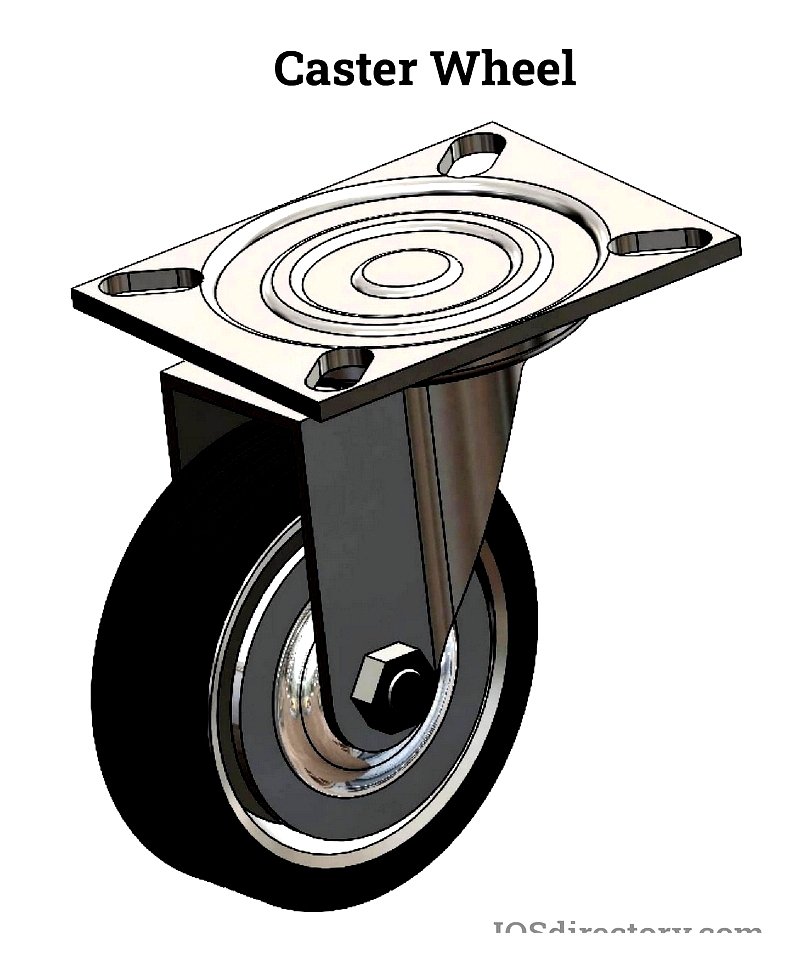

Caster wheels are unpowered wheels mounted to objects for easier movement. Commonly found on shopping carts, office chairs, hospital beds, and material handling equipment, they come in various types for specific applications.

These wheels provide mobility benefits like durability and resistance to corrosion, weather, and water. Selection depends on terrain and load weight - heavier loads require sturdier wheels, while larger objects may need multiple casters for weight distribution.

How Caster Wheels Are Made

This section outlines the manufacturing processes for caster wheels.

