Introduction

This article provides a comprehensive discussion on roller tables.

After reading this feature, readers should understand:

- The fundamentals of roller tables: their working principles and selection criteria

- Roller table construction methods

- Key components of roller tables

- Different types of roller table drives, slide bearings, and configurations

- Applications and advantages of roller tables

- Additional relevant information

Chapter One: Fundamentals of Roller Tables - Working Principles and Selection Criteria

Understanding Roller Tables

Roller tables are compact, rigid linear guide devices featuring integrated cross-roller guides. Typically powered by electrical or mechanical systems, they facilitate heavy load movement. These precision devices, sometimes called motorized linear slides with rail sets, support substantial weights with minimal friction. Unlike conventional ball bearings, roller tables employ crossed roller bearings to achieve precise linear motion, low friction, and excellent load-bearing rigidity. Their accurate linear guidance system allows simple bolt-on installation, consisting of a fixed base and movable carriage.

Roller tables feature single or multi-axis roller slides with tables and shafts for optimal directional control. Design considerations include intended use size, material composition, weight capacity, and mobility requirements. They can be mounted in various configurations (X, XY, or XYZ) for multi-axis positioning. Additional features may include shock absorbers, rubber bumpers for slide prevention, and stroke adjustments for precise alignment. Some models incorporate air-bearing slides that use controlled pressurized air between platform and base to minimize system errors.

These machines, equipped with mechanical or drive systems, efficiently move heavy loads. Ideal for high-precision, low-friction applications like optical measurement and electronics assembly, roller tables serve diverse industries including industrial automation, fiber optics, semiconductor manufacturing, precision instruments, communications equipment, surface grinding, assembly fixtures, and material handling.

