Introduction

This guide provides comprehensive information about self-drilling screws.

You will learn about:

- What self-drilling screws are

- Their applications

- Manufacturing process

- Industries that utilize them

- And more...

Self-Drilling Screws with Indented Hex Washer

Self-Drilling Screws with Indented Hex Washer (from fordfasteners.com)

Chapter 1: Understanding Self-Drilling Screws

Self-drilling screws feature a unique drill-bit-like tip that creates its own hole. As the name suggests, these screws eliminate the need for pre-drilled pilot holes, making them excellent fasteners. They are designed to penetrate materials including soft steel, wood, and various metals.

Choosing the right self-drilling screw requires considering several application-specific factors. Key considerations include material type and thickness, as different screws are optimized for different materials. Additionally, evaluating the drill load—the force applied during installation—is crucial for successful application.

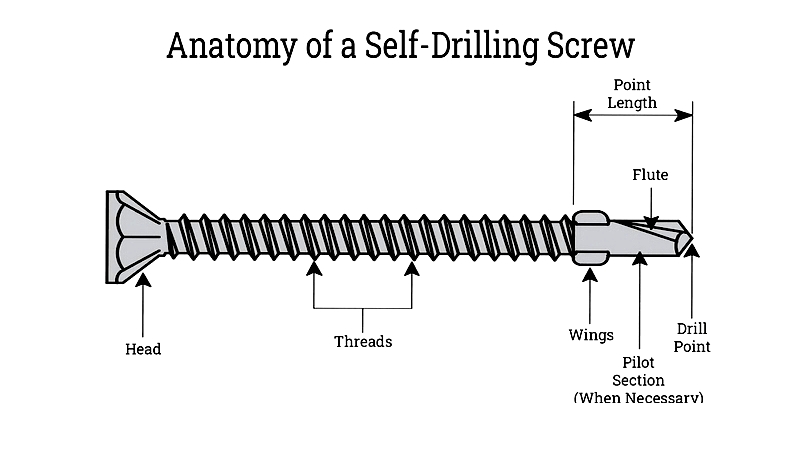

Before using a self-drilling screw, it's important to assess the materials being joined. Critical factors for effective performance include point types (such as flute designs), length, and the presence of wings.

Chapter 2: How Self-Drilling Screws are Used

Commonly called Tek® screws or self-piercing screws, these innovative fasteners enable quick and secure installation. Essential in modern construction and manufacturing, they allow professionals and DIYers to efficiently join metal, wood, plastic, and other materials. Their drill-shaped points eliminate pilot hole requirements, streamlining assembly, boosting productivity, and accelerating projects. The precise thread design ensures reliable grip and durable, vibration-resistant connections across diverse applications, making them indispensable in commercial, residential, and industrial projects.

Various self-drilling screw types suit numerous construction, engineering, and fabrication tasks. From metal roofing to final assembly work, they provide crucial fastening solutions in manufacturing, metalworking, sheet metal fabrication, HVAC systems, machinery, and general production. Options include corrosion-resistant coatings (like zinc-plated or stainless steel), multiple drive types (Phillips, hex, Torx), and specialized head styles, ensuring optimal performance for every environment and substrate.

While often confused with self-tapping screws, self-drilling screws differ in engineering and mechanics. The key distinction is the point: self-drilling screws have twist-drill-bit-shaped tips that penetrate materials on contact. In contrast, self-tapping screws (which form or cut threads) may have pointed, blunt, or flat tips and typically require pilot holes, especially in tougher materials. Understanding these differences ensures proper screw selection for each application, optimizing safety and durability.

Roofing Applications

metal roofing self-drilling screws typically include bonded neoprene washers to create weather-tight seals. These roofing fasteners prevent water intrusion and are ideal for corrugated metal sheets, steel panels, and cladding systems where leak prevention is critical. Like other self-drilling screws, their drill-bit-shaped points simplify and accelerate insertion while minimizing material fractures and improving roof integrity. Stainless steel or coated versions offer enhanced corrosion resistance for harsh rooftop environments.

Self-Drilling Screw with Washer (from fordfasteners.com)

Self-Drilling Screw with Washer (from fordfasteners.com)

