Introduction

This comprehensive guide covers everything you need to know about bottle brushes and their applications.

Key topics include:

- Bottle Brush Basics

- Practical Applications

- Varieties Available

- Manufacturing Process

- Additional Insights

Chapter One – Understanding Bottle Brushes

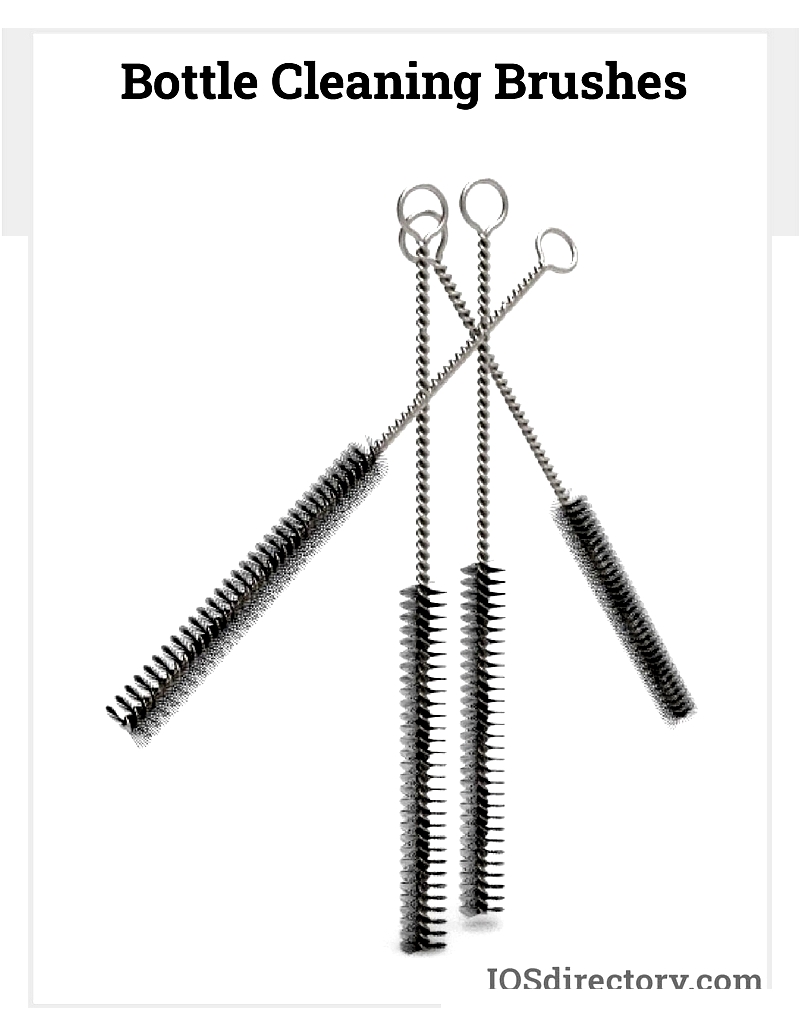

A bottle brush features flexible bristles attached to a long handle made of plastic, wood, or wire. The bristles may form a tubular shape along part of the handle or cluster near the tip, positioned slightly back from the end. Attachment methods vary by manufacturing technique. While primarily used for cleaning bottles, their versatile design suits multiple applications. Though all share a basic structure of a long handle with bristles, variations in bristle configuration create specialized brushes for different purposes.

The elongated bristled design excels at cleaning bottles by reaching areas inaccessible to other tools. Beyond bottles, these brushes effectively clean test tubes, rubber hoses, cylinders, and similar cylindrical items. Available for industrial, kitchen, and household use, each variant meets specific application requirements.

Chapter Two – Bottle Brush Varieties

Essential across laboratories, food production, medical fields, hospitality, brewing, and homes, bottle brushes offer versatile, durable cleaning for bottles, jars, glassware, and narrow containers. Selecting the appropriate type ensures thorough residue removal, prevents contamination, and maintains hygiene standards. Understanding different types helps achieve optimal cleaning results for both delicate and industrial applications.

