Introduction

This article provides an in-depth examination of Concealed Hinges.

Continue reading to explore key topics including:

- What are Concealed Hinges?

- Fundamental Components of Concealed Hinges

- Varieties of Concealed Hinges

- Industrial-Grade Heavy Duty Hinges

- Specifications and Features for Industrial and Household Hinges

- And more...

Chapter 1: What is a Concealed Hinge?

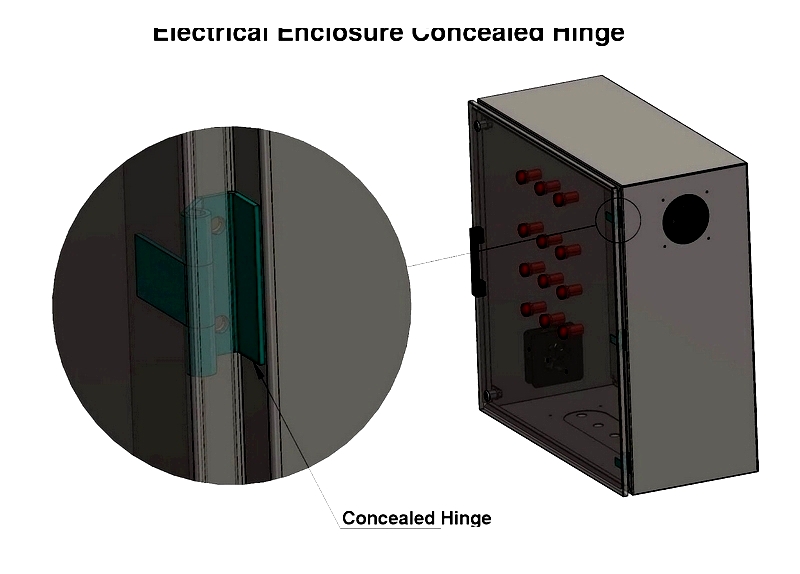

A concealed hinge, commonly called a hidden or European hinge, is designed to fit flush inside cabinet doors, aligning with the cabinet surface for a seamless exterior appearance. Available in multiple styles, these hinges vary in leaf designs, pin sizes, and dimensions. Industrial-grade concealed hinges support door weights between 50 lbs and 90 lbs, allowing easy installation of short, wide panels.

Modern concealed hinges accommodate various door styles and offer features like soft-close mechanisms, adjustable arms, and quick-detach options. They are typically made from materials such as steel, zinc, stainless steel, and aluminum. Heavy-duty models, built for commercial settings, often use aluminum, stainless steel, or cold-rolled steel with surface treatments like zinc plating or electropolishing for enhanced durability.

Chapter 2: Basic Components of Concealed Hinges

Concealed hinges, also known as European or hidden hinges, are essential in modern cabinetry, furniture, and enclosure manufacturing. Unlike traditional butt hinges, they remain invisible when doors are closed, offering a clean appearance. Key components include a pin, leaves, and knuckle, though designs vary by application. The cup hinge, a popular type, differs from conventional assemblies and often requires precise door drilling for optimal soft-close or self-closing functionality in kitchen and bathroom cabinets.

The enclosure hinge combines traditional design with a quick-release pin system, ideal for industrial electrical enclosures and server cabinets. This feature enables rapid door removal for maintenance, reducing downtime in environments like data centers and manufacturing facilities.

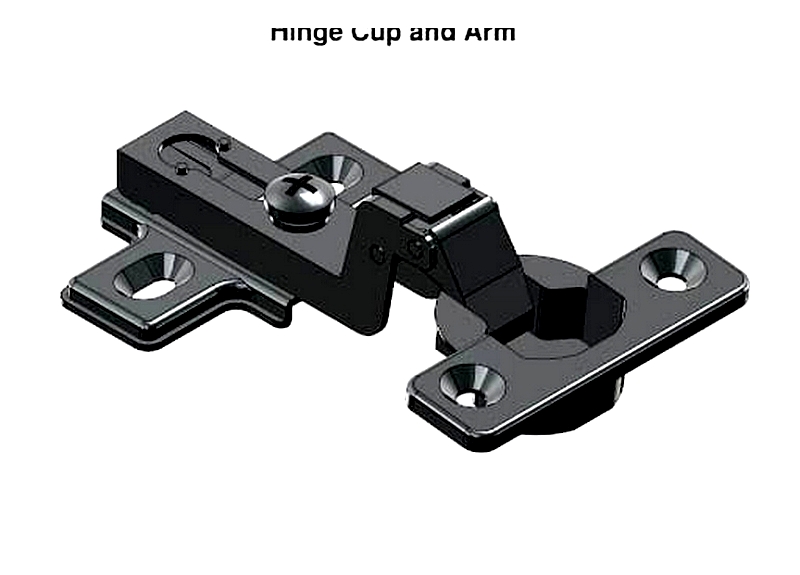

Cup Hinge Components

Hinge Cup

The hinge cup is a circular part attached to the cabinet door's interior. Standard bore diameters include 26 mm, 35 mm, and 40 mm, suitable for different door thicknesses. The cup's depth depends on the hinge arm design, with variations for heavy-duty applications. Dual flanges ensure secure screw fastening for long-term reliability. Selecting the correct cup diameter is crucial for systems requiring precise alignment, such as soft-close cabinets.

Hinge Arm

The hinge arm, made from high-strength steel or alloys, connects the cup to the mounting plate. It includes adjustment mechanisms like eccentric cams for fine-tuning door alignment, accommodating frameless and face-frame cabinetry. Options include standard, full overlay, half overlay, and inset hinges, each designed for specific clearance needs.

The concealed hinge assembly consists of the hinge cup and arm, ensuring smooth, hidden movement. Most sets include the main hinge and mounting plate, with compact versions available for limited-space applications.

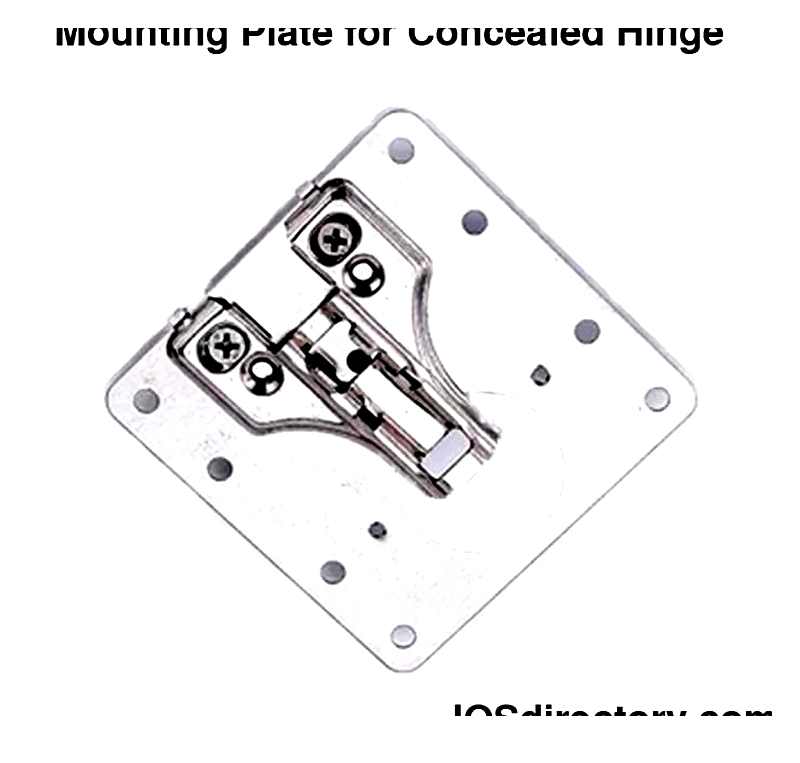

Mounting Plate

The mounting plate, secured to the cabinet frame, features notches or clips for hinge arm engagement. Available in various heights and offsets, it ensures uniform appearance in kitchens, offices, or lab casework. Proper plate selection is vital for silent soft-close operation in high-end cabinetry.

Industrial Enclosure Hinges

Industrial concealed hinges protect electronic components in harsh environments. Options range from basic models to advanced versions with tamper-proof fasteners and corrosion-resistant finishes. Custom solutions address unique load or security needs.

Curved Pivot Concealed Hinge

Curved Pivot

This mechanism ensures smooth door movement with minimal stress. Available with screw holes for wood or weld-ready versions for metal, it suits diverse installation needs.

Brackets

Designed for precise alignment, brackets may be pre-drilled or solid for custom machining, ideal for OEM or retrofit projects.

Pin

Removable pins enable quick door detachment for maintenance, commonly used in electrical panels or industrial control boxes.

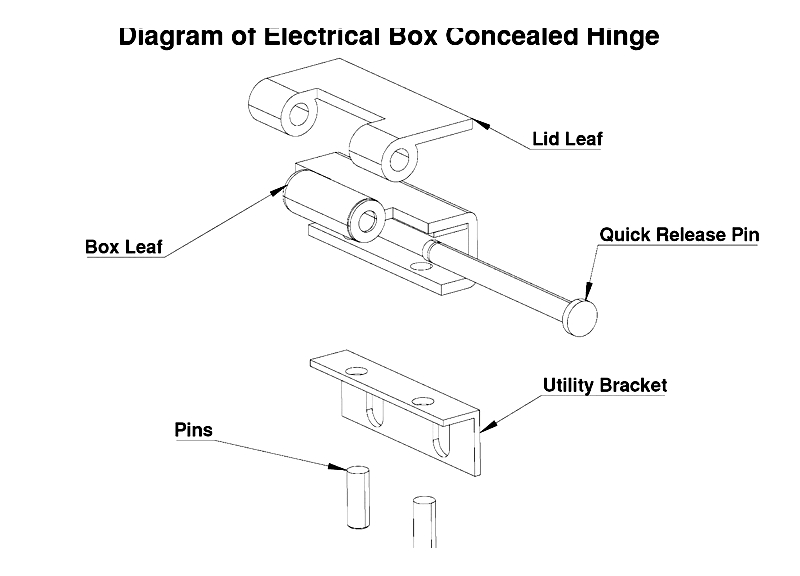

Electrical Box Concealed Hinge

These hinges provide secure access to electrical components, featuring durable materials for dust and moisture resistance. Key parts include:

Quick Release Pin

A sturdy pin simplifies door removal, essential for industrial maintenance and safety compliance.

Box Leaf

Precision-drilled holes ensure secure attachment to enclosure brackets.

Hex Bolts

Industrial hex bolts offer strength for heavy or frequently used doors.

Lid Leaf

Ensures smooth pivot action, critical for power distribution or control cabinets.

Selecting the right concealed hinge is crucial for achieving durability, security, and aesthetics. Whether for kitchen cabinets, commercial enclosures, or electrical boxes, understanding components ensures project success.

For assistance, consult our directory of hinge manufacturers or contact specialists for application-specific recommendations.