Introduction

This comprehensive guide covers everything you need to know about emulsifiers and their applications.

Key topics include:

- What are Emulsifiers?

- Different Types of Emulsifiers

- Practical Applications of Emulsifiers

- Key Components of Emulsifiers

- And much more...

Chapter 1: What is an Emulsifier?

An emulsifier is a specialized device that creates stable emulsions by dispersing immiscible liquids using emulsifying agents. It enables the mixing of liquids that would normally separate, employing techniques like rotating propeller mixers, vacuum systems, rotor-stator arrangements, and high shear mixers. These processes reduce droplet sizes to less than one micron (µ), forming finely textured emulsions through high-pressure methods.

Various emulsifier machines can mix, disperse, homogenize, and emulsify both viscous ingredients and immiscible liquids. Designed to prevent dead zones, these electronically operated machines can create vacuum conditions and control temperatures. They're widely used for products like creams, lotions, ointments, and medications due to their ability to blend incompatible substances.

Chapter 2: The Emulsification Process

Emulsification is essential in food production, pharmaceuticals, cosmetics, and chemical manufacturing. It creates stable, homogeneous emulsions from immiscible materials like oil and water by generating tiny droplets through mechanical mixing, high-shear blending, or ultrasonic homogenization. This process affects product consistency, mouthfeel, quality, stability, shelf life, and sensory attributes.

The process involves transforming one phase (dispersed phase) into minute droplets within another (continuous phase), requiring energy from mechanical agitation, ultrasonication, or chemical techniques. Understanding the balance between phases and the desired emulsion type (oil-in-water or water-in-oil) is crucial for product functionality.

Key objectives of emulsification:

- Physicochemical Stability – Ensures product structure, uniformity, and long-term stability

- Sensory Properties – Controls appearance, texture, mouthfeel, and flavor release

- Surface Quality – Creates even, smooth surfaces affecting visual and tactile qualities

- Bioavailability – Enhances absorption and efficacy of active ingredients

Emulsification differs from simple blending by specifically mixing immiscible liquids through chemical, physical, and mechanical methods. High-shear mixers, inline homogenizers, and ultrasonic equipment help achieve desired droplet sizes.

Three scientific theories explain stable emulsion formation:

- Surface Tension Theory – Reduction in interfacial tension between phases

- Repulsion Theory – Electrical charge or steric barriers prevent droplet coalescence

- Viscosity Modification – Increased viscosity slows droplet movement

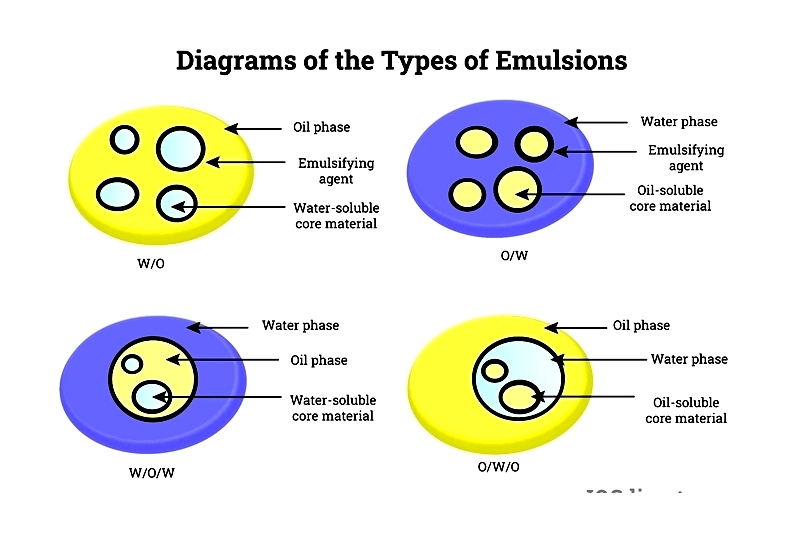

Types of Emulsion

Emulsions are categorized as simple or complex:

- Simple Emulsions –

- Oil-in-Water (O/W) – Oil droplets in water (e.g., milk, creams)

- Water-in-Oil (W/O) – Water droplets in oil (e.g., butter, ointments)

- Complex Emulsions – Multiple emulsions (O/W/O or W/O/W) for controlled release and encapsulation

Emulsifiers

Emulsifiers (surfactants) stabilize emulsions by reducing interfacial tension. Their hydrophilic and hydrophobic components position at oil-water interfaces, preventing droplet merging. Common examples include lecithin, monoglycerides, and polysorbates. Selection is guided by the Hydrophilic-Lipophilic Balance (HLB) system.

