Introduction

This article provides an in-depth discussion on gas springs.

It covers the following aspects:

- What are Gas Springs?

- How Gas Springs Work

- Construction of Gas Springs

- Types of Gas Springs

- Benefits and Applications of Gas Springs

- Selection and Installation Considerations for Gas Springs

- And More...

Chapter 1: Understanding Gas Springs

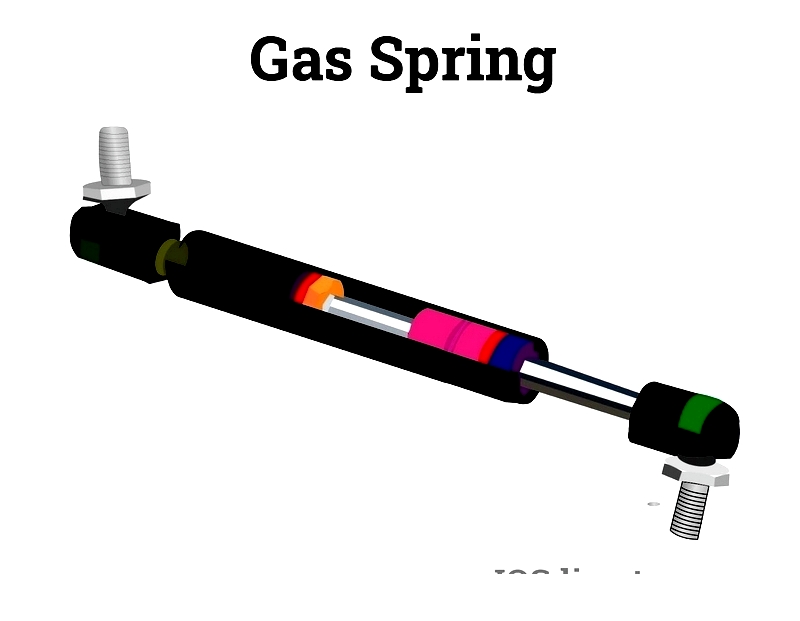

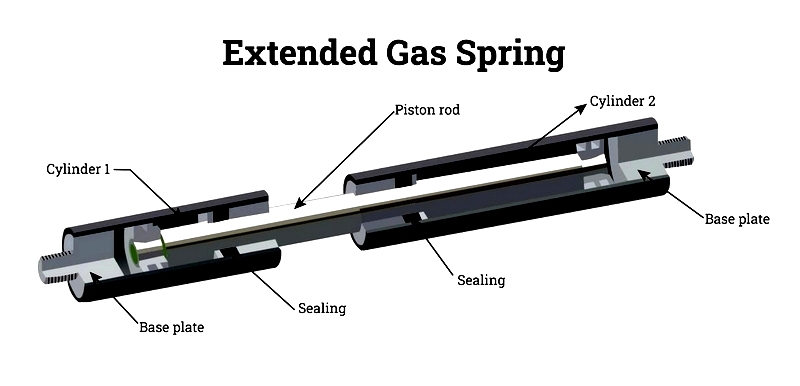

A gas spring is a hydro-pneumatic device that stores potential energy by compressing gas within a sealed cylinder, regulated by a moving piston.

Unlike conventional springs, gas springs don't rely on elastic deformation. They function as self-contained units filled with inert nitrogen during assembly, requiring no additional gas.

The pressure around the piston remains consistent regardless of position due to the rod's small cross-sectional area. The force (F) exerted depends on the pressure differential (P) between internal and external pressures applied to the rod's area (A). In high-pressure environments, careful management of ΔP is crucial.

Gas springs can be examined under various conditions:

Terminology Related to Gas Spring Operation

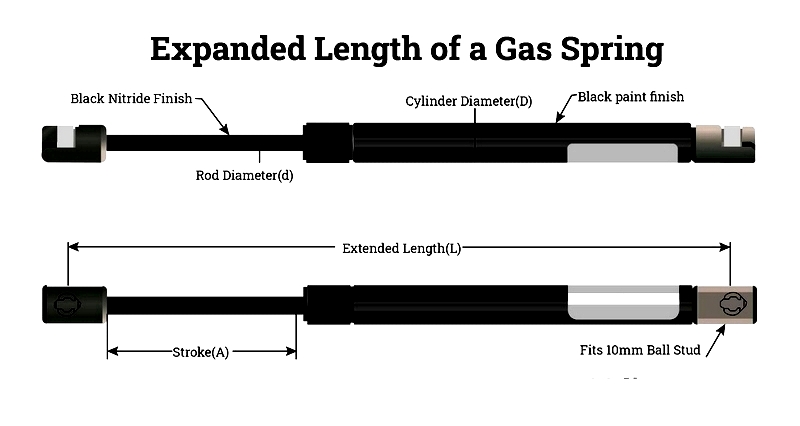

Stroke of a Gas Spring

This refers to the rod's maximum range of motion from fully retracted to fully extended positions.

