Introduction

This article provides an in-depth discussion on plate heat exchangers.

Readers will gain a comprehensive understanding of:

- Plate Heat Exchanger Operation Principles

- Design Characteristics of Plate Heat Exchangers

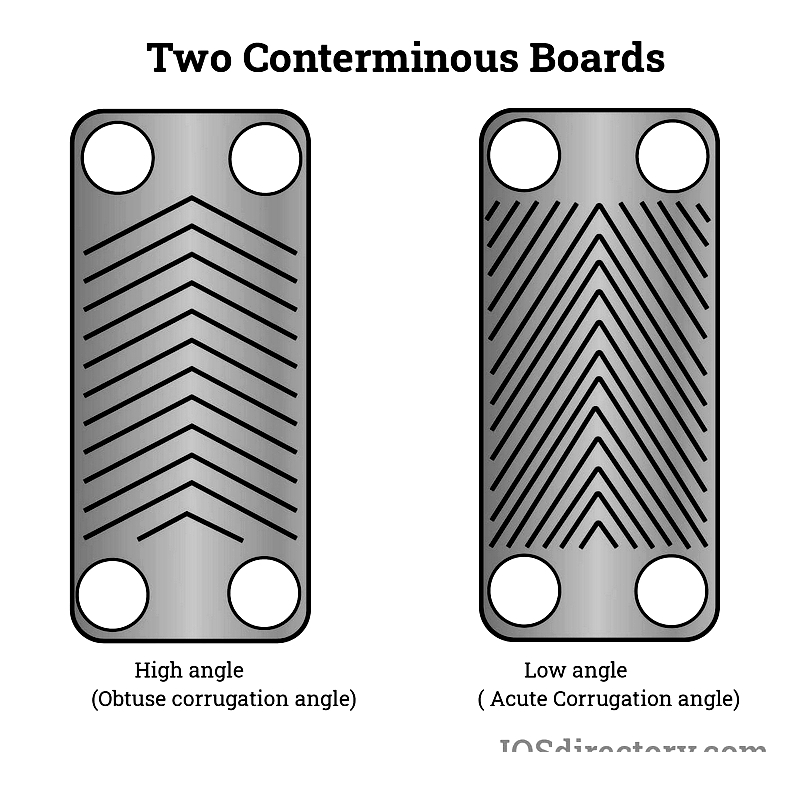

- Plate Configurations and Patterns

- Industrial Applications

- Advantages and Maintenance Procedures

- Additional Relevant Topics

Chapter 1: Plate Heat Exchanger Fundamentals and Operation

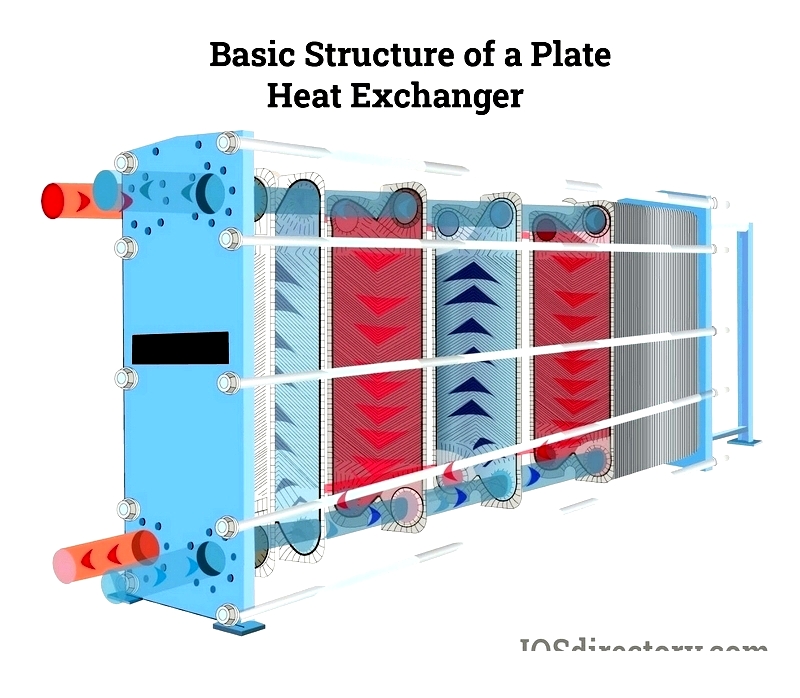

Plate heat exchangers (PHEs) are compact thermal devices that efficiently transfer heat between two fluid streams at different temperatures through a series of thin metal plates.

