Introduction

This article describes different types of load pins, their applications, and provides a list of load pin manufacturers.

The topics covered include:

- What are Load Pins?

- Considerations When Choosing Load Pins

- Applications of Load Pins

- Types and Calibration of Load Pins

- Working Principle of Load Pins

- Load Pins Signal Transmission

- And much more...

Chapter 1: What are Load Pins?

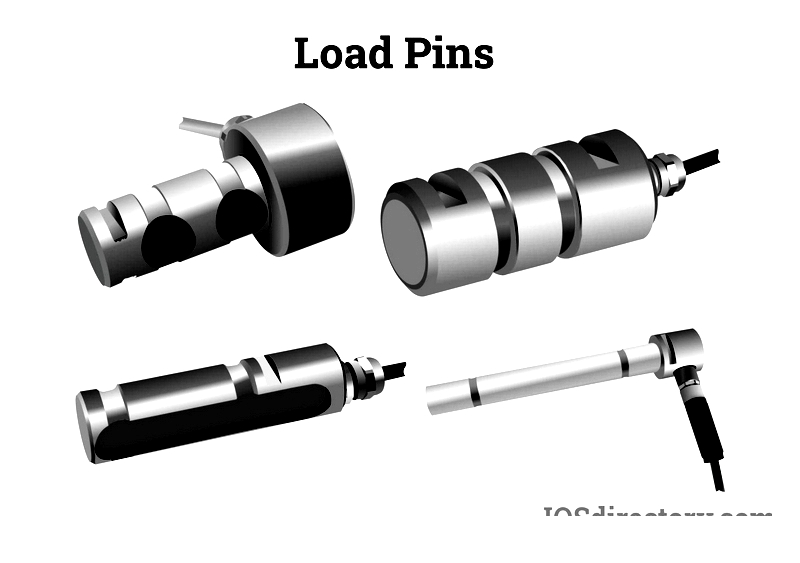

Load pins are specialized force sensors designed to measure weight and force in various applications including research, control systems, and testing environments. These sensors convert applied force into electrical signals, providing accurate measurements even in extreme conditions like space, marine environments, mines, and deserts. They play a vital role in detecting forces and preventing overloads in pin joint applications.

A key advantage of load pins is their integrated strain gauge technology, which has been used for over 60 years. The pins feature an internal bore along the neutral axis to house and protect the instrumentation from environmental factors. Made from high-strength stainless steel or alloy steels, load pins ensure excellent linearity and repeatability.

While standard load pins are versatile, custom designs are increasingly popular for specialized applications. These can be tailored to specific requirements, with cost-effective and rapid production options available.