Emulsification Process

Used in food, pharmaceuticals, cosmetics, paints, and adhesives, the process requires:

- Emulsifiers – Reduce surface tension for mixing immiscible liquids

- Mechanical Force – Achieves uniform dispersion through blending, homogenization, etc.

Stabilization is crucial for product shelf life. Process parameters like shear force, temperature, and emulsification time must be carefully controlled. Advanced technologies enable precise droplet size control.

Lipophilic and Hydrophilic Emulsifiers

Specialized emulsifiers are used in surface treatments:

- Lipophilic – Interact with oil-based penetrants for removal

- Hydrophilic – Emulsify residues for washing away

Laser Diffraction

This particle sizing technique analyzes droplet size distribution, crucial for product quality. It measures light scattering patterns to determine droplet sizes rapidly and accurately.

Conclusion: Mastering emulsification techniques is fundamental for producing high-quality, stable emulsions across various industries.

Chapter 3: Types of Emulsifiers

Emulsification requires different energy sources and mechanical mechanisms. Key equipment includes:

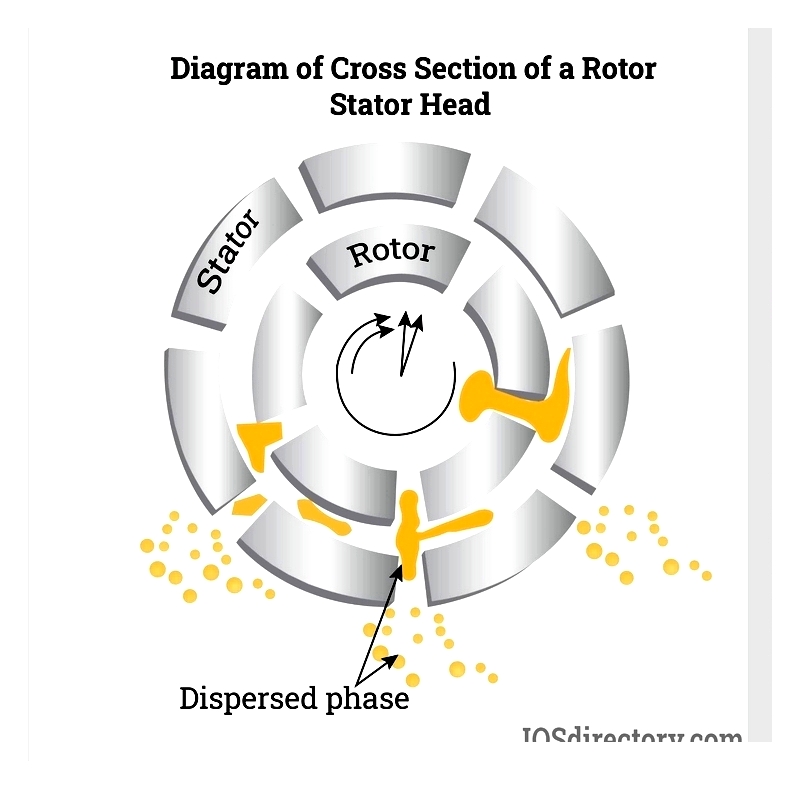

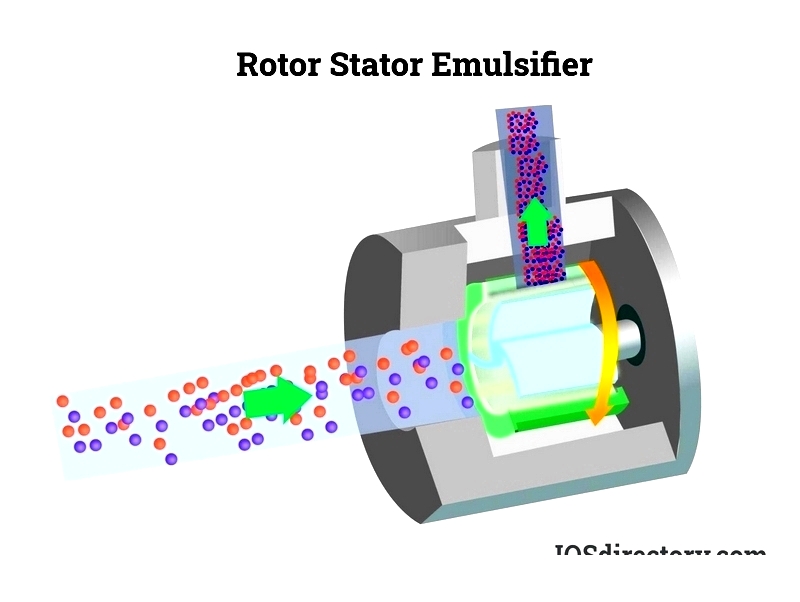

Rotor Stator Mixers

Industrial mixers that deliver high-speed dispersion through rotating components and perforated stators, creating fine, stable emulsions.

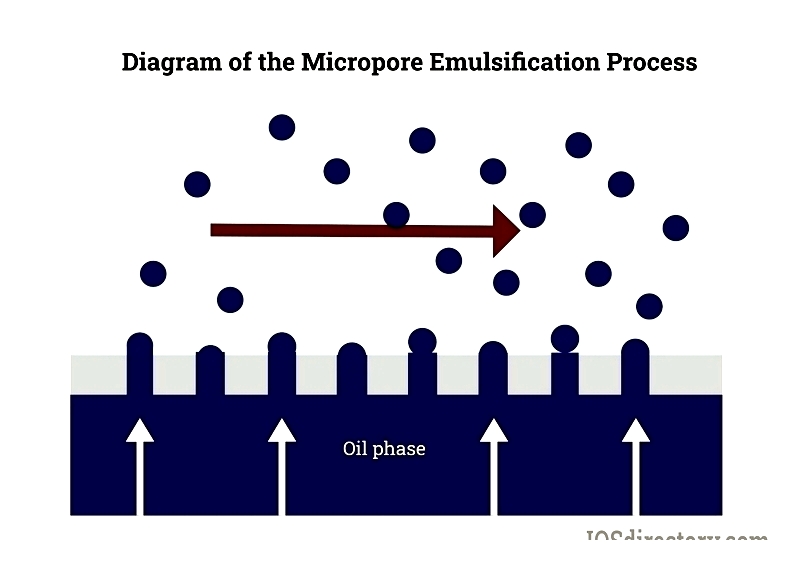

Micropore Emulsification

Produces uniform droplet sizes through microscopic pores, ideal for high-viscosity ingredients.

