Introduction

This article provides an in-depth exploration of ceramic machining.

Key topics covered include:

- Principles of Ceramic Machining

- Types and Methods of Ceramic Machining

- Categories and Types of Ceramics

- Advantages, Disadvantages and Applications of Ceramics in Machining

- And More...

Chapter 1: Understanding the Principles of Ceramic Machining

This section examines the fundamentals of ceramic machining, including its definition, execution methods, and key considerations.

Defining Ceramic Machining

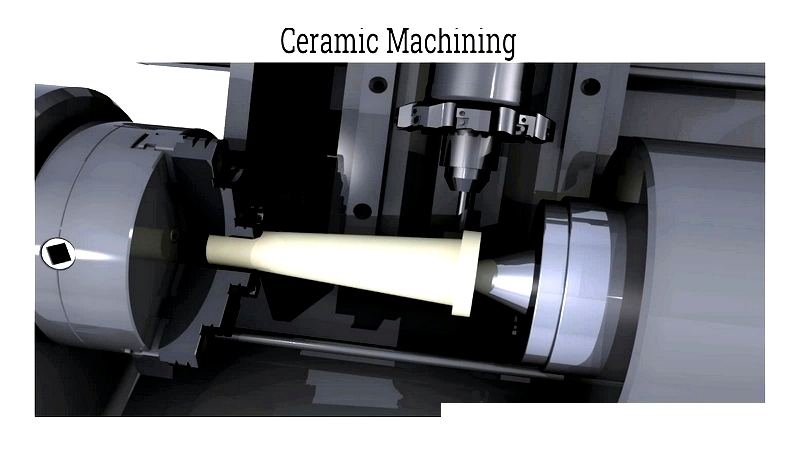

Ceramic machining involves various techniques for cutting and shaping ceramic materials to achieve precise tolerances. The process includes operations like milling, drilling, grinding, and turning. Machining can occur at different production stages: either as green body machining (pre-firing) or full-density machining (post-firing).

Green body machining uses standard steel tools on bisque-fired ceramics before full densification. Full-density machining requires specialized diamond-tipped tools due to the material's hardness.

Similar to metal machining, ceramic machining is a precise material removal process requiring careful control to achieve accurate tolerances and surface finishes. Green ceramics allow standard machining practices due to their initial softness.

Ceramics are characterized by their hardness, brittleness, heat resistance, corrosion resistance, high strength, low density, and rigidity. These materials are formed by shaping and firing non-metallic minerals like clay at high temperatures.

The Necessity of Ceramic Machining

Machining fired ceramics is essential for achieving tight tolerances unattainable during green machining. While basic shapes can be formed in the green state, precise features like hole diameters and surface finishes often require post-firing adjustments. Some ceramic rod and tube features must be added after sintering.

Sintering strengthens ceramics but may cause shrinkage and warping, necessitating corrective machining. Complex ceramic components for technical applications often require post-sintering machining.

Executing Ceramic Machining

Ceramic machining employs milling, drilling, grinding, and turning on fully dense ceramics. While similar to metal machining, ceramic's hardness requires robust cutting tools.

Green ceramics can be machined with standard steel tools, but precision components are typically processed post-firing.

The Process of Making Ceramics

Ceramic production begins with raw clay processing, evolving from ancient pottery techniques to modern industrial applications.

Mixing

Ceramic materials are mixed with water or chemicals to form slurries, then shaped through slip casting, extrusion, injection molding, or dry powder pressing.

Sintering

Sintering involves heating formed clay to 1832°F (1000°C), where particles bond without melting. The process includes bisque and glaze firing stages.

- Bisque Firing - Items are heated until glassy. Water evaporates by 662°F (350°C), and clay becomes ceramic by 932°F (500°C). The process continues to 1742°F (950°C), producing bisqueware ready for glazing.

- Glaze Firing - A decorative coating is applied, and the kiln is heated to specific temperatures before gradual cooling.

Considerations in Ceramic Machining

This section addresses common challenges and solutions in ceramic manufacturing and machining.

Deformation in Ceramic Products

Improper kiln-drying practices, particularly rapid temperature changes, can cause deformation. Careful temperature control is essential.

Cracking in Ceramic Products

Rapid temperature variations may lead to surface cracking from uneven shrinkage.

Foaming in Ceramic Products

Foaming occurs when insufficient oxidation causes glaze bubbling, often due to sulfate or organic impurities.

Chapter 2: Ceramic Machining Methods

Advanced ceramics production creates precision parts with varying sizes, shapes, and strengths. Machining can account for 50-90% of production costs, with productivity measured by material removal rate (MRR).