Extended Length

This measurement represents the gas spring's total length from one end fitting's midpoint to the other.

Compression Length

This indicates the fully closed length from one end fitting's center to the other. Without specified fittings, it measures from rod end to tube end.

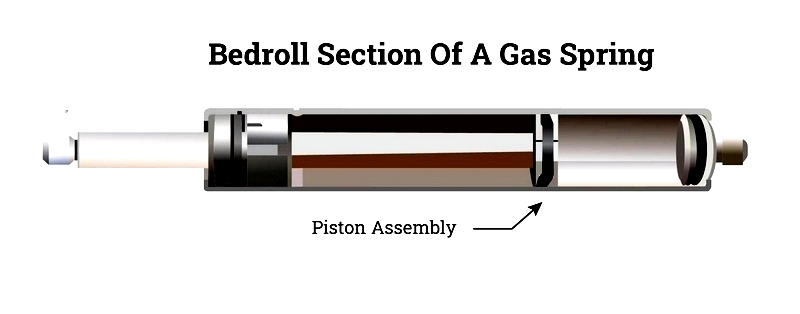

Beadroll Section

This grooved tube section secures the guide and seal assembly, protecting the seal package during piston extension.

Differentiating Gas Spring Types

Gas springs are also called gas props, struts, or lifts across industries. "Nitrogen gas springs" is another term, as nitrogen is the standard gas due to its non-reactive properties.

Gas struts in vehicle suspensions combine a coil spring for weight support and a shock absorber for vibration damping. They support the vehicle while absorbing impacts and aiding wheel movement.

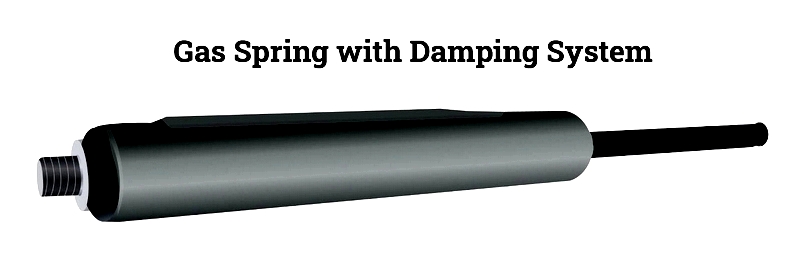

Gas springs with damping functions are called dampers or shocks, depending on application. They support dynamic loads while controlling motion.

Dampers use viscous friction for motion control, typically working with external springs or movable parts like doors. They generate force opposing movement, proportional to velocity.

Comparing Coil and Gas Springs

The key difference lies in compression methods: coil springs use mechanical deformation while gas springs use pressurized gas. Coil springs are cost-effective and adjustable but noisier. Gas springs offer smoother, quieter operation.

Gas springs require less initial compression force, which increases exponentially near stroke end. Fewer gas springs can achieve what multiple coil springs do, making them more efficient for certain applications.

Gas springs provide stronger force with shorter strokes, offering reliability and controlled lifting speeds with fewer units needed.

