Introduction

This article provides an in-depth exploration of power cords. Continue reading to learn about key topics including:

- What is a Power Cord?

- Power Cord Terminology

- Coupler Standards for Power Cords

- Plug Standards for Power Cords

- And much more...

Chapter 1: What is a Power Cord?

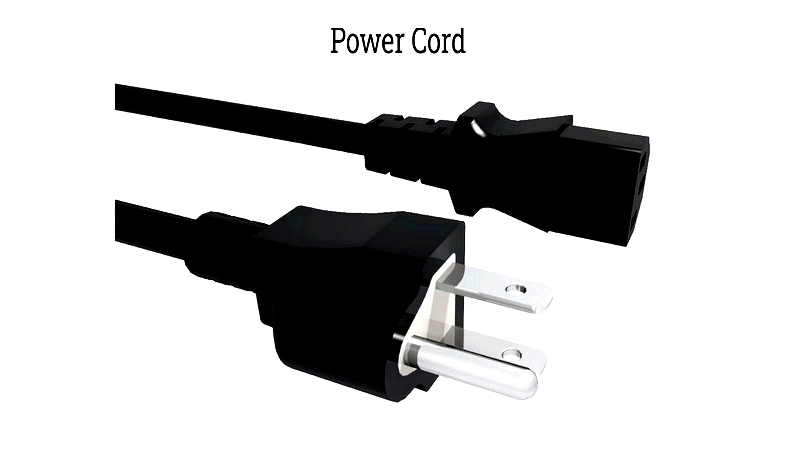

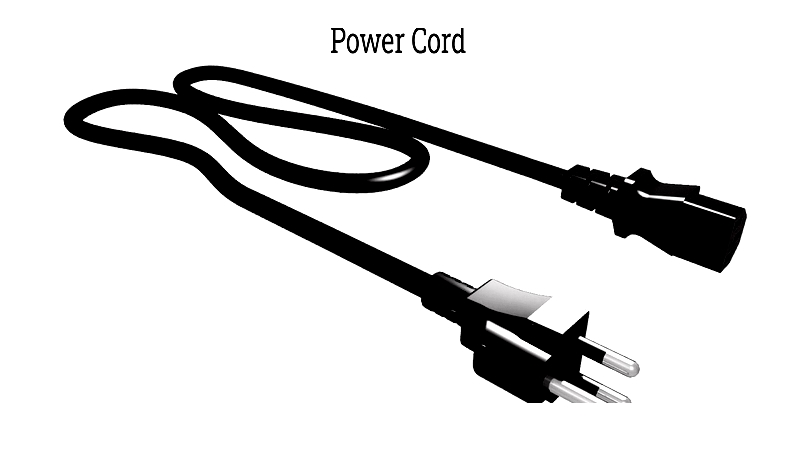

A power cord is an essential electrical component that connects appliances to power sources or electrical utilities. It typically consists of an insulated cable with molded connectors on one or both ends. One end usually features a male plug for connecting to electrical outlets, wall sockets, or extension cords, while the other end often has a female connector for attaching to appliances. In some cases, the female connector may be replaced by a fixed cable directly wired to the appliance.

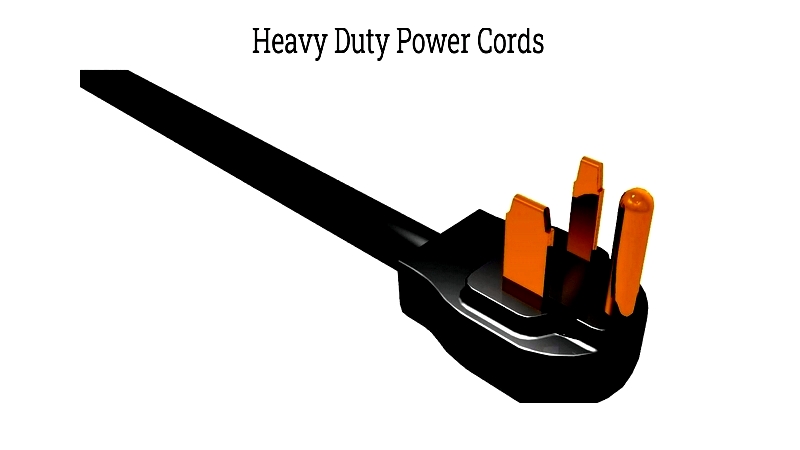

Power cords are widely used in homes and businesses to connect various electrical devices like televisions, computers, refrigerators, and air conditioners. They are less common in industrial settings where machinery requires higher current and voltage levels. Most power cords are rated for 16 A to 20 A and 125 V to 250 V, which may be insufficient for heavy industrial equipment.

Chapter 2: Power Cord Terminology

Understanding power cord terminology is crucial for selecting the right product. While some terms are used interchangeably in everyday language, their precise meanings help ensure safety, performance, and compatibility. Familiarity with these terms simplifies the process of choosing power distribution solutions and reduces risks of electrical hazards or equipment failure. This knowledge is particularly valuable when sourcing replacement cords, extension cords, or custom cable assemblies.

What is the Difference Between a Power Cord and a Power Cable?

Though often used synonymously, "power cords" and "power cables" have subtle differences. Power cords typically refer to flexible cables with molded connectors for connecting appliances to outlets. Power cables encompass a broader range, including rigid cables for industrial applications. Recognizing these distinctions helps in selecting appropriate products and maintaining electrical safety standards.

Power cords are commonly used for consumer electronics and household appliances, while power cables include heavier-duty options for industrial use. The latter may handle higher currents or voltages in commercial settings. Understanding these differences ensures proper selection for specific needs, whether for standard household use or industrial applications.

The following terms help identify various power cord components and features, aiding in product comparison based on technical specifications and application requirements.

Electric Cords

The most basic term for devices that transmit electricity from outlets to appliances. Electric cords can carry AC or DC current and consist of insulated conductors for protection. They serve diverse environments, from household use to industrial applications.

Power Supply Cord

Used primarily to connect appliances to outlets, these cords may be removable or permanently attached. They often comply with global safety standards like UL, CSA, or IEC for various applications.

Cord Set

A complete assembly including a plug, cable, and connector for connecting appliances to power sources. Cord sets are identified by connector types, length, voltage rating, and wire gauge, ensuring proper electrical connections and safety compliance.

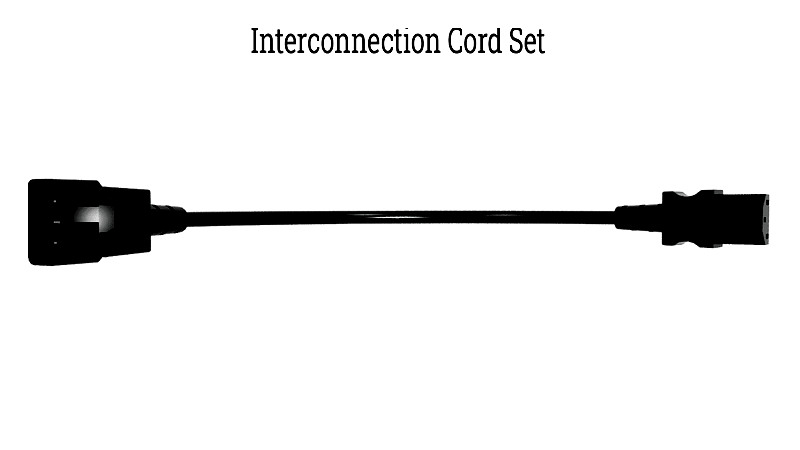

Interconnection Cord Set

Featuring male and female connectors, these sets link two electrical appliances. Common in data centers and AV setups, they provide modular connectivity for equipment like UPS systems and monitors.

AC Power Cords

Designed for alternating current, these cords are standard for most household and business outlets. Key considerations include plug type, voltage/amperage rating, and certification when selecting AC power cords.

Custom Power Cords

Tailored to specific requirements, these cords offer unique combinations of plugs, connectors, and cable characteristics. Suppliers provide customization for medical, industrial, or specialized applications.

Extension Cords

These extend the distance between power sources and appliances, featuring sockets at one end and plugs at the other. Available in various lengths and gauges, they must be chosen based on the intended power load.

Generator Power Cords

High-capacity cords designed for generator use, often featuring weather-resistant materials. Proper matching to generator outlets is essential for safe operation in residential, commercial, or industrial settings.

NEMA Power Cords

Cords conforming to National Electrical Manufacturers Association standards, common in North and South America. NEMA plugs ensure compatibility with regional electrical systems.

NEMA 5-15P Power Cords

Featuring standard North American three-prong plugs, these cords are rated for 15 A and 125 V. They're widely used for consumer electronics and small appliances.

Electrical Plug

A male connector with protruding pins that match socket openings. Plugs vary by region and application, with features like grounding pins or insulated sleeves for safety.

Sockets or Electrical Receptacles

Fixtures that receive electrical plugs, connecting to power distribution systems. Specialized sockets like GFCI or weatherproof types offer additional protection for specific environments.

Plug Adapters

Devices enabling connections between different plug types. While convenient, they should be used cautiously to maintain safety features of original equipment.