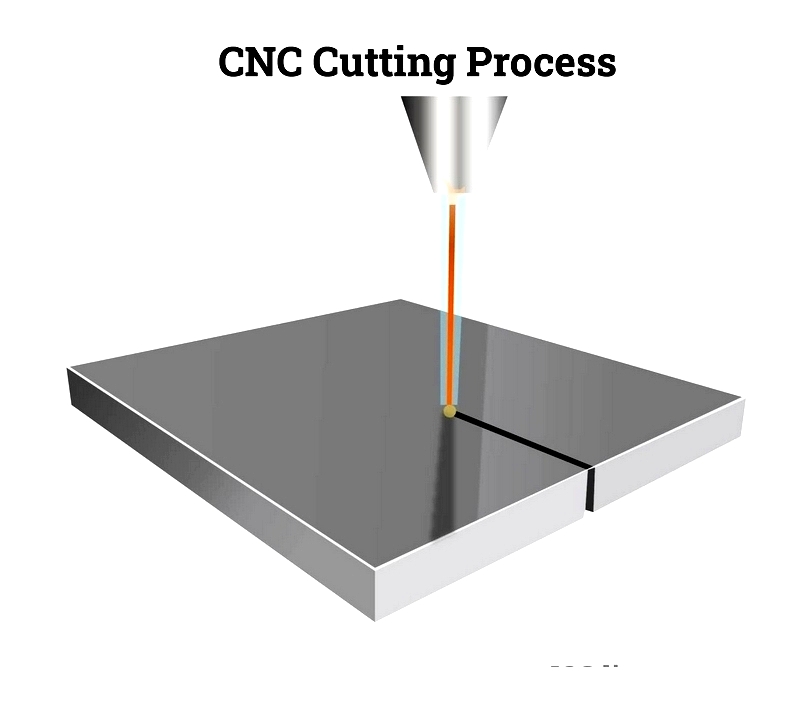

metal Plate Cutting

The first step involves cutting the top plate using a CNC plasma cutter. This thermal process melts through thick steel sheets with precision and speed.

Next, steel coils are shaped into forks using punch presses. Ball bearings are added for swiveling, and components are assembled with pneumatic presses.

Material Extrusion

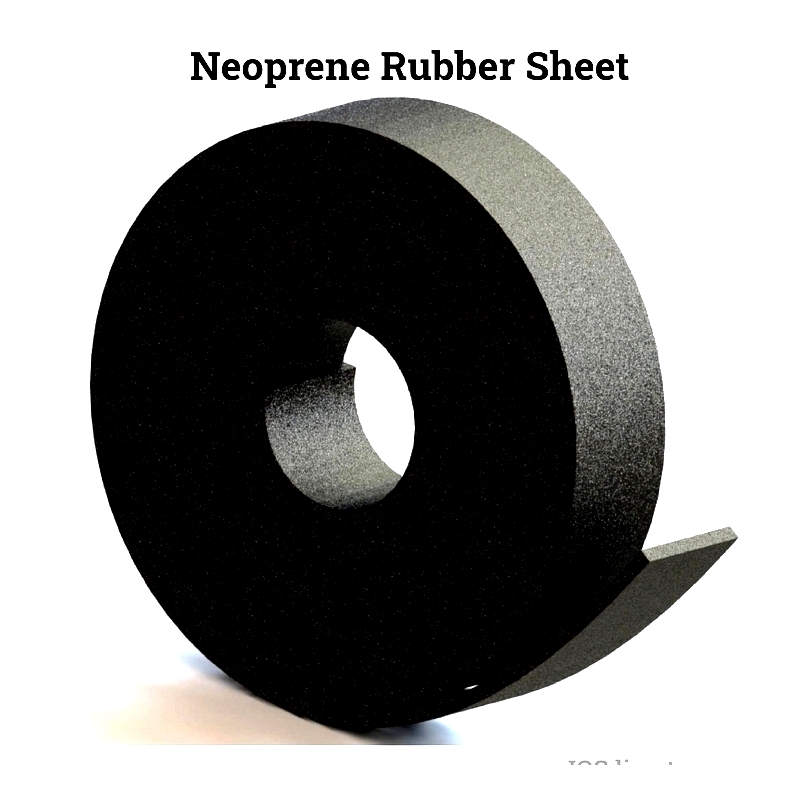

Nylon inserts are molded with neoprene rubber to create shock-absorbing wheels that protect floors and reduce noise.

Larger wheels use similar molding techniques but require bigger presses and longer cooling times.

