Introduction

This article provides an in-depth examination of industrial furnaces.

You'll explore key topics including:

- What is a Furnace?

- How Furnaces Work

- Types of Furnaces

- Furnace Heating Methods

- And more...

Chapter One – What is a Furnace?

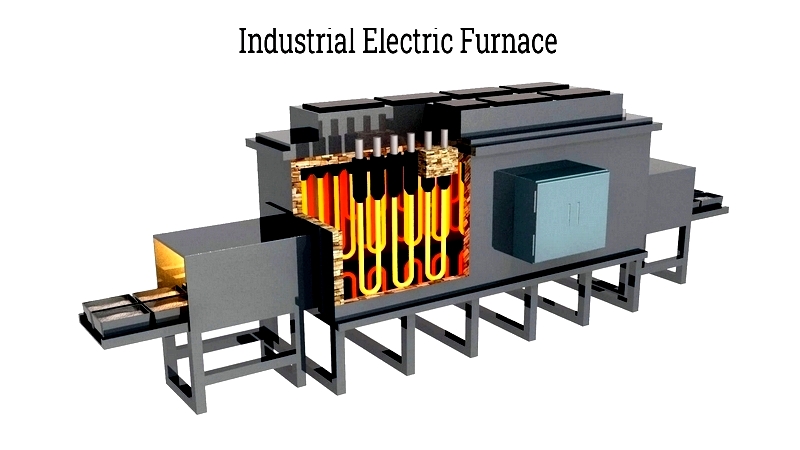

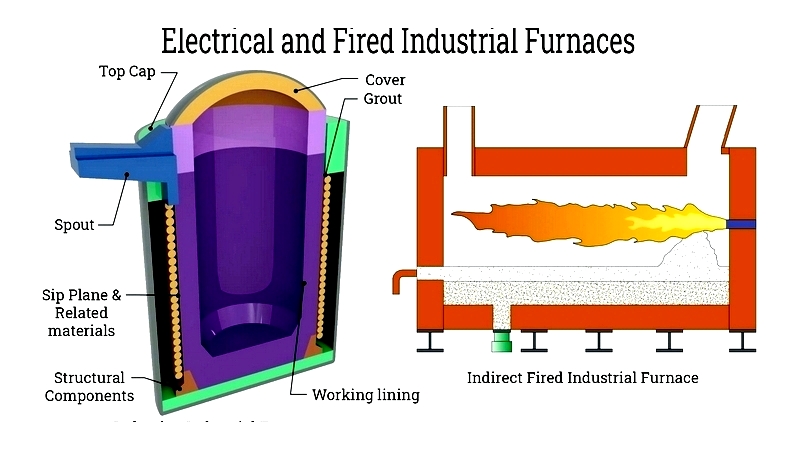

An industrial furnace is a heating device designed to deliver direct electric or fired heat for applications requiring temperatures above 752°F (400°C). Many manufacturing processes depend on this level of heating to treat materials or complete specific tasks. Both electric and fired furnaces offer durable, reliable performance with precise temperature control, essential for efficient production.

Industrial furnaces primarily fall into two categories: electric and fired. Electric models include arc furnaces for refining and high-frequency induction furnaces for metal melting. Fired furnaces generate heat through fuel combustion, providing direct or indirect heating for raw materials or product sintering.

Furnace designs vary significantly based on energy source and model type. Key differences exist between electric and fuel-fired units, with all constructed from heat-resistant materials. Critical design considerations include target process temperature, furnace height, outer diameter, overall length, and required pressure range.

Chapter Two – How Furnaces Work

Furnaces serve as vital components in residential, commercial, and industrial heating systems, generating and distributing heat for diverse applications. Different furnace types operate uniquely using various fuel sources, each optimized for specific environments and needs. While early furnaces relied on wood or coal requiring manual fueling, modern systems use automated fuel delivery—including natural gas, propane, oil, and electricity—improving efficiency, output, and convenience while reducing manual intervention.

How a Furnace is Fueled

Furnace efficiency and cost-effectiveness depend largely on fuel source and delivery systems. Traditional coal and wood furnaces created pollution and inconsistent heat, while modern high-efficiency models feature automated fuel systems with electronic ignition and smart thermostats. Cleaner fuels like natural gas and electricity now provide consistent heating with minimal emissions.

