Introduction

This article provides an in-depth exploration of aluminum tubing and piping.

Key topics covered include:

- Fundamentals of Aluminum Tubing & Piping

- Varieties of Aluminum Tubing & Piping

- Applications and Advantages of Aluminum Tubing & Piping

- And More...

Chapter 1: Understanding the Basics of Aluminum Tubing and Piping

This chapter examines the definition of aluminum tubing and piping, their manufacturing processes, and key selection criteria.

Defining Aluminum Tubing & Piping

Aluminum tubing and piping are recognized for their silvery-white appearance, malleability, and softness. As part of the boron group, aluminum is Earth's third most abundant element. It features low density and forms a protective oxide layer in corrosive environments, preserving its internal structure. Typically alloyed with elements like copper, manganese, zinc, magnesium, and silicon, aluminum's properties are enhanced for various applications.

With only about 30% of copper's density, aluminum piping and tubing maintain excellent electrical and thermal conductivity. Under specific conditions, aluminum can act as a superconductor, efficiently conducting electricity at low temperatures.

Piping vs. Tubing: Key Differences

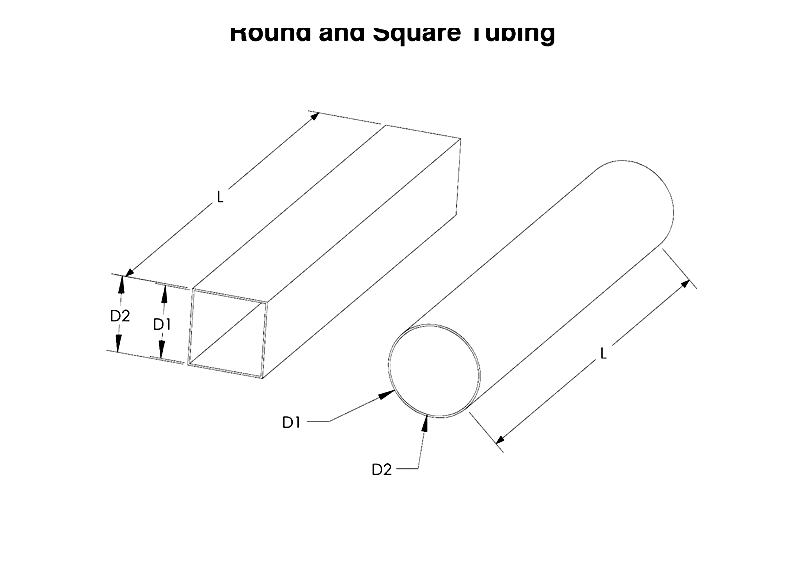

Piping refers to cylindrical tubes designed for transporting gases and liquids, typically sized to indicate system capacity. Tubing may be circular, oval, rectangular, or square, specified by outer diameter and wall thickness in millimeters or inches.

Selecting the right tubing can be challenging, as both aluminum and stainless steel offer numerous alloys and tempers with distinct mechanical and physical properties.

Comparing Aluminum and Steel Tubing Strength

Strength is measured using Young's modulus of elasticity, which evaluates force per unit area. This helps compare the strength of aluminum and steel tubing.

Young's Modulus – At 70°F, aluminum's elasticity modulus is approximately 10 million psi, while steel's is about 30 million psi, indicating steel tubing is roughly three times stronger than aluminum for equivalent dimensions.

Material Weight – Steel weighs about three times more than aluminum for similar sizes. To match steel's strength, aluminum tubing walls must be three times thicker, reducing aluminum's weight advantage.

Diameter – Tubing strength, whether aluminum or steel, is influenced by diameter—larger diameters generally increase strength while smaller diameters decrease it.

Manufacturing Methods for Aluminum Tubing & Piping

Aluminum tubing and piping are produced through various methods, including:

Aluminum Extrusion Process

Aluminum extrusion involves forcing aluminum alloy through a die with a specific cross-sectional shape.

This process resembles squeezing toothpaste from a tube. A powerful ram pushes aluminum through a die, shaping it as it exits. The resulting profile matches the die's shape and moves along a run-out table. Common extruded profiles include round and square shapes.

Like toothpaste taking its tube's shape, aluminum assumes the die's form during extrusion. This method can produce complex shapes and profiles.

The diagrams above illustrate die creation. Extrusion can generate intricate shapes and profiles.

Step 1: Preparing the Extrusion Die

Circular dies are typically made from H13 steel. When a suitable die is selected, it's preheated to 450-500°C to extend its lifespan and ensure stable metal flow during extrusion. The heated die is then placed in the extrusion press.

Step 2: Heating Aluminum Billets

A cylindrical aluminum alloy billet is cut from a larger batch and heated to 400-500°C in an oven. This softens the billet for extrusion without melting it.

Step 3: Loading the Billet

The preheated billet is transferred to the extrusion press. Lubricant is applied to the billet and ram to prevent sticking.

Step 4: Pressing the Billet

The softened billet enters the press, where a hydraulic ram applies up to 15,000 tons of force. This pressure expands the billet against the chamber walls.

Step 5: Forming Extruded Solids

When the metal fills the chamber, it encounters the die under pressure. The aluminum exits only through the die openings, forming finished pipes or tubes.

Step 6: Extrusion and Cooling

As the extrusion exits the die, a puller guides it along the run-out table at matching speed. Simultaneous cooling occurs via fans or water baths.

Step 7: Cutting to Length

When the extrusion reaches the table's end, a heated saw cuts it free from the process. Temperature control remains crucial throughout.

Step 8: Final Cooling

Cut extrusions move to a cooling table to reach room temperature. After cooling, tubes or pipes proceed to stretching.

Step 9: Straightening

Natural twists are removed using a stretcher, which clamps and stretches each piece until perfectly straight.

Step 10: Final Cutting

Aligned extrusions are cut to specific lengths (typically 8-21 feet) on a saw table. Initial T4 temper can be further aged to T6 or T5.

Heat Treating, Finishing, and Fabrication

Post-extrusion, pipes and tubes may undergo heat treatment to enhance properties. Various surface finishes improve appearance and corrosion resistance.

Fabrication processes finalize dimensions as needed.

Heat Treating for Enhanced Properties

7000, 6000, and 2000 series alloys can be heat-treated to improve yield stress and tensile strength.

Aging ovens accelerate this process, producing T6 or T5 tempers.

For example, untreated 6061 aluminum (T4) has 241 MPa tensile strength, while treated (T6) reaches 310 MPa.

Finishing follows heat treatment.

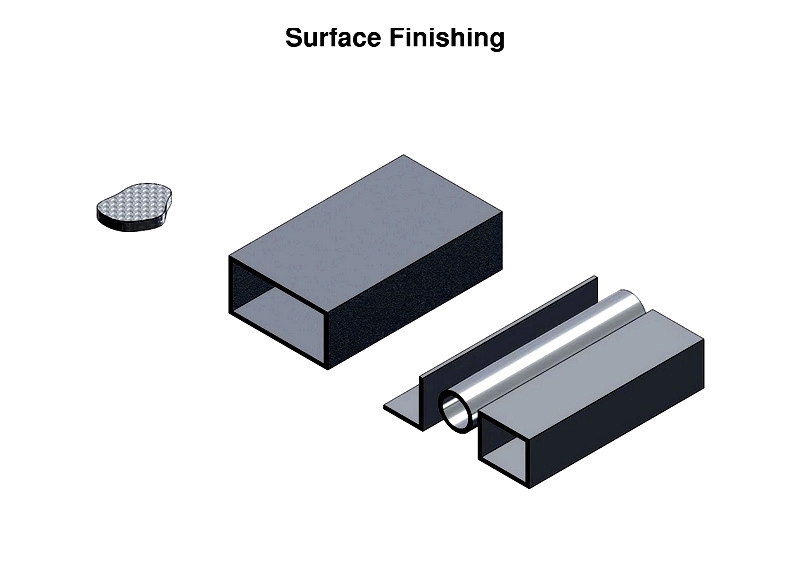

Surface Finishing Options

Aluminum pipes often receive finishing treatments for better aesthetics and corrosion resistance.

Anodizing thickens the natural oxide layer, improving corrosion and wear resistance while allowing color variations through dye absorption.

Additional options include powder coating, sandblasting, painting, and sublimation.

Fabrication for Custom Dimensions

Fabrication tailors extrusions to precise requirements. Drilling, punching, cutting, and machining adapt tubing for specific projects.

Aluminum Tubing & Piping Alloys

Key aluminum alloys for tubing include 2024, 3003, 6061, 5052, and 7075. Alloying elements