Introduction

This guide covers everything you should know about plastic tanks and their applications.

You'll discover:

- The definition of plastic tanks

- Plastic tank manufacturing processes

- Common plastic materials used in production

- Key industries utilizing plastic tanks

- Additional valuable information

Chapter 1: What is a Plastic Tank?

Plastic tanks offer versatile storage solutions for liquids and granular materials. Available in vertical and horizontal configurations, they suit both aboveground and underground installations. These durable containers resist wear, weathering, and deterioration, making them ideal for manufacturing, agriculture, and fuel industries that require reliable material storage and handling.

Compared to steel or lined tanks, plastic versions provide superior durability and cost-effectiveness. With proper installation, they typically last 20-30 years. Factors affecting lifespan include correct installation methods, stored chemical types, adequate ventilation, and proper fitting selection.

Chapter 2: How Plastic Tanks are Made

Modern manufacturing processes create strong, durable plastic tanks for water storage, chemical containment, agriculture, and industrial use. Primary production methods include rotational molding, blow molding, and injection molding. Manufacturers typically use HDPE, LLDPE, and polypropylene for their UV, corrosion, and impact resistance. These materials perform well in demanding environments for potable water, fuel, and chemical storage applications.

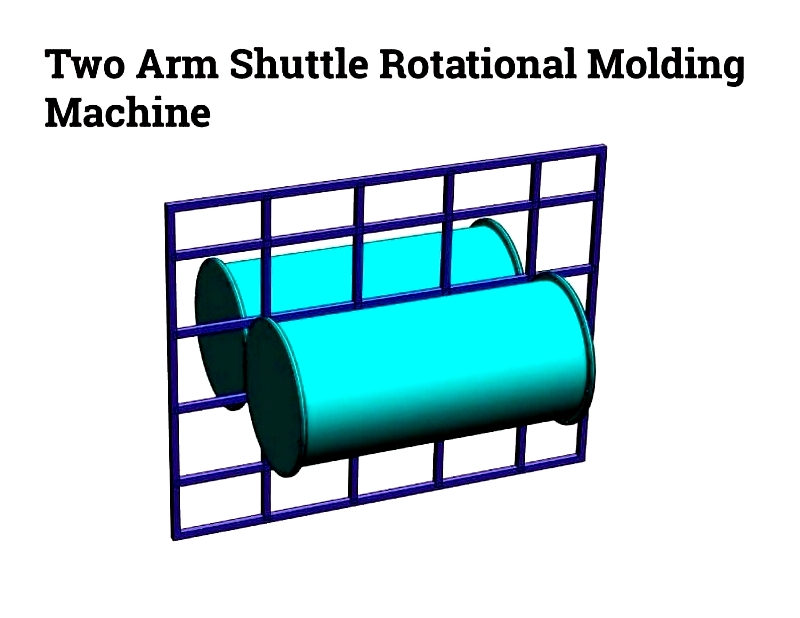

Rotational Molding

Rotational molding produces large, seamless tanks through low-pressure, high-temperature processing. The rotating multi-axis mold ensures even polymer distribution, creating leak-resistant tanks for chemical storage, wastewater, and agricultural applications.

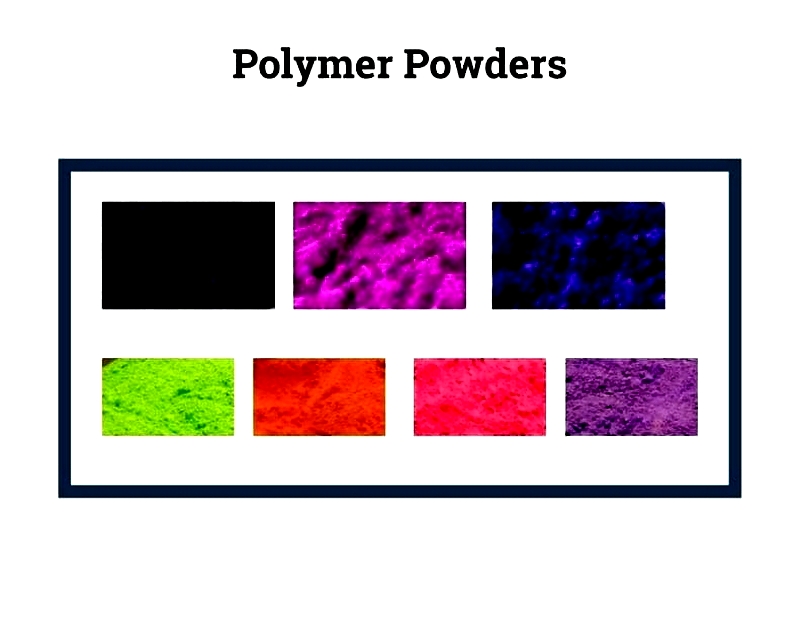

Loading

Manufacturers precisely measure powdered polymer resin to achieve required wall thickness. Tank colors vary from white to black, with darker shades reducing algae growth in water storage. Color selection depends on intended use and safety standards.

Tank Oven

The heated mold rotates in an industrial oven, melting resin evenly across the interior surface. Computer-controlled rotation ensures uniform wall thickness and structural integrity. Processing time ranges from one to three hours depending on tank size.

Cooling

Controlled cooling solidifies the polymer while maintaining rotation to prevent deformation. This critical phase lasts about an hour and ensures dimensional accuracy for long-term performance.

Molded Tank Removal

Workers carefully extract finished tanks, using equipment for larger units. Post-molding modifications include adding fittings and ports according to customer specifications. The seamless construction makes these tanks ideal for critical storage applications.

Rotational molding offers cost-effective production of durable, weather-resistant tanks. Quality testing includes hydrostatic and pressure checks to ensure industry compliance.