Fuel-fired furnaces dominate industrial and commercial applications. Fuel choice—whether natural gas, oil, propane, or biofuels—affects design, combustion technology, and operating costs. Many contemporary units are multi-fuel capable for operational flexibility. Regardless of fuel type, proper oxygen supply and engineered combustion systems are crucial for efficiency and safe operation.

Electric furnaces are gaining popularity in both residential and industrial settings due to their clean operation, producing no flue gases or combustion byproducts. While typically more expensive to operate than gas or oil alternatives, they offer environmental benefits and simpler maintenance. Electric furnaces come in two main types: induction heating and resistance heating, each suited to specific applications.

Resistance heating represents the most energy-intensive electric furnace operation. These systems use circulating fans for even heat distribution, with heating elements made from ceramics, metals, or graphite. In specialized applications, the workpiece itself may serve as a resistor for direct heating.

Induction heating targets specific workpiece areas, making it ideal for metal melting, forging, and annealing. This method uses alternating electromagnetic fields from copper coils to induce heating currents in the material. Water-cooled induction coils prevent overheating while optimizing performance.

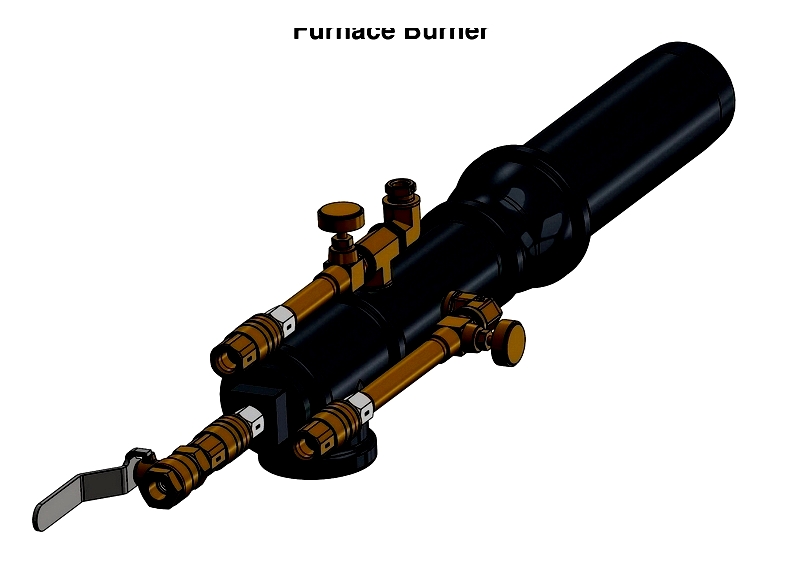

Furnace Burner Types

In fuel-fired furnaces, burners are critical for controlled heat generation. Modern furnaces often employ multiple burners for temperature uniformity. Each burner system includes an oxidizer to convert chemical energy into thermal energy. Burner technology varies by fuel type—gas burners differ from oil or dual-fuel burners in air-fuel mixing and ignition.

Key burner components include fuel nozzles, mixing tubes, flame stabilizers, and air-fuel ratio controls—all essential for efficiency and emissions management. Forced air systems enhance mixing for complete combustion. Energy-efficient burners provide stable, reliable operation with optimized flame profiles.

Industrial burners produce six primary flame patterns (A, C, E, F, G, H) for different applications:

- Type A – Standard feather-shaped flame for general-purpose heating

- Type C – Swirling ball flame for rapid heat-up in batch furnaces

- Type E – High-swirl flame for direct radiant heating

- Type F – Long luminous flame for tunnel furnaces

- Type G – Steady luminous flame for uniform heating

- Type H – High-velocity flame for large industrial furnaces

Heat Transfer in Furnaces

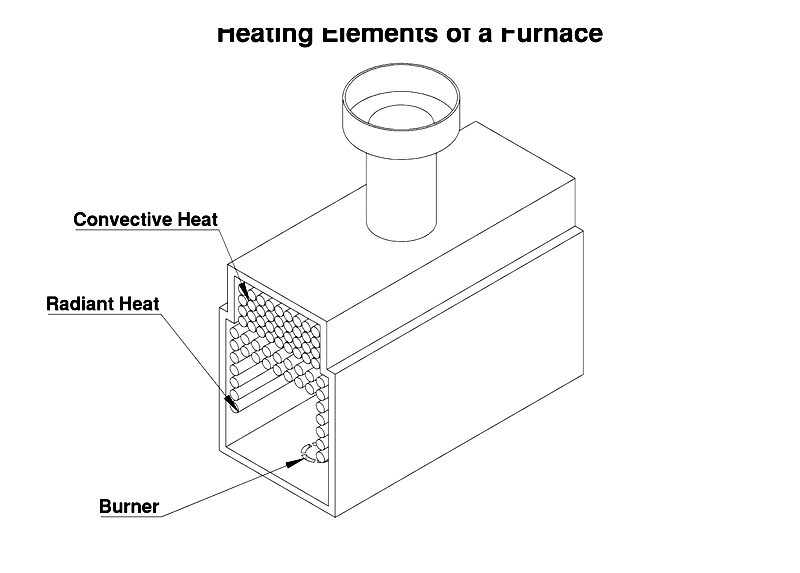

Furnace performance depends on three heat transfer mechanisms: radiation, convection, and conduction. Their interaction determines efficiency, temperature uniformity, and process results.

Radiation in Furnaces

Radiation dominates high-temperature furnace heat transfer. Burners emit infrared radiation that rapidly heats chamber contents—gases, liquids, or solids—making it ideal for steelmaking and glass production.

Convection in Furnaces

Convection transfers heat through moving gases or fluids. Modern designs optimize convection with heat exchangers that recover waste heat to preheat incoming air or fuel, improving efficiency and sustainability. Strategically placed tubes maximize heat absorption from exhaust gases.

Conduction in Furnaces

Conduction moves heat through solid materials like furnace walls and workpieces. Proper refractory and tube material selection ensures efficient energy transfer to materials being processed.

The diagram below shows radiation and convection processes in an industrial furnace.

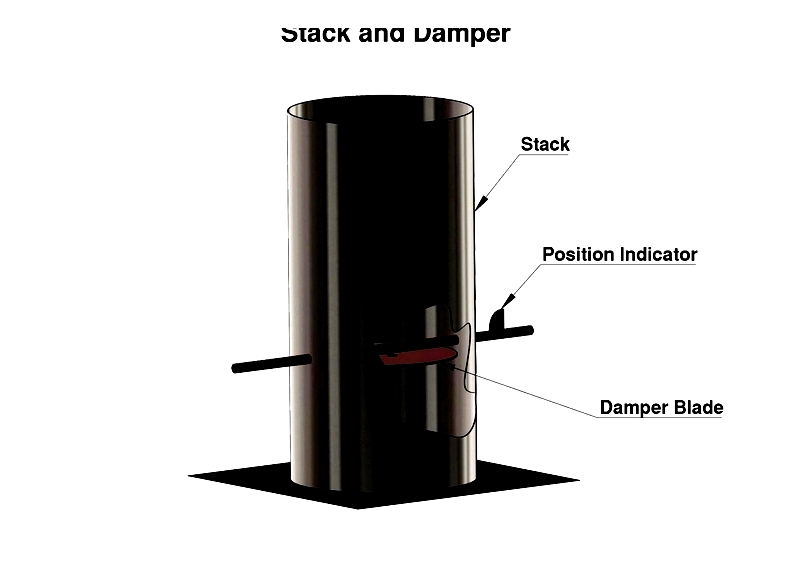

How Furnace Stacks Work

The furnace stack (flue or chimney) vents combustion gases from the heating chamber. Modern stacks incorporate filtration systems like electrostatic precipitators and scrubbers to meet emission standards, removing pollutants before release.

Stack systems may include damper blades for airflow and pressure control. Multi-blade dampers in large installations ensure proper ventilation and safety. High external pressure aids efficient gas expulsion while maintaining furnace balance.