Available in various configurations, bottle brushes differ in bristle diameter, material (nylon, polyester, horsehair, or stainless steel), handle composition, and length. Precision brushes with narrow handles and soft bristles suit laboratory glassware, while industrial versions with mechanical power clean pipes and large containers efficiently.

Handles come in wood, twisted wire, polypropylene, or plastic. Twisted wire models secure bristles between galvanized or stainless steel strands. Plastic/wooden handles feature bristles inserted into pre-drilled holes for enhanced durability in commercial use.

Choosing the Right Brush for Your Industry

With numerous options available, selection depends on container shape/size, material compatibility, cleaning frequency, and residue type. Below we outline common varieties, their features, and ideal uses.

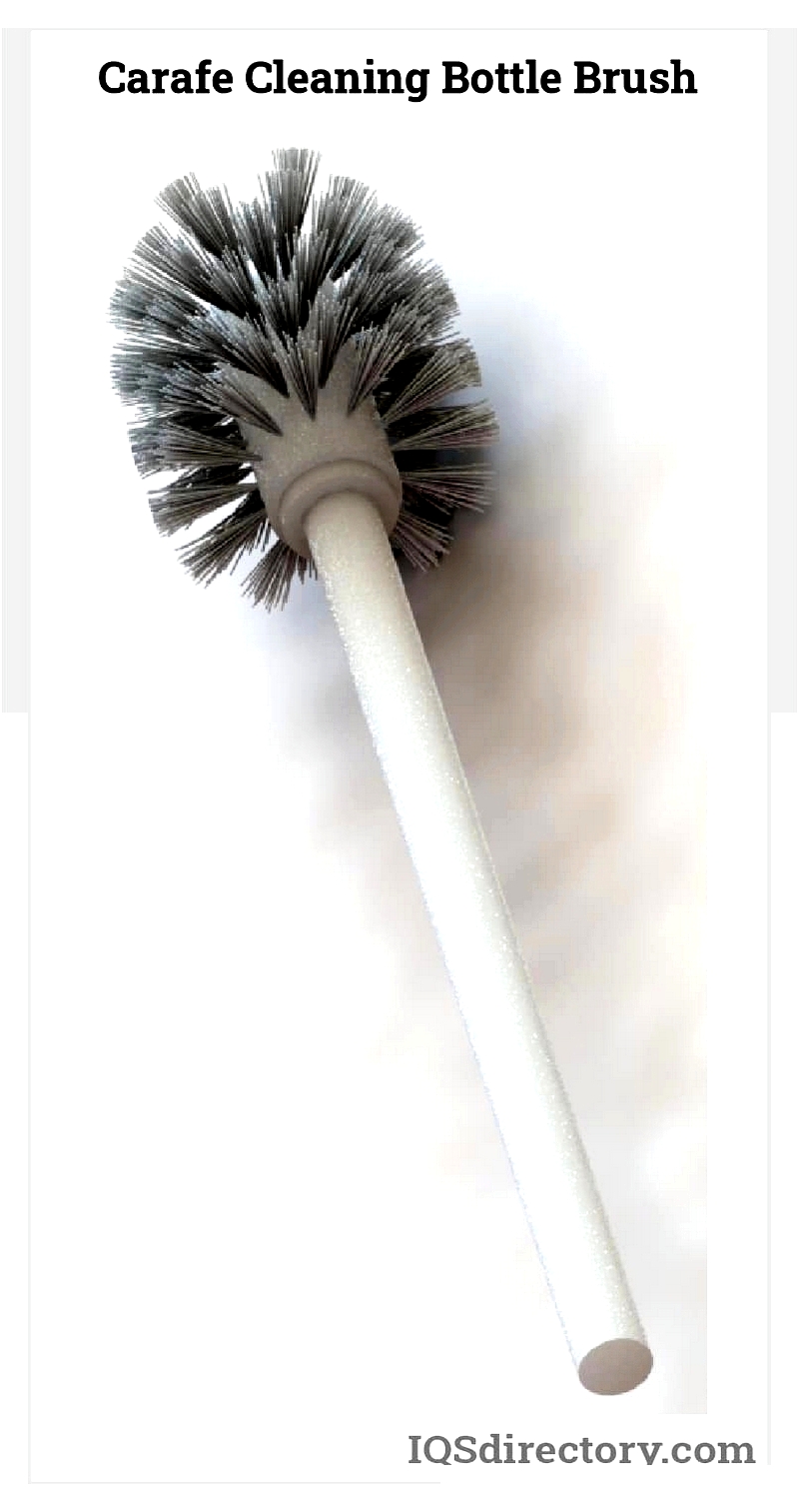

Carafe Cleaning Brush

Designed for bottles, jars, and serving containers, these feature long plastic handles with crimped bristles. The soft yet sturdy bristles remove dried liquids. Most include handle holes for convenient storage, making them kitchen staples in restaurants and homes.

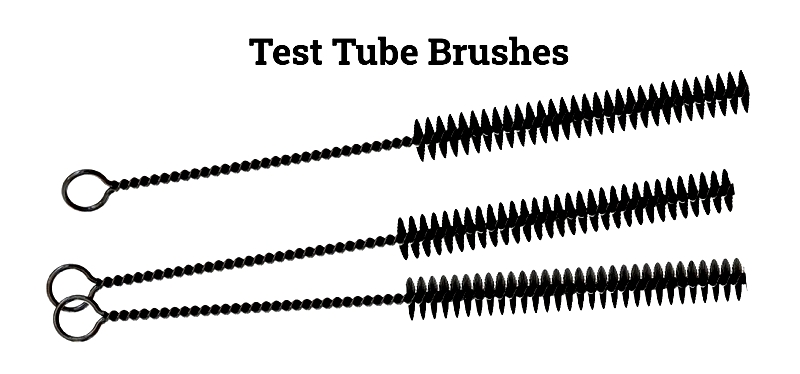

Test Tube Brush

Specialized for laboratory glassware, these smaller brushes often use corrosion-resistant steel wire. Extra tufted bristles at the tip effectively clean test tube bottoms, preventing contamination and ensuring accurate lab results.

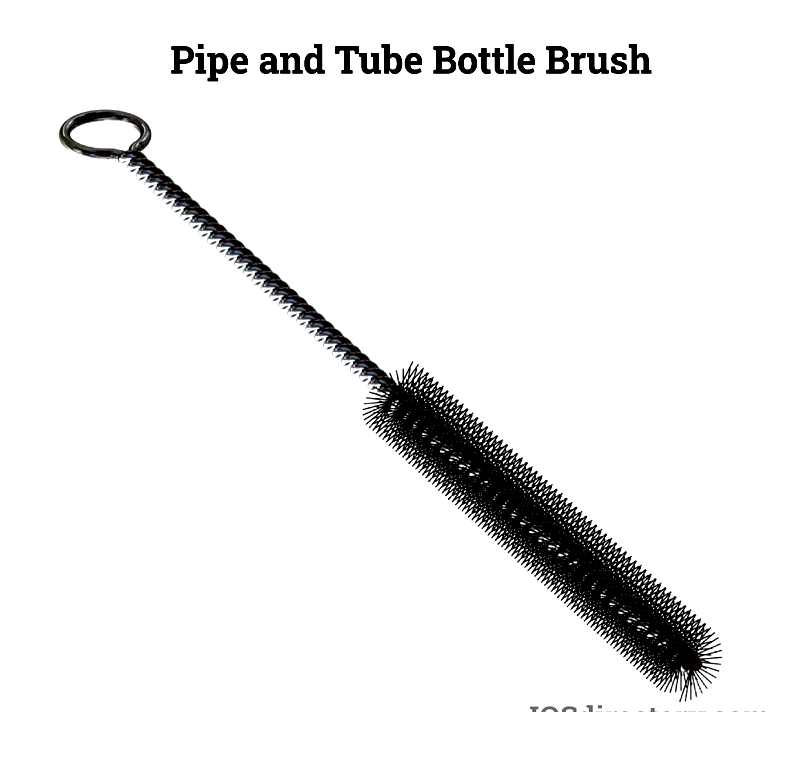

Pipe and Tube Brush

Industrial-grade brushes with stiff nylon, polyester, or wire bristles remove stubborn buildup from pipes and hydraulic lines. Their long (1-2 foot) flexible handles access tees, elbows, and complex networks. Bristle diameter and stiffness match specific pipe requirements.

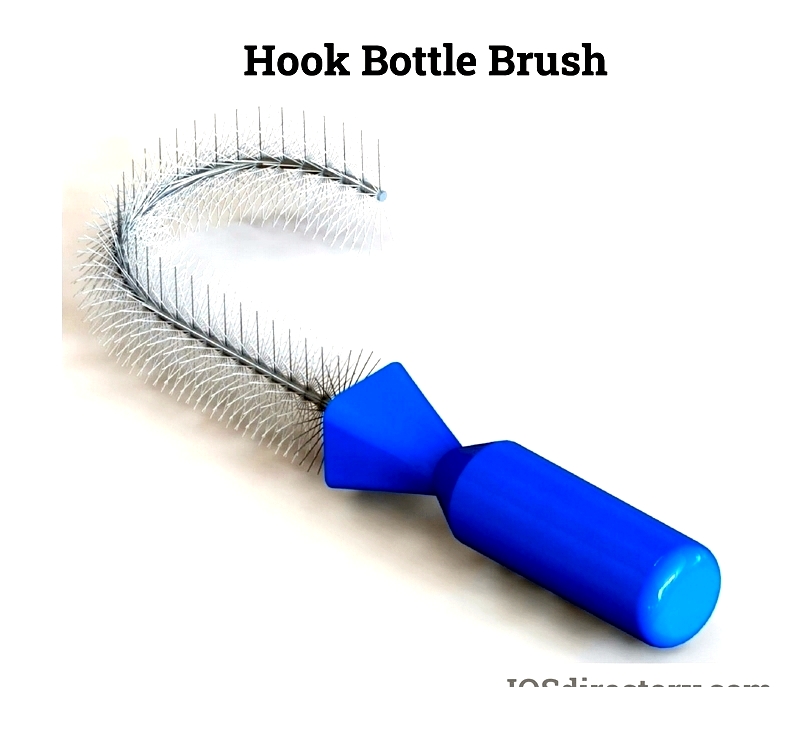

Hook Brush

Curved design cleans bends in piping and flasks. Common in bottling lines and breweries, these corrosion-resistant brushes reach high or difficult areas.

Sponge Brush

Combining bristles with sponge tips, these clean delicate glassware and baby bottles effectively. The sponge enhances removal of milk deposits and dried residues in healthcare and brewing applications.

Dairy Brush

Versatile industrial brushes clean tubing and dispensers in food service. Tapered tips accommodate various containers, with handle options (wood, plastic, wire) for different sanitation needs.

Tufted Brush

Commercial-grade brushes with tightly secured bristles resist chemicals and withstand heavy use. Collapsible tips adapt to varying container necks, cleaning large bottles and brewing equipment effectively.

Fan-Tipped Brush

Fan-shaped bristles contour container walls, thoroughly cleaning cylinders and tanks exposed to harsh chemicals. Popular in industrial maintenance and laboratories.

Flask Brush

Angular design reaches flask interiors and rounded shoulders. Color-coded nylon bristles clean without scratching, essential for laboratory accuracy.

These eight types represent just a sampling of available options. ongoing innovations include eco-friendly designs and custom solutions. When selecting, consider material compatibility, chemical resistance, usage frequency, and replacement needs to maintain optimal hygiene and performance in commercial environments.