Working Principles

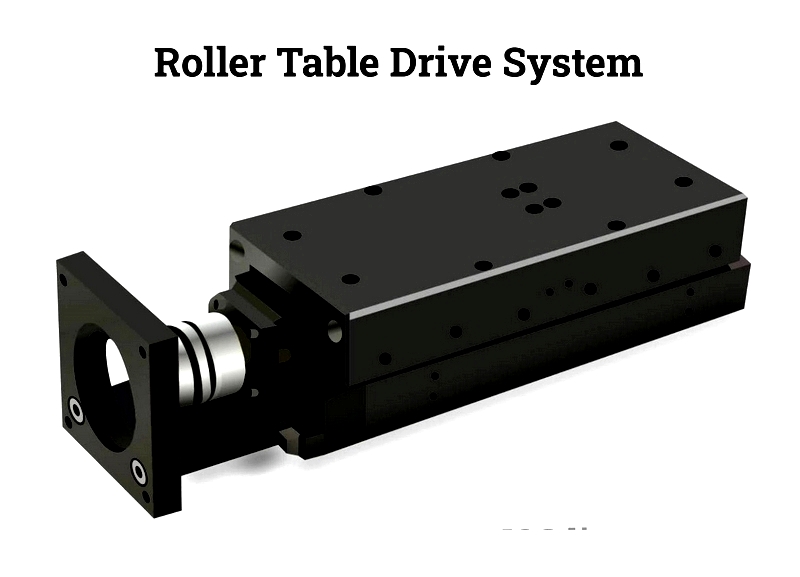

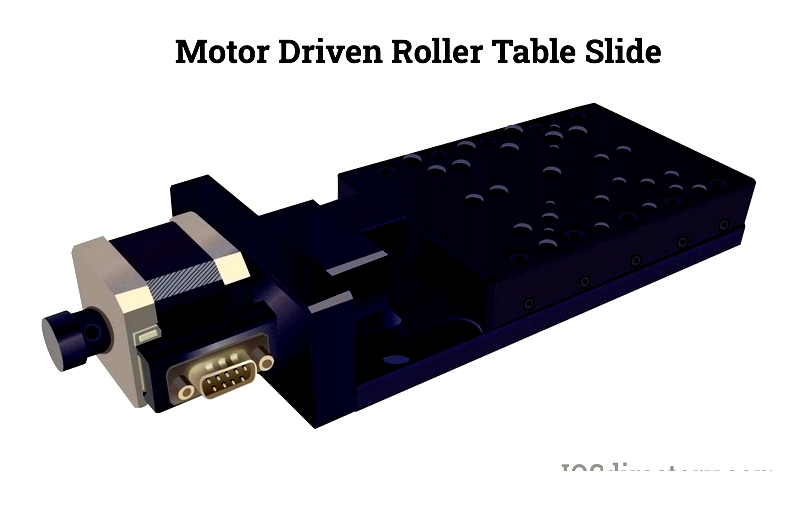

Operation can be manual (via micrometer), motorized, or combined. Most models use lead screws with cylindrical bearings as the driving mechanism for carriage movement. Designed for straightforward linear motion, they feature a stationary base and moving carriage. In motorized versions, the screw attaches to the base while the nut assembly mounts on the carriage. Screw rotation (manual or motor-driven) produces precise linear carriage movement.

Alternative drive methods include linear motors, pneumatic cylinders, and hydraulic cylinders. Linear motor models move the carriage directly along the slide. The slide assembly comprises a locked base and manually movable platform. Multiple slides enable heavy load support. In hydraulic/pneumatic models, the cylinder body mounts on the base while the rod attaches to the carriage.

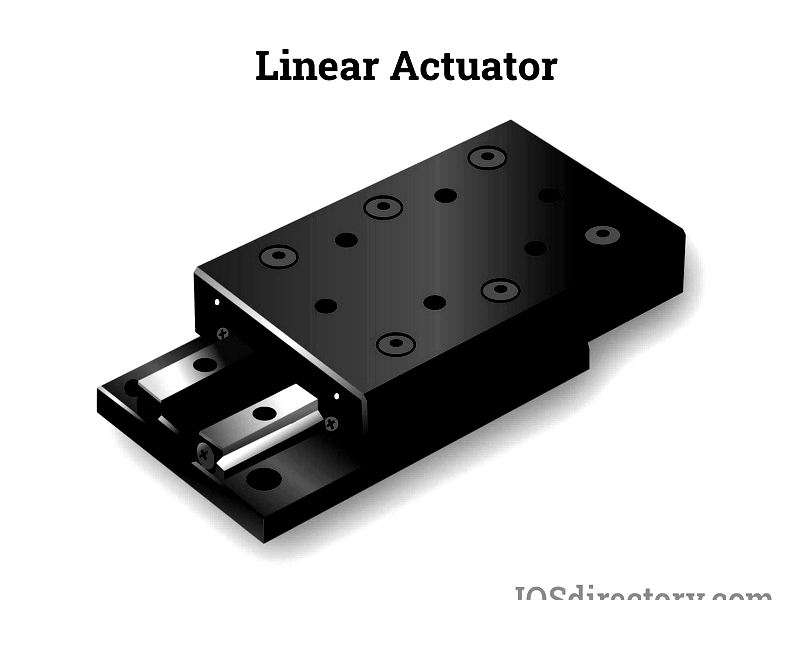

Functioning as linear actuators, roller tables convert rotational motion to linear movement. Unlike conventional motors, they produce push-pull motion for sliding, tilting, and lifting objects. Various bearing methods minimize friction, stick-slip, and energy consumption while ensuring smooth operation. Roller cages enhance load stability and prevent slipping, while protective covers shield against dust contamination.

The moving carriage, attached to a linear base, contains cylindrical or roller bearings for low-friction movement. Cylindrical bearings are preferred for their quiet operation. Designed for precision and heavy loads, these tables accurately position, push, or pull objects. Available in crossed rail, heavy-duty, and low-profile configurations, they offer single or multi-axis control through roller slides.

Delivering smooth, precise motion, roller tables benefit various automated machinery. Steel assemblies achieve 0.0008 inches/inch accuracy, while aluminum/stainless steel models reach 0.0000040 inches/inch. Load capacities range from a few pounds to over 2600 lbs (1180 kg).

