Introduction

This article provides an in-depth exploration of iron castings.

It covers key topics including:

- Principles of Iron Castings

- Types of Iron Castings

- Applications and Benefits of Iron Castings

- And More...

Chapter 1: Understanding the Core Concept of Iron Castings

This section examines the fundamentals of iron castings, including their definition, production methods, and various casting processes.

Defining Iron Castings

Iron casting is a durable material created by combining iron with carbon, making it easy to mold. It typically contains 2% to 4.3% carbon, higher than steel.

Besides iron, cast iron includes silicon, manganese, and trace impurities like sulfur and phosphorus. The production process starts with reducing iron ore in a blast furnace to produce molten iron, which is poured into molds to form raw ingots called pigs. These pigs are remelted with scrap metal and alloys in cupola furnaces for final casting.

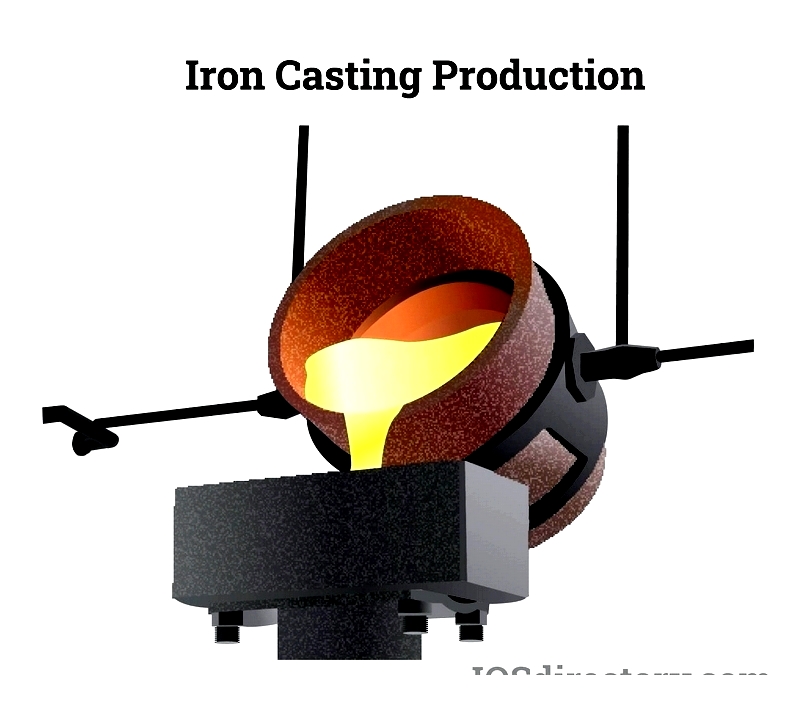

The Production Process of Iron Castings

Cast iron production begins with pig iron from blast furnaces. It can be made directly from molten pig iron or by remelting pigs. Other additives like steel, limestone, and coke are often included, with processes to remove impurities.

While sulfur and phosphorus can be burned off, this may reduce essential carbon, which must be replenished. Carbon and silicon levels are adjusted based on the final product's use, typically maintaining 2%-3.5% carbon and 1%-3% silicon. Additional elements are added before final casting.

Casting involves pouring liquid metal into a mold with a negative impression of the desired shape. The metal flows through a sprue, and after cooling, the casting is removed.

This method is ideal for complex shapes that are difficult or expensive to produce otherwise. Traditional techniques include lost wax casting, centrifugal casting, and vacuum-assisted casting. Other methods are plaster mold and sand casting.

Cast iron is often melted in cupola furnaces, though electric induction or arc furnaces can also be used. After melting, the iron is transferred to holding furnaces or ladles for further processing.

Mechanical Properties of Iron Castings

Iron castings are known for their hardness, offering resistance to abrasion and indentation. They exhibit toughness for energy absorption, elasticity for shape recovery, and ductility for deformation without fracturing.

Their malleability allows compression without breaking. Key properties include tensile strength (resistance to breaking under stress) and fatigue strength (endurance under repeated stress).