Operational Principles

This section explains the working mechanism of plate heat exchangers.

Core Functioning Principles

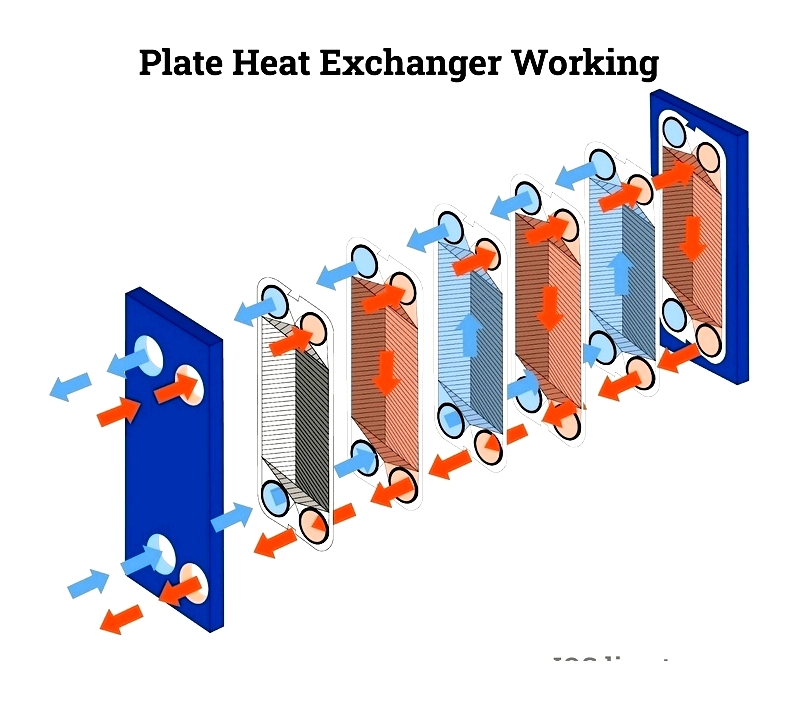

PHEs operate on thermodynamic principles. Each plate pairs with a concave tubular shell, creating narrow rectangular channels that optimize heat transfer. Gaskets control fluid movement through these channels, ensuring proper flow distribution.

Cold and hot fluids alternate between plates, facilitating efficient heat transfer. The extensive plate surface area enables superior heat transfer rates compared to tubular designs.

The illustrated configuration shows cold fluid (blue) entering at the bottom and exiting at the top, while hot fluid (red) follows an opposite path. This counterflow arrangement maximizes thermal exchange efficiency.

Design and Operation

Key operational considerations include:

Pressure Management

Maintaining design pressure drops is crucial. Deviations may indicate fouling or flow issues:

- Excessive pressure drop requires temperature program verification

- If temperatures are normal, inspect for blockages

- Channel constriction with temperature variance may require CIP cleaning

Installation Guidelines

Install on level surfaces with minimum 1.5m clearance for maintenance access. Follow manufacturer specifications for spacing requirements.

Connection Procedures

Verify dimensional compatibility before piping. Maintain adequate working space around the unit.

Safety Protocols

Pre-Operation Checks

Ensure proper bolt tightness and plate alignment. Start gradually to prevent pressure shocks.

Critical procedures:

- Apply correct plate pack pressure

- Avoid sudden temperature/pressure changes

- Follow pump startup sequences

- Monitor nameplate limits

Operating Conditions

Key operational parameters:

- Prevent liquid hammer effects

- Maintain within design limits

- Ensure proper system venting

Standard Operation

Recommended sequence:

- Start with cold circuit

- Complete system venting

- Follow controlled pump startup

Shutdown Procedures

Temporary shutdown:

- Isolate hot circuit first

- Cool down gradually

- Secure all valves

Long-term storage:

- Cool completely before opening

- Drain all fluids

- Lubricate and protect components

Chapter 2: Plate Heat Exchanger Design Characteristics

PHEs are high-efficiency thermal devices used across multiple industries. Their design enables effective heat transfer without fluid mixing, with various configurations available for different applications.

Structural Components

The carrying beam maintains structural integrity and proper plate alignment in the upper section.

Fixed Plate Assembly

This durable stainless steel component forms the stationary framework, with fluid connections typically welded or bolted.

Support Structure

The support column provides stability, featuring guide bars for precise plate positioning.

Pressure Plate

This movable component ensures uniform plate compression for optimal thermal contact.

Alignment System

Guide bars maintain proper plate positioning and force distribution.

Compression Mechanism

Tightening units maintain proper gasket compression through tensioning hardware.

Sealing Solutions

Gaskets prevent fluid mixing and are selected based on chemical compatibility and temperature requirements.

Gasket Varieties

Different gasket types serve specific applications:

Clip-on Gaskets

Enable quick replacement, ideal for sanitary applications.

EPDM Gaskets

Suitable for high-temperature and chemical applications.

PTFE Gaskets

Provide superior chemical resistance for aggressive media.

PHE Configurations

Various designs cater to specific application needs:

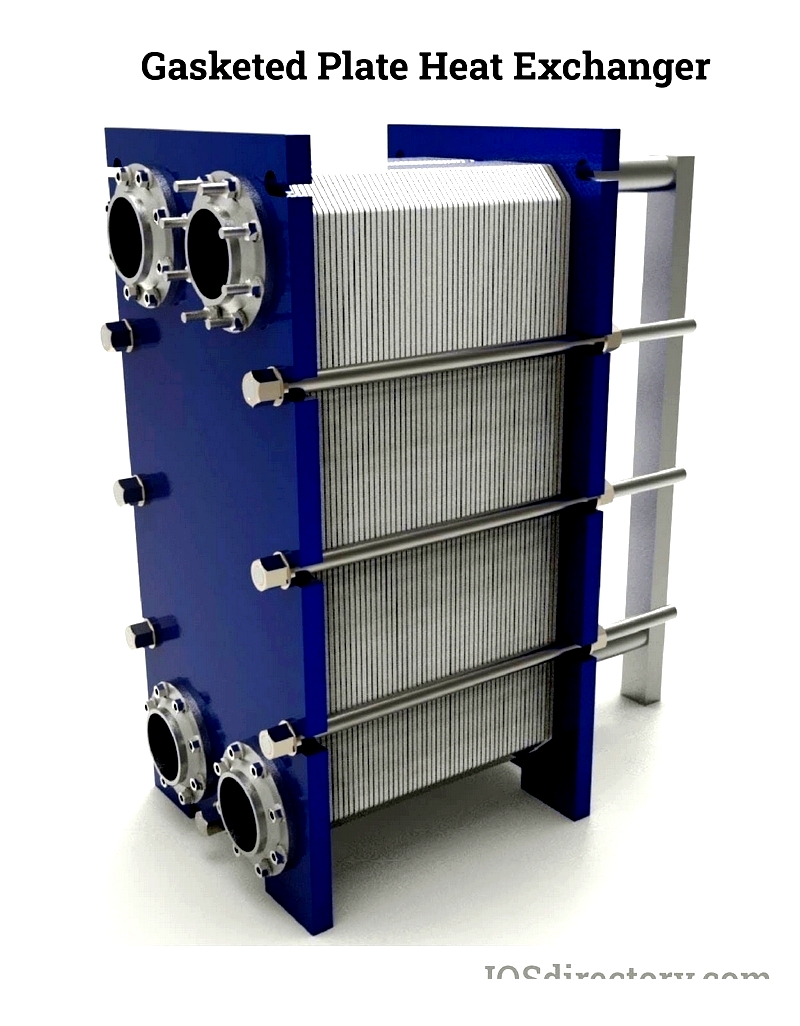

Gasketed PHE

Feature removable plates for easy maintenance, common in HVAC and food processing.

