Introduction

This article provides an in-depth exploration of aluminum extrusions.

You will learn about:

- The fundamentals of Aluminum Extrusions

- Various Extrusion Types

- Aluminum Profile Varieties

- Heat Sink Applications

- And many more aspects...

Chapter One: Understanding Aluminum Extrusions

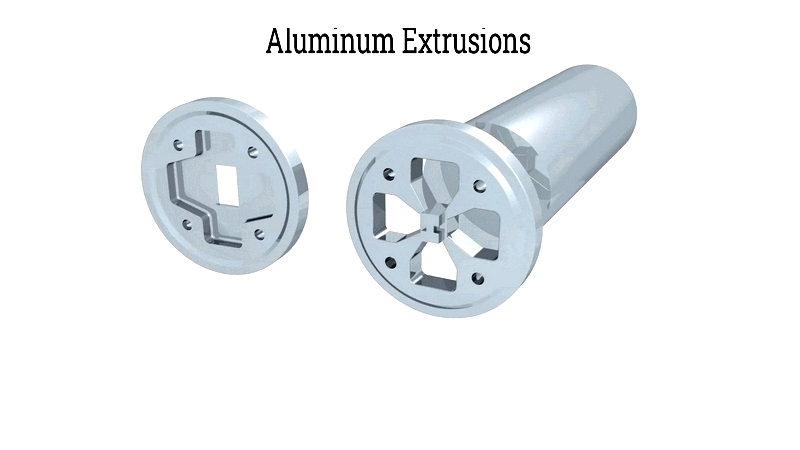

Aluminum extrusions are manufactured in solid, semi-hollow, and hollow configurations through a process that forces aluminum billets through specialized dies. The extrusion methods—hot, warm, and cold—produce durable yet lightweight forms including angles, beams, and channels, along with various tubing dimensions. These precision-engineered profiles feature tight tolerances for seamless integration with other aluminum frameworks.

Industrial demand for aluminum extrusions continues growing as new applications emerge, driven by aluminum's exceptional strength-to-weight ratio and versatility. A wide selection of aluminum alloys allows for optimal material choices tailored to specific requirements.

The primary advantage of aluminum extrusions lies in their combination of lightweight properties and high durability. They offer cost-effective solutions, particularly for complex projects. Additionally, regardless of the extrusion method used, aluminum extrusions typically feature smooth, aesthetically pleasing finishes.

Chapter Two: The Aluminum Extrusion Process

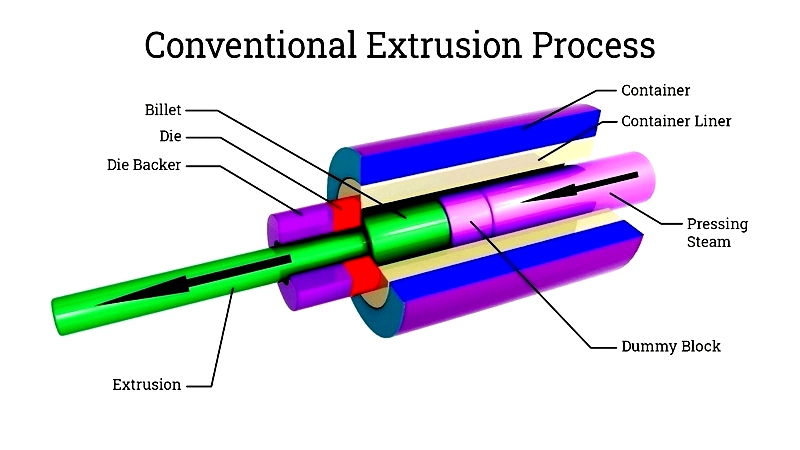

Aluminum extrusion is a specialized metal forming process available in hot, warm, or cold variants. Process selection depends on application requirements, desired mechanical properties, and alloy characteristics. Hot extrusion dominates industrial manufacturing due to its superior product strength, tighter tolerances, and enhanced surface finishes. Warm extrusion occurs above room temperature but below recrystallization points, balancing formability with material strength. Cold extrusion, performed at or near room temperature, produces precise, high-strength components without thermal distortion.

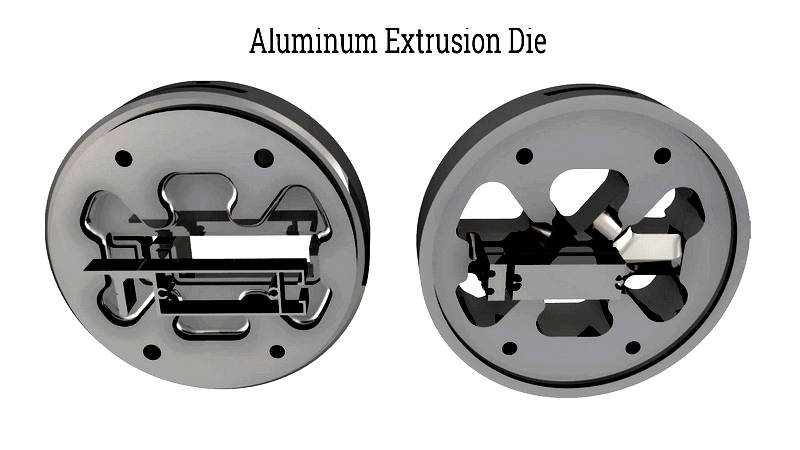

The process fundamentally involves shaping heated or cold billets by forcing them through precisely engineered dies. These high-strength steel tools withstand extreme pressures and temperatures, typically requiring 100,000-125,000 psi to form aluminum alloys. Dies are categorized as solid, semi-hollow, or hollow based on their produced profiles, enabling customized solutions for construction, automotive, aerospace, and electronics industries.

Die lifespan depends on design, alloy type, and operating temperatures. Advanced thermal management and surface treatments like nitriding can extend tool life. While regular die replacement is necessary, the process remains cost-effective. Optimizing profile complexity and tolerance allowances further enhances die longevity, with alloys like 6061 and 6063 offering ideal strength-formability combinations.

Raw materials begin as aluminum billets, alloyed with elements like magnesium or silicon to achieve specific properties. After smelting and purification, molten aluminum is cast into dense, defect-free billets ready for extrusion.

Hot extrusion heats billets to 800-925°F (427-496°C) to facilitate metal flow. Lubricants prevent adhesion during pressing. The ram forces softened aluminum through dies, with emerging profiles rapidly cooled to stabilize dimensions. Subsequent stretching and trimming ensure straightness and precision length.

Cold extrusion forms profiles at ambient temperatures, producing components with excellent dimensional accuracy and surface finishes. Techniques include direct, indirect, and upset extrusion methods.

Warm extrusion operates at 800-1800°F (427-982°C), increasing ductility for intricate shapes while reducing required forces. This method benefits brittle alloys in automotive and medical applications.

Precise temperature control through advanced monitoring systems ensures consistent quality and mechanical properties across production runs.

Key benefits include cost efficiency, rapid prototyping, design flexibility, and lightweight corrosion resistance. Industries from transportation to renewable energy rely on extruded aluminum for structural integrity and manufacturing efficiency. When selecting extrusion services, consider alloy options, die design expertise, finishing capabilities, and industry-specific experience.

Chapter Three: Aluminum Extrusion Varieties

The aluminum extrusion market offers extensive shape variations serving diverse industrial applications. From basic structural components to complex custom profiles, these extrusions form the backbone of modern construction and manufacturing. Standard profiles like angles, tubes, and channels remain readily available, while custom solutions address specialized requirements in automotive, aerospace, and architectural sectors.

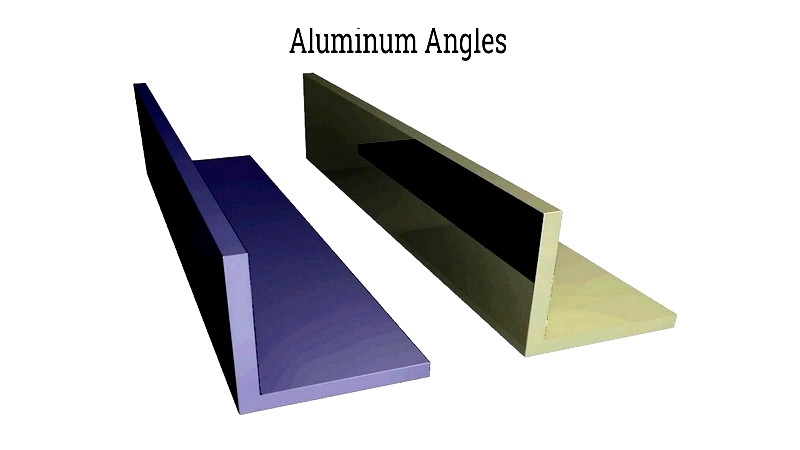

Aluminum Angles

These L-shaped profiles, typically made from 6061-T6 or 6063-T6 alloys, provide structural support with excellent strength-to-weight ratios. Available in equal or unequal leg configurations, they serve construction, transportation, and industrial applications. Heat treatment and anodizing enhance their durability and corrosion resistance.

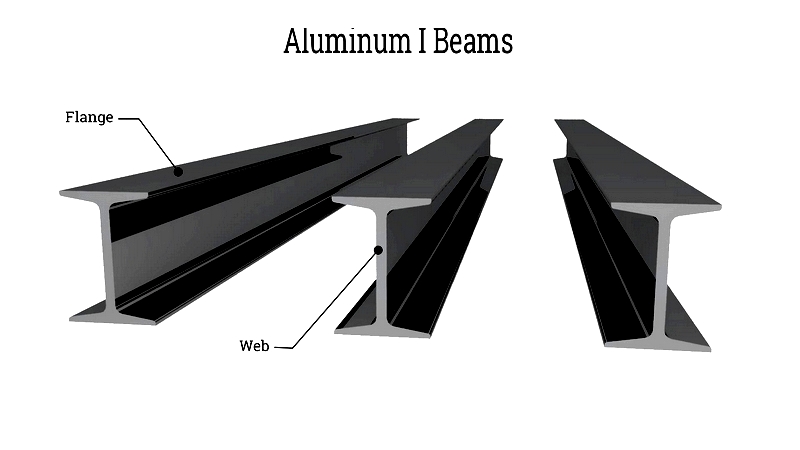

Aluminum Beams

Structural beams like I-beams and H-beams offer lightweight alternatives to steel, featuring superior corrosion resistance. Their high tensile strength makes them ideal for building frameworks, bridges, and vehicle chassis. Alloying with magnesium and silicon enhances their stress and fatigue resistance.

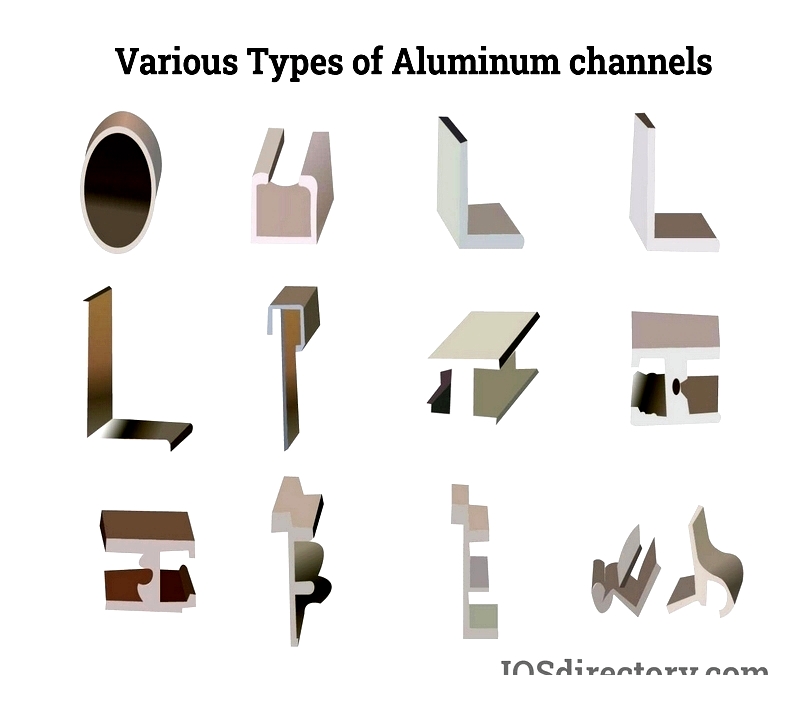

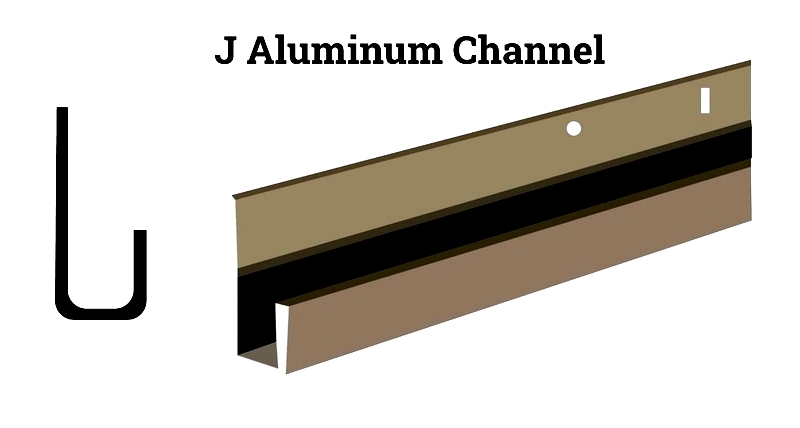

Aluminum Channels

These versatile profiles serve as structural supports in construction, manufacturing, and HVAC systems. Their excellent thermal properties make them suitable for heat management applications. Available in various configurations, they can be finished with anodizing or powder coating for enhanced durability.

Aluminum Tubing

Extruded tubing comes in round, square, and rectangular profiles for structural, fluid transfer, and architectural applications. Its thermal conductivity and corrosion resistance make it valuable across multiple industries.

T-Slot Extrusions

These modular building systems feature T-shaped slots for easy assembly and reconfiguration. Ideal for machine frames, automation equipment, and workstations, they offer rapid prototyping capabilities and structural flexibility.

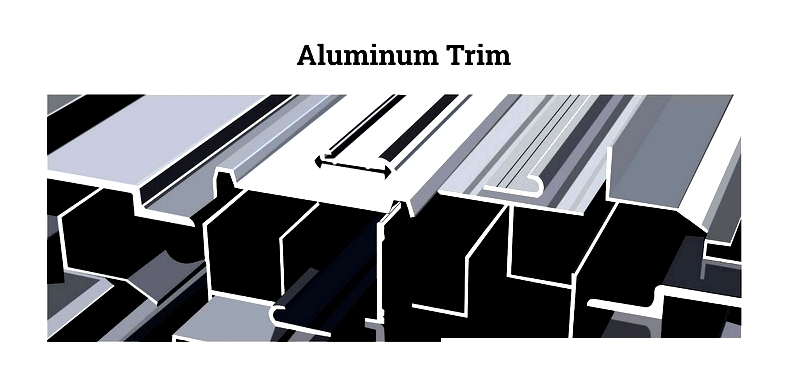

Aluminum Trim

Used for both functional and decorative purposes, aluminum trim enhances architectural and automotive designs. Its formability allows for complex shapes, while various finishes provide weather resistance and aesthetic appeal.

From structural components to specialized profiles, aluminum extrusions continue evolving to meet modern engineering challenges across industries. Their combination of lightweight properties, strength, and design flexibility ensures ongoing relevance in sustainable manufacturing and construction solutions.