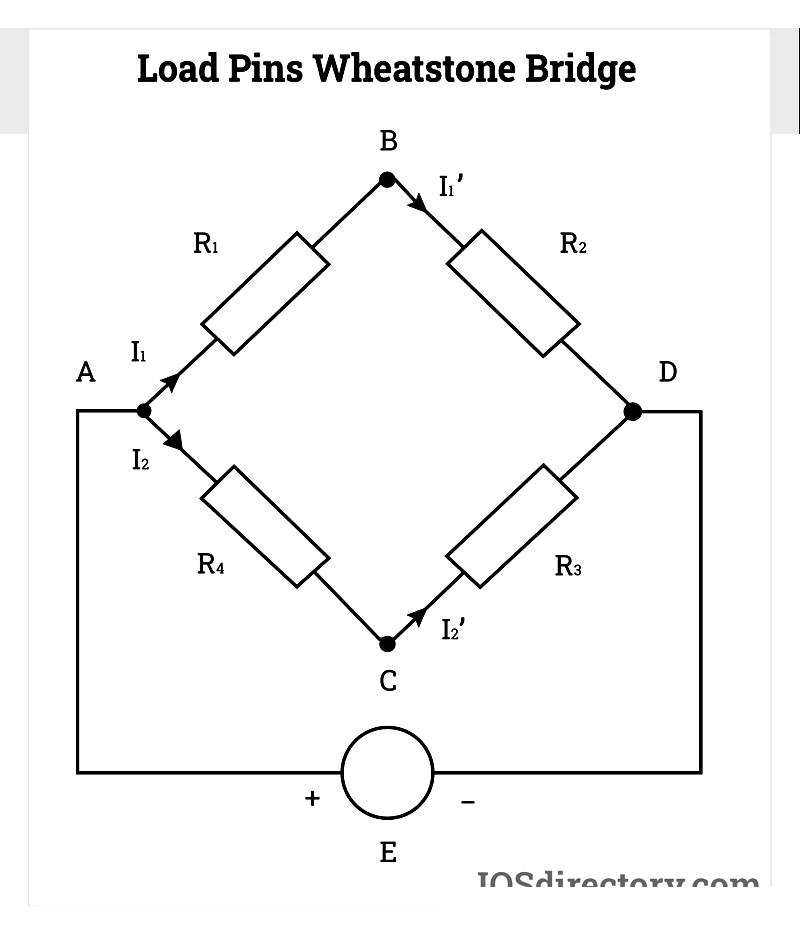

Also known as "Clevis pins" or "dynamometric axles," load pins have a shaft-like structure with a Wheatstone bridge to detect shear forces or overhead loads. They serve as pivot points, clevis pins, sheave pins, and other load-bearing components in various machinery.

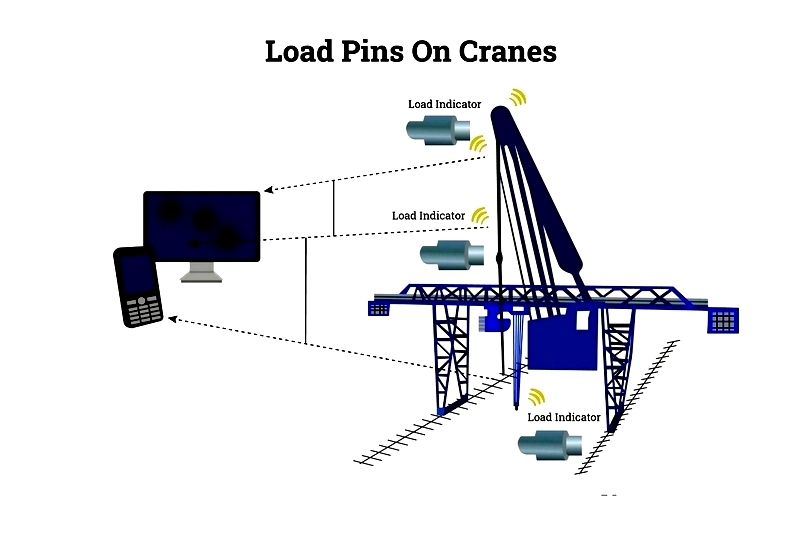

Load pins are widely used in cranes, winches, elevators, hoisting equipment, sheaves, shackles, and bearing blocks. Like load cells, they measure force-induced electrical signal changes that are converted into weight readings.

Chapter 2: How Load Pins Work

Load pins are precision force measurement devices crucial for industrial safety and efficiency. They use strain gauges wired into a Wheatstone bridge circuit that produces voltage outputs proportional to applied force, enabling real-time load monitoring.

- Force - Mechanical force is converted into internal stress based on material strength principles.

- Stress - Stress is transformed into micro-strain according to Hooke's law.

- Strain - Strain causes resistance changes detected by embedded strain gauges.

- Variation - Resistance changes alter the Wheatstone bridge output voltage, creating a measurable signal.

When force is applied, the pin's slight deformation is captured by strain gauges and converted into precise electrical signals. This method ensures accurate measurements in cranes, winches, and other heavy machinery.