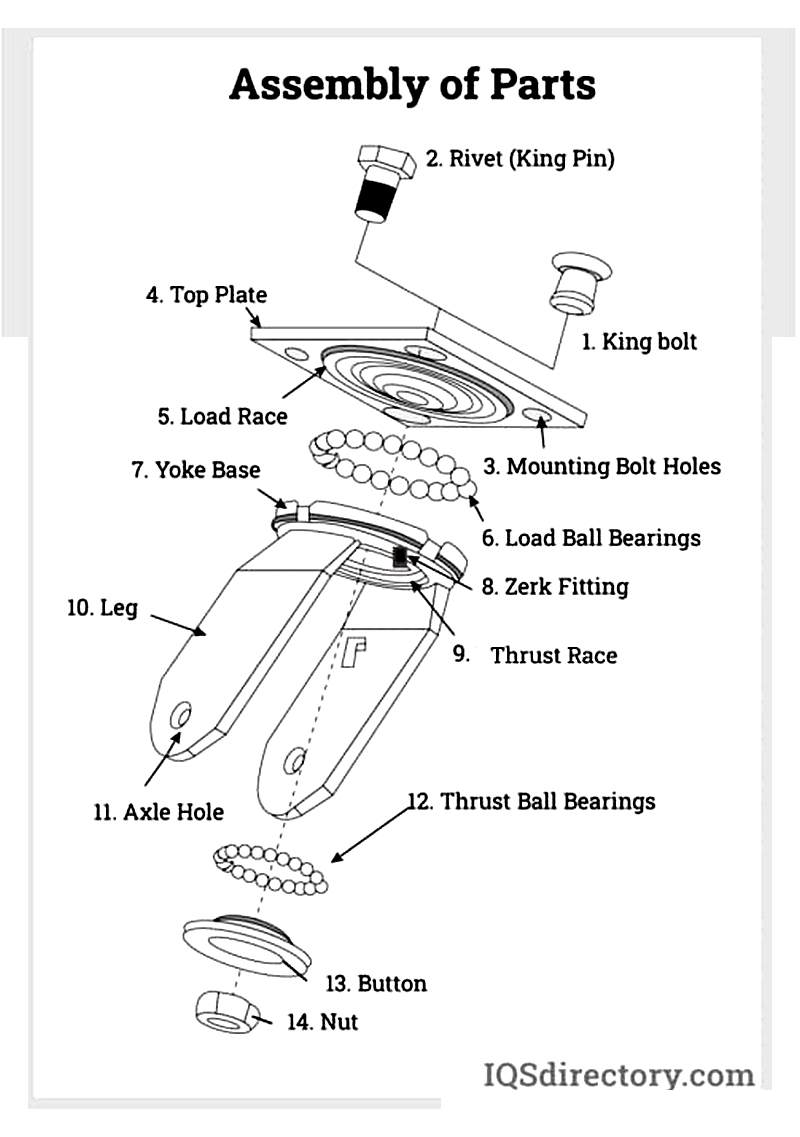

Component Assembly

Bearings are pressed into wheels, steel guides are added, and axles are secured with bolts and grease for smooth operation.

Each wheel undergoes quality testing for durability.

Choosing the Right Caster Wheels

Consider these factors when selecting caster wheels:

Maneuverability Needs

Fixed casters work for straight-line movement, while swivel casters offer greater flexibility.

Mounting Options

Stem mounts suit lighter loads; plate mounts better distribute heavy weights.

Application Requirements

Consider load weight, environment, and noise requirements when choosing wheel types.

Chapter 2: Caster Wheel Varieties

Caster wheels serve critical roles across industries. Proper selection ensures optimal mobility, safety, and floor protection.

