Introduction

Learn about graphic overlays, their applications, and a list of manufacturers.

You will discover:

- What is a Graphic Overlay?

- How Graphic Overlays are Produced

- Common Uses of Graphic Overlays

- Different Types of Graphic Overlays

- And much more...

Chapter 1: What is a Graphic Overlay?

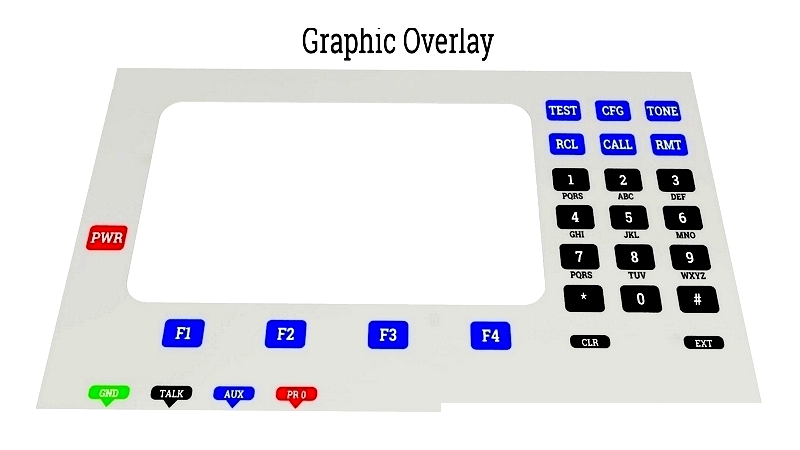

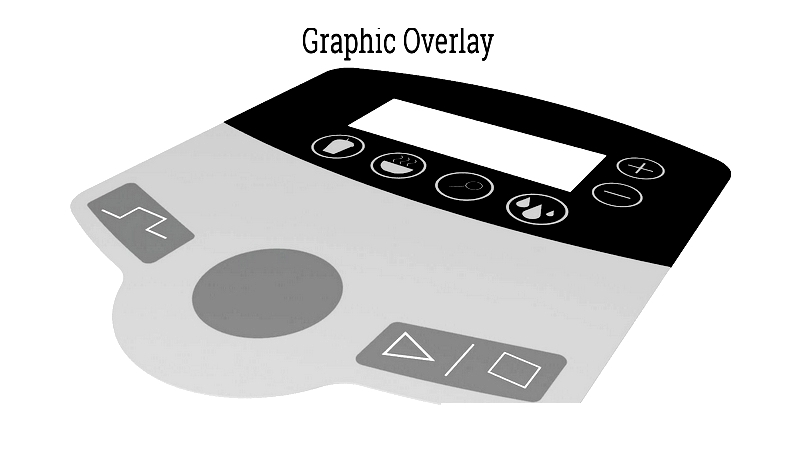

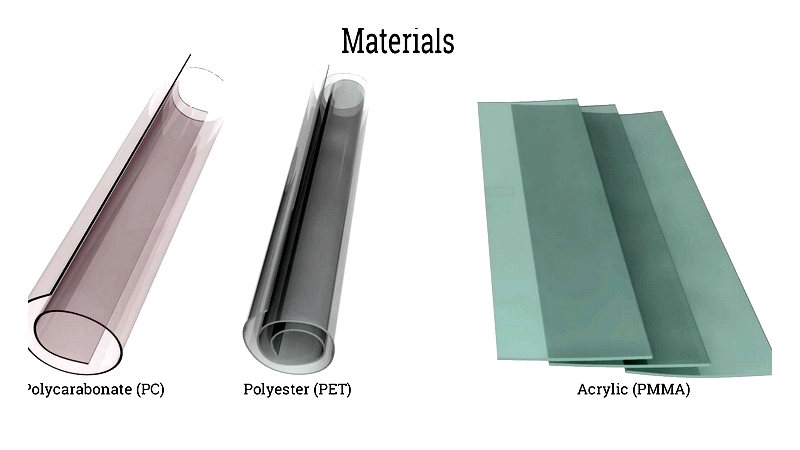

Graphic overlays, also known as faceplates, dead front panels, or user interfaces, are durable printed components attached to equipment. They provide essential information about machine controls and switches, enabling effective human-machine interaction. These overlays serve as operational guides for workers and enhance workplace safety. Typically made from robust materials like polycarbonate, vinyl, or polyester, they may include display windows, embossed buttons, vibrant colors, graphics, and various shielding options to improve functionality.

In today's technology-driven world, graphic overlays play a vital role in delivering clear operating instructions. They are fundamental components that allow users to interact with electronic circuits and machinery. Early versions were simple paper or plastic labels placed near controls, indicating switch functions. However, these lacked durability for repeated use, leading to the development of more sophisticated overlays.

For decades, graphic overlays have been essential to various machinery, tools, and products, combining visual appeal with critical operational functions. The rapid growth of commercial and industrial electronics has spurred the creation of versatile overlay designs to meet specific customer and product needs.

Chapter 2: Design Considerations for Graphic Overlays

The design phase is crucial for creating effective graphic overlays, involving multiple factors to optimize user experience and performance. Key functions include protecting circuitry, providing operational guidance, enhancing appearance, ensuring ease of use, and delivering essential information. These elements shape the design process, ensuring overlays meet both functional and aesthetic requirements across industries.

Design Specifications

The first step in the design process is determining precise dimensions—size, shape, thickness, and placement. The overlay's location depends on available space, nearby components, and integration with existing circuitry. With modern human-machine interfaces (HMI), ergonomic design ensures user comfort, intuitive operation, and easy access to controls.

