Introduction

This article provides an in-depth exploration of Broaching.

You will learn about various aspects including:

- What is Broaching?

- Machinery used for Broaching

- Different types of Broaches

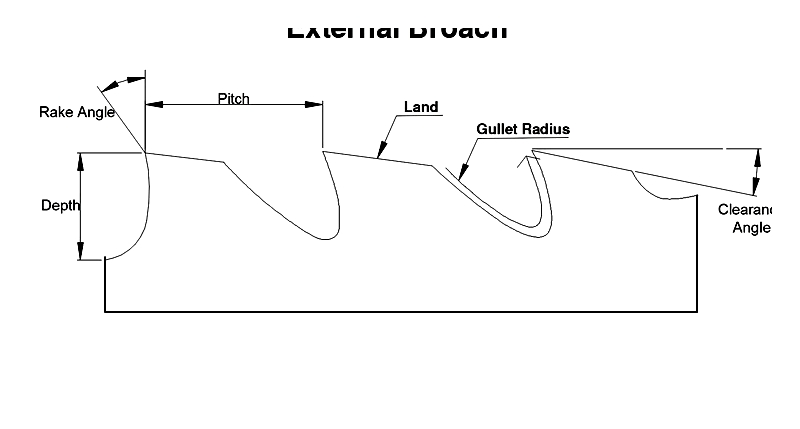

- Broaching tool design terminology

- And much more...

Chapter One - What is Broaching?

Broaching is a precise machining process that uses a hardened tool with serrated edges to systematically remove material from a workpiece. This method employs a tool featuring teeth of varying sizes, which progressively shave off material with each pass over the workpiece.

In broaching, the multi-toothed tool either moves while the workpiece remains stationary or vice versa. In some cases, there may be relative rotational movement between the tool and workpiece. Broaching can be performed internally through the workpiece's center or externally along its surface.

External or surface broaching includes techniques like slab, slot, contour, pot, and straddle broaching. Internal broaching encompasses methods such as keyway, concentricity, and cut recut. The specific broaching technique depends on the workpiece section being machined.

Chapter Two - The Broaching Process

Broaching is a widely used machining technique for precisely removing material to create specific contours, shapes, and profiles. As a specialized metalworking process within subtractive manufacturing, it's valued for efficiently producing intricate internal and external geometries in high-precision industries like automotive and aerospace. Unlike milling, turning, or drilling, broaching uses purpose-built tools with progressively sized cutting teeth to achieve accurate results in a single pass.

The broach presses, pulls, or pushes against the workpiece to form precise holes, slots, teeth, or patterns. This enables manufacturers to create unique internal features (keyways, splines) and external features (surfaces, slots) that are often difficult or inefficient to produce with other methods. Broaching excels in speed, repeatability, and cost-effectiveness for mass production while delivering superior surface finishes.

Broaching Machine

A broaching machine is a straightforward CNC or manual industrial tool consisting of a broaching tool, holding fixture, drive mechanism (typically hydraulic or electromechanical), and sturdy frame. The two main types are horizontal and vertical machines, which may feature single or multiple rams for improved efficiency. These machines operate by pulling or pushing the broach through or past the workpiece.

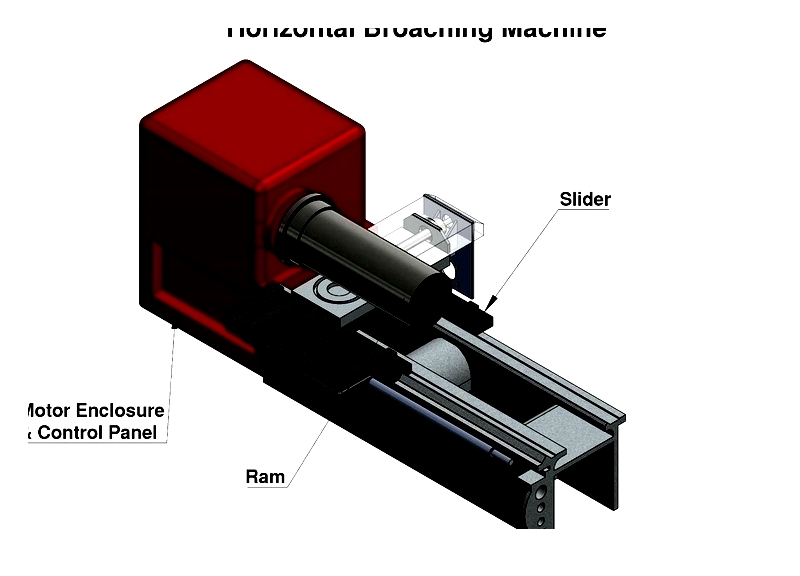

Horizontal Broaching Machine

Horizontal machines use pull-type broaching, ideal for internal applications and some external work. Commonly used for keyways, splines, and complex internal shapes, they feature an elongated bed and broach pilot for alignment. While requiring significant floor space, they offer high accuracy and quick changeovers.

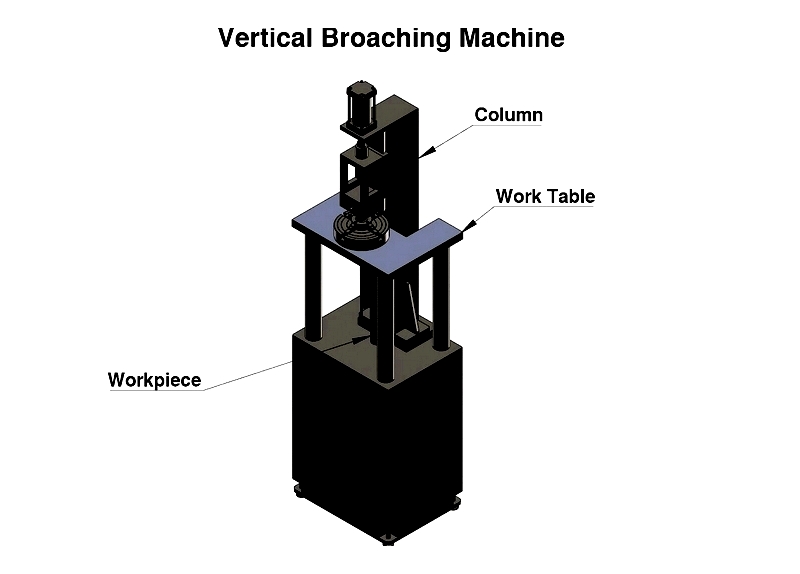

Vertical Broaching Machine

Vertical machines push or pull the tool vertically relative to the workpiece, offering versatility for both internal and surface broaching. The three main types (push down, pull up, pull down) cater to different production needs, with hydraulic models providing superior force control.

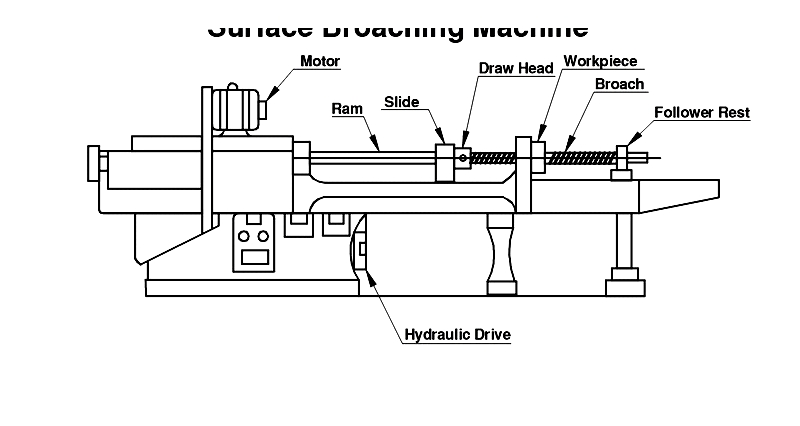

Surface Broaching Machine

Designed for flat or contoured surfaces, these machines use reciprocating rams to cut multiple profiles in one pass. They're efficient for complex contours on components like turbine blades and pistons, available in horizontal or vertical configurations.

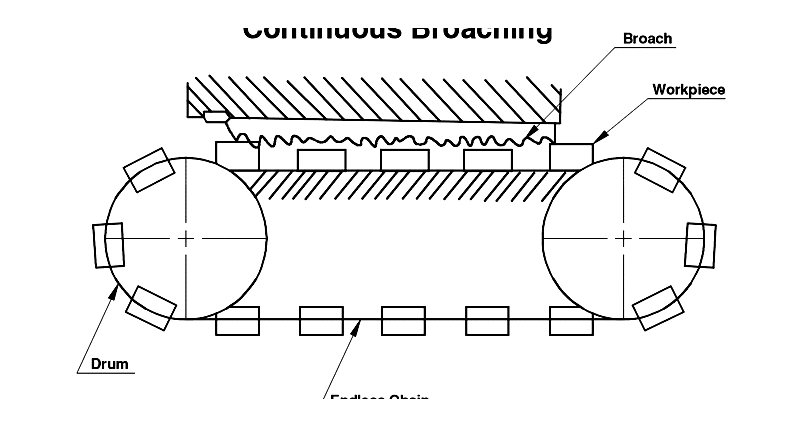

Continuous Broaching Machine

In continuous broaching, workpieces move steadily past stationary broaches via conveyor systems. Ideal for mass-producing identical parts like gears and fasteners, this method maximizes productivity in high-volume manufacturing.

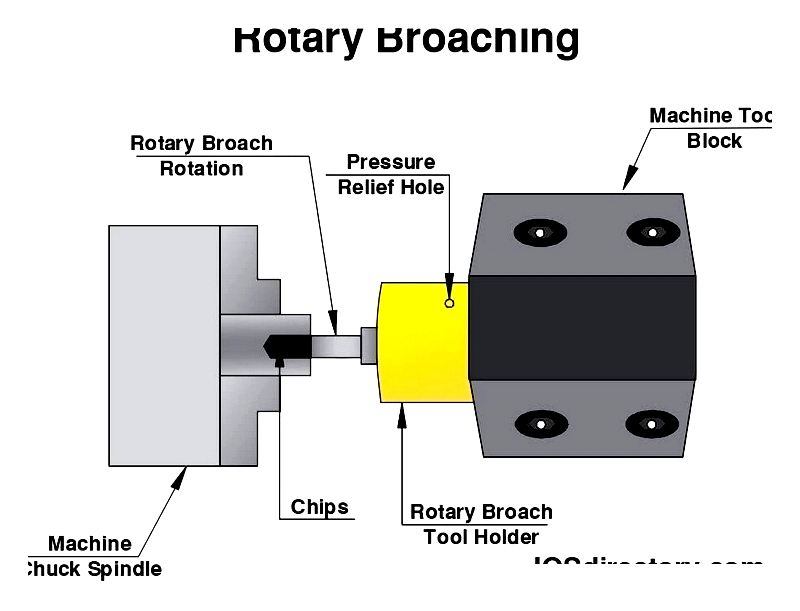

Rotary Broaching Machine

This precision method creates intricate polygonal shapes by angling the broach 1° from the workpiece centerline. Valued in aerospace and medical industries, it produces finished forms in one quick pass with tight tolerances.

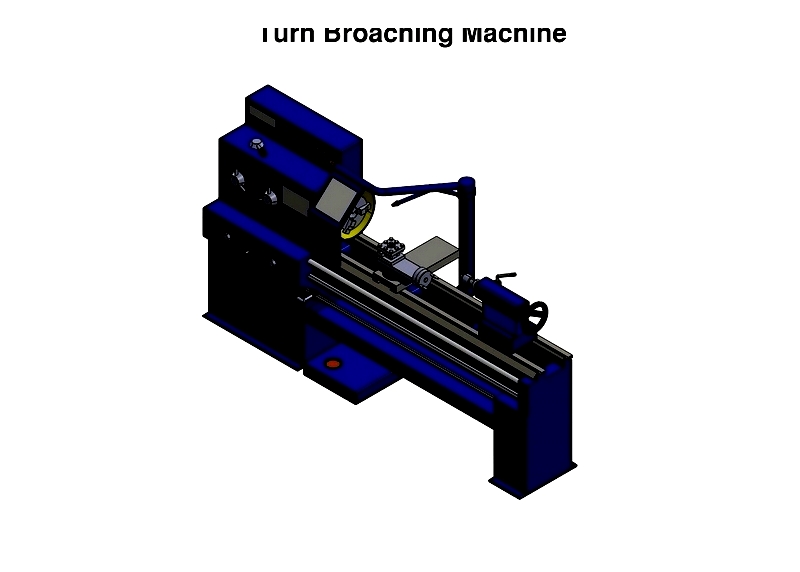

Turn Broaching Machine

Used for circular, linear, and spiral cutting, these machines combine rotating workpieces with multi-insert tools. They're preferred for high-quality finishes on components like crankshafts in automotive and aerospace applications.

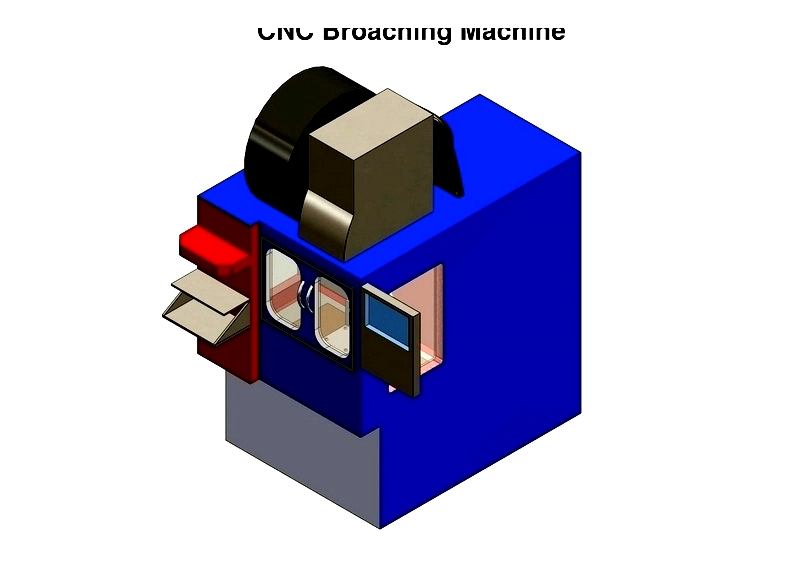

CNC Broaching

CNC technology has transformed broaching with programmable tool paths and automation. These systems handle diverse operations (rotary, keyway, spline) while improving surface finish and reducing cycle times for precision components.

In summary, broaching encompasses various techniques and machines for different applications. Understanding each type's capabilities helps manufacturers optimize processes for quality and efficiency in metalworking production.

Chapter Three - Leading Broaching Machines

Broaching requires precision and durability to meet modern manufacturing standards. Leading manufacturers have advanced the industry through innovative designs and automation. Below are five renowned brands in the U.S. and Canada, highlighting their key models and distinguishing features.

Brand: American Broach & Machine Co.

Model: AB-2500H Broaching Machine

Description: Known for robust engineering, the AB-2500H excels in high-volume production for automotive and aerospace sectors. It offers computerized control, flexibility, and consistent dimensional accuracy.

Brand: Colonial Tool Group

Model: Colonial G-Series Broaching Machine

Description: This versatile machine handles both internal and surface broaching with advanced CNC controls and multi-station loading, ensuring high precision for complex metalworking.

Brand: Ohio Broach & Machine Co.

Model: OB Series Vertical Broaching Machine

Description: Featuring space-saving vertical designs, these machines provide efficient broaching with customizable options for various industrial applications.

Brand: Broaching Machine Specialties (BMS)

Model: BMS Horizontal Broaching Machine

Description: BMS horizontal machines offer reinforced structures for heavy-duty cycles and advanced controls for precision in diverse part geometries.

Brand: Nachi America Inc.

Model: Nachi Gear Cutting Broach Machine

Description: Specializing in gear manufacturing, Nachi machines deliver high-speed, high-torque performance with exceptional tolerance control for complex gear profiles.

For current specifications and support, contact manufacturers directly. Choosing the right machine depends on application needs, production volume, materials, and required tolerances.

Selecting the Best Broaching Machine

Consider these factors when choosing a broaching machine:

- Broach Type: