Introduction

This article provides an in-depth exploration of poster tubes.

It covers detailed information on the following topics:

- How Poster Tubes Work

- Different Types of Poster Tubes

- Common Uses of Poster Tubes

- Advantages and Disadvantages of Poster Tubes

Chapter 1: Understanding the Basics of Poster Tubes

This chapter explains the fundamental concepts of poster tubes and their practical applications.

What Is a Poster Tube?

A poster tube is a hollow cylinder, typically triangular or rectangular in shape, designed for transporting rolled artwork, important documents, or long narrow items. These tubes effectively prevent damage like bending, crushing, and creasing during transit. They're commonly used for architectural plans, sign banners, and large documents.

Available in various sizes at office supply stores and shipping outlets, poster tubes provide better protection than cardboard boxes. Their cylindrical design evenly distributes stress, while thick walls safeguard contents. Some models feature waterproof materials, shoulder straps, or zippered compartments for added functionality.

How Poster Tubes Are Designed and Used

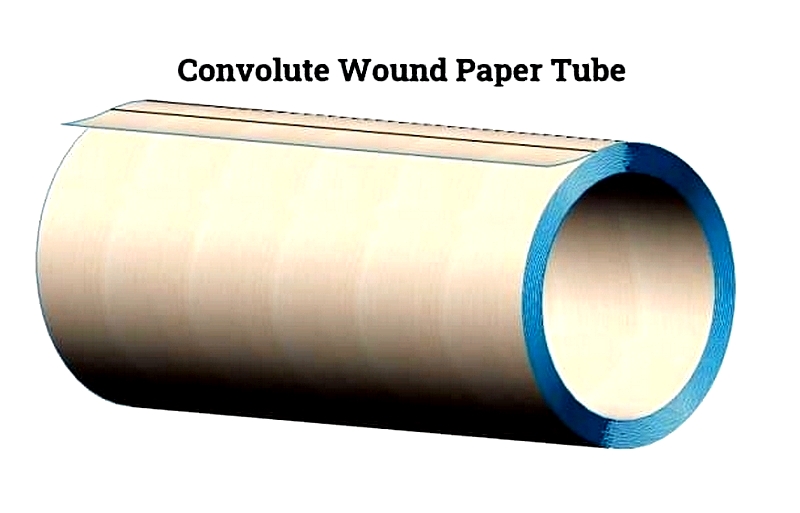

Made from wood pulp fibers, poster tubes are primarily cylindrical. Manufacturers layer cardboard, reinforce it with adhesive, then spiral it around a mandrel before cutting to length. Proper sizing is crucial - too large allows contents to shift, while too small risks bending or tearing.

Ideal tubes should slightly exceed the length of their contents. End caps, made of plastic, wood, or metal, secure the contents. Custom options include kraft paper finishes with printed designs or colors.

Chapter 2: Types of Poster Tubes

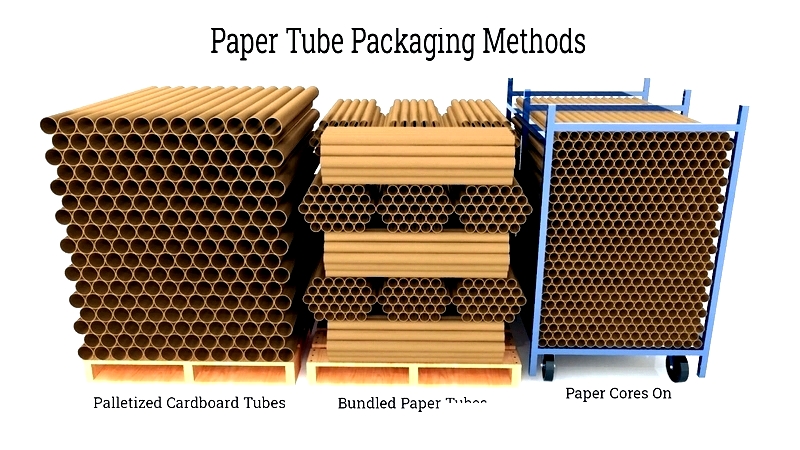

Modern packaging solutions protect valuable items like artwork and blueprints during shipping. As e-commerce grows, demand increases for reliable mailing solutions. Today's advanced poster tubes come in various shapes (round, triangular, square) and sizes, made from durable materials like cardboard, plastic, or metal.

Telescoping Poster Tubes

These adjustable-length tubes feature nested sections that slide for customization. Made from thick cardboard, they protect fragile items during shipping. Popular among artists and architects, they're ideal for industrial components and textiles.

Snap Seal Poster Tubes

Economical and easy to use, these tubes have one crimped end and one open end for loading. After insertion, the open end crimps shut without needing tape. Made from kraft paper, they're lightweight yet durable.

Triangular Poster Tubes

These three-sided tubes don't roll and stack securely. Made from die-cut corrugated board, they're ideal for engineering drawings and trade show graphics.

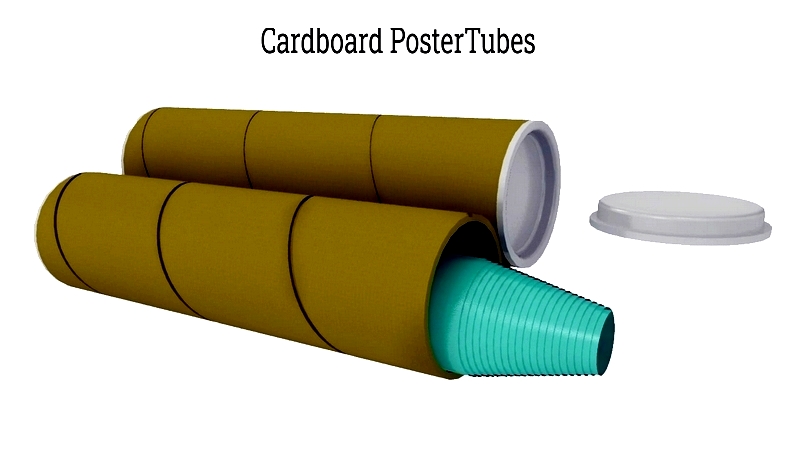

Plastic Plug Poster Tubes

Featuring removable plastic plugs, these moisture-resistant tubes protect against weather damage. Available in various sizes, they're perfect for fine artwork and valuable documents.

metal Poster Tubes

Constructed from steel or aluminum, these premium tubes offer maximum protection. Used in aerospace and defense industries, they secure sensitive materials during transport.

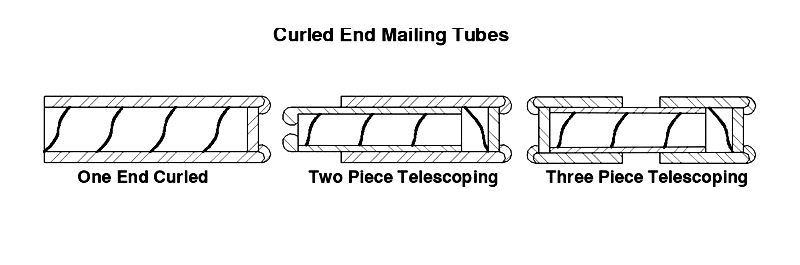

Curled End Poster Tubes

These tubes feature inward-folded edges sealed with paperboard covers. Their seamless design prevents crushing, making them suitable for archival storage.

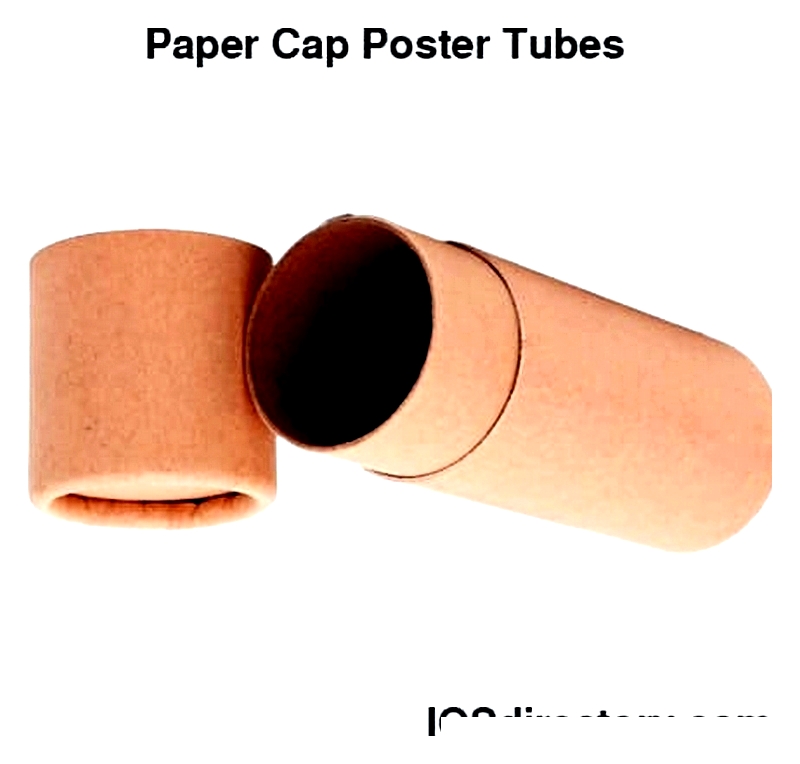

Paper Cap Poster Tubes

Traditional tubes with kraft paper end caps, these reusable options are cost-effective and eco-friendly. Commonly used for blueprints and student artwork.

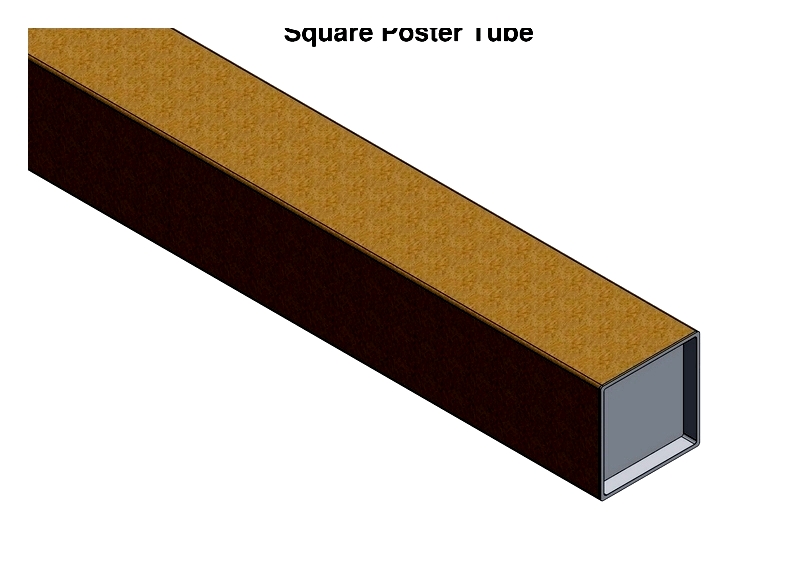

Square Poster Tube

With flat sides for stability, these corrugated tubes don't roll and stack efficiently. Ideal for bulk shipments and warehouse storage.

When selecting a tube, consider your specific needs: security requirements, moisture protection, or shipping method. This guide helps you compare features to choose the best option for your items.