Introduction

This article provides an in-depth examination of graphite rods.

It covers detailed information on various aspects including:

- Working Principles of Graphite Rods

- Different Types of Graphite Rods

- Applications and Advantages of Graphite Rods

- And More...

Chapter 1: Understanding the Principles of Graphite Rods

This section examines the definition of graphite rods, their structural design, and fundamental operating principles.

What Are Graphite Rods?

Graphite rods are slender, elongated tools made from various materials including plastic, metal, ceramic, or organic compounds. Their simple design enables diverse applications depending on the materials and dimensions used.

Specially crafted from processed graphite, these rods demonstrate excellent resistance to thermal shock, extreme temperatures, corrosion, and chemical reactions. Their durability and stability result from graphite's non-fatiguing properties.

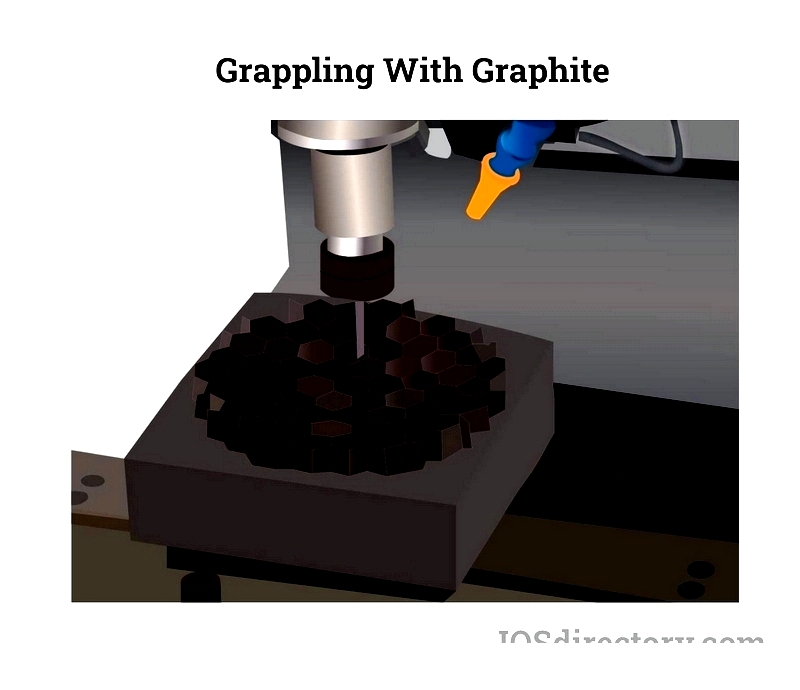

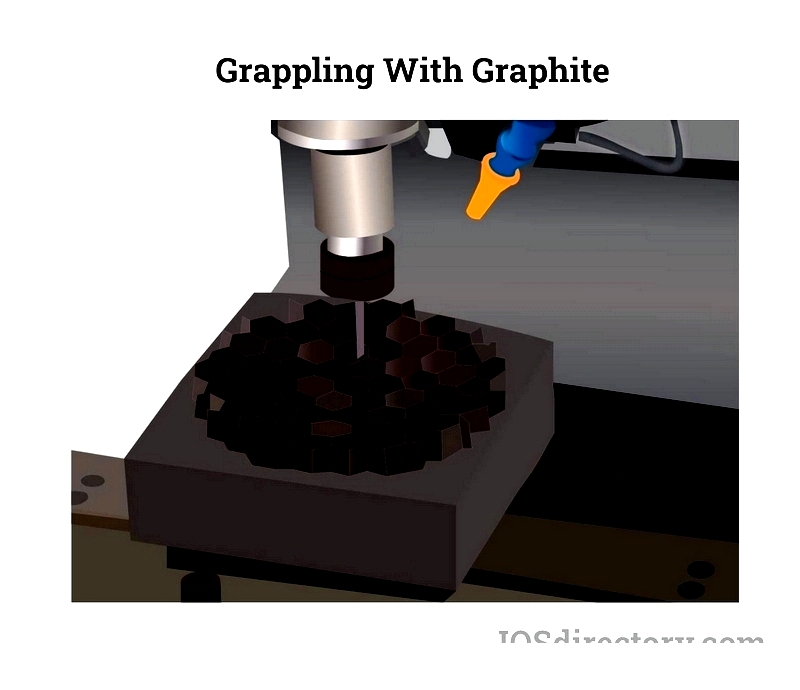

Graphite Machining Techniques

As one of the hardest materials, graphite plays a crucial role in industries from pencil production to EDM operations. Its strength often exceeds basic steel and carbon composites, making it ideal for demanding industrial uses. However, raw graphite requires machining for industrial applications.

Machining graphite involves shaping it for various applications, typically using diamond or carbide tools to overcome its hardness. Despite machining challenges, graphite offers numerous benefits including durability, corrosion resistance, and natural lubrication that reduces the need for additional lubricants.

Graphite Machining Methods

Graphite machining resembles cast iron processing, involving the removal of fine powder-like chips. Tools cut rather than grip the material.

Graphite's high compressive strength allows secure clamping during machining, though optimal clamping force must be determined to prevent material damage.

Specialized, durable tools are essential for machining graphite. Diamond-tipped tools are preferred for longevity, while tungsten carbide tools are also effective. High-speed steel has limited use due to shorter lifespan. Incorrect tool use or machining parameters may cause chipping and material breakage.

Graphite Formation

Composed of layered carbon atoms, graphite derives its unique properties from this structure. While naturally occurring deposits exist worldwide, major sources are found in China, Brazil, Canada, and Madagascar. It forms under high pressure and temperature conditions in metamorphic and igneous rocks.

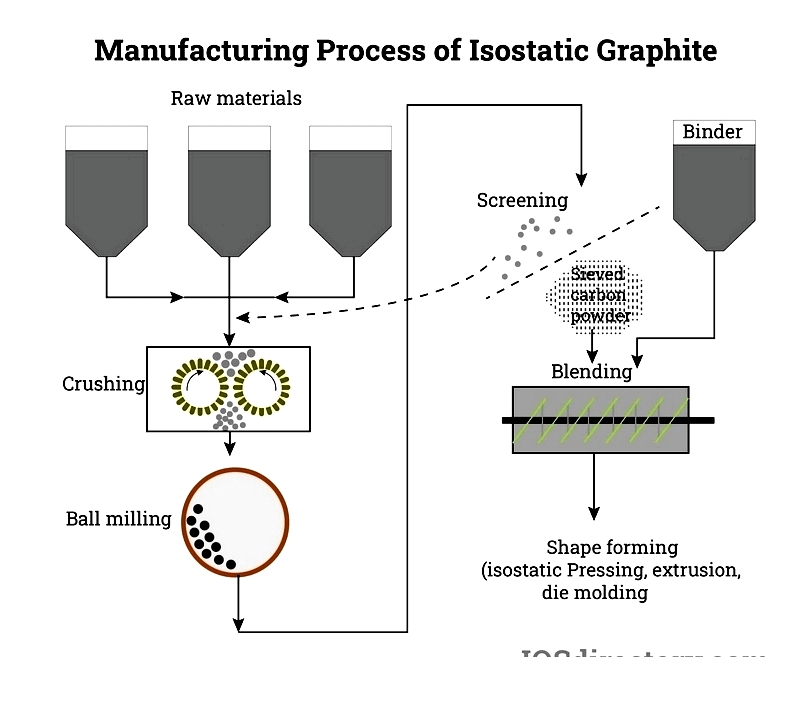

Synthetic graphite, made from high-purity carbon, offers superior resistance to extreme temperatures and corrosion. Typically produced from calcined petroleum coke and coal tar pitch, these materials undergo blending, heat treatment, molding, and baking in a complex manufacturing process.

Graphite Rod Production

Common production methods include compression molding, isostatic pressing, and rod extrusion, similar to techniques used for graphite tube manufacturing.

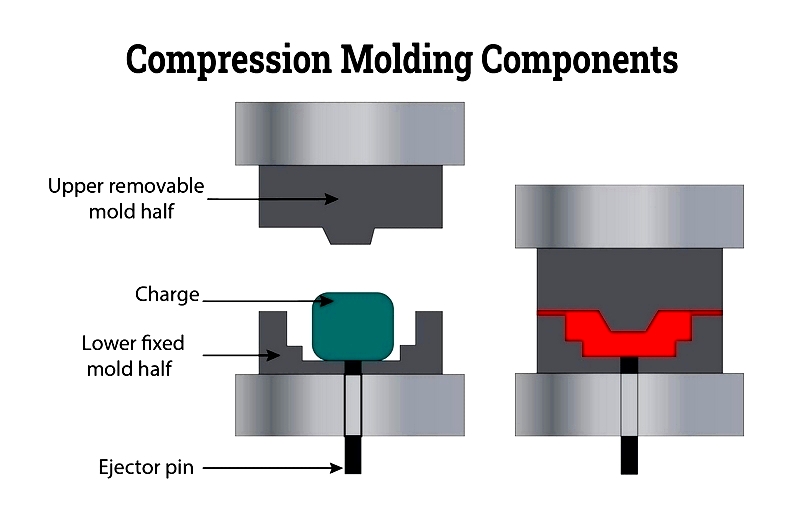

Compression Molding

This method softens material before pressing it into a preheated mold. Pressure and heat enable the material to fill the mold's shape until curing completes the process.

Mold Preheating

Preparation involves cleaning the mold, applying release agent, and heating to optimize material viscosity.

Material Preparation

Materials are unpacked, cleaned, sized, weighed, and heated to prepare them for compression, accommodating various shapes and conditions.

