Introduction

This article covers everything you need to know about Cartridge Heaters.

You'll explore topics including:

- What is a Cartridge Heater?

- How Cartridge Heaters Work

- How Cartridge Heaters are Made

- Types of Cartridge Heaters

- And much more…

Chapter One – What is a Cartridge Heater?

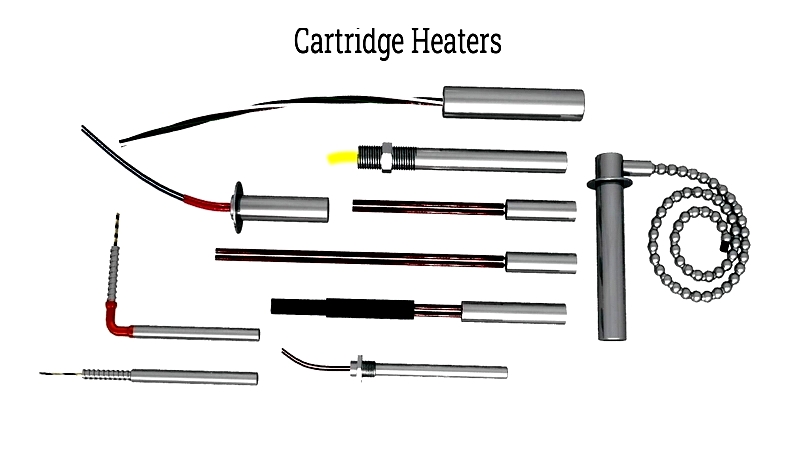

A cartridge heater is a cylindrical heating element designed to provide precise, consistent heat to various materials, machinery, and equipment. Unlike immersion heaters, cartridge heaters are inserted into pre-drilled holes in objects requiring heating, delivering internal radiant heat. These heaters are widely used in manufacturing for targeted localized heating applications.

Engineered for easy installation, cartridge heaters ensure uniform heat distribution and feature customized watt densities. Their diameter is slightly smaller than the insertion hole, ensuring a secure fit for optimal performance.

Chapter Two – How a Cartridge Heater Works

Cartridge heaters are high-performance industrial heating elements that heat metal blocks and solid materials from within. Commonly used in plastic injection molding, die casting, packaging machinery, and medical device manufacturing, they deliver precise, localized heat at specified wattages. Installation requires a custom-drilled hole slightly larger than the heater diameter to accommodate insertion and thermal expansion.

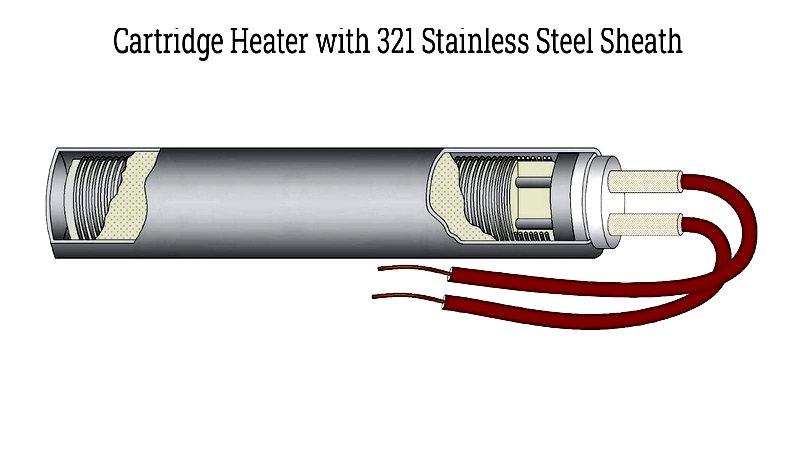

The construction of a cartridge heater includes a ceramic core wound with high-resistance wire (typically nickel-chromium), encased in a durable metal sheath (usually stainless steel or Incoloy). High-purity magnesium oxide insulation fills gaps, enhancing heat transfer efficiency from the wire to the sheath and surrounding material.

Available in various watt densities and voltages, cartridge heaters can reach temperatures up to 1400°F (760°C). Their rapid thermal response and uniform heat distribution make them ideal for applications requiring precise temperature control, such as sealing bars, medical equipment, food processing, and semiconductor manufacturing.

When selecting a cartridge heater, consider wattage, voltage, dimensions, sheath material, watt density, and application-specific thermal requirements. Proper sizing ensures optimal performance, energy efficiency, and extended service life.

Insertion Point

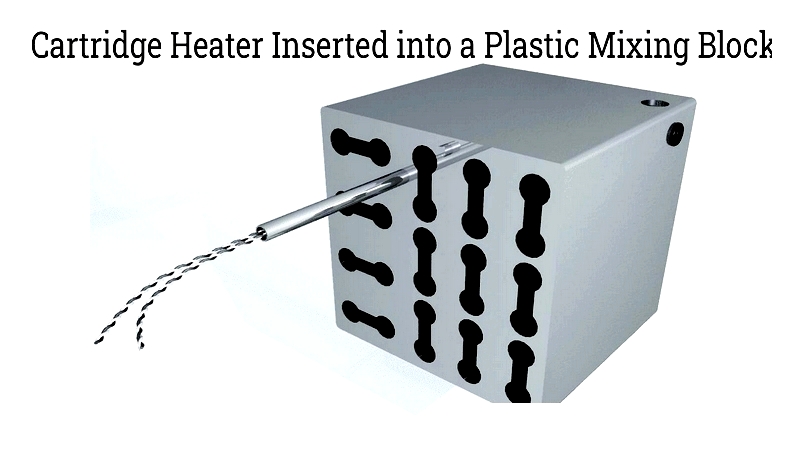

Proper installation begins with the insertion point. Industrial equipment typically has pre-drilled ports matching heater dimensions. For custom applications, accurately drill holes to recommended specifications.

Uniform heat distribution requires careful heater alignment, especially in complex molds. Proper hole placement prevents cold spots and ensures consistent temperature profiles.

The image below shows a plastic mixing block with a dedicated port for a ten-inch cartridge heater, demonstrating strategic placement for efficient heating.

Cartridge Heater Diameter

Matching heater diameter to hole size is crucial for efficient heat transfer. The heater diameter should be 0.004 inches smaller than the hole for a snug fit that accommodates thermal expansion. This prevents overheating and uneven temperatures while minimizing bore seizure risk. Refer to the chart below for standard diameter specifications.