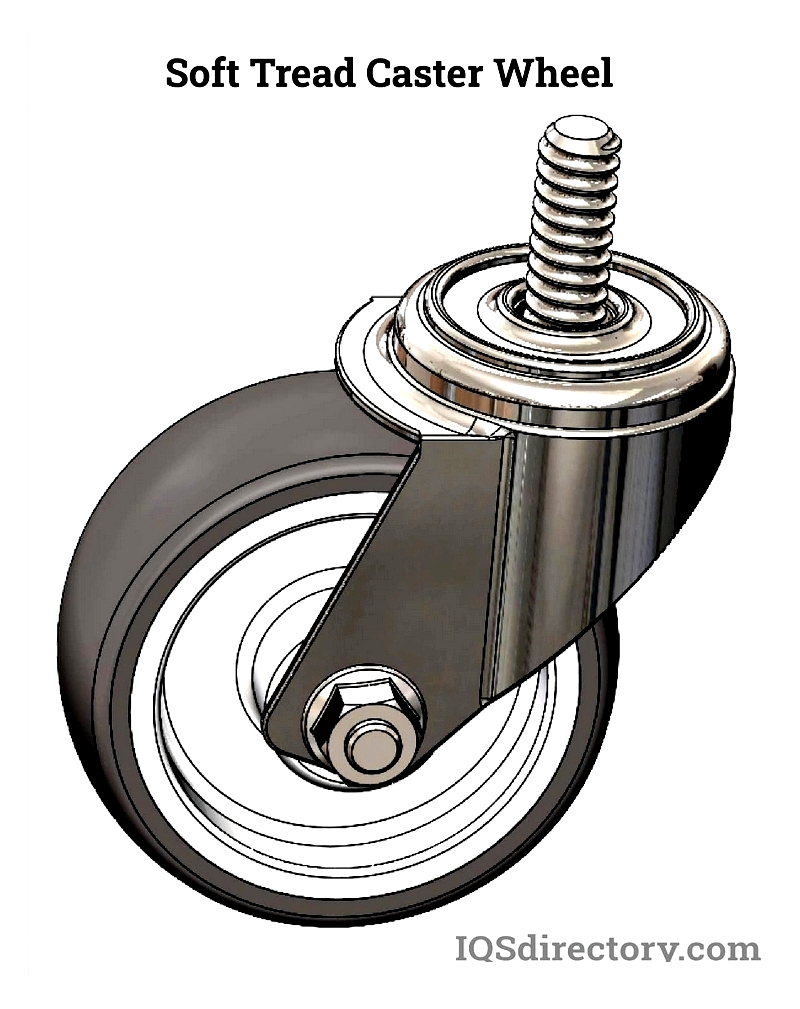

Soft Tread Wheels

Ideal for delicate floors, these quiet wheels absorb shock and resist chemicals.

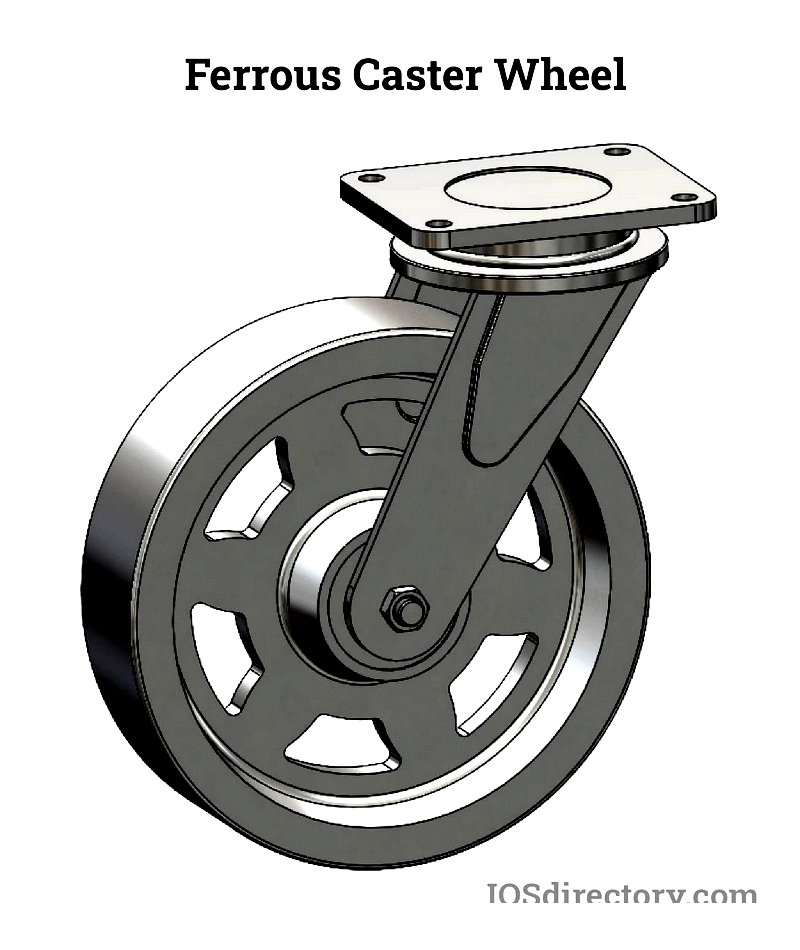

Ferrous Wheels

Steel or cast iron wheels handle heavy loads in industrial settings.

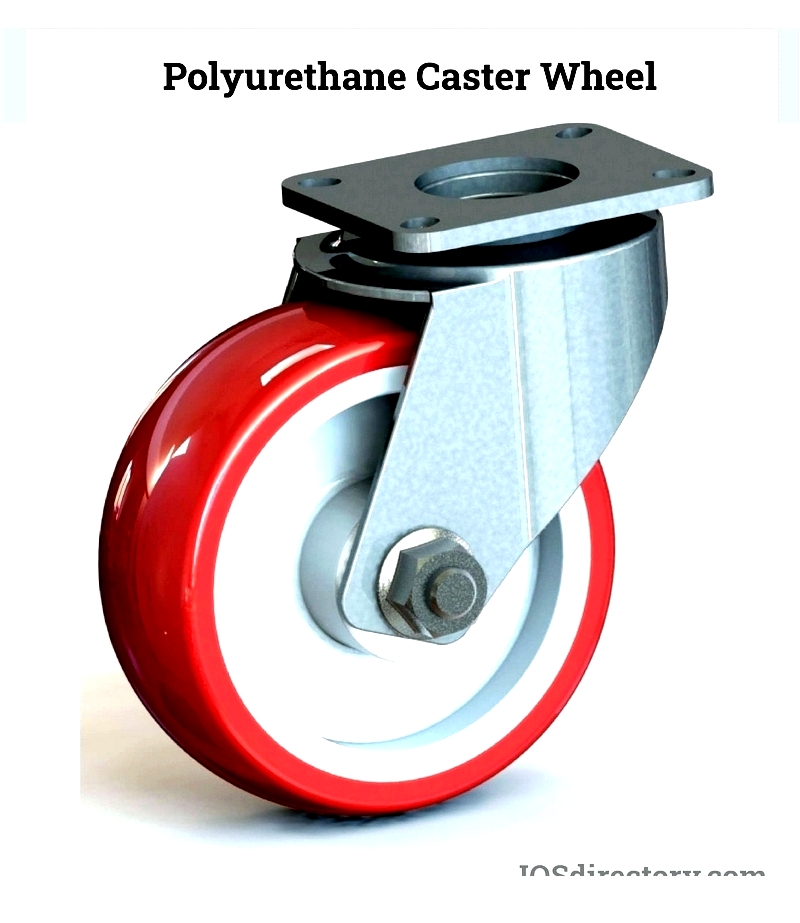

Polyurethane Wheels

Combine high capacity with floor protection and chemical resistance.

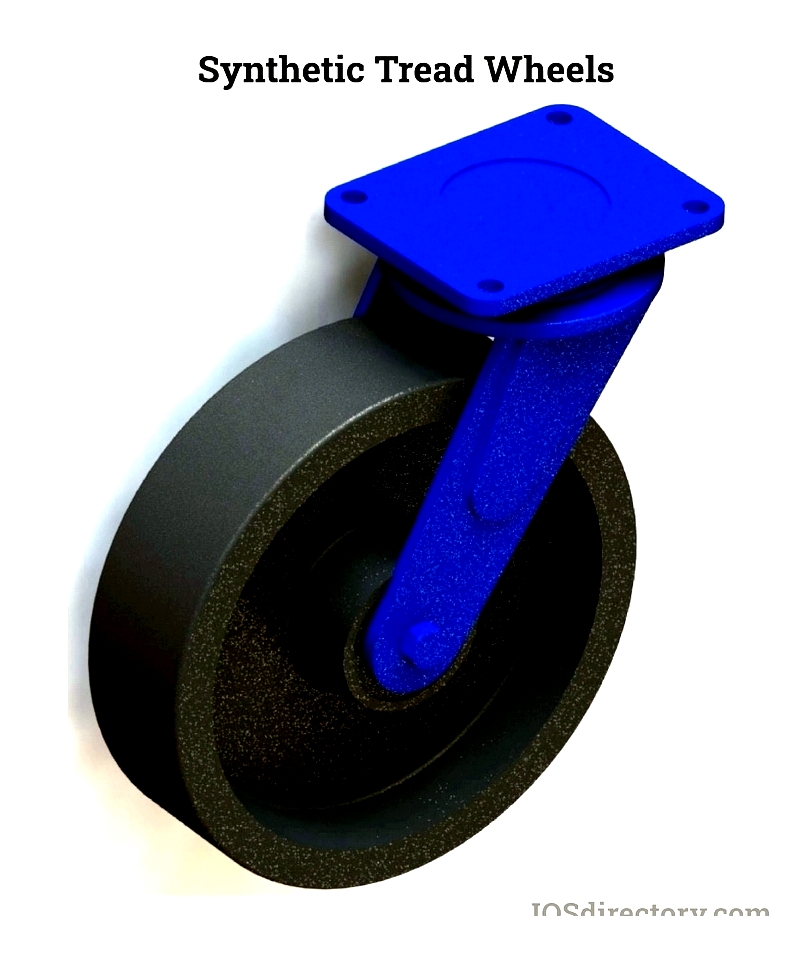

Synthetic Tread Wheels

Durable polymer wheels for harsh industrial environments.

Cast Iron Wheels

Extreme-duty wheels for heavy manufacturing applications.

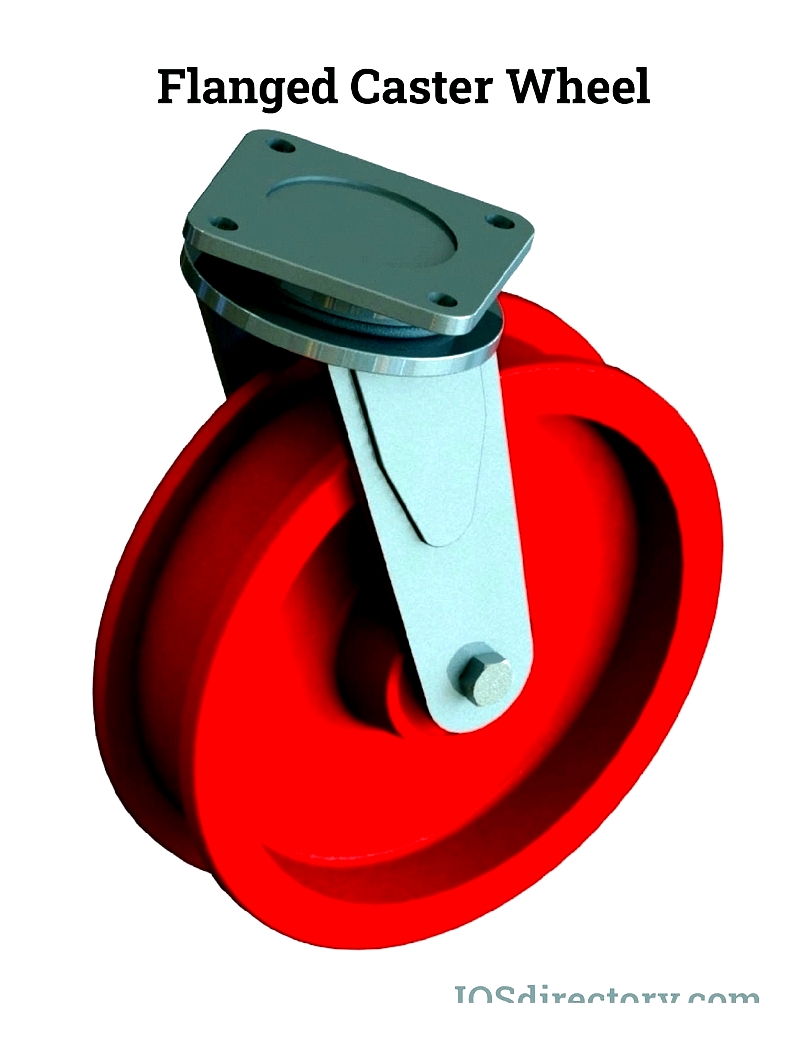

Flanged Wheels

Designed for guided movement on steel tracks.