Technical Specifications

- Axes: Single-axis (X-axis), vertical lift (Z-axis), multi-axis (X-Y/X-Z), or three-axis (X-Y-Z) configurations

- Drive Mechanism: Ball screw drives with motors for stiff applications; manual positioning with hand wheels; pneumatic/hydraulic drives for rapid actuation

-

Performance Ratings: Dependent on bearing system and construction

- Load capacity: Maximum functional force

- Moment rating: Force resistance before undesired rotation

- Stiffness: Resistance to bending under force

Additional Considerations:

- Bearing system determines accuracy (linear bearings ensure precise motion)

- Linear travel: Full slide movement range

- Linear speed: Carriage movement velocity

Selection Criteria

Cage Materials

Roller cages, made of plastic or metal, control roller movement by preventing direct contact. This reduces friction and extends roller life.

metal cages (typically stainless steel) use tab-and-notch fastening. While cost-effective, they limit roller proximity, reducing load capacity. Suitable for high-temperature, medical, and cleanroom applications due to corrosion resistance and low outgassing.

Resin cages allow closer roller spacing, increasing contact area by 30-58% and load capacity up to 250%. Selection depends on application requirements, considering cage type, speed, and material compatibility.

Cage Creep

Potential cage displacement (especially in vertical mounts or partial strokes) can restrict motion and cause component damage. Shock/vibration exacerbates this issue.

Anti-creep mechanisms maintain roller alignment, enabling multi-orientation mounting and reducing maintenance needs.

Load Capacity

Maximum weight for smooth operation with minimal deformation. Critical for precision applications.

Supplier Selection

Choose experienced suppliers offering diverse configurations and expert guidance.

Size Constraints

Crossed roller bearings require rails twice the travel length; plastic cages enable longer strokes.

Precision Requirements

Higher load margins compensate for deformation near capacity limits. Preloaded tables ensure accuracy through precise machining.

Operating Speed

Consider throughput requirements when evaluating velocity specifications.

Chapter Two: Construction and Components of Roller Tables

Construction Details

Precision-engineered roller tables incorporate advanced bearings for low-friction linear motion. Cylindrical roller bearings are preferred for quiet, durable, high-load operation in automation systems.

Aluminum construction offers strength, corrosion resistance, and lightweight durability. Stainless steel suits harsh environments, while engineering plastics reduce weight and noise. Customizable options include track width, dimensions, capacity, and travel length.

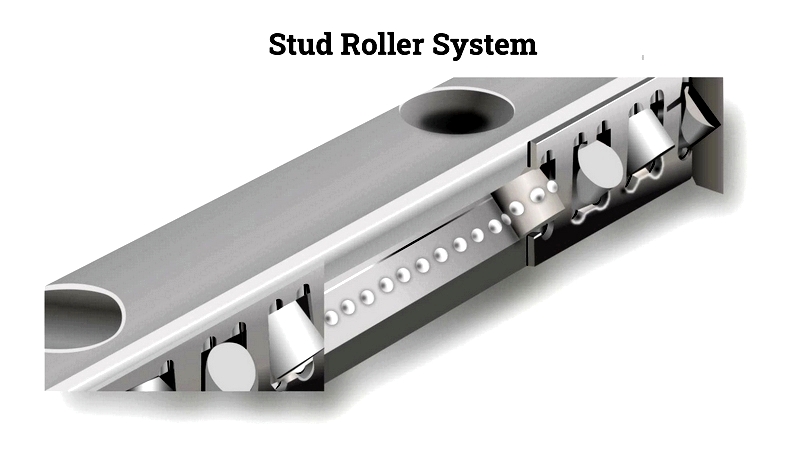

Bearing types (recirculating/non-recirculating roller, ball, flat, crossed) offer varying load ratings, precision, speed, and environmental suitability. Roller cages enhance stability and accuracy during high-speed operation.

Protective features (dust covers, bellows) maintain performance by preventing contamination. Regular maintenance (cleaning, lubrication, inspection) preserves accuracy and extends service life.

Innovations like stud roller mechanisms and polymer retainers enable multi-directional precision movement. Advanced designs optimize rigidity and repeatability for high-speed automation.

Component Breakdown

High-quality roller tables combine two linear bearings with single-piece bases and tops for precision guidance.

- base: Stationary foundation (