Introduction

This article provides comprehensive information about metal brackets and their applications.

You will learn about:

- What metal Brackets Are

- metal Bracket Manufacturing Processes

- Materials Used in metal Bracket Production

- Different Types of metal Brackets

- Advantages of Using metal Brackets

- And More...

Chapter One: Understanding metal Brackets

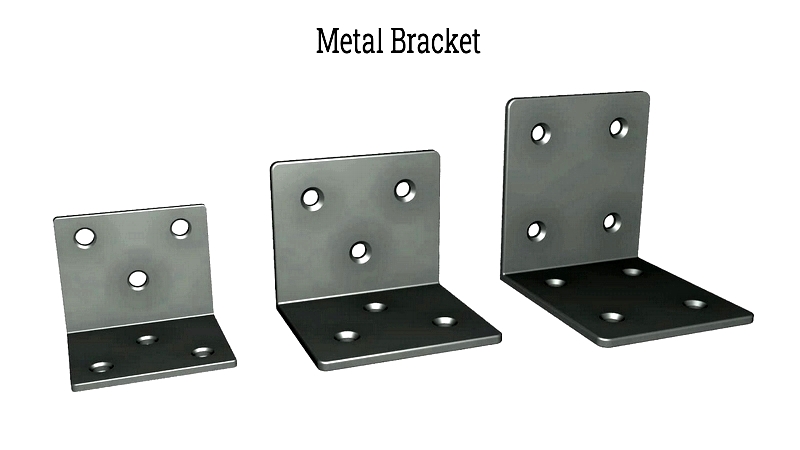

metal brackets are fastening devices specifically designed to connect and secure components. Commonly used to support shelves, stabilize machinery, mount structures, or add decorative elements, these brackets may include holes or threads for screw attachment. As essential hardware, they facilitate item securing, door operations, and may incorporate hasps for enclosure locking.

Renowned for their versatility, strength, and durability, metal brackets serve diverse industries including construction, manufacturing, automotive, and aerospace. Production methods vary, incorporating techniques like CNC machining, casting, and sheet metal fabrication.

Manufacturers select bracket materials based on factors such as load capacity, appearance, surface finish, thickness, angles, and cost. Common choices include steel, stainless steel, aluminum, and brass, available in configurations like L-shaped, U-shaped, Z-shaped, and gusset brackets.

Chapter Two: metal Bracket Manufacturing Processes

The diverse requirements for bracket styles, shapes, thicknesses, and materials necessitate various production methods, including casting, metal stamping, CNC machining, laser cutting, and metal extrusion. These techniques enable the creation of both standard and custom brackets for industrial applications ranging from construction to electronics. Finishing processes like powder coating, electroplating, anodizing, polishing, and painting enhance appearance, durability, corrosion resistance, and load-bearing capacity.

Casting

Casting involves pouring molten metal into molds to create brackets with complex geometries. Suitable for various metals including aluminum, brass, bronze, steel, and stainless steel, this method offers strength and design flexibility. Common casting techniques include sand casting, investment casting, die casting, and mold casting, each producing brackets with specific characteristics for specialized applications.

CNC Machining

CNC machining uses computer-controlled tools to precisely shape metal brackets from digital designs. Starting with CAD models converted to machine instructions, this process enables high-accuracy production of prototypes and complex components. Evolving from 1940s numerical control systems, modern CNC machining supports both small-scale and mass production across industries requiring tight tolerances.

