Introduction

This article provides an in-depth exploration of isolation transformers.

Key topics covered include:

- Working Principles of Isolation Transformers

- Varieties of Isolation Transformers

- Electrical Noise in Isolation Transformers

- Applications and Benefits of Isolation Transformers

- And more...

Chapter 1: Understanding the Principle of Isolation Transformers

This chapter examines the operation, design, and customization of isolation transformers, emphasizing key considerations for selection.

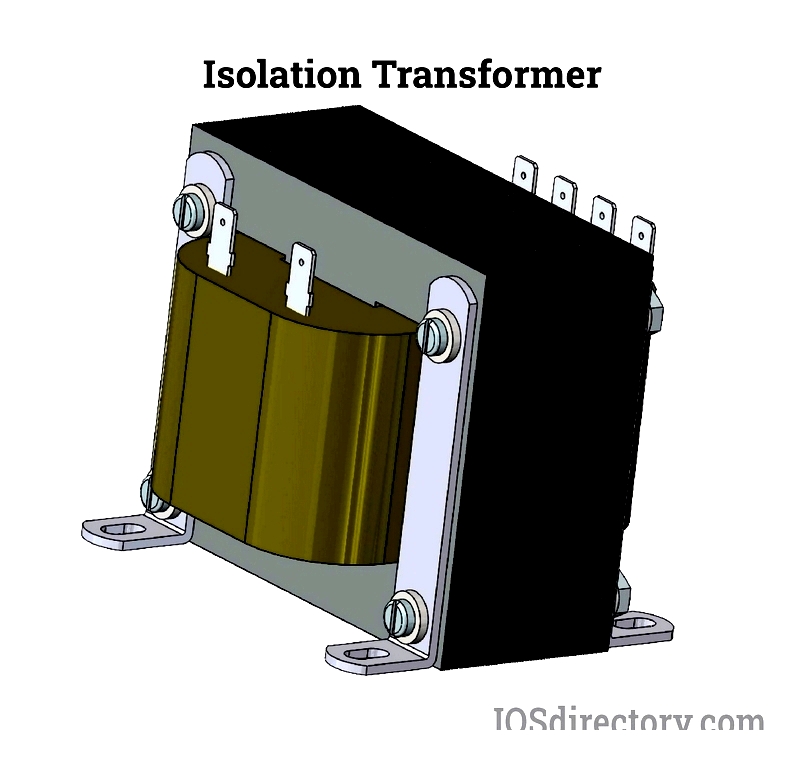

Defining Isolation Transformers

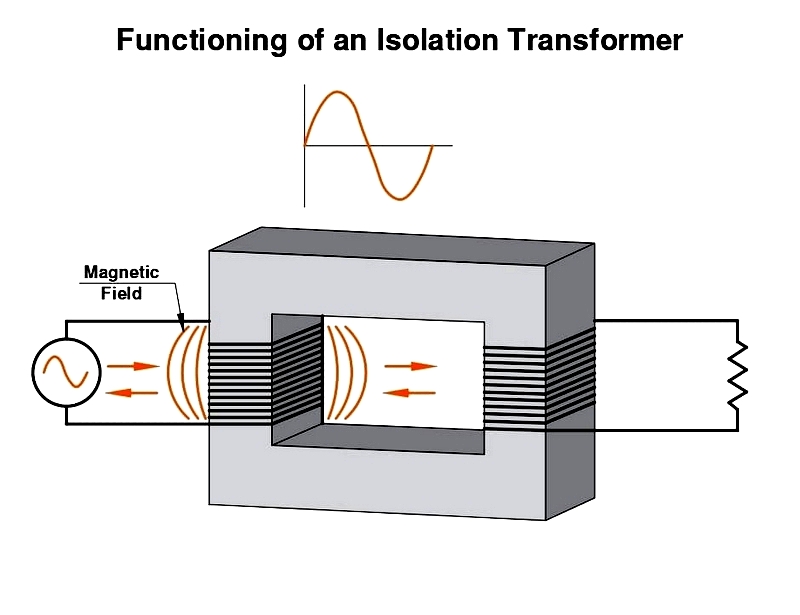

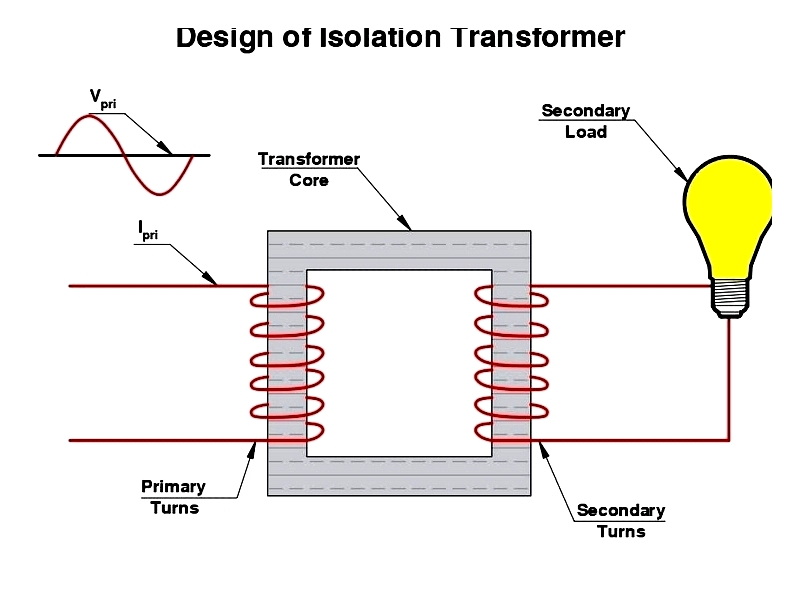

An isolation transformer is a stationary device designed to physically and electrically separate primary and secondary windings. This complete circuit isolation enables energy transfer through magnetic induction while maintaining the original frequency. The transformer uses a magnetic field to induce electromotive force (EMF) in the secondary circuit.

In power systems, isolation transformers adjust voltage levels through step-up or step-down conversion to match coil specifications. They protect against voltage spikes that could disrupt operations or damage equipment. Positioned between power lines, these transformers suppress voltage fluctuations before they reach connected loads.

