Introduction

This article provides a comprehensive overview of gasket materials.

You'll learn about various topics including:

- What gaskets are

- The functions of different gasket materials

- Common gasket materials and their properties

- Formulations and grades of gasket materials

- Pressure-sensitive adhesive-backed gaskets

- Key factors in selecting gasket materials

- And more...

Understanding Gasket Materials

Gasket materials are crucial for manufacturing gaskets and determining their performance in specific environments. These components prevent leaks, maintain secure connections, and protect against contaminants in critical processes.

Factors like pressure and temperature significantly impact material selection. Choosing the right material ensures operational efficiency, minimizing maintenance needs and downtime.

The following sections explore different gasket materials in detail.

Gasket Materials and Their Uses

Selecting gasket materials or designing custom gaskets offers numerous options. Common gasket materials include:

Solid Materials

Solid materials provide a durable alternative to sponge materials in gasket production. They offer greater longevity and withstand higher compression forces, making them ideal for demanding applications.

Manufacturing processes for solid material gaskets include waterjet cutting, die cutting, and CNC machining. Some can also be 3D molded.

Key solid materials include:

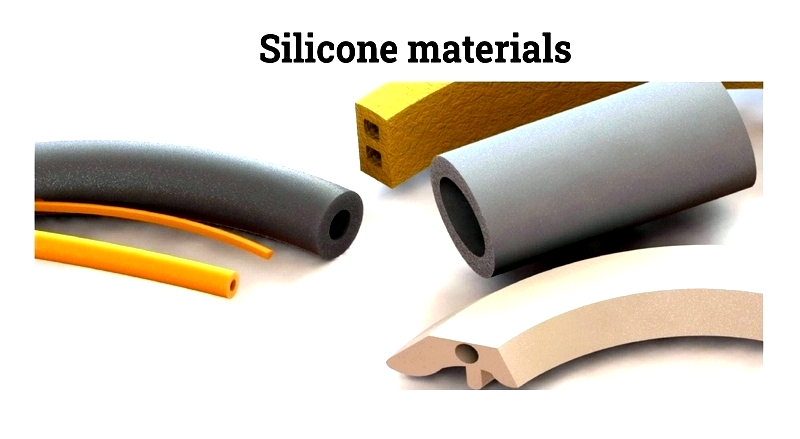

Silicone

Solid silicone gaskets excel in outdoor applications with moderate environmental stress. They perform well in extreme temperatures and resist UV degradation.

Fluorosilicone

Similar to silicone but with enhanced chemical resistance, fluorosilicone gaskets handle fuels, oils, and extreme temperatures effectively. They're particularly valuable in automotive and aerospace fuel systems despite higher costs.

Nitrile

Nitrile gaskets withstand harsh industrial conditions, offering excellent resistance to oils and fuels. Some variants are suitable for food and agricultural applications.

Neoprene

More affordable than fluorosilicone and silicone, neoprene gaskets resist oils and water while providing good elasticity and tear resistance.

EPDM

EPDM gaskets offer weather, water, ozone, and UV resistance. They handle steam and high temperatures well but aren't suitable for oil exposure.

Butyl

Butyl rubber excels in moisture and gas retention, making it valuable in medical and aerospace applications.

Fluoroelastomer

Fluoroelastomer stands out for exceptional chemical and temperature resistance, justifying its higher cost in critical aerospace applications.

Fluorocarbon

Fluorocarbon gaskets work well in reusable, non-critical applications but lose strength at high temperatures.

Sponge Materials

Sponge material gaskets suit applications with lower compression requirements, particularly when:

- Housing assemblies may bend or warp

- Compression stop cracking is possible

- Plastic housings are involved

These materials reduce housing stress and often feature UL flame ratings.

Silicone Sponge

Silicone sponge offers excellent compressibility and temperature resistance, with closed-cell construction preventing water absorption.

Neoprene Blend

This cost-effective alternative provides flexibility for shock absorption and basic sealing applications.

EPDM Sponge

EPDM sponge offers superior ozone resistance compared to neoprene, though at higher cost.

Foam Materials

Foam materials work well for minimal compression applications, providing affordable solutions for basic sealing needs.

Silicone Foams

These materials offer excellent temperature tolerance for cushioning and insulation applications.

Filter Foams

Specially designed for dust filtration while maintaining airflow in electronic applications.

Polyurethane Foams

Affordable options for gasketing and energy absorption, available in various densities.

Polyolefin

Cost-effective material for basic gaskets that prevent surface contact.

Form-In-Place Materials

FIP gaskets suit small, complex applications where traditional methods are impractical, reducing assembly costs.

Silicone

Silicone sealants cure at room humidity and resist environmental stresses while providing electrical insulation.

UV Curing Materials

These materials enable rapid production in high-volume environments with minimal curing time.

EMI Shielding Materials

These precision materials provide effective EMI shielding in aerospace and electronic applications.

EMI Shielding

Creates barriers against electromagnetic interference between components.

Silicone Extrusions

Combine EMI shielding with environmental sealing in a single product, ideal for groove-mounted gaskets.

Silicone

Conductive silicone products incorporate metal fillers for flexible EMI solutions, though less suitable for harsh environments.

Fluorosilicone

- Fluorosilicone combines chemical resistance with conductivity through specialized fillers and tear-resistant reinforcement.

- While more expensive than silicone, it handles harsh chemicals effectively.

Nickel Taffeta Foam

- This low-compression material works well in layered electronic assemblies.

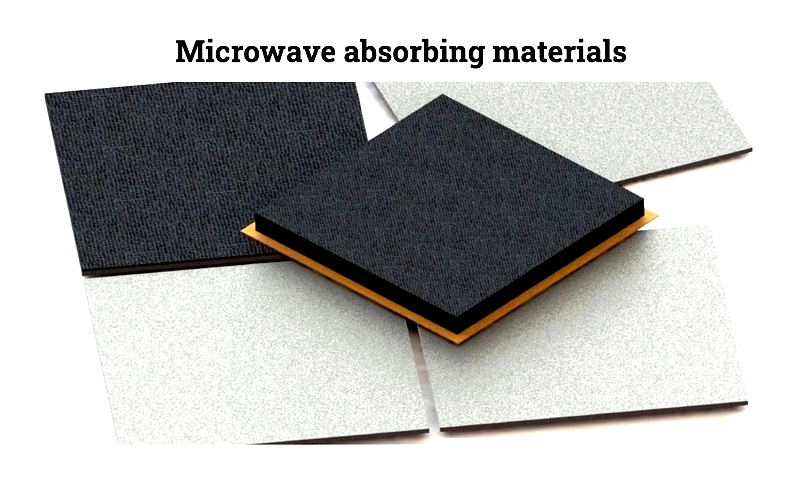

Microwave Absorbing Materials

- These specialized materials absorb rather than reflect frequencies, resisting environmental degradation.

Thermal Interface Materials

These materials facilitate heat dissipation, with silicone being particularly effective for high-temperature applications.

Silicone Gap Fillers

- Custom solutions for heat transfer between components like PC