Chapter 2: How Gas Springs Work

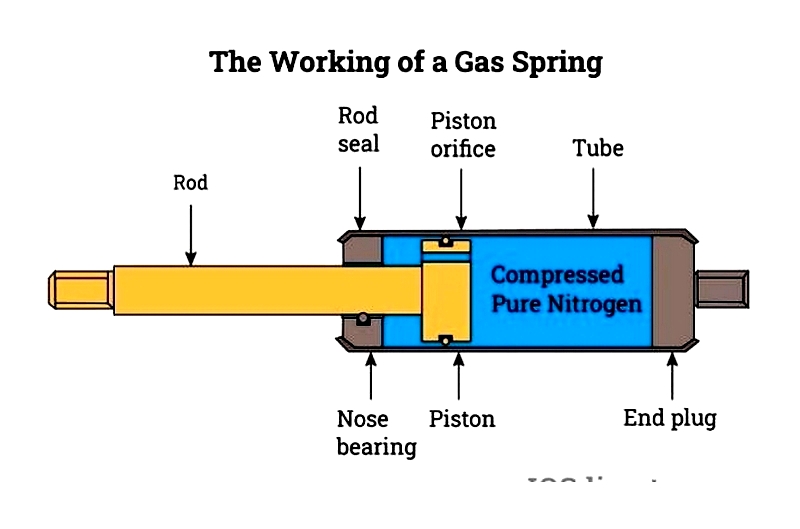

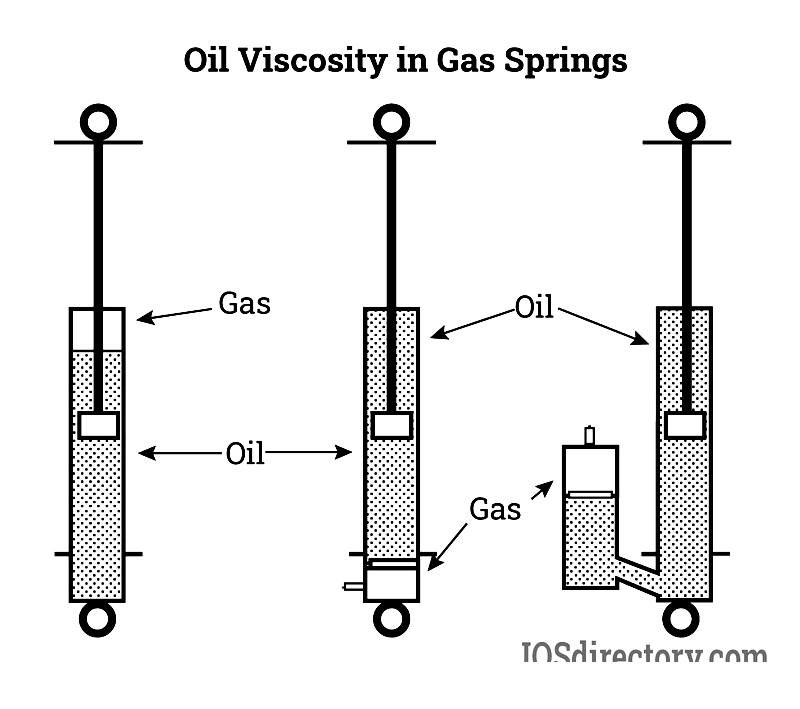

Gas springs operate using compressed nitrogen gas as an elastic energy medium within a sealed cylinder. A 50% mixture of specialized hydraulic oils ensures sealing, lubrication, and force transmission. As the piston rod compresses, gas volume decreases, increasing pressure per Boyle's Law. This results in growing force output, peaking at full compression.

The diagram shows how pressure increases (solid line) as volume decreases (dashed line) during compression, illustrating thermodynamic behavior.

The K-factor (progression rate) indicates force change between unloaded (P1) and loaded (P2) positions. Quality gas springs have low K-factors (1.05-1.8), ensuring steady force output. Always use P1 force as the baseline for calculations.

Damping Control

Hydraulic oil lubricates moving parts and controls damping. Proper damping slows extension gently near full extension, preventing damage or injury. Optimal damping occurs when the piston approaches the oil column in rod-down orientation, preferred for longevity.

Key damping factors:

Operating Temperature

Temperature affects force and damping. Higher temperatures increase pressure but reduce oil viscosity, speeding extension while diminishing damping. Lower temperatures have the opposite effect.

Oil Viscosity

Viscosity determines flow resistance. Higher viscosity increases damping for smoother deceleration. Temperature changes affect viscosity, requiring careful fluid selection.

Oil Volume

More oil engages damping earlier, providing greater motion restraint for heavy-duty applications.

Pour Point

The lowest temperature at which oil flows. Below this point, damping fails as oil solidifies.

Metering and Speeds

Metering regulates speed via piston orifice size. Larger orifices allow faster movement; smaller ones slow it down. Breakaway friction after inactivity requires additional initial force.

Safety Practices

Key safety guidelines:

- Never disassemble, weld, heat, or modify gas springs

- Don't recharge or adjust pressure

- Operate within 0-40°C (32-104°F) limits

- Wear protective eyewear during disposal

- Protect from chemicals and moisture

Common Installation Issues

- Off-axis loads causing premature wear

- Insecure fastening risking detachment

- Uneven load distribution

- Movement obstructions

- Unauthorized modifications

- Temperature extremes

Always consult manufacturer documentation for proper installation and maintenance.

