Introduction

This article provides an in-depth examination of rubber bushings and their applications.

You will explore various topics including:

- What are Rubber Bushings?

- Different Types of Rubber Bushings

- Manufacturing Process of Rubber Bushings

- Applications of Rubber Bushings

- Materials Used in Rubber Bushing Production

- And More...

Chapter One – What is a Rubber Bushing?

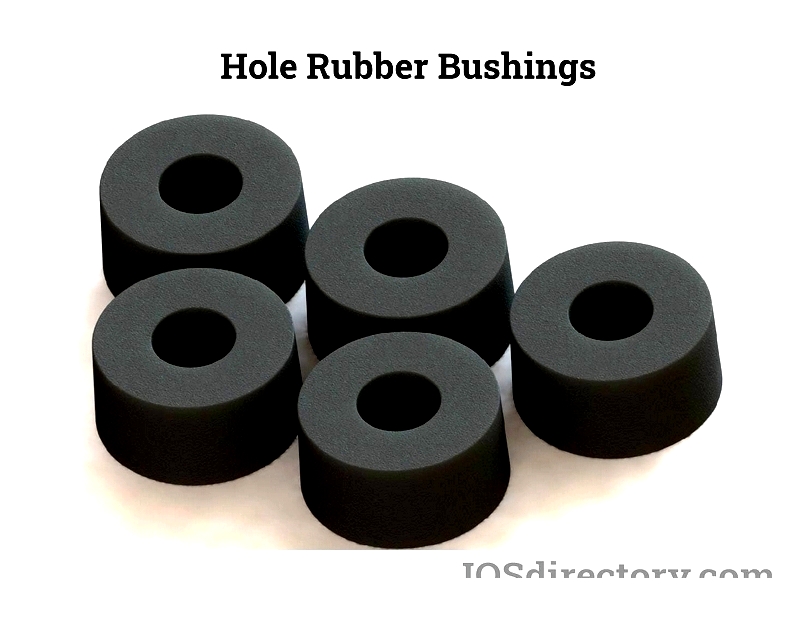

Rubber bushings serve as vibration isolators, installed between components to restrict movement while absorbing and dissipating energy from their interaction. These versatile components can be molded and customized for diverse applications, with cylindrical designs featuring central holes being the most common configuration.

Their primary function is to minimize vibration and movement between connected parts, thereby reducing wear and potential damage. Despite their compact size and rubber composition, these bushings demonstrate remarkable resilience, enduring significant stress and substantial deformation.

Manufactured from both natural and synthetic rubber, the material choice significantly influences bushing performance. Each rubber type possesses distinct characteristics that determine its suitability for specific applications. Originally developed for automotive applications, rubber bushings remain indispensable due to their elastic properties and vibration-damping capabilities.

Chapter Two – Types of Rubber Bushings

Rubber bushings are critical components across various machinery, automotive systems, and equipment, valued for their durability, flexibility, and superior vibration isolation. As anti-vibration mounts, they serve vital functions not only in vehicles but also in industrial settings, HVAC systems, marine technology, heavy equipment, and precision electronics. Their ability to dampen vibrations, absorb shocks, and reduce mechanical joint wear significantly enhances equipment longevity and performance.

Available in multiple shapes, sizes, and hardness levels (durometers), rubber bushings can be customized to meet specific requirements for dynamic/static stiffness, load capacity, and environmental resistance. Manufacturers utilize various elastomers including natural rubber, silicone, neoprene, SBR, and EPDM, each selected for unique properties like heat, oil, ozone, or chemical resistance. Each bushing's design, volume, and dimensions are optimized to achieve desired performance characteristics, ensuring effective vibration absorption and noise reduction in both light and heavy-duty applications.

Despite their simple structure, rubber bushings are essential for high-stress mechanical systems. Their elastomeric cores typically separate metal components, functioning as flexible couplings or vibration isolators to prevent direct metal contact. Beyond noise and vibration reduction, modern bushings offer additional benefits including corrosion protection and improved ride comfort. These combined features make them widely applicable in suspension systems, control arms, exhaust hangers, machinery mounts, conveyor systems, and numerous other industrial applications.

Natural Rubber Bushings

Natural rubber bushings are prized for their exceptional tensile strength, elasticity, and resistance to tearing and fatigue. These properties make them ideal for static and dynamic mounting applications requiring superior vibration control and noise reduction, such as automotive suspensions, engine mounts, and industrial machinery. Their popularity stems from their ability to withstand repeated impacts, absorb energy, and maintain rebound elasticity even at low temperatures, offering an optimal balance of flexibility, shock absorption, and cost-effectiveness for general applications.

However, natural rubber degrades in high-temperature environments or when exposed to ozone, oil, or hydrocarbon solvents. It's unsuitable for applications exceeding 155°F or involving prolonged chemical exposure. For tension applications, alternatives like neoprene or silicone bushings may be preferable. When selecting rubber bushings for automotive or industrial use, always match material properties to specific environmental and performance requirements for optimal results.

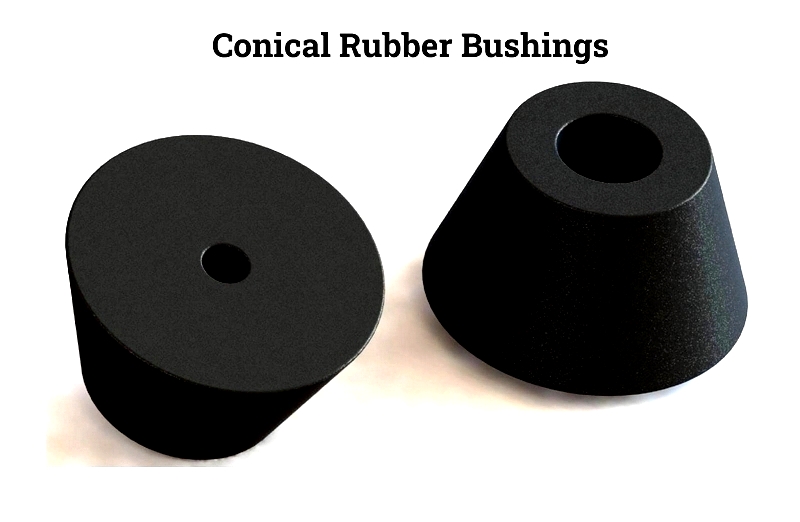

Conical Bushings

Conical rubber bushings, typically made from silicone rubber or other high-performance elastomers, feature low compression set and excellent heat resistance. Silicone-based conical bushings maintain flexibility and durability when exposed to heat, oils, or greases, making them ideal for automotive suspensions, marine engines, and industrial machinery. Their cone-shaped design efficiently distributes forces while providing high load-bearing capacity and superior vibration damping, making them particularly effective under dynamic and alternating loads.

Leaf Spring Bushings

Leaf spring bushings are crucial in automotive suspension systems, cushioning the interface between leaf springs and vehicle chassis. Available as all-rubber or steel-sleeved versions, they minimize friction, absorb shock, and reduce vibration transfer. Steel-encased bushings typically support front spring loads, while all-rubber variants are common at rear positions. Equalizer bushings at spring ends or equalizer arms facilitate smooth movement and proper alignment. Proper bushing selection ensures quieter operation, reduced maintenance, and improved handling for both passenger and commercial vehicles.

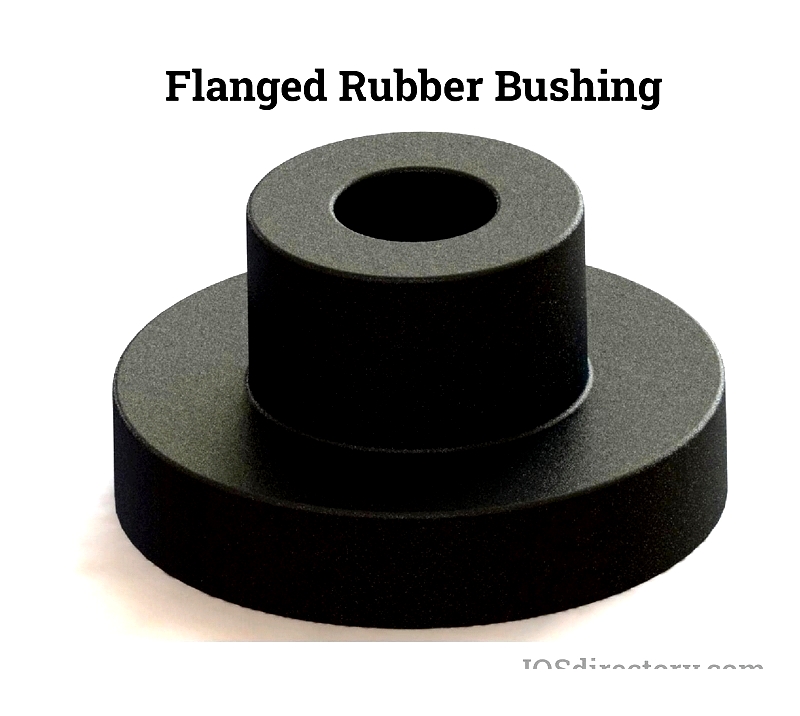

Flanged Bushings

Flanged bushings feature a flared end that provides additional axial load support. Typically made from high-grade SBR or EPDM rubber, they resist water, heat, and chemicals, making them suitable for outdoor equipment, electrical enclosures, and industrial valves. Their integrated washer-like design distributes pressure over larger areas, reduces component wear, and simplifies installation, making them ideal for rotating shafts, conveyor rollers, and other assemblies requiring enhanced stability and vibration damping.

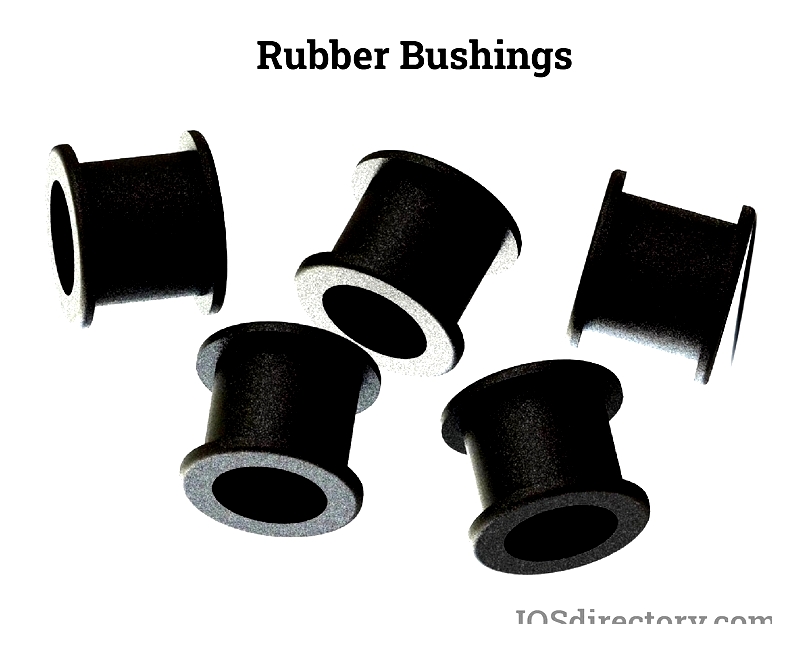

Sleeve Bushings

Rubber sleeve bushings provide excellent insulation and abrasion resistance for shafts, bearings, and sensitive components. By isolating moving parts, they protect against vibration, corrosion, and physical impact. Common variants include shaft sleeves, bearing sleeves, suspension sleeves, and sway bar bushings. Their shock-absorbing nature helps maintain alignment, extend service life, and improve operation in automotive sway bars, commercial door hardware, and industrial actuators, even under continuous mechanical stress.

Control Arm Bushings

Control arm bushings, typically made from durable rubber or polyurethane, are vital for vehicle suspension systems. They isolate control arms from chassis contact, preventing metal-to-metal abrasion, reducing noise, and dampening road vibrations for smoother operation. These bushings maintain proper wheel alignment and handling, with failure symptoms including clunking noises, excessive vibration, uneven tire wear, or reduced steering response. Selection considerations include material composition (OEM rubber vs. performance polyurethane), heat/contaminant resistance, and lifespan under demanding conditions.

Bonded Bushings

Bonded rubber bushings combine elastomers with metal sleeves for superior vibration isolation and structural integrity, commonly used in automotive, machinery, and engine applications. Two primary styles exist:

Center Bonded – These feature a cylindrical metal core completely encased in rubber, allowing multi-directional movement while minimizing friction and noise. Suitable for compressive, torsional, and shear loads, they're invaluable for suspension pivots, steering assemblies, and heavy machinery.