Basic specifications include user interface considerations. Overlays act as tactile or visual interfaces between operators and electronic circuits. The design must account for signal transmission, feedback mechanisms, and compatibility with keypads, membrane switches, or touchscreens. Proper design ensures efficient interaction and reliable performance.

Environment

Graphic overlays are used in diverse settings, from industrial automation to medical devices and consumer electronics. Material selection must account for harsh conditions like extreme temperatures, chemicals, moisture, UV radiation, and physical impacts. Premium materials such as polycarbonate and polyester offer durability tailored to specific needs.

Designers use user data and environmental analysis to select suitable materials and printing methods (like screen printing or digital printing). Factors like abrasion resistance, chemical resistance, and product lifecycle are critical for overlays that maintain performance in challenging conditions.

Lighting

Effective lighting is essential for readability and safety. Solutions like LED lighting, electroluminescent panels, or light guide films enhance visibility in all environments. Lighting choices are integrated early to ensure optimal panel visibility and energy efficiency.

Finishes

Surface finishes enhance durability and aesthetics. Options include glossy, matte, textured, anti-glare, and UV-resistant coatings. These finishes improve usability and compliance in sectors like healthcare and automotive.

Text and Symbols

Clear symbols and intuitive icons are vital for control panels and indicator panels. Compliance with standards like ISO or ANSI ensures global usability. Designers prioritize legibility and accessibility during usability testing.

Color

Color selection impacts both function and branding. The Pantone Matching System (PMS) ensures consistency across materials. Advanced printing allows for vibrant colors suited to any application, from medical devices to industrial machinery.

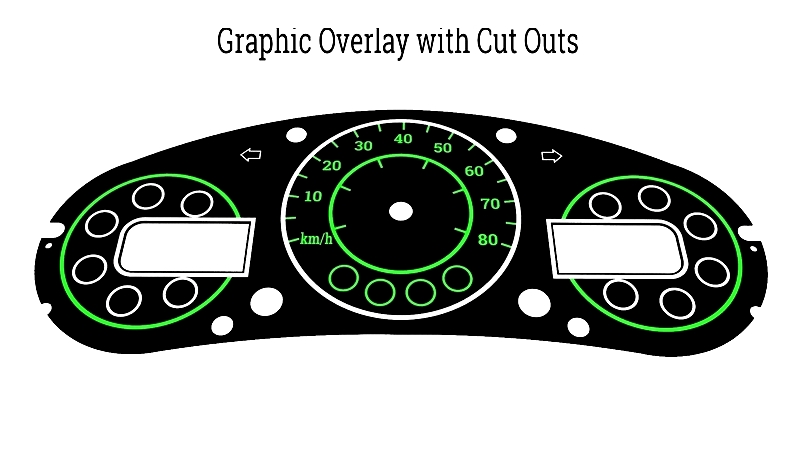

Cut Outs

Cut outs provide access to displays, lights, or controls. Precision engineering ensures seamless integration with equipment. Early planning is essential, as modifications are difficult post-production. Well-designed cut outs enhance both aesthetics and usability.

Additional Design Considerations

Customization may include EMI/RFI shielding or specialized adhesives for harsh environments. Prototyping ensures material selection, backlighting, and durability meet requirements. Partnering with manufacturers early avoids costly revisions.

- Key takeaways:

- Select materials and finishes based on the operating environment.

- Incorporate lighting for readability.

- Prioritize ergonomic design for safety and ease of use.

- Use compliant colors and symbols.

- Collaborate with experts for quality control.

Chapter 3: How Graphic Overlays are Made

Manufacturing graphic overlays involves precise steps to ensure performance and longevity. Material selection and printing techniques are central to creating durable, visually clear overlays. Engineers guide clients in choosing materials and methods suited to their applications.

Materials

Common materials include polyester (PET), polycarbonate (PC), and vinyl, each offering unique benefits. Thickness typically ranges from 5 to 20 mils, with thicker materials posing fabrication challenges.

Printing

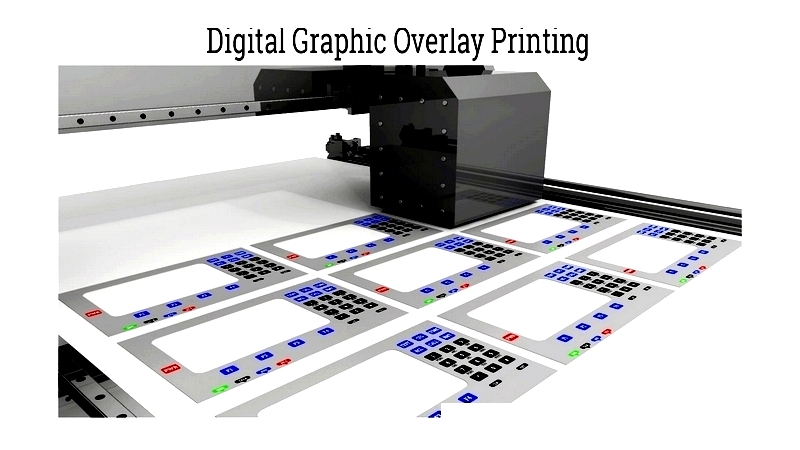

Techniques include screen printing, digital printing, and UV printing, each suited to different requirements. These methods ensure durability and clarity for various industries.

Screen Printing

Ideal for solid colors and tactile features, screen printing offers excellent durability and color vibrancy.

Digital Printing

Enables high-resolution graphics and rapid prototyping, perfect for customized or low-volume production.

Thermal Transfer

Creates durable overlays resistant to chemicals