Introduction

This article provides an in-depth examination of perforated metals and their applications.

You will explore topics including:

- What Perforated metals Are

- The Manufacturing Process of Perforated metals

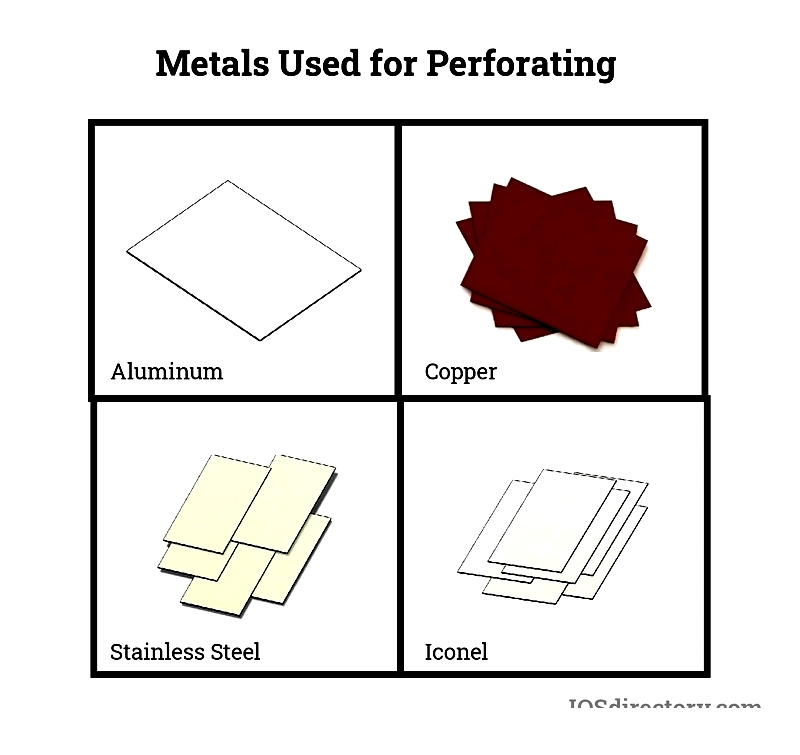

- Types of metals Used for Perforation

- Applications of Perforated metals

- And more...

Chapter One – What are Perforated metals?

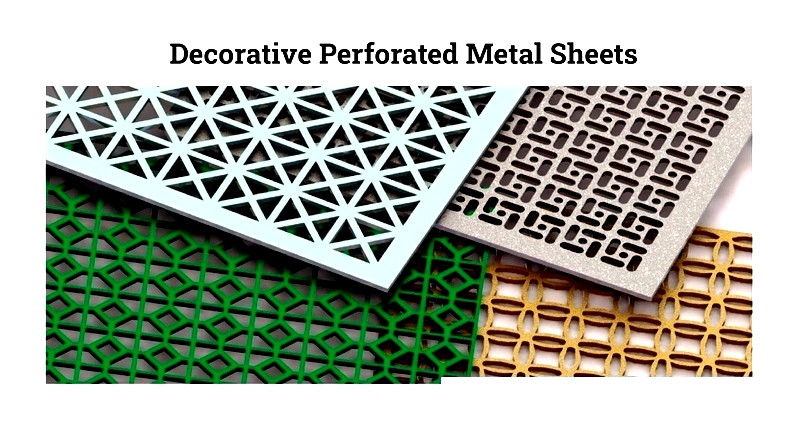

Perforated metals consist of metal sheets that have been punched or stamped with decorative shapes and holes. This modification serves both functional and aesthetic purposes. The perforation process creates various geometric patterns, making these metals highly versatile for numerous applications. Their flexibility enhances both structural functionality and visual appeal.

Beyond aesthetics, perforated metals perform essential functions. They effectively diffuse light while reducing its intensity. A key application is in noise reduction, helping create quieter environments. Architects frequently use them as decorative elements, while industries like food processing, chemicals, energy, and acoustics employ them for practical purposes such as fluid filtration and sound control.

Chapter Two – How Perforated metals are Made

Multiple methods exist for perforating metals. The process primarily depends on the sheet metal type, typically thin and flat for easy cutting and bending. metal thickness, measured in gauges, affects the perforation process, structural integrity, and final application. Higher gauge numbers indicate thinner sheets, with proper selection being crucial for industrial, architectural, or decorative uses.

While various shapes can be punched into metals, the specific technique matters less than achieving the desired holes. Common metal perforation methods include dies and punches or roller needles. Industries like construction, automotive, and filtration increasingly demand high-quality perforated metals with consistent hole patterns to meet functional and aesthetic requirements.