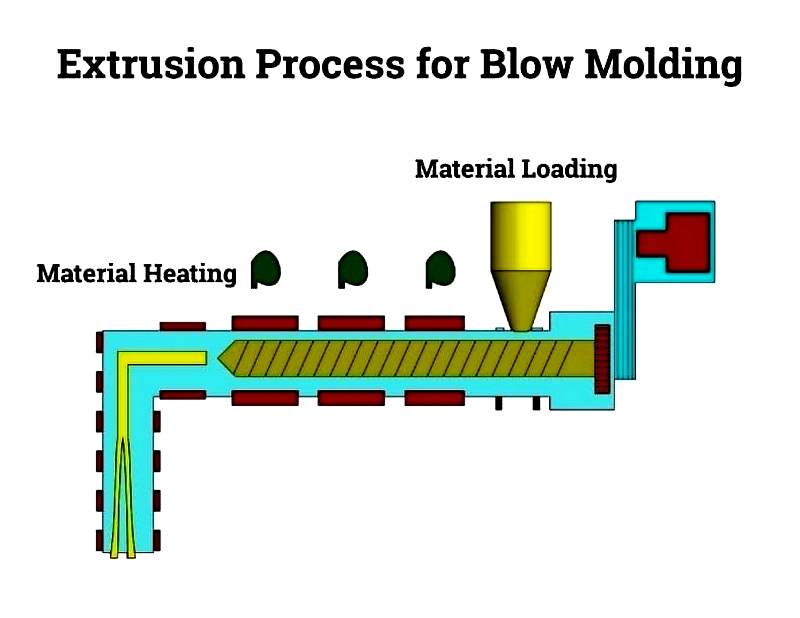

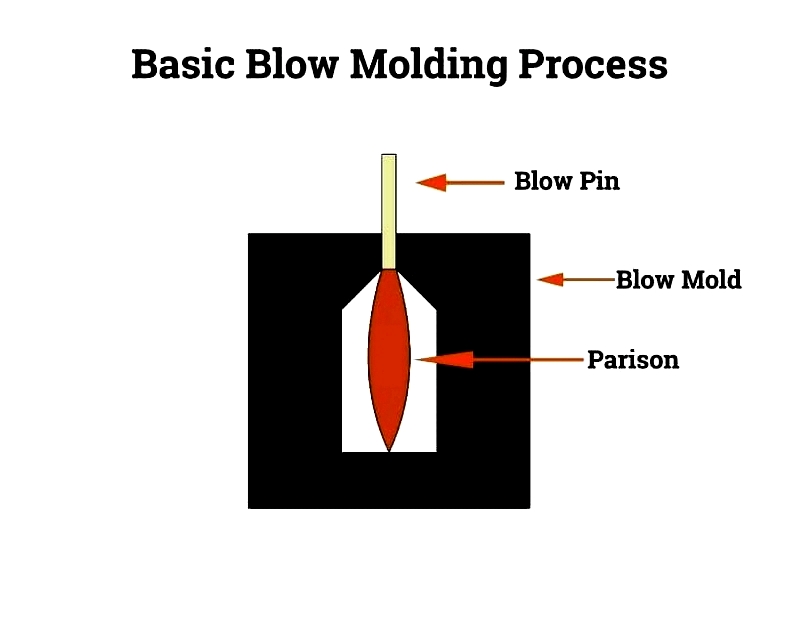

Blow Molding

This high-volume method produces smaller tanks, bottles, and drums by inflating molten plastic within molds. Common materials include HDPE, polypropylene, and PVC, suitable for portable water containers, fuel tanks, and chemical transport vessels.

Melting

Extrusion processes heat resin to form a parison, whose dimensions determine the final product size. Material selection depends on intended contents and chemical compatibility.

Blowing

Compressed air shapes the parison within the mold cavity, ensuring uniform wall thickness. The automated process supports rapid production for various industries.

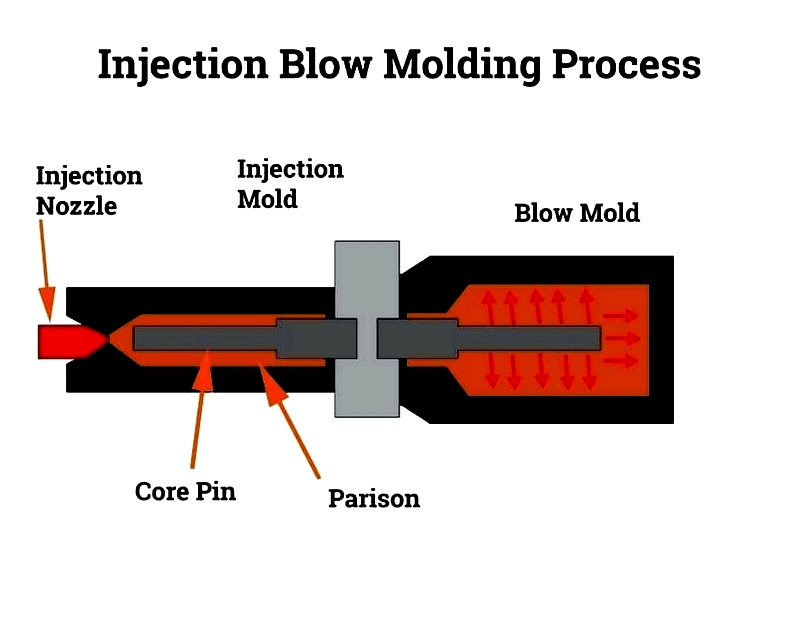

Injection blow molding offers greater precision for small-to-medium tanks requiring tight tolerances and smooth surfaces.

Stretch blow molding produces pressure-resistant containers through preform stretching and expansion.

Plastic Welding

This technique joins plastic components through heat and pressure, creating strong, airtight bonds. Proper material matching ensures optimal strength and chemical resistance.

The welding process involves surface preparation, heat application, and controlled cooling. "V" groove cutting enhances fusion quality.

Welding surpasses alternative joining methods in strength and durability, particularly for hazardous material storage.

Manufacturers use welding to customize tanks with specialized fittings and features, extending their utility across industries.