Stamping

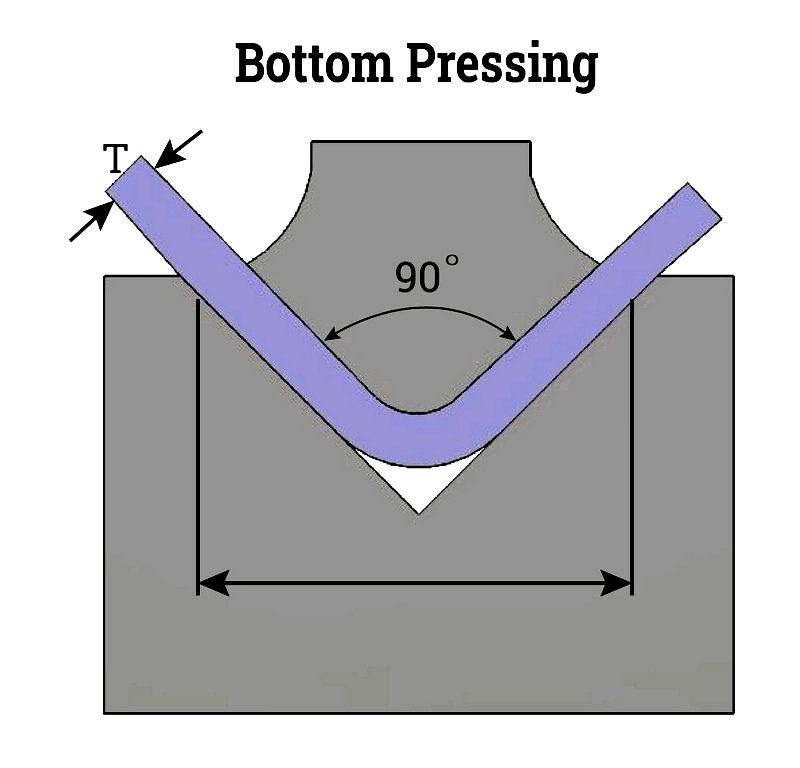

Stamping transforms metal sheets into brackets through pressing operations like bending and embossing. Suitable for various metals, this cost-effective method efficiently produces large quantities of brackets. Techniques include progressive stamping, transfer die stamping, fine blanking, and four-slide stamping, each suited to different bracket complexities. Press types (mechanical, hydraulic, servo) are selected based on production requirements.

Extrusion

Extrusion forces heated metal billets through dies to create continuous profiles like L-brackets and U-channels. Primarily used for non-ferrous metals, this process yields lightweight, corrosion-resistant brackets ideal for architectural and industrial applications.

Laser Cutting

Laser cutting produces precise, complex bracket shapes from CAD files, offering clean edges with minimal post-processing. This method excels for custom designs and low-volume production, particularly where traditional tooling costs would be prohibitive.

Quality Assurance & Finishing

All brackets undergo rigorous quality checks before receiving surface treatments like galvanizing, anodizing, or powder coating to enhance performance. Understanding these manufacturing processes helps professionals select optimal production methods based on cost, material properties, and application requirements.

Chapter Three: Key Machines for metal Bracket Production

North American manufacturers utilize advanced equipment to produce high-quality metal brackets efficiently. Selection depends on production volume, material type, and precision requirements.

Amada EMK 3610 NT Punch Press

Manufacturer: Amada America Inc.

This CNC turret punch press handles various metals with high-speed precision, featuring automated tooling and user-friendly controls for flexible production.

Trumpf TruBend 5130

Manufacturer: Trumpf Group

A versatile CNC press brake offering precise bending with programmable settings and automation features to optimize production efficiency.

Bystronic Bystar Fiber Laser Cutter

Manufacturer: Bystronic Inc.

Delivers fast, accurate cutting with fiber laser technology, suitable for various metals and compatible with automated loading systems.

Haas VF-2SS Vertical Machining Center

Manufacturer: Haas Automation, Inc.

Compact CNC machine ideal for precision machining of bracket components, featuring high spindle speeds and efficient tool changing.

Mazak Integrex i-200S Multi-Tasking Machine

Manufacturer: Yamazaki Mazak Corporation

Combines turning, milling, and drilling capabilities in one setup, reducing production time for complex bracket designs.

Selecting appropriate machinery involves evaluating product specifications, material requirements, and production volumes to optimize manufacturing efficiency.

Chapter Four: metal Bracket Components

While designs vary, most metal brackets share these fundamental elements:

base Plate

The mounting surface featuring attachment holes, available in various metals and sizes to support the bracket's load.

Support Arm

Extends from the base to hold objects, designed in different configurations based on application requirements.

Mounting Holes

Pre-drilled or customizable openings for securing brackets with appropriate fasteners.

Fasteners

Screws, bolts, or rivets selected based on environmental conditions and load specifications.

Bracing

Reinforcements like gussets, flanges, or cross-bracing that enhance structural integrity under various stresses.

Adjustment Mechanisms

Features like movable fasteners, shims, or braces that enable precise positioning during installation.

Coatings

Protective finishes including zinc, powder coatings, or anodizing that improve