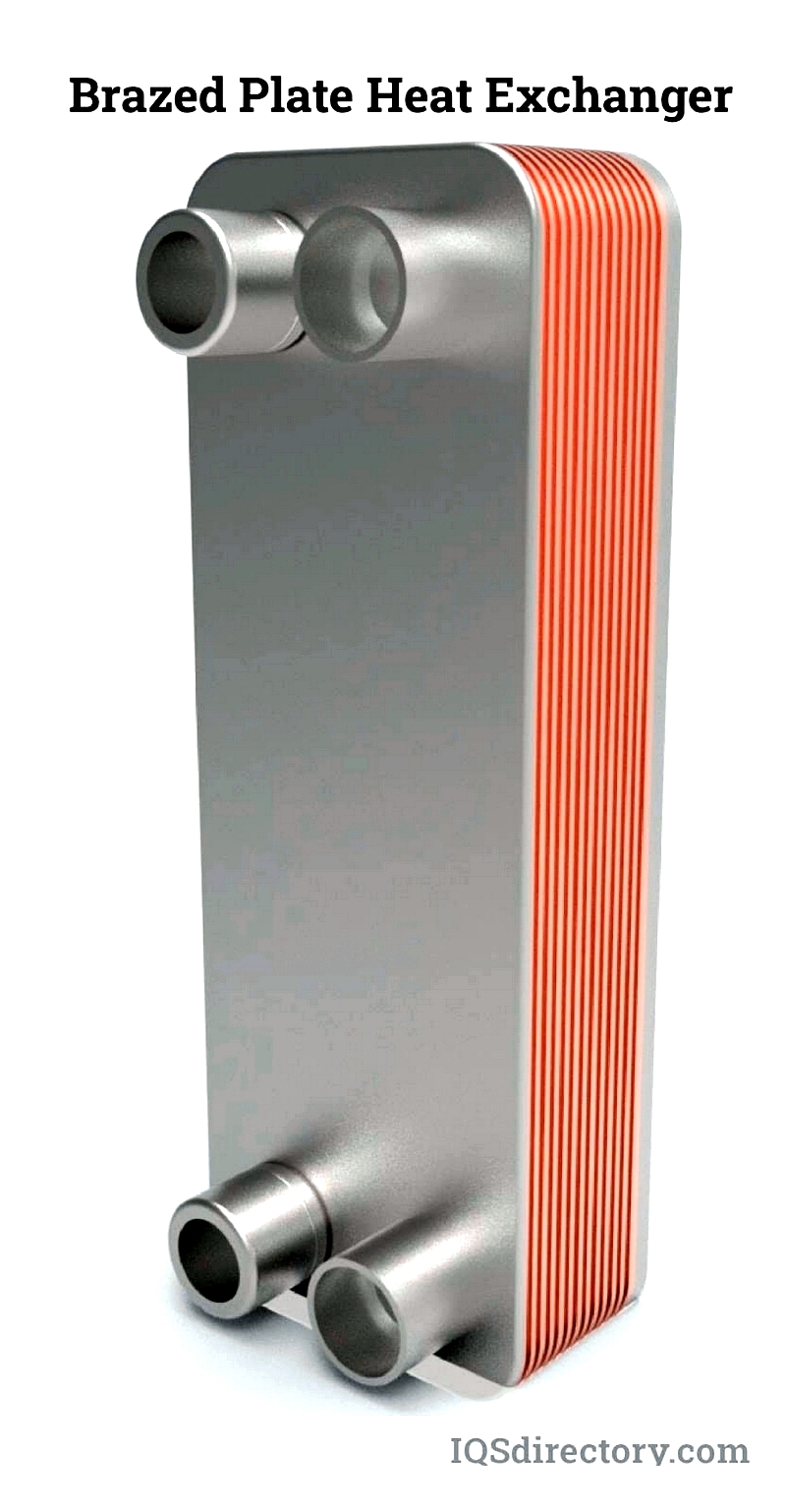

Brazed PHE

Compact, maintenance-free units ideal for refrigeration applications.

Welded PHE

Suitable for high-pressure/temperature applications with aggressive media.

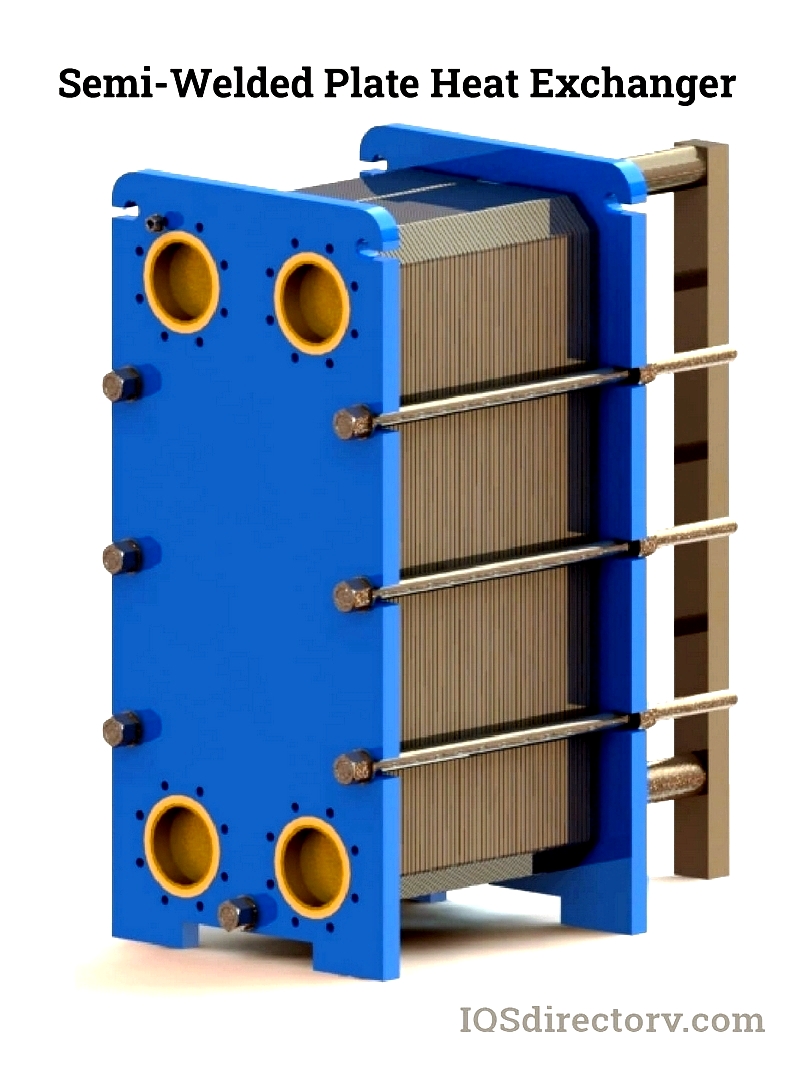

Semi-Welded PHE

Combine welded durability with gasketed maintenance advantages.

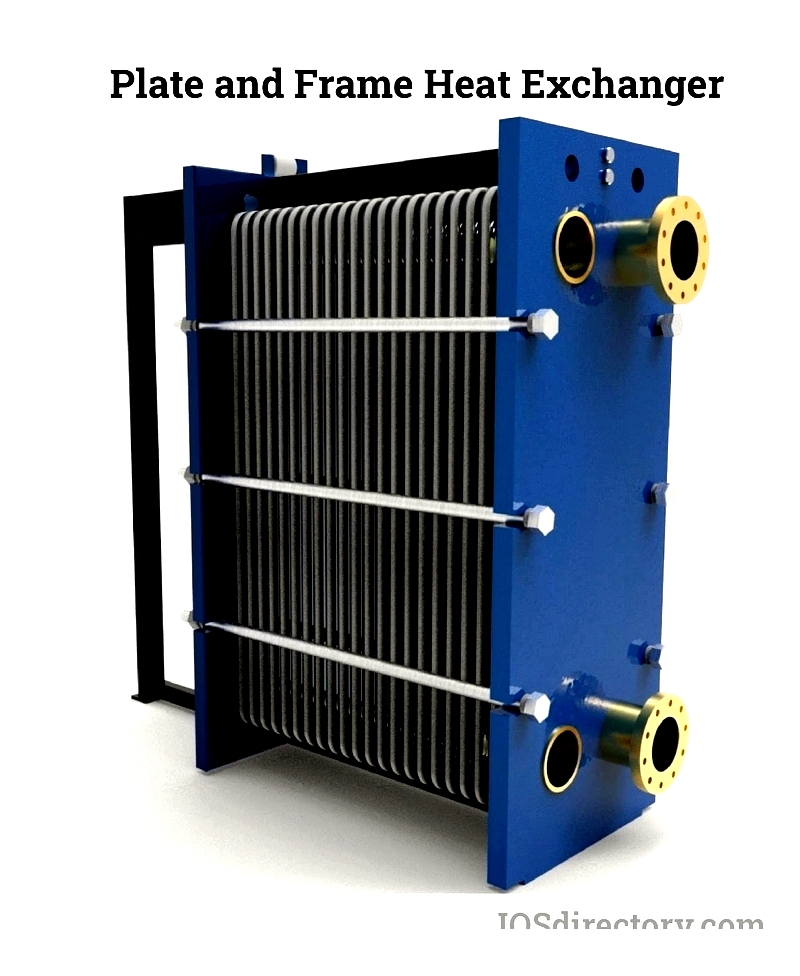

Plate-and-frame PHE

Versatile design with customizable plate configurations for various applications.