Ceramic machining methods fall into two categories based on material properties. Dense ceramics require superabrasive tools (diamond/CBN), while green ceramics can use conventional tools. Green machining occurs pre-densification, while dense machining provides final precision. Method selection depends on surface quality, tool wear, cycle times, and tolerances.

Abrasive Machining

This dominant technique replaces traditional methods for hard-to-machine ceramics like alumina and silicon carbide, offering better surface integrity and tolerances.

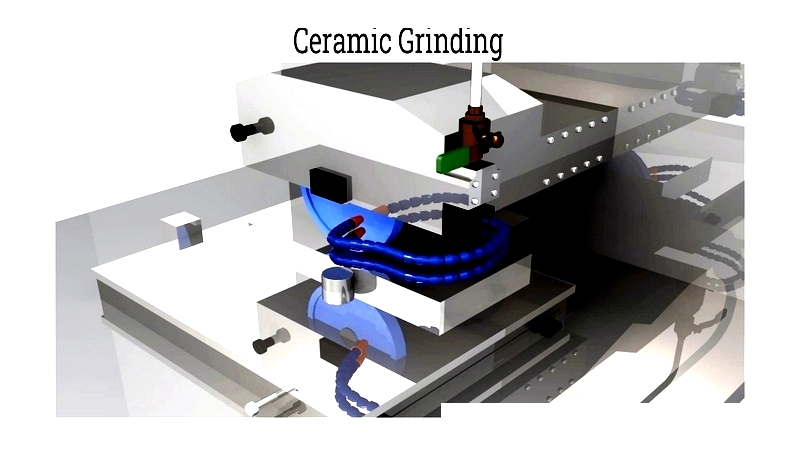

Grinding Process

Grinding uses diamond/CBN wheels to remove material precisely. Coolant flushing prevents thermal damage and maintains surface finish.

Diamond abrasives cut rapidly but wear faster than CBN. Grit size, bond type, and wheel speed affect results.

Honing Process

Honing achieves tight tolerances and surface quality on internal features using diamond-coated tools at slower speeds than grinding.

Honing also finishes external features with minimal thermal distortion.

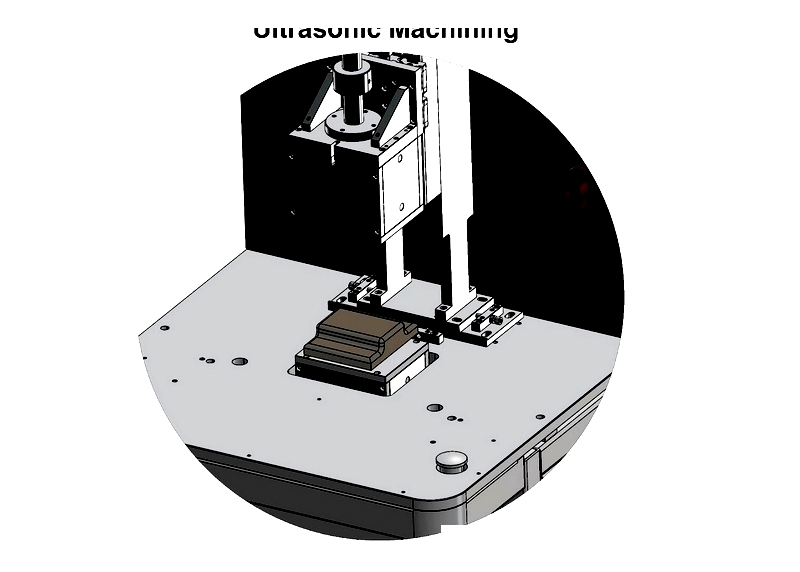

Ultrasonic Machining Process

USM uses high-frequency vibration and abrasive slurry to machine brittle ceramics without heat or chemicals, ideal for complex geometries.

The tool agitates abrasives to remove material via micro-chipping, suitable for silicon nitride and alumina.

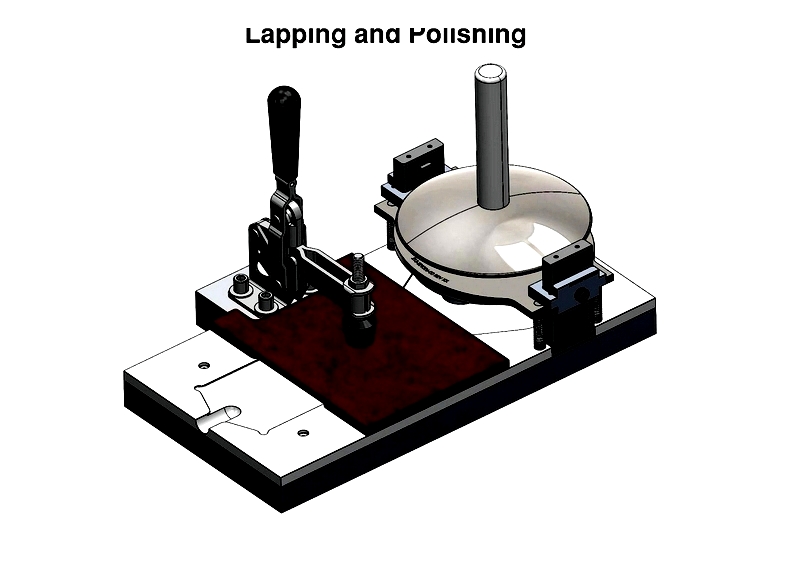

Lapping and Polishing Process

These finishing processes achieve sub-micron tolerances and smooth surfaces for optics and electronics.

Lapping uses abrasive slurry for flatness, while polishing employs fine abrasives for ultra-smooth finishes.

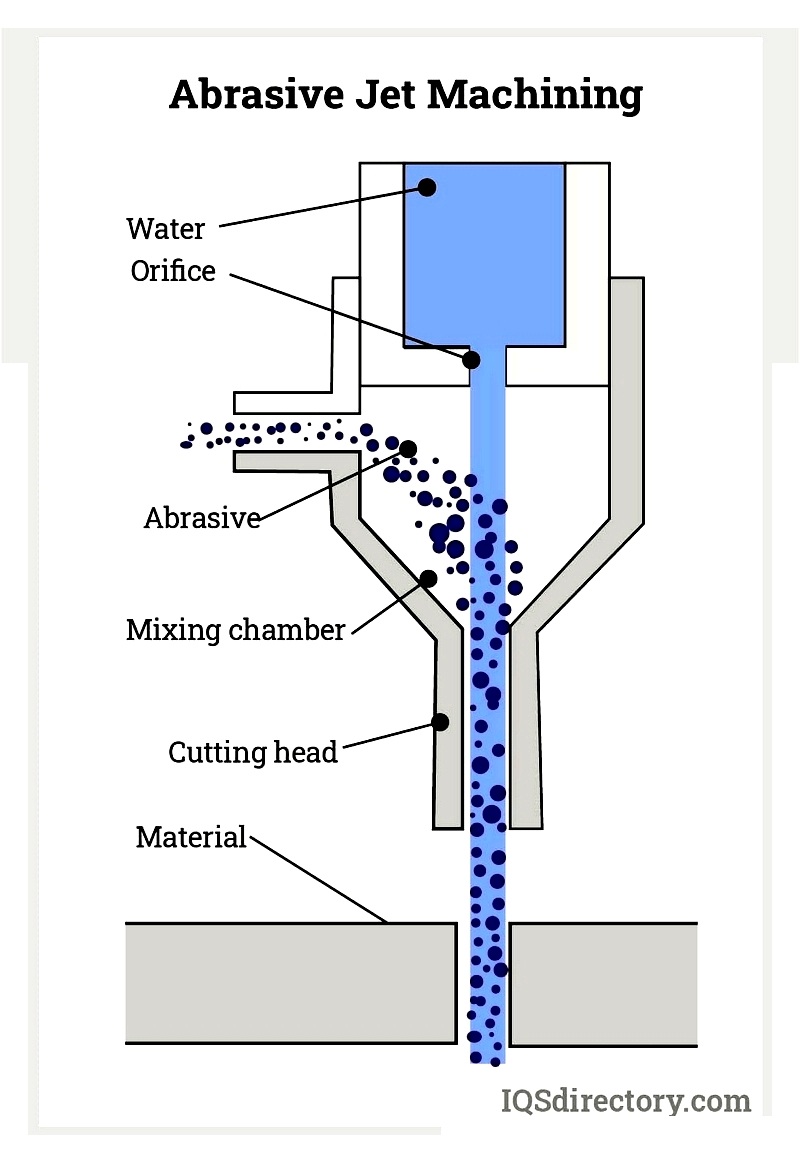

Liquid Abrasive Jet-Cutting Process

This contactless method cuts porous ceramics rapidly using abrasive-laden water, avoiding thermal stress.

Less effective on dense ceramics, it's used for intricate patterns and prototyping.

Non-Abrasive Machining

These methods suit conductive or abrasive-sensitive ceramics, enabling complex features.

Electrical Discharge Machining (EDM)

EDM uses sparks to erode conductive ceramics, creating complex shapes difficult to achieve mechanically.