Chapter 3: Gas Spring Design Considerations

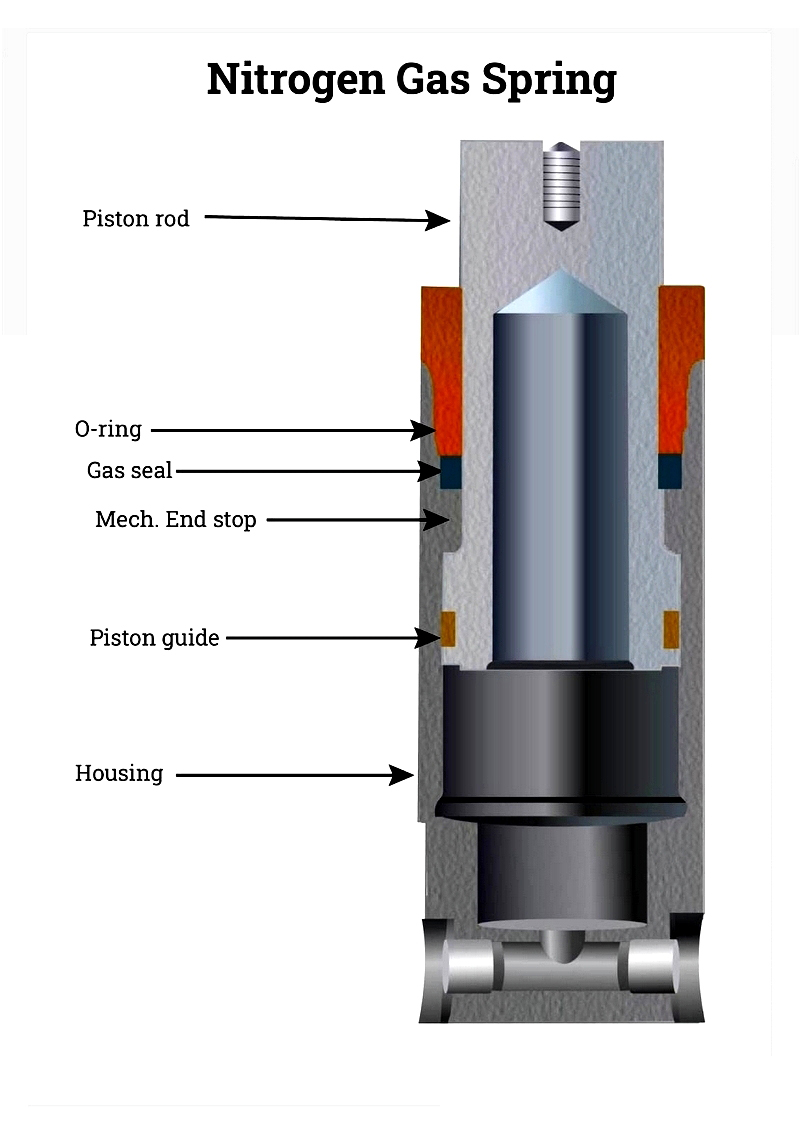

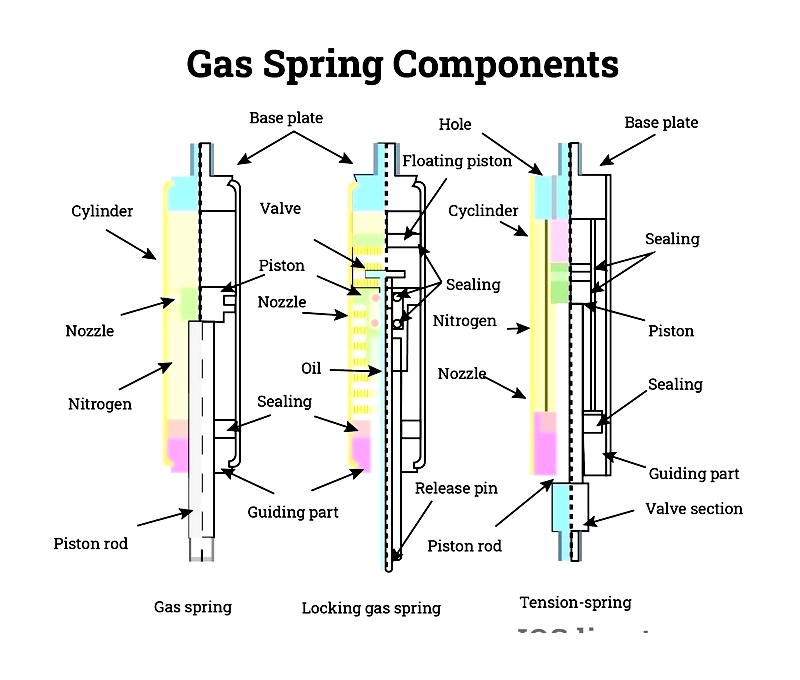

Designing gas springs requires evaluating components, materials, pressures, and application needs. The diagram shows essential components.

Rod Component

Rods come in polished carbon steel, ground steel, or stainless steel. Surface treatments like nitriding enhance durability. Chrome-pl