Introduction

This article provides an in-depth exploration of spring latches.

It covers essential topics including:

- Working Principle of Spring Latches

- Various Types of Spring Latches

- Applications and Advantages of Spring Latches

- And more...

Chapter 1: Understanding Spring Latch Principles

What is a Spring Latch?

Spring latches are mechanical fastening devices designed to securely join two components while preventing accidental movement. Their spring-loaded mechanism maintains a locked position that resists vibration-induced disengagement. Typically made from corrosion-resistant materials, these latches offer durability and strength.

There are two primary spring latch variants: deadbolts and slam latches. Deadbolts feature solid rods with blunt ends that insert into matching door or cabinet frame holes. Slam latches employ an angled bolt that engages with a strike plate during door closure, automatically locking into place.

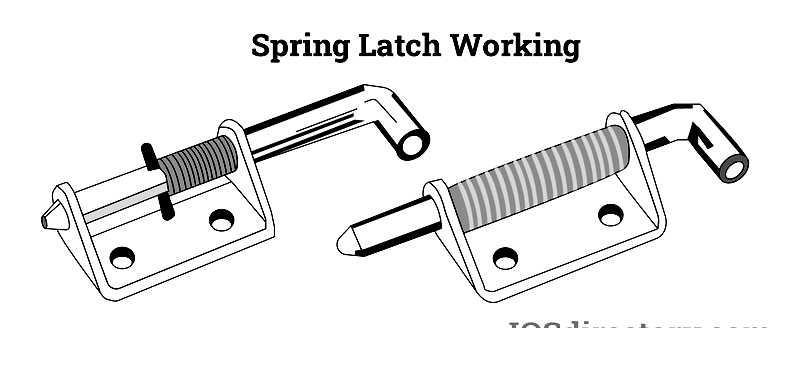

The simplest spring latch design incorporates an L-shaped plunger bolt with a pin insertion hole. Two notched lips on the back plate support the plunger, while a spring between the pin and lips maintains proper positioning.

Spring Latch Manufacturing

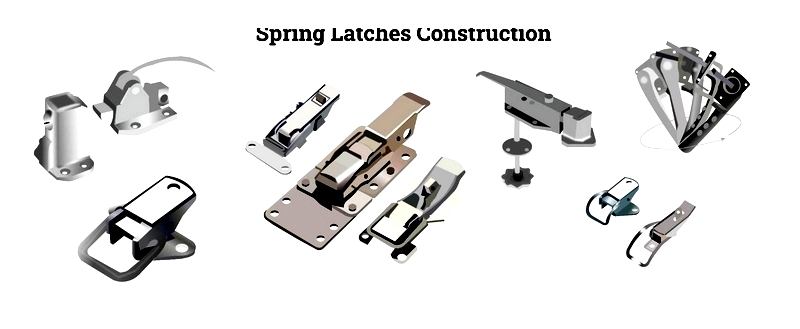

Manufacturers produce spring latches with various surface finishes including zinc, nickel, chrome plating, or stainless steel tumbling.

Available in numerous designs, spring latches provide secure fastening with stability and reliability, capable of withstanding forces up to 7,000 kg. Some models feature quick-release mechanisms for convenient access in machinery applications.

The fundamental operating principle involves a calibrated cam system that maintains secure locking. Unlocking requires sufficient force, with handle length affecting the necessary leverage.

Spring Latch Materials

Common manufacturing materials include brass, aluminum, bronze, stainless steel, and iron, selected for their durability and weather resistance. Material choice significantly affects both performance and cost.

Brass and Bronze Latches

Brass offers robust performance for exterior applications with its classic appearance, though it may tarnish over time. Bronze, a premium copper alloy, develops an attractive patina without requiring protective coatings and resists chipping.

Stainless Steel Latches

Stainless steel provides superior weight and resilience compared to aluminum, resisting deformation under stress or extreme temperatures. While naturally corrosion-resistant, powder-coated versions offer enhanced protection in harsh environments.