Chapter 2: Different Casting Processes

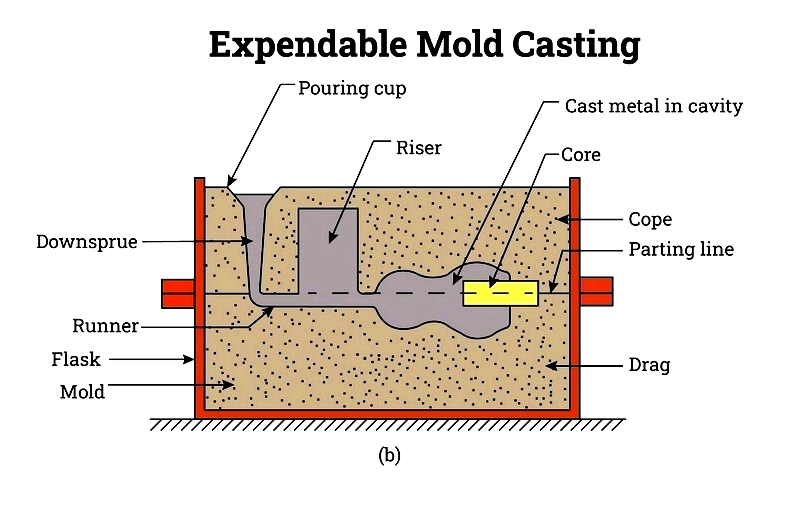

Casting is a fundamental manufacturing technique where molten material is poured into molds to create metal parts. There are two main types: expendable and non-expendable molds, categorized by mold material (sand, plaster, ceramic, or metal) and pouring method (gravity, vacuum, or low-pressure). Understanding these processes helps select the best method for industrial, automotive, and engineering applications requiring specific properties, finishes, or volumes.

Expendable Mold Casting

This includes sand, plastic, plaster, shell, and investment moldings, using temporary molds for complex shapes and prototypes. These methods are ideal for engineering parts and custom metalwork.

Sand casting is cost-effective for small batches, suitable for various metals like iron, steel, and aluminum. Production rates range from 1-20 pieces per hour per mold, with green sand having no weight limit and dry sand having practical limits.

Sand is bonded with clay or chemical binders and can be recycled. Additional techniques like core making enhance versatility. Loam molding creates large objects like bells by mixing clay, sand, and straw.

Plaster mold casting uses plaster for fine details and smooth finishes, ideal for prototypes. It takes less than a week to prepare, producing 1-10 units per hour for items weighing 30g-45kg. It's limited to low-melting-point metals like copper and aluminum.

Shell molding uses a sand-resin mixture for finer finishes and tighter tolerances, suited for gear housings and valve bodies. Investment casting, or lost wax casting, produces high-precision components with excellent finishes, ideal for aerospace and medical devices.

Investment casting is versatile for metals like stainless steel and titanium, often requiring no secondary machining. Though costly, it's efficient for complex, small to medium-sized castings.

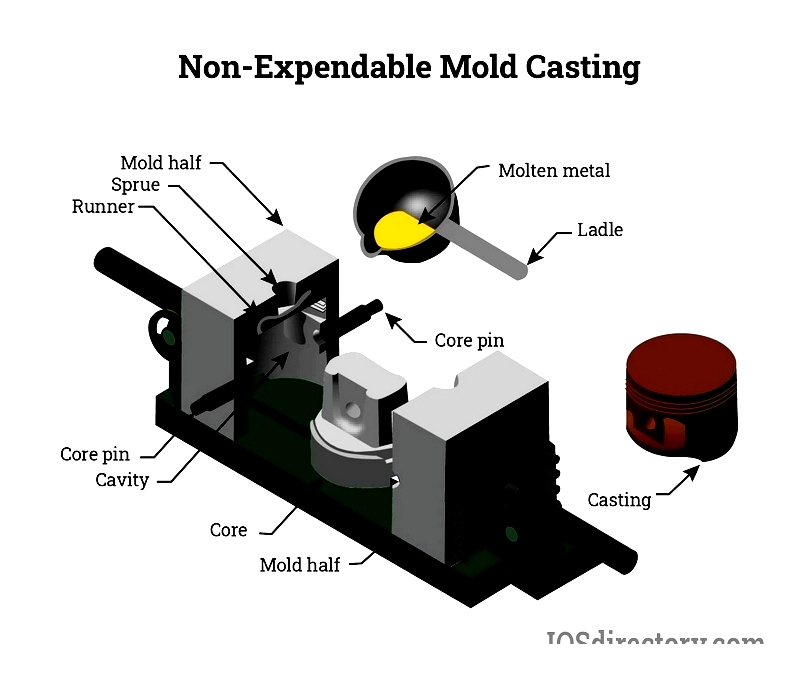

Non-Expendable Mold Casting

This method uses reusable molds, improving part quality and accuracy. It includes permanent mold, die, centrifugal, and continuous casting, popular in automotive and industrial manufacturing.