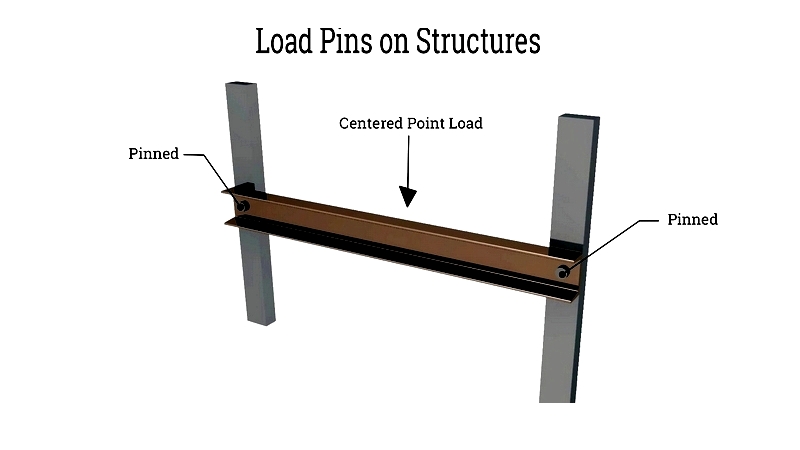

The sensing area between two grooves isolates the measurement zone for accurate force detection. Load pins can replace standard pins without compromising safety or performance, allowing retrofitting for load monitoring in existing equipment.

Essential for industries like construction, marine, and mining, load pins provide reliable monitoring in harsh conditions. Their corrosion-resistant stainless steel construction and sealed strain gauges ensure durability.

Load pins function as advanced strain gauge sensors that convert physical deformation into electrical signals. These can integrate with control systems for real-time monitoring.

Using material science principles, force is precisely transformed into measurable electrical signals. The Wheatstone bridge amplifies even minor resistance changes for accurate data.

As replacements for mechanical pins, load pins ensure operational safety in lifting applications. They support predictive maintenance and can incorporate wireless monitoring systems.

For load measurement, safety compliance, or equipment monitoring, load pins deliver reliable performance in demanding environments.

Chapter 3: Considerations When Choosing Load Pins

Selecting the right load pin is crucial for safety and performance in industrial weighing, structural monitoring, and crane applications. Key factors include potential geometry changes in the pin or load-bearing structure, as even slight bending can affect measurement accuracy.

Capacity and Resolution

Determine required force capacity (in pounds, kg, or newtons) and resolution to match application needs. The load pin's rated capacity should exceed expected loads while maintaining a safety margin.

Modern load pins use strain gauge technology with millivolt outputs. Higher resolution requires sensitive detection of small signal changes, necessitating compatible amplifiers and indicators.

Environmental Considerations

Verify compliance with NTEP and NIST standards, especially for regulated applications. Consult manufacturers for certified load pins meeting safety and accuracy requirements.

Choose corrosion-resistant materials like stainless steel and check IP ratings for environmental protection. Consider temperature compensation for extreme conditions and vibration-resistant designs where needed.

Manufacturers can provide custom solutions for specialized needs, including wireless monitoring options.

- Load Pin Selection Checklist:

- Determine load requirements

- Assess resolution needs

- Verify certifications

- Consider environmental factors

- Account for temperature/vibration

- Consult manufacturers

Proper selection ensures long-term accuracy and reliability in demanding industrial applications.

Chapter 4: Applications and Calibration of Load Pins

Load pins measure force in research, control, and testing applications, converting force to electrical signals. They provide reliable measurements in harsh environments and help prevent overloads in pin joints.

Their integrated strain gauge technology, protected by an internal bore, enables diverse applications. Made from high-strength materials, they offer excellent performance.

While standard pins suit many applications, custom designs address specialized needs with flexible production options.

Applications for Load Pins

Load pins replace existing pins to provide force measurement without expensive equipment modifications. They measure loads including overload conditions in various industries.

Applications range from simple systems to advanced technologies like space equipment and submersible vehicles.

Load Cell Use for Research and Testing

Used in product development and testing, load cells verify designs, analyze force distribution, and determine operational loads. They also validate computer models with real-world data.

They're essential for testing existing equipment being adapted for new requirements or expanded capacities.

Load Cell Measurement and Control Applications

In process control, load cells ensure proper force application and detect overloads. They can trigger alarms or automated responses when unsafe conditions occur.

Common applications include:

- Bearing Blocks

- Brake Anchors

- Structural Tests

- Flight Simulators

- Lifting Systems

- Aircraft Components

- Marine Applications

- Industrial Machinery