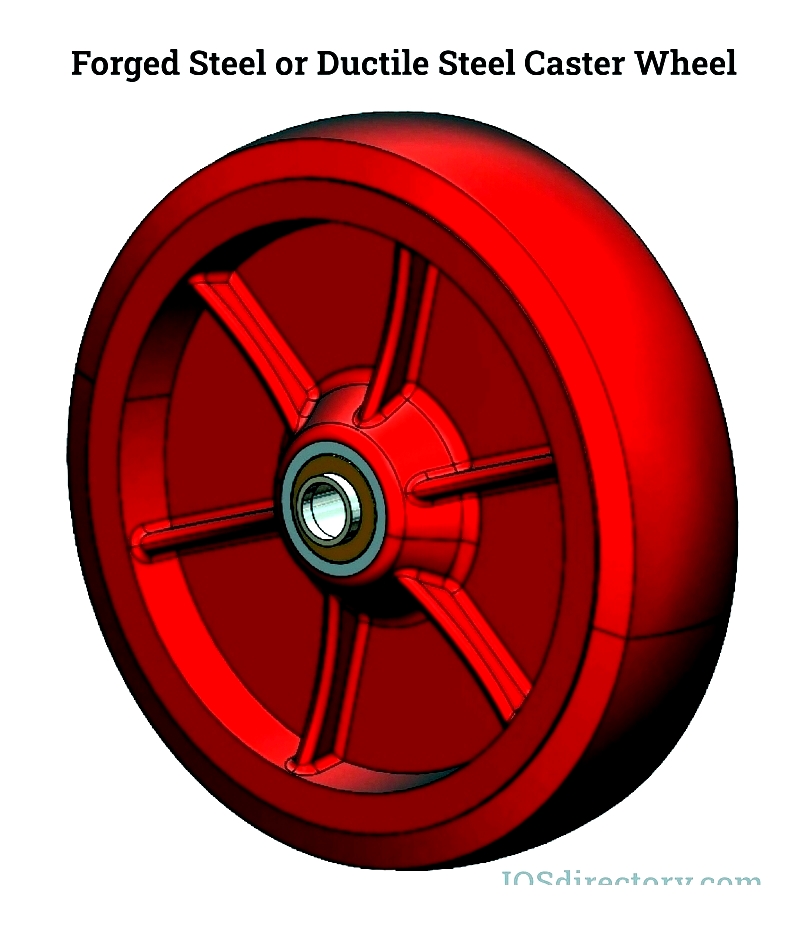

Forged Steel Wheels

Indestructible wheels for extreme conditions.

Glass-Filled Nylon Wheels

Chemical-resistant wheels for harsh environments.

Hard Rubber Wheels

Durable general-purpose wheels for various applications.

Pneumatic Wheels

Air-filled tires for rough terrain and delicate loads.