Permanent Mold Casting

This technique uses reusable iron or steel molds, filled by gravity or pressure. It's ideal for aluminum, copper, and magnesium parts like pistons and cylinder heads, offering superior finishes and properties.

Die Casting Process

Die casting forces molten metal under pressure into hardened dies, producing high-volume, precise components. It's used for electronic housings and automotive parts, with modern machines offering computer controls for efficiency.

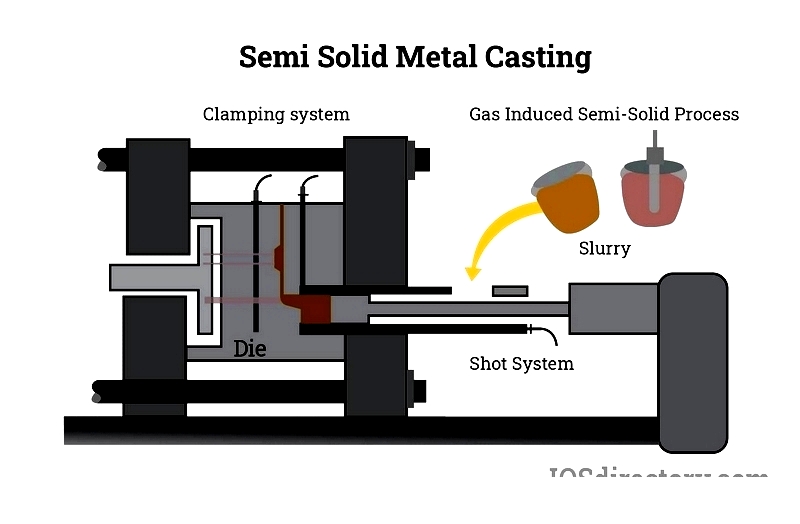

Semi-Solid metal Casting

This hybrid method uses partially solid metal to reduce porosity, improving strength and uniformity. It's ideal for automotive and aerospace components.

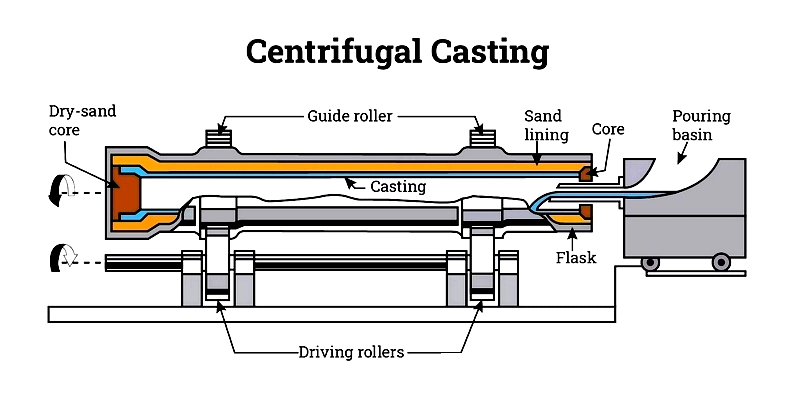

Centrifugal Casting

Molten metal is poured into a rotating mold, creating dense, uniform parts like pipes and bushings. Production rates are 30-50 pieces per hour, with mass limits up to 9000kg.

Continuous Casting

This high-volume process produces uniform metal sections by pouring molten metal into water-cooled molds. It's essential for steel mills and foundries, reducing costs and improving quality.

Understanding these processes helps balance cost, material properties, and production needs. Consult specialists for tailored solutions.

Chapter 3: Top Machines for Iron Castings

Selecting the right equipment is crucial for quality iron castings. Modern foundries use advanced machinery for efficient production. Here are five notable brands and models:

Hunter Foundry Machinery Corporation:

Model: Hunter HLM Series

Features: High-pressure molding for precision, with hydraulic and pneumatic systems for consistent quality. Ideal for green sand molding.

Sinto America, Inc.:

Model: FBO Series Flaskless Molding Machine

Features: