Introduction

This section covers mixer blades, their significance, and manufacturers of mixer blades.

You will learn about:

- Types of Impeller Mixing Blades

- Types of Propeller Mixing Blades

- How Mixer Blades are Manufactured

- And much more...

Chapter 1: What is a Mixer Blade?

A mixer blade is a key component that blends or agitates substances to create homogeneous mixtures. Designed to handle liquids, viscous pastes, and granular materials, mixer blades come in various forms essential for industrial mixers. These components are known by many names, including impellers, propellers, and blades, with "impeller" being the most common term—referring to a metal piece on a rotating shaft that mixes ingredients.

All mixer blades move materials either vertically or horizontally, with the blade type determined by the material's properties. Some materials require gentle rotation, while others need strong shearing forces for homogeneity. Blade strength, composition, and shaft design vary widely among manufacturers and mixer types.

Chapter 2: Types of Impeller Mixer Blades

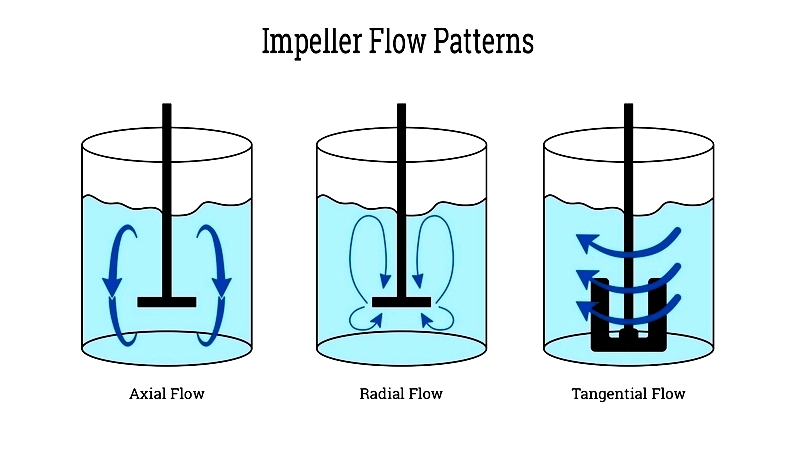

Impeller blades are critical for industrial mixers, each creating unique flow patterns essential for achieving homogeneous mixtures. The primary flow patterns are axial (up and down) and radial (side to side), while tangential flow involves horizontal movement with minimal vertical mixing, ideal for high-viscosity materials.

Impeller Design Parameters

Impeller performance depends on geometric factors such as angles, curves, diameters, and blade shapes, which ensure stability and reliability.

- Diameter – Affects flow rate and energy consumption. Typically one-third of the tank diameter.

- Blade Angle – Ensures smooth fluid entry and exit, minimizing turbulence and improving energy transfer.

- Number of Blades – Balances efficiency and construction complexity.

- Blade Shape – Tailored to application needs; curved blades reduce turbulence and enhance energy efficiency.

- Width – Wider blades handle higher flow rates but increase friction, while narrow blades are more efficient.

- Materials – Chosen for durability, wear resistance, and corrosion resistance based on operating conditions.

- Surface Finish – Smooth finishes reduce friction and turbulence, improving efficiency.

Different impeller types serve specific mixing needs. Axial blades excel in solid suspension, while radial blades provide high shear with lower flow rates. Blade selection is critical for meeting application requirements.

Axial Flow Pattern

Axial flow is commonly used for bulk material mixing. Downward-angled blades force materials to the tank bottom, where they rebound and circulate upward along the sides. This pattern prevents solids from settling and is ideal for suspending particles in liquids.

Radial Flow Pattern

Radial flow directs materials toward the tank walls, splitting the flow upward and downward. This pattern generates high shear, making it suitable for low-level mixing in elongated tanks and viscous materials like pastes.

Tangential Flow Pattern

Tangential flow creates a circular motion, best for high-viscosity materials. It lacks vertical movement, making it ineffective for low-viscosity liquids but useful for breaking down viscous material boundaries.

Types Of Impeller Mixer Blades

Impeller blades vary widely, categorized by flow direction and designed to alter fluid pressure and movement.

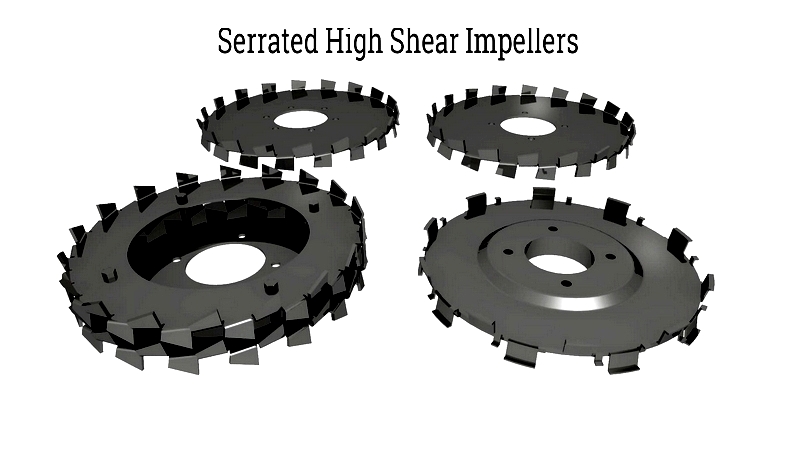

High Shear Impeller Mixer Blades

High shear blades break up solids and disperse materials efficiently. Made from durable metals like stainless steel, they operate at high speeds, creating vortices for rapid dispersion.

Ribbon Impellers

Ribbon impellers combine helical ribbons with screw impellers for low-speed mixing of medium to high-viscosity materials. Their design promotes inward, outward, forward, and backward movement, ideal for slurries and powders.

Paddle Impeller Mixer Blades

Paddle blades generate radial flow with flat blades mounted on