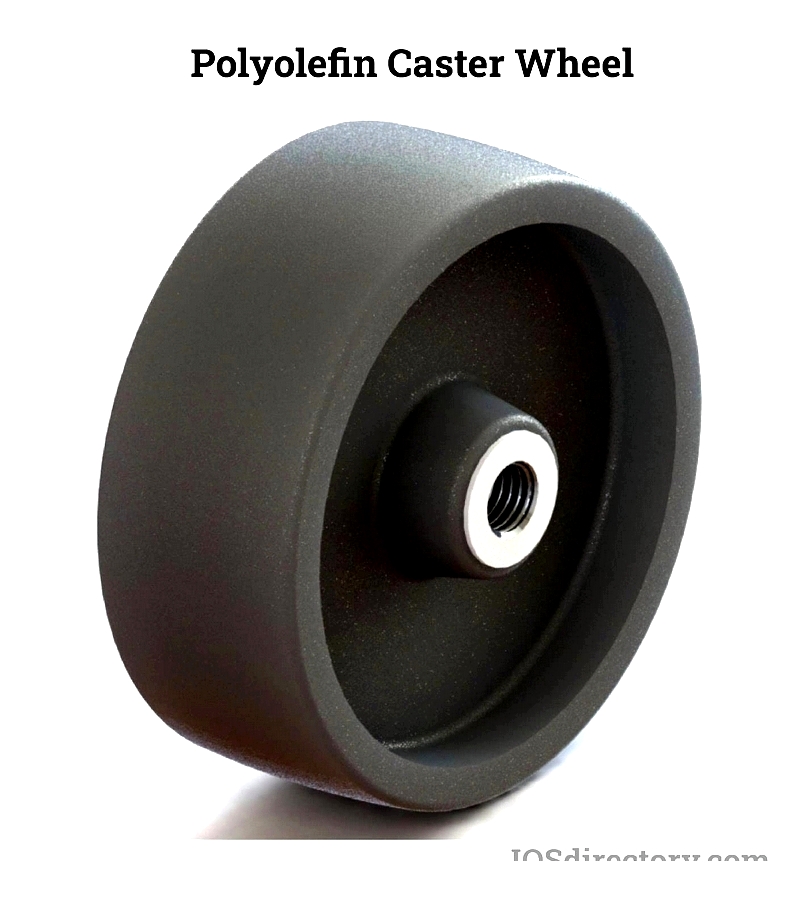

Polyolefin Wheels

Cost-effective wheels for food processing and light industry.

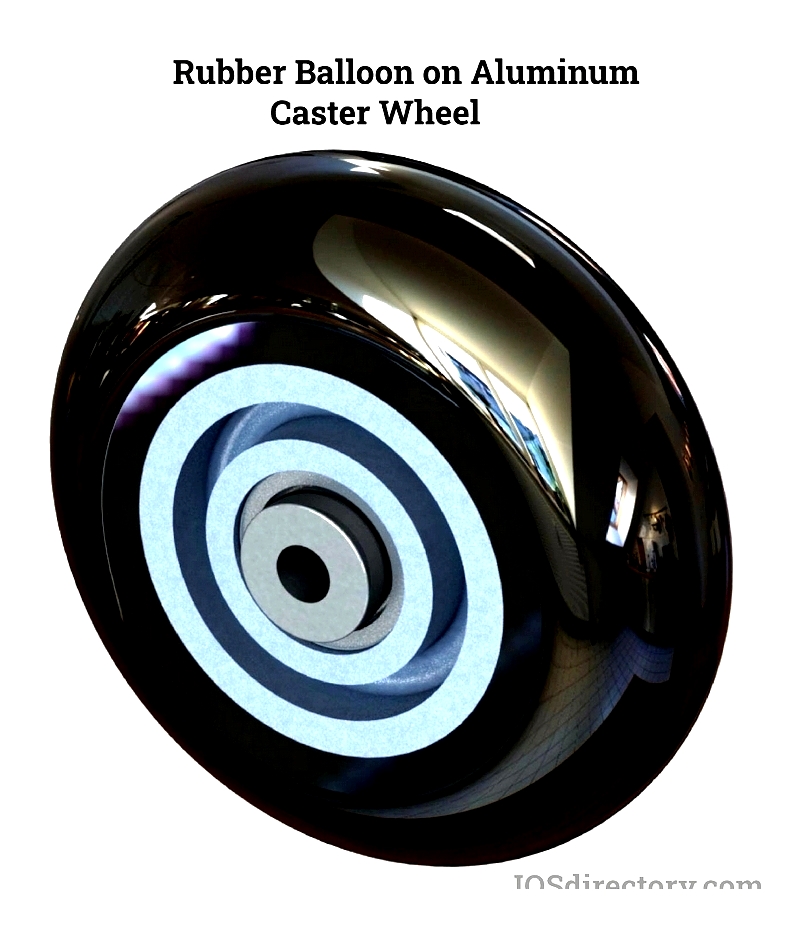

Rubber Balloon Wheels

Cushioned wheels for smooth, quiet operation.

V-Groove Wheels

Specialized wheels for track systems.