Introduction

This article provides an in-depth examination of load cells.

You will learn about the following topics:

- What is a load cell?

- Load cell design

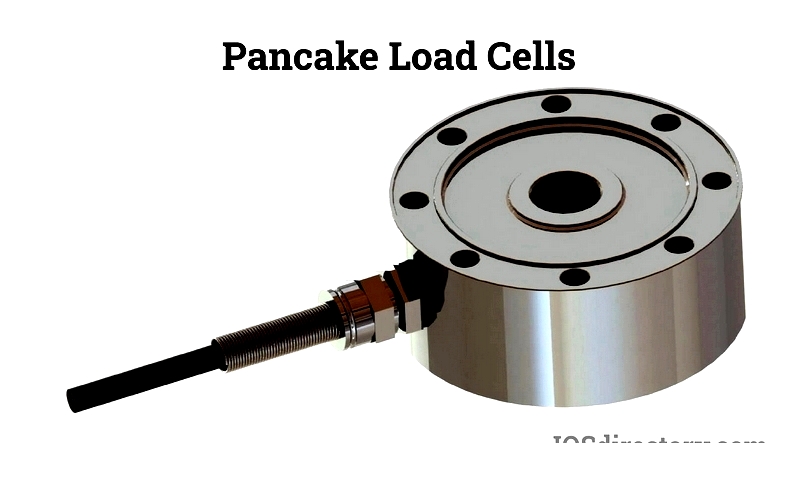

- Types of load cells

- Applications of load cells

What is a Load Cell?

A load cell is a specialized transducer designed to convert various forces—including tension, compression, pressure, and torque—into electrical signals. When an object is placed on a load cell, it detects the force exerted by the object's weight due to gravity. This force is processed through an electronic circuit and displayed as measurable data. Load cells serve as precise mechanical transducers, delivering accurate measurements.

A force transducer is a device that converts applied force into an electrical signal, which can then be measured and standardized digitally. As the applied force increases, the electrical output from the transducer or load cell rises proportionally.

Load cells are highly accurate instruments used for precise weight measurement. Their ability to measure both lightweight objects, such as a needle, and heavy machinery, like drilling rigs, demonstrates their versatility and precision.

The global standard unit for weight measurement is kilograms (kg). Load cells adhere to this metric but can also record in newtons (N), representing the force a mass generates under standard gravity. One kilogram equals 9.8 newtons. To ensure accuracy, load cell measurements can be expressed in newtons (N), kilonewtons (kN), or meganewtons (MN).

How is the design of load cells structured to convert measurements?

Load cells are precision instruments engineered to measure weight, force, and pressure by converting mechanical energy into readable electrical signals. Their core structure consists of a highly resilient spring element, typically made from durable materials like stainless steel or aerospace-grade aluminum, known for corrosion resistance and minimal deformation under stress. This robust spring element ensures load cells withstand heavy industrial use while maintaining accuracy.

The spring element is bonded to strain gauges—ultra-sensitive sensors that detect minute deformations caused by applied loads. A strain gauge consists of a fine electrical conductor patterned on a thin film substrate. When force is applied, the flexure bends slightly, causing the strain gauge to expand or contract. This deformation alters the conductor's electrical resistance, which is measured using a Wheatstone bridge circuit. This circuit converts resistance changes into analog or digital signals for processing in weighing scales, industrial systems, and material testing machines. Advanced load cell designs may also incorporate piezoelectric sensors, which generate electric charge in response to mechanical pressure, enhancing sensitivity for dynamic force measurement.

Modern load cells can produce various output types, including analog voltage, 4-20mA current, frequency signals, digital serial (RS232/RS485), and parallel outputs, as well as relay switches or alarms. Single-point or bending beam load cells often use four strain gauges for optimal sensitivity and temperature compensation, while high-precision multi-axis load cells may integrate up to thirty gauges in a full Wheatstone bridge configuration. Multi-gauge load cells offer improved sensitivity, repeatability, and error compensation, essential for industrial automation.

When assessing a load cell's rated capacity, manufacturers consider factors such as rated force, dynamic or static measurement needs, sensor placement, overload protection, and safety margins. Rigorous testing ensures compliance with ISO calibration standards and durability in harsh environments, including shock loading and off-axis forces.

Optimal load cell accuracy depends on proper installation and application-specific considerations. Forces must be applied centrally and axially to avoid measurement errors from side or eccentric loading. Secure mounting and rigid framing are critical for reliable results, especially in high-speed production lines. Key selection criteria include required accuracy, environmental resilience (e.g., water resistance, temperature range), vibration levels, and integration with control systems like PLCs. By addressing these factors, users can ensure precise, repeatable measurements for industrial weighing, automation, and material testing.

For guidance on selecting the right load cell, calibration procedures, or troubleshooting, consult leading manufacturers or certified distributors. Expert advice and high-quality sensors help achieve reliable measurements for industrial, testing, and research applications.