Introduction

This article covers everything you need to know about industrial blenders and their applications.

You will learn about:

- What Industrial Blenders Are

- Types of Industrial Blenders

- The Difference Between Blenders and Mixers

- How Industrial Blenders Are Manufactured

- Industrial Blender Applications

- Materials Processed in Industrial Blenders

- And much more...

Chapter One – What is an Industrial Blender?

An industrial blender is large-scale equipment designed to mix and homogenize various manufacturing materials in sizable containers. These machines are valued for their ability to effectively blend materials and facilitate reactions between them, making them suitable for numerous industrial applications. Their substantial capacity and cost-efficient operation contribute to their widespread use in various mixing processes.

Industrial blenders are commonly used in scientific applications requiring precise chemical and pharmaceutical mixing. Their ability to provide accurate measurements and consistent results makes them essential for combining substances precisely, often using advanced PLC programming to control the mixing process.

Most blenders are constructed from stainless steel. However, when strict sanitation isn't necessary, they can also be made from materials like steel, cast iron, or aluminum.

Chapter Two – Types of Industrial Blenders

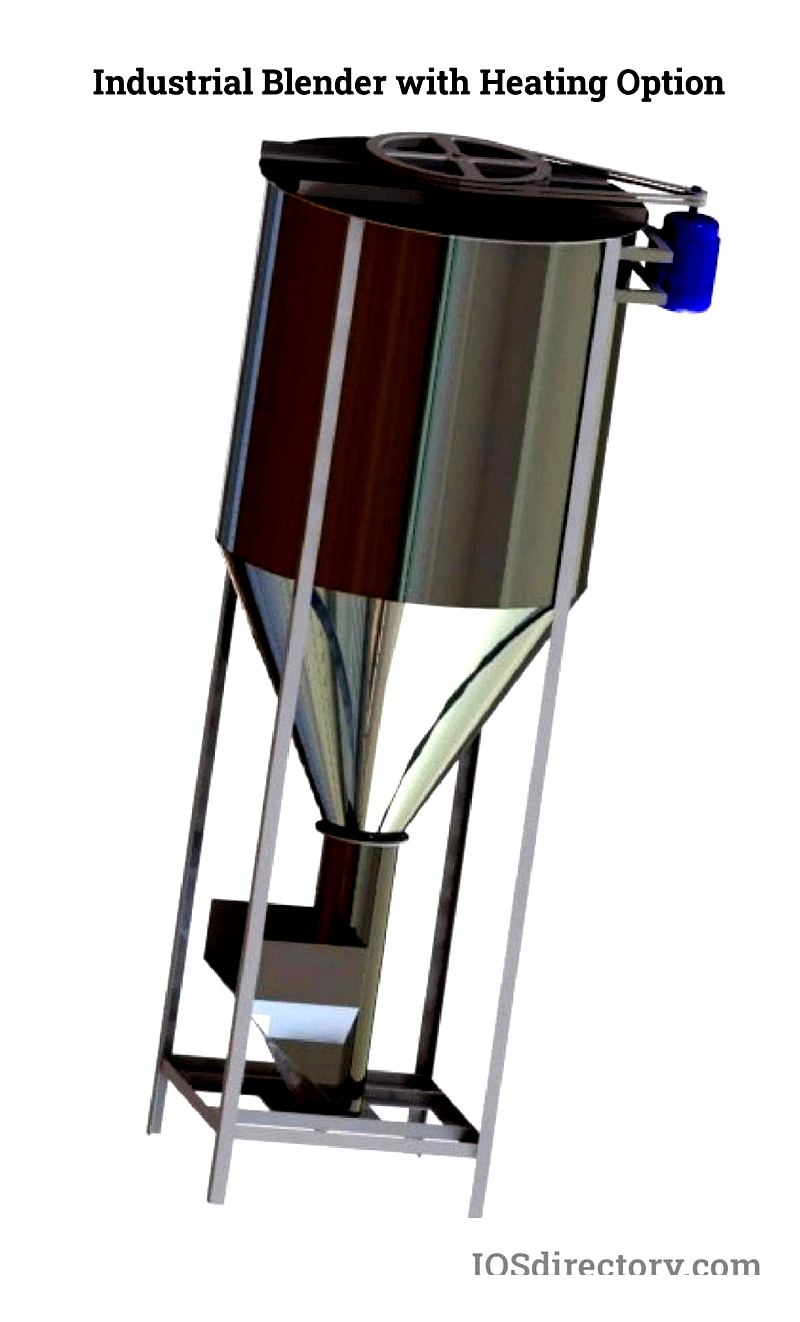

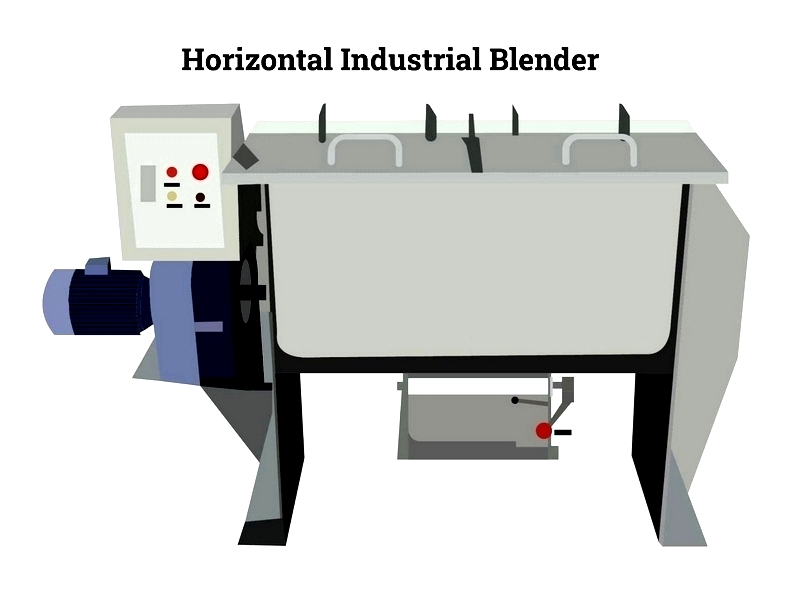

Industrial blenders come in various types, each designed for specific mixing applications. They can process diverse materials including solids, liquids, powders, granules, viscous pastes, abrasive substances, and even stones. Selecting the right industrial blender significantly impacts process efficiency, production consistency, and product quality across industries like food processing, pharmaceuticals, chemicals, construction, plastics, and cosmetics.

Choosing the appropriate industrial blender ensures it suits the processed materials and meets industry requirements for scale, consistency, and throughput. With options ranging from batch blenders to continuous mixing systems, finding the right blender for dry mixing, liquid blending, dispersion, emulsification, or homogenization requires careful evaluation of process needs and desired outcomes.