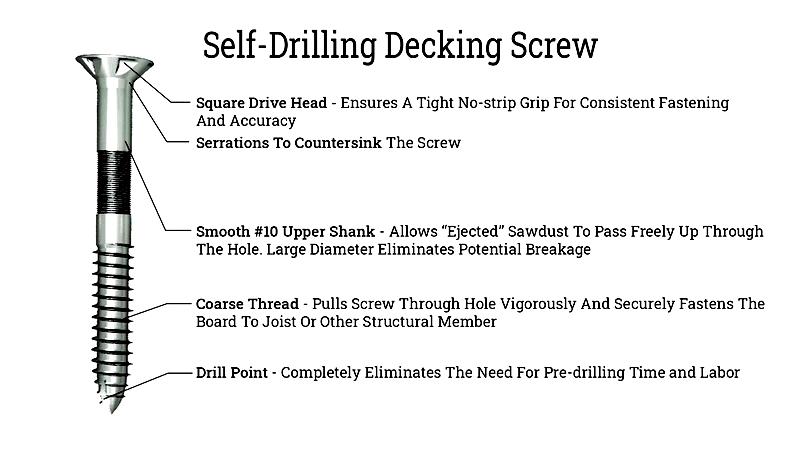

Decking Installation

Before self-drilling screws, builders needed to pre-drill pilot holes, especially for hardwoods and composite decking. These screws revolutionized the process by eliminating pre-drilling, significantly reducing time and labor costs while enabling precise, high-speed fastening. Featuring hardened drill tips and corrosion-resistant coatings, deck screws withstand outdoor conditions and provide rust-proof performance when securing deck boards to joists. This advancement ensures stronger connections, minimal splitting, and cleaner finishes.

Sheet metal Fabrication

Essential for framing, ductwork, enclosures, and industrial products, self-drilling screws accelerate production while ensuring firm, vibration-resistant connections. Their integral drill tips excel at penetrating 20 to 14 gauge metals, outperforming traditional methods and offering superior pull-out resistance. Common uses include HVAC installation, steel furniture manufacturing, automobile assembly, and building facades. Advanced materials like coated carbon steel, stainless steel, or bi-metal designs enhance longevity for indoor and outdoor applications.

Medical Engineering

In orthopedics, spinal surgery, and tissue repair, medical-grade self-drilling locking screws (often titanium or surgical stainless steel) enable rapid insertion without pre-drilling, reducing surgery time and thermal necrosis risk. Proper use requires precise length calibration and biomechanical stability assurance. These screws are vital in trauma plating systems and meet strict medical device fastener standards.

Framing and Structural Steelwork

Self-drilling framing screws connect heavy-duty metal studs and cold-formed steel components. Specialized drive heads (wafer, hex, or pan) facilitate high torque application while maintaining strong holding power. Capable of penetrating up to 0.125-inch-thick metals at ~1500 RPM, these structural fasteners come in hardened carbon steel and alloy steel. Whether joining metal lath, channel framing, or 12-20 gauge sheets, they ensure code-compliant, load-bearing connections crucial for commercial and industrial buildings.

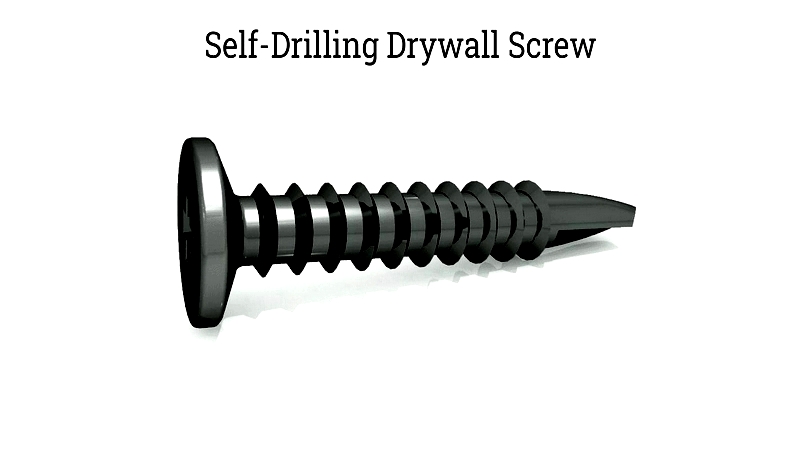

Drywall Installation

Drywall self-drilling screws feature sharp points and bugle heads that embed cleanly into gypsum board, preventing tears and pops. Typically phosphate-coated for corrosion resistance, they come in 6, 7, 8, and 10 diameters. Their thread geometry securely fastens to wood and metal studs in walls/ceilings, improving speed and reducing overdriving/stripping risks. Rolled threads provide strong holding power, making them a contractor favorite for interior construction.

Concrete and Masonry Fastening

Concrete self-drilling screws (or masonry drill screws) are designed for concrete, brick, and block. Unlike softer materials, masonry requires pilot holes for thread engagement. Available in 3/16-3/4 inch diameters, these anchoring screws come in flat head Phillips or slotted hex styles for flush or tamper-resistant finishes. Structurally certified, they ensure secure attachment of framing members, fixtures, or plates to masonry surfaces.

Trim Head Fasteners

Trim head self-drilling screws have slender, discreet heads that countersink below wood, MDF, or laminate surfaces. Ideal for cabinetry, molding, and finish carpentry, their self-drilling tips