Two primary stainless steel grades are used:

Stainless Steel 304

The most common global variant offers excellent corrosion resistance through its chromium-nickel composition (16-24% Cr, ≥35% Ni). While resistant to most acids, it's susceptible to chloride-induced pitting corrosion.

Stainless Steel 201

This cost-effective alloy reduces nickel content by substituting manganese and nitrogen. It becomes magnetic when cold-worked but remains non-magnetic in annealed state.

Aluminum Latches

Lightweight and corrosion-resistant, aluminum latches suit various environments. Anodized finishes provide aesthetic options, though aluminum is more brittle than iron.

Iron Latches

Iron offers economical solutions for gates and doors, often with powder-coated black finishes for weather protection. Suitable for non-corrosive environments, it provides reliable performance at lower cost.

Spring Latch Operation

Pulling the bolt compresses the spring for release; releasing allows spring decompression and automatic re-locking. This action resembles pinball machine mechanics where bolt movement controls ball release.

Chapter 2: Spring Latch Varieties

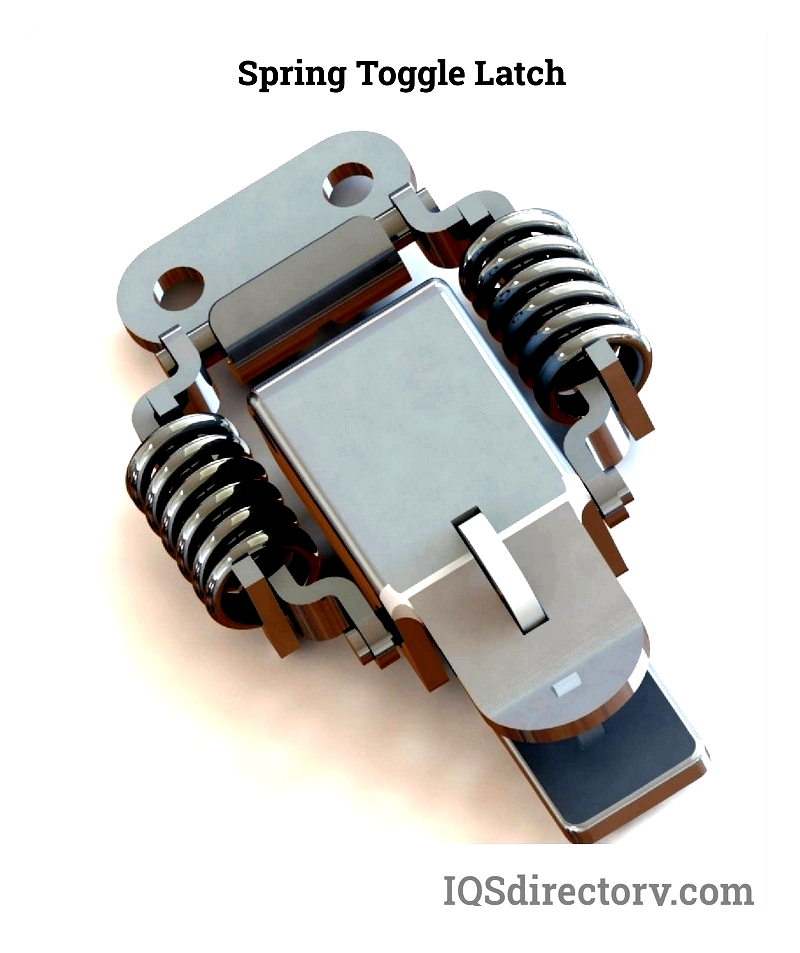

Spring Toggle Latches

Widely used across industries for secure fastening, these latches serve automotive, agricultural, industrial, and electrical applications. Alternative names include:

- Lever latch

- Draw latch

- Over-center fastener

Classified by tensile strength:

- Light-Duty: 11-90 kg capacity

- Medium-Duty: 125-750 kg capacity

- Heavy-Duty: 1000-2500 kg capacity

- Super Heavy-Duty: Up to 7000 kg capacity

Additional Spring Latch Types

Specialized variants address specific requirements:

- Flush Fitting: For smooth surface applications

- Under Center: Wide-angle fastening

- Flexible Fastener: Vibration-resistant designs

Security-enhanced options include:

- Key-operated locks

- Padlock-compatible models

- Safety catch mechanisms

Optimal Latch Angles

15° engagement angle ensures maximum holding force. Proper hole alignment along the pivot centerline maintains secure closure in high-vibration environments.

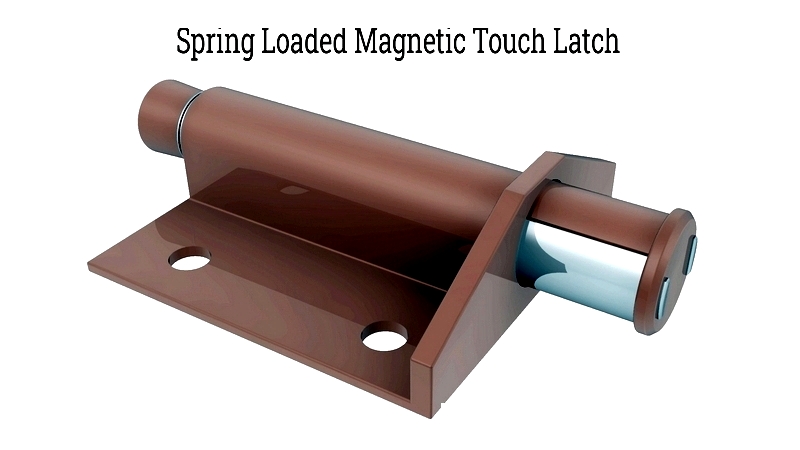

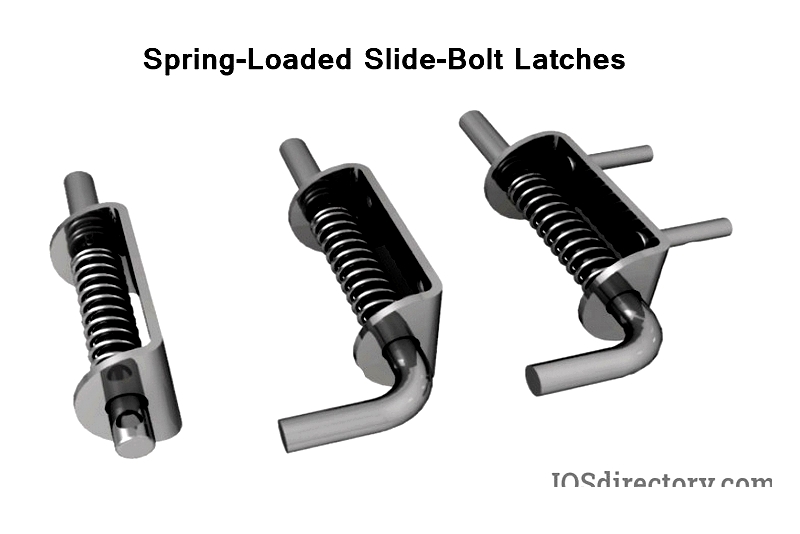

Spring-Loaded Slide-Bolt Latches

These automatic-securing devices are ideal for industrial enclosures and transport containers, offering durable, vibration-resistant performance.

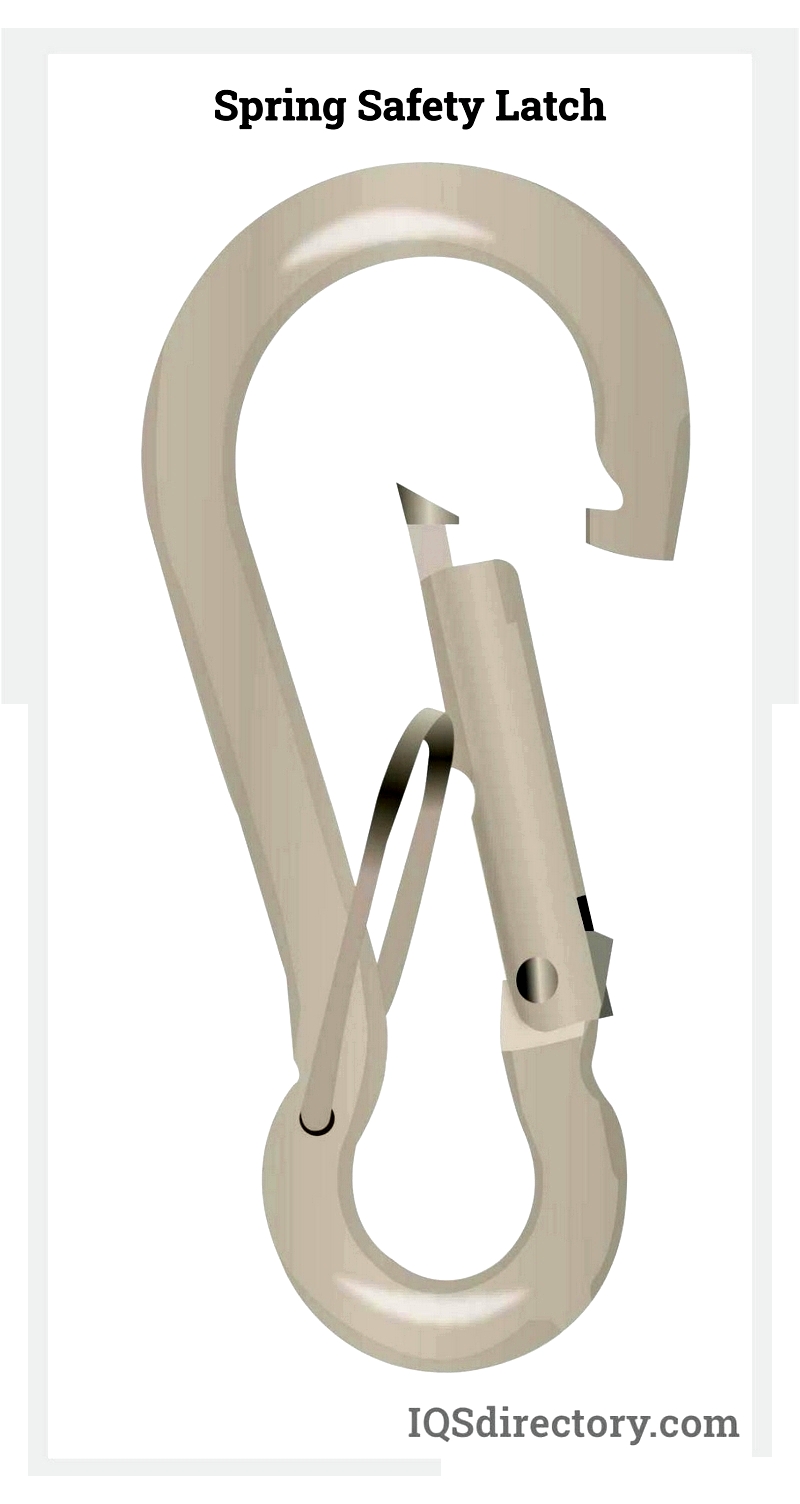

Spring Safety Latches

Hook-and-pinhole designs ensure load security in construction and marine applications, meeting OSHA/ISO standards with corrosion-resistant materials.

Quick-Disconnect Hinges

Spring-loaded pin mechanisms enable tool-free panel removal for maintenance-intensive systems.

Chain-Grip Latches

Remote operation capability makes these suitable for hard-to-reach access points with 180° bolt rotation for versatile installation.

Tight-Hold Draw Latches

Integrated compression springs provide vibration-resistant, rattle-free closure