Introduction

This comprehensive guide covers the deburring process and deburring machines. You'll discover:

- The definition of deburring

- Why deburring matters

- Various burr types

- Different deburring techniques

- And additional insights...

Chapter 1: What is Deburring?

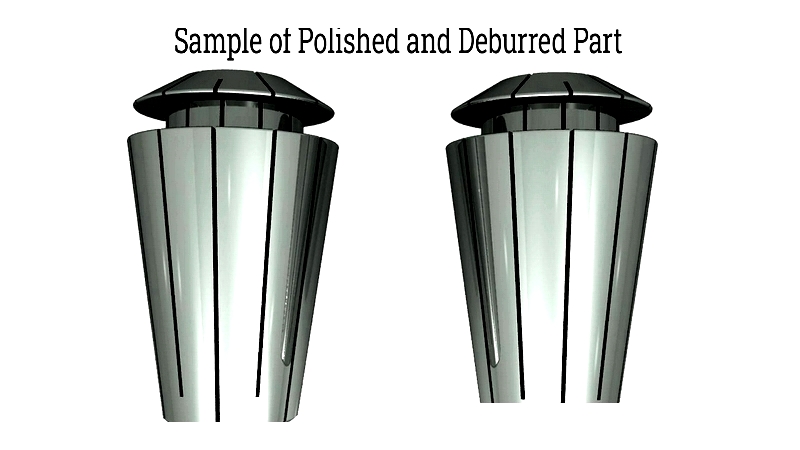

Deburring is a vital secondary machining process that improves product quality by removing burrs - raised edges and excess material left from primary machining operations. These imperfections typically form during shearing, bending, cutting, piercing, or compressing, especially in soft, malleable materials. Deburring machines utilize mechanical, electrochemical, and thermal methods to remove these defects efficiently.

When materials undergo shearing or bending to their breaking point, plastic deformation occurs, creating bent, stretched, or extruded sections along edges. These distortions appear most prominently at cutting tool entry, sides, and exit points. Since burr characteristics vary unpredictably, deburring efficiency often requires empirical testing through multiple production trials.

Various deburring methods exist, many affecting the entire workpiece. These "global" approaches may unintentionally alter dimensions or leave residues, making technique selection and control crucial for maintaining desired product specifications.

In manufacturing, deburring can represent significant production costs, particularly in precision industries. Aerospace components may allocate 30% of manufacturing costs to deburring, while automotive parts typically spend 15-20%. Despite these expenses, deburring doesn't increase product value, highlighting the need for efficient, precise processes.

Chapter 2: Why is Deburring important?

Despite challenges and costs, deburring remains essential in manufacturing and metalworking for several key reasons:

- Burrs hinder proper assembly of precision components, increasing defects and rejection rates

- Burrs initiate fatigue cracks in high-stress applications

- Crevices and burr surfaces promote corrosion, reducing durability

- Sharp edges pose safety risks during handling and installation

- Burrs diminish aesthetic quality and surface finish

Edge quality profoundly affects product form, performance, and lifespan. Burrs compromise dimensional accuracy, particularly critical in aerospace, automotive, electronics, and medical device manufacturing. For mating components like gears and rollers, burrs increase friction, accelerate wear, and shorten service life.

Burr-containing parts typically exhibit reduced fatigue resistance. Machining processes like milling and drilling introduce residual stresses through work hardening, altering mechanical properties and increasing failure risks. Edge irregularities at holes and notches act as stress concentrators, especially problematic in high-performance applications.

Corrosion prevention also suffers from burrs. Thermal and roll-over burrs create crevices prone to localized corrosion. Protective coatings often inadequately cover raised areas, accelerating degradation in harsh environments like marine or chemical processing industries.

Safety concerns extend throughout the supply chain, as sharp edges can damage components and injure workers. Compliance with safety standards often requires chamfering or radiusing edges.

Material selection offers the best burr prevention, though application requirements often dictate material choices. For ductile materials, advanced deburring methods like automated mechanical systems, abrasive flow, or electrochemical techniques may be necessary. Process selection depends on part geometry, production volume, and budget considerations.

Comparison with Tumbling and Finishing

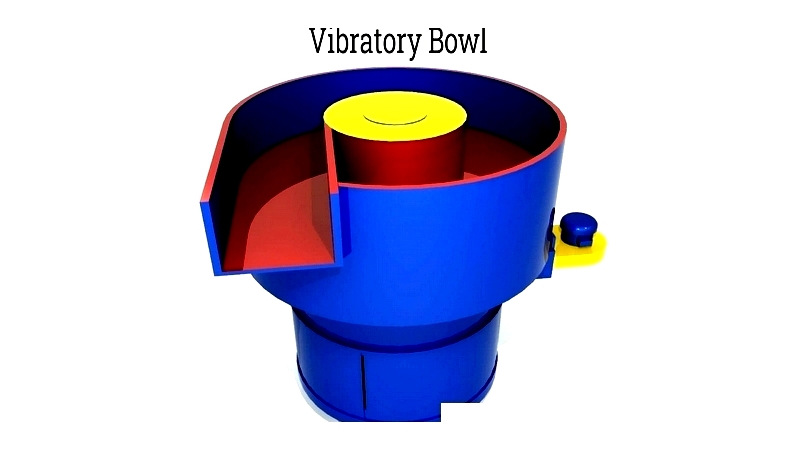

Finishing, deburring, and tumbling are complementary processes enhancing surface quality and functionality. Finishing includes various surface treatments, while deburring specifically removes burrs and sharp edges. Tumbling, a deburring subset, uses rotating barrels with abrasive media for batch processing small or complex parts. Vibratory and centrifugal machines offer high-volume solutions.

Selecting the optimal process depends on material, part size, geometry, surface requirements, and available resources. Consultation with deburring specialists helps balance cost, efficiency, and quality for specific manufacturing needs.