Making Perforated metals

metal Sheets

Softer metals like aluminum and copper perforate more easily, though most metals including stainless steel and brass can be processed. metal thickness determines the required punching force. Selection depends on the product's intended use - stainless steel sheets offer corrosion resistance for harsh environments, while aluminum suits lightweight applications.

Thinner metals are cost-effective and easier to work with, ideal for decorative screens and ventilation grilles. The metal's strength must match its application, whether for industrial uses like filtration or decorative purposes in architecture. For structural elements, strength is paramount, while decorative pieces prioritize visual impact. Choosing the right metal type and gauge ensures both performance and design goals are met.

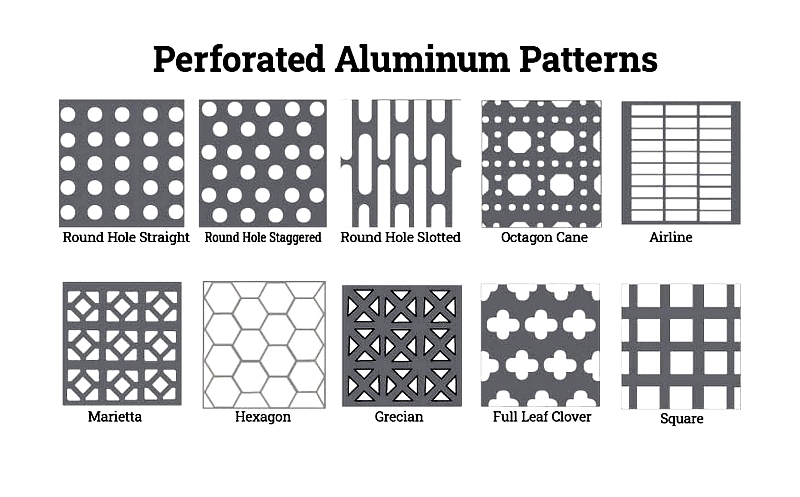

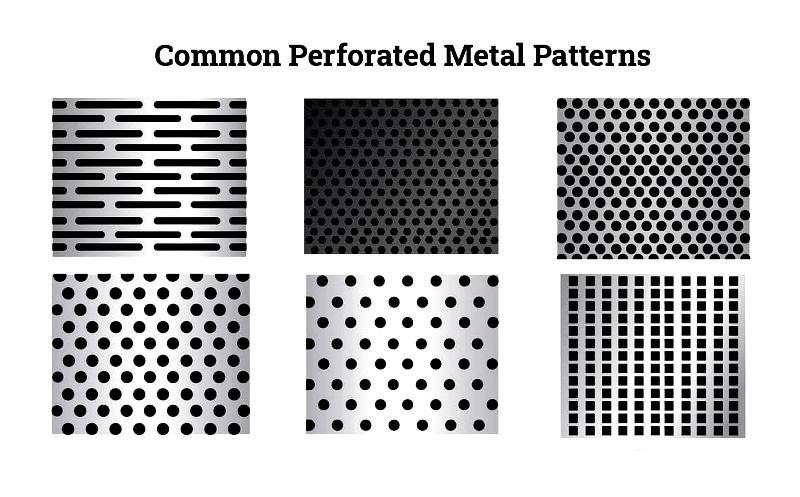

Pattern Variety

Perforated metals offer diverse patterns for specific functions. Architectural patterns emphasize decoration, while industrial patterns for filtration or acoustic panels prioritize functionality. Patterns range from basic round holes to complex custom designs supporting branding needs.

Staggered patterns may have finished or unfinished edges, with unfinished being standard for seamless joining. This modular approach benefits large installations like building facades.

The margin refers to the space between sheet edges and first perforation. No-margin sheets extend patterns to the edge. Pattern selection affects open area percentage, influencing airflow, light transmission, and structural properties.

Method of Perforating

Various metal perforation methods exist, each suited to specific materials. Rotary pinned perforation rollers are common, using heated or cold pins to create shapes. Hot processing increases tensile strength, while cold processing suits thinner materials.

Advanced methods include laser cutting, plasma cutting, and water jet cutting. Laser perforation offers superior precision for custom panels where tolerance matters most, though at higher cost.

Method selection depends on production volume, material thickness, and budget. Rotary methods suit mass production, while laser cutting excels for detailed, small-batch work across industries like electronics and soundproofing.

Lubrication of metal Sheets

Modern perforation can achieve 1,000,000 punctures per minute with precision. The high-speed process generates friction requiring cooling. Lubrication with light oil preserves tool life and ensures pattern integrity by reducing burr formation and minimizing post-processing needs.

Proper lubrication is essential whether producing perforated screens, acoustic panels, or ventilation grilles, guaranteeing quality across diverse applications.