Industrial Blender Types

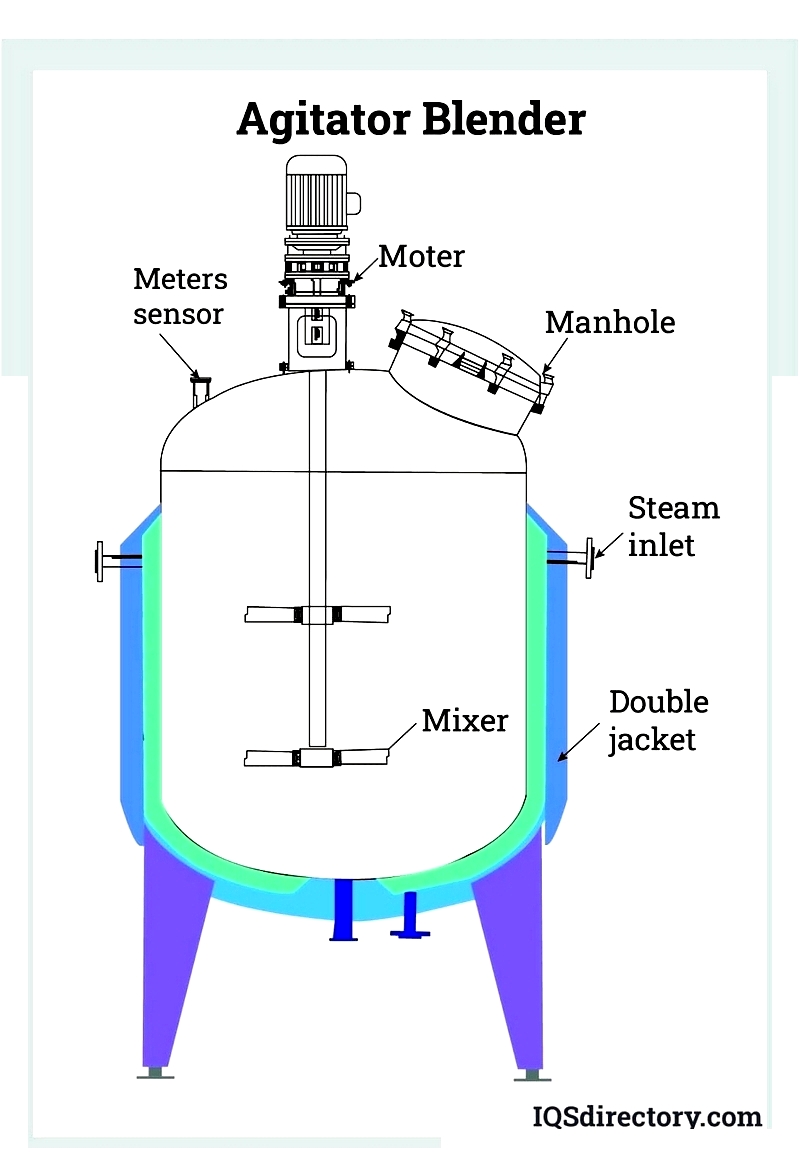

Agitator Blender

Agitator blenders provide continuous liquid mixing through constant motion. They use rotating paddles or impellers to agitate fluids, primarily handling low-viscosity materials like liquid solutions or light slurries. With sturdier paddles or upgraded motors, they can also process high-viscosity substances. Common in food processing, beverage, paint, and chemical manufacturing, they ensure uniform liquid mixing.

Paddle Mixer

Paddle mixers, a type of agitator, blend dry bulk materials and powders gently. They're used for coating nuts, mixing salads, blending pharmaceutical powders, or creating wet slurries. Some models support thermal applications like cooking while blending. Available in sizes from 5 cu ft to 500 cu ft, they accommodate both small-batch and large-scale mixing.

Paddle blenders operate with paddles on a central shaft, stirring materials in a tumbling motion for thorough mixing. They may include discharge valves or tilting mechanisms for efficient batch changeover. Operating at slower speeds protects particle integrity, making them ideal for food processing, nutraceuticals, chemicals, and animal feed production.

Emulsifiers

Emulsifiers mix immiscible substances like water and oil. The process forces materials through filters or perforated plates to break down molecular structures, enabling effective combination. Essential for stable emulsions in products like mayonnaise, creams, lotions, and dressings, they may use emulsifying agents for tougher materials.

Unlike blade-based blenders, emulsifiers employ specialized mixing chambers or high-shear heads for rapid, uniform consistency. Industries like cosmetics, pharmaceuticals, and food processing rely on them for product stability and quality.

Dual Shaft Blender

Dual shaft blenders have two adjacent tubs with central shafts. The shafts may rotate in parallel, opposing, or reversing directions, powered by single or separate motors. Close spacing allows material transfer between shafts, while wider spacing prevents contact.

With dual motors, shafts can operate at different speeds or directions, offering versatile mixing capabilities. Equipped with ribbon or blade elements, they excel in processing high-viscosity materials, adhesives, and pastes.

Ribbon Blenders

Ribbon blenders use elongated, ribbon-shaped blades for mixing solids. These blades rotate around a central axis, effectively breaking up lumps in stored liquids. The helical mixing tool creates a spiral flow, moving material upward along the edges and downward in the center.

Versatile for powders, pellets, flakes, granules, pastes, and dough, they're used in food, pharmaceuticals, chemicals, and plastics for dry blending and batch processing.

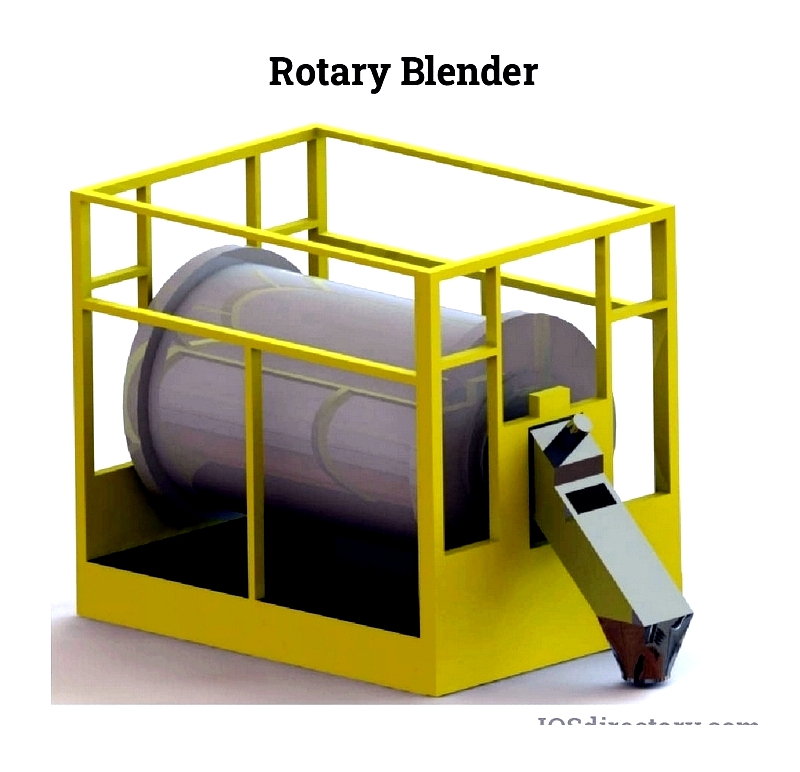

Rotary Blenders

Rotary blenders, or drum blenders, use welded baffles or lifting scoops instead of blades. This gentle design avoids shearing sensitive materials, ideal for fragile products and bulk powders.

The fluidizing effect from each rotation blends materials efficiently with minimal degradation. Suitable for seeds, grains, supplements, and minerals, they're preferred for homogeneous batch blending.

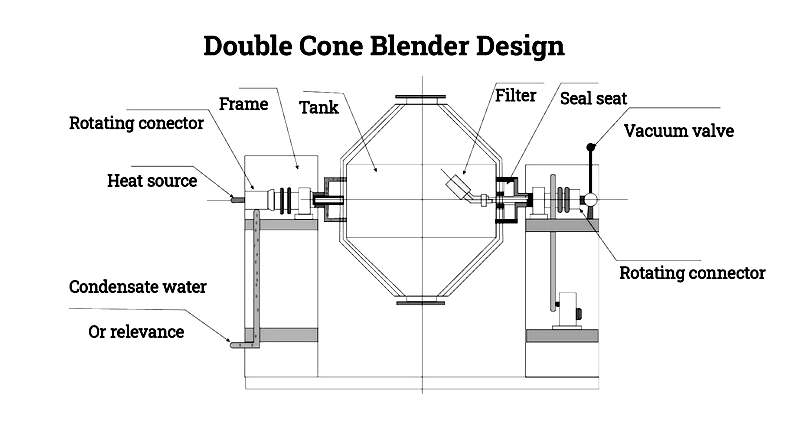

Double Cone Blender

Double cone blenders, or tumble blenders, rotate to mix materials with a compact footprint. As cones rotate, contents move to the vessel bottom for uniform mixing. Access covers facilitate cleaning and inspection, meeting sanitary standards.

Using free flow, they gently blend granules and powders, mixing up to five ingredients simultaneously. Ideal for pharmaceuticals, food, and metal powder processing.

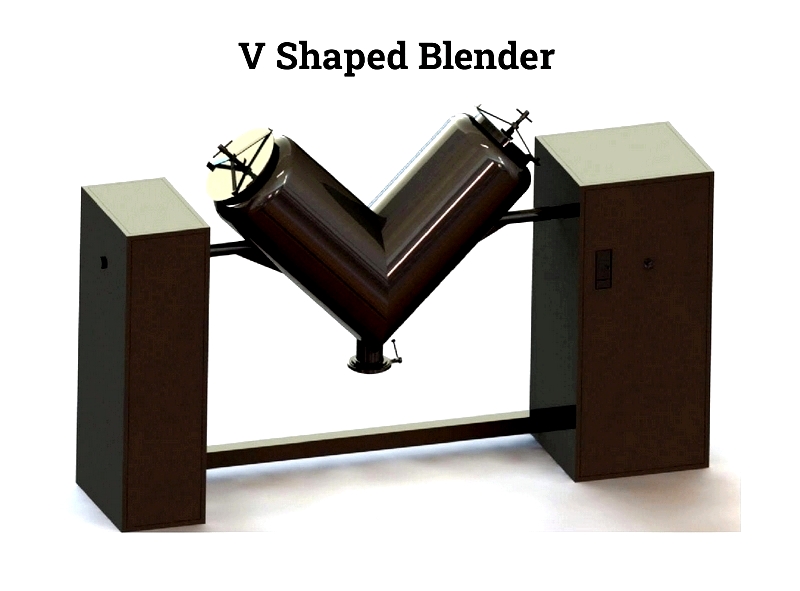

V Shaped Blender

V-shaped blenders tumble materials in a metal V structure. Materials divide between wings and blend back together during rotation. Welded at 75° or 90° angles, they achieve efficient blending with minimal rotations.

Like double cone blenders, they mix free-flowing powders and bulk solids. Top openings enable easy discharge and fast batch turnaround in pharmaceuticals, nutraceuticals, and food industries.

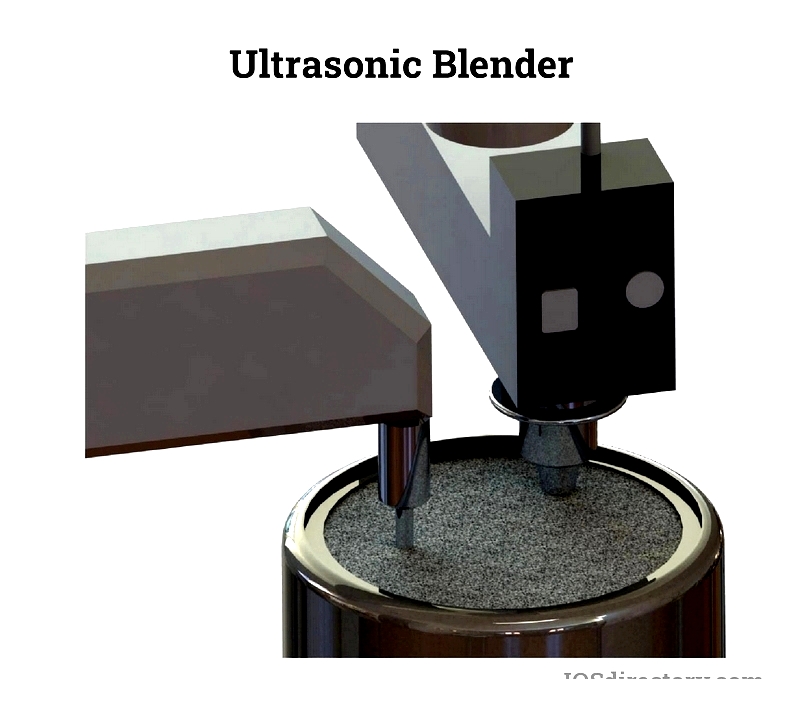

Vibrational Blenders

Vibrational blenders use ultrasonic waves to mix fine powders. Ultrasonic cavitation creates vacuum bubbles that collapse, dispersing particles throughout the liquid.

Precise control over wave amplitude, frequency, and duration makes them suitable for pharmaceuticals, nanotechnology, and electronics for particle reduction and emulsification.