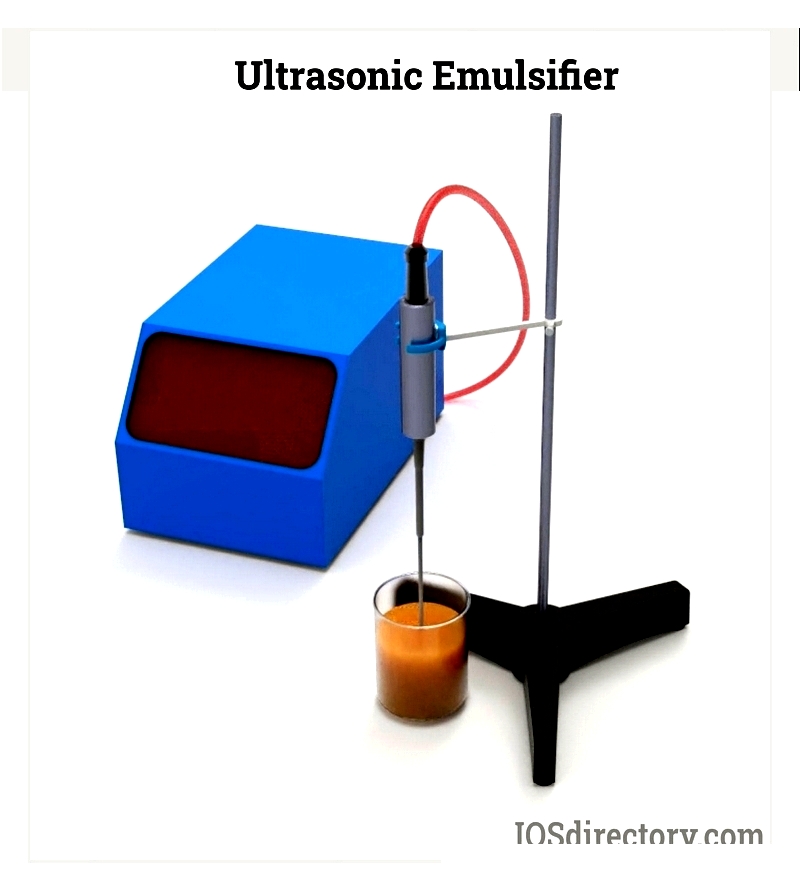

Ultrasonic Emulsifier

Uses ultrasound to create nanoemulsions for pharmaceuticals, coatings, and food science.

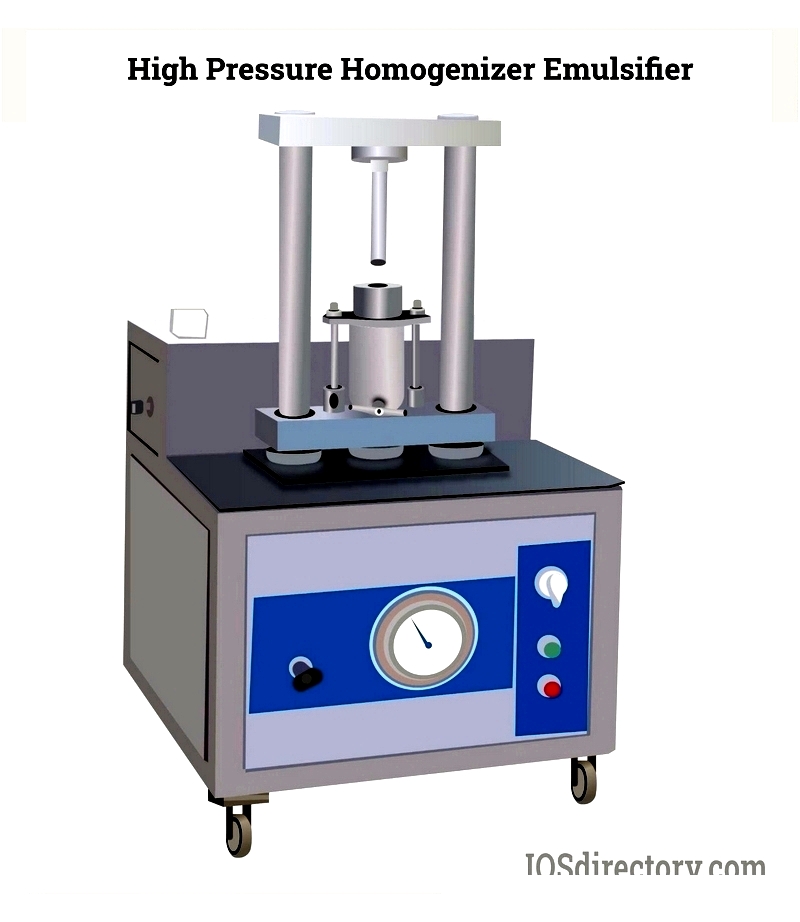

High Pressure Homogenization

Industrial-scale equipment for high-throughput nanoemulsion production.

High Shear Mixers

Essential for emulsification and dispersion across various industries.

Inline Emulsifier

Continuous processing systems with rotor-stator assemblies for stable emulsions.