Isolation transformers also prevent secondary-side grounding issues, reducing ground loop interference and minimizing equipment noise. Their design ensures electrical separation between primary and secondary circuits while safely transmitting AC power to devices. This separation enhances safety by reducing electrical transients and harmonics.

Step-up transformers feature more secondary winding turns, while step-down transformers have more primary turns. The voltage output adjusts according to input voltage, current requirements, and turns ratio. Three-phase systems outperform single-phase AC by eliminating voltage oscillations, resulting in smoother operation, reduced vibration, and simpler equipment design - making them ideal for industrial applications.

Role of an Isolation Transformer

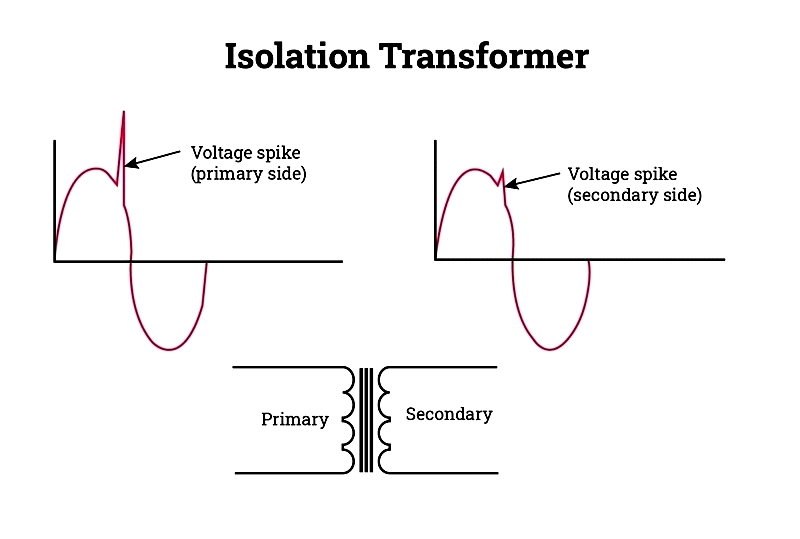

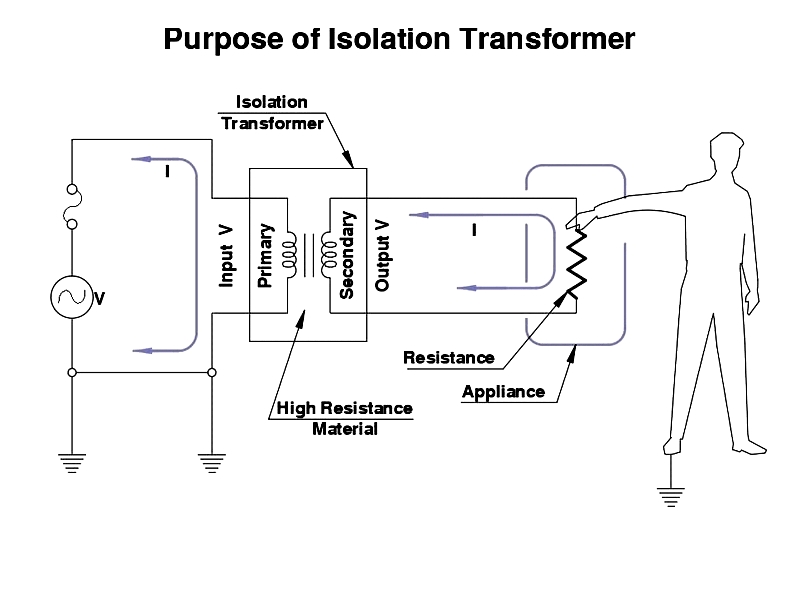

Isolation transformers physically and electrically separate circuits to protect equipment and personnel from electrical hazards. They transfer power through magnetic coupling while attenuating voltage spikes caused by lightning, static, or power surges.

These transformers handle brief voltage increases (≥3ns duration) that could otherwise damage sensitive equipment. By limiting current changes through winding resistance, they prevent immediate secondary voltage spikes. The inductive properties of windings resist rapid spike transmission, with faster changes encountering greater resistance.

Isolation transformers eliminate ground loops and reduce noise, making them essential for protecting medical, laboratory, and measurement equipment. Their enhanced design includes electrostatic shielding for superior noise reduction compared to autotransformers.

Design and Customization of Isolation Transformers

Toroidal isolation transformers offer compact, lightweight solutions with evenly distributed windings. Their silicon iron or nickel-iron cores improve efficiency, while amorphous alloys suit high-frequency applications. These designs reduce audible noise and stray emissions, with optional metal bands for additional magnetic field containment.

Additional insulation meets stringent requirements for medical monitoring equipment. Custom configurations address specific interference and safety needs across applications.

Chapter 2: Types of Isolation Transformers

Various isolation transformer types serve distinct applications in power distribution, offering safety, noise reduction, and voltage regulation benefits.

Ultra Isolation Transformer

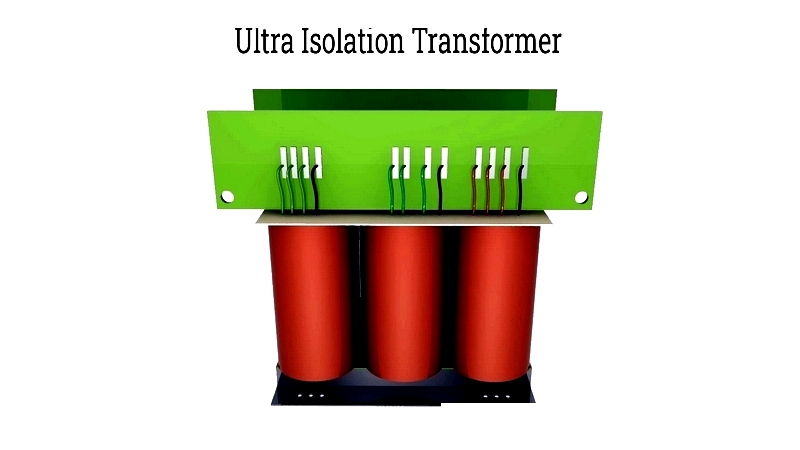

Ultra isolation transformers eliminate electrical interference through complete winding separation and independent secondary grounding. Their advanced shielding and insulation (1000-4000V rating) protect sensitive equipment like medical devices and communication systems from noise and surges.

Ideal for healthcare, telecom, and industrial applications, these transformers feature low capacitance and multi-layer shielding for superior high-frequency noise suppression.

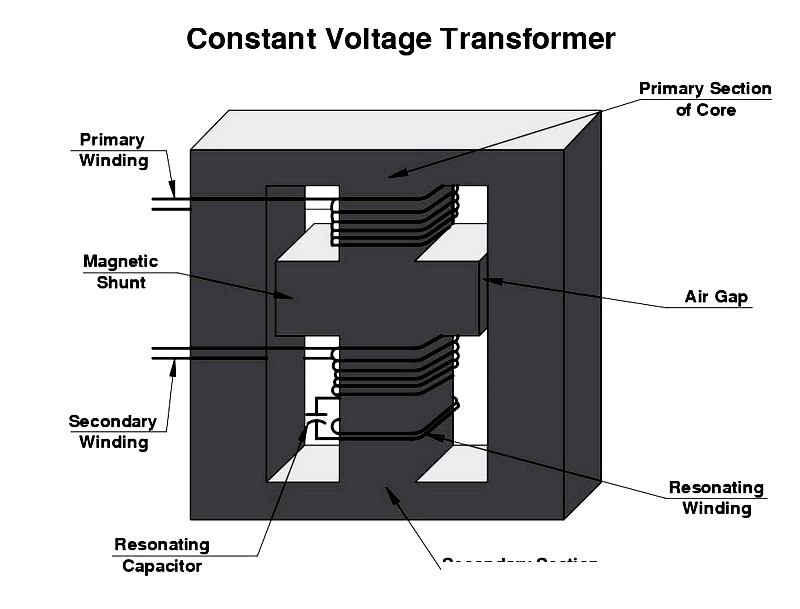

Constant Voltage Transformer (CVT)

CVTs maintain stable output voltage using ferroresonant technology and capacitor-based tank circuits. Their energy storage capability provides uninterrupted power during input fluctuations, protecting critical systems like lab equipment and telecom infrastructure.

These transformers offer superior spike suppression and transient filtering for voltage-sensitive applications.

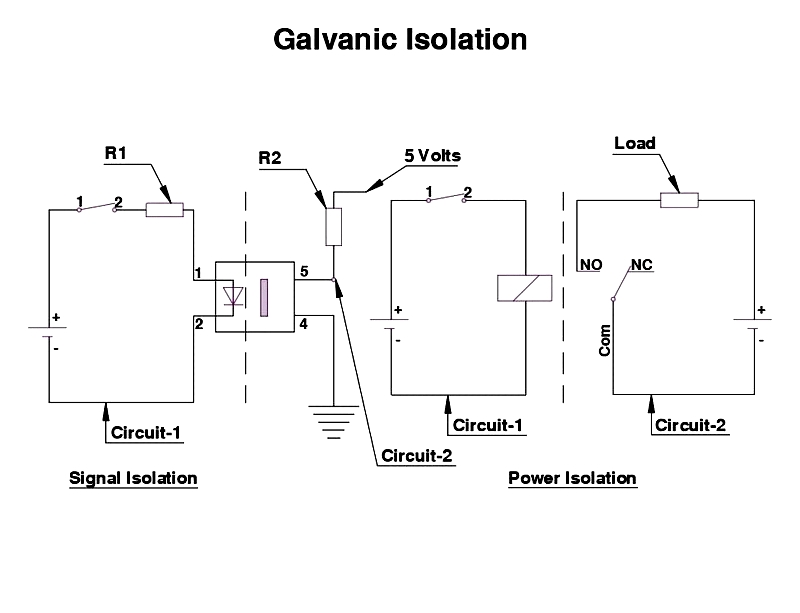

Galvanic Isolation Transformer

These transformers prevent direct current flow while allowing AC power transfer, meeting IEC safety standards for industrial and computing applications. They effectively reduce low-frequency noise but may require supplemental EMI filters for high-frequency protection.

Consider thermal management when integrating galvanic isolation in UPS systems for optimal performance.

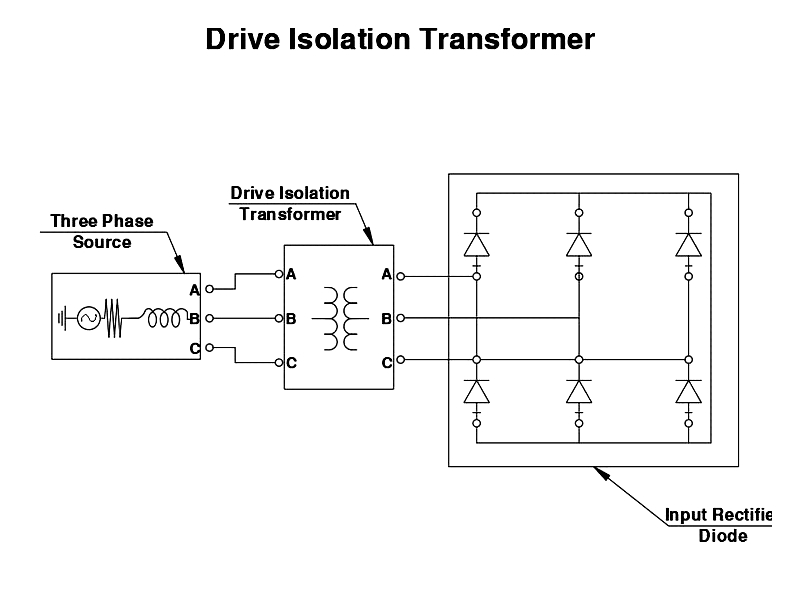

Drive Isolation Transformers

Designed for VFD applications, these transformers handle harmonic distortion and high-frequency noise in motor control systems. Delta-wye configurations and solid grounding improve reliability in industrial automation and HVAC applications.

Modern designs incorporate thermal protection to prevent motor bearing failures and system tripping.

Dry Isolation Transformers

Encapsulated in epoxy or vacuum-sealed enclosures, dry-type transformers resist environmental hazards in schools, hospitals, and chemical plants. Available as cast resin or VPI designs, they offer:

- Voltage conversion for diverse loads

- Surge and fault protection

- Ground loop interference elimination

- EMI/RFI noise reduction

- Leakage current minimization

- High efficiency with low energy loss

- Fire-safe, eco-friendly operation