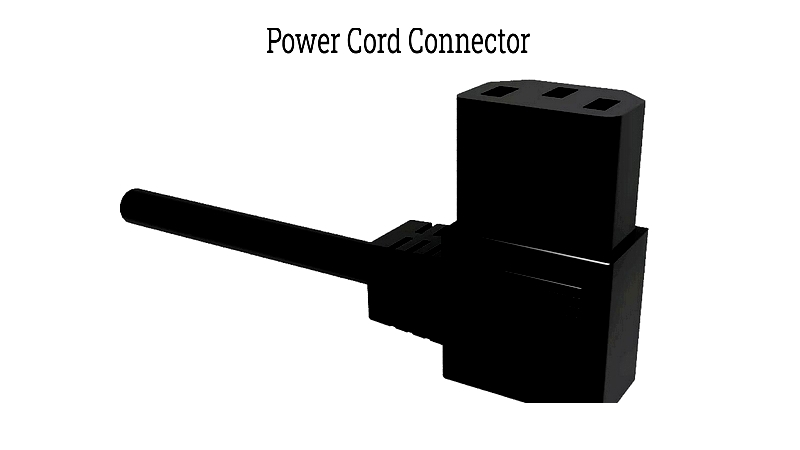

Connector

Temporary attachment points in power cord assemblies, ensuring compatibility and safety. Various types serve different applications in modular cord systems.

Appliance Inlet

The appliance component that accepts power cord connectors. Standardized under IEC 60320, these ensure proper matching for safe operation.

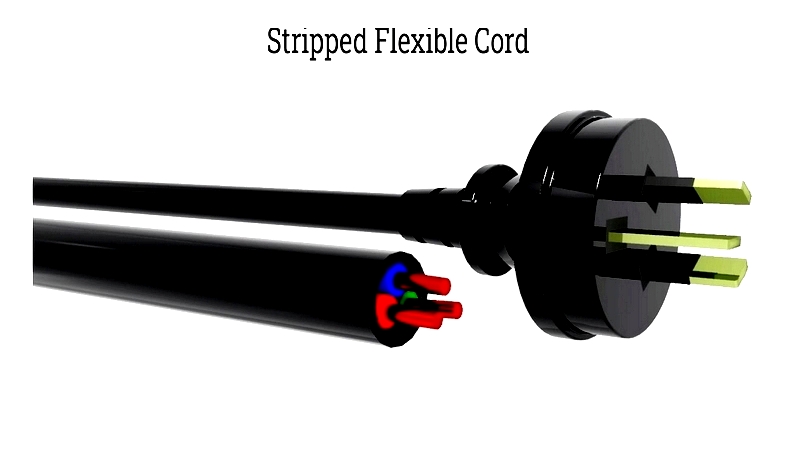

Flexible Cord

The insulated, stranded wire portion of power cords, offering durability and flexibility. Available in various lengths with different temperature and abrasion ratings.

Power cords may have 2 or 3 cores depending on electrical system requirements. Color coding identifies live, neutral, and ground wires according to regional standards.

Additional features may include grounding wires and specialized jacket materials for environmental resistance.

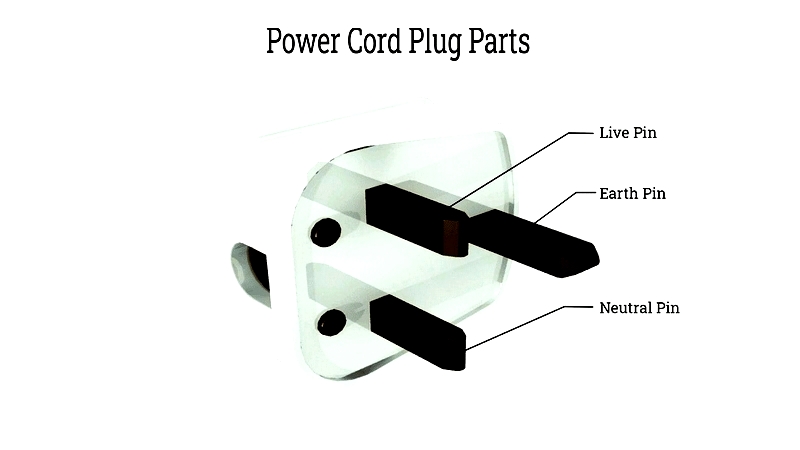

Pin

Conductors on plugs that complete electrical circuits when connected. Configuration varies by regional standards and safety requirements.

Live Pin

The conductor supplying current from the power source. Proper identification is crucial for safe installation.

Neutral Pin

Provides the return path for electrical current. Correct wiring ensures proper function and reduces shock risks.

Earth Pin

The grounding connection for appliance safety. Typically longer than other pins to ensure proper grounding sequence.

Insulated Sleeves

Protective coverings on plug pins that prevent accidental contact. These safety features comply with international electrical standards.

Polarized Connection

Designed for specific orientation to prevent incorrect wiring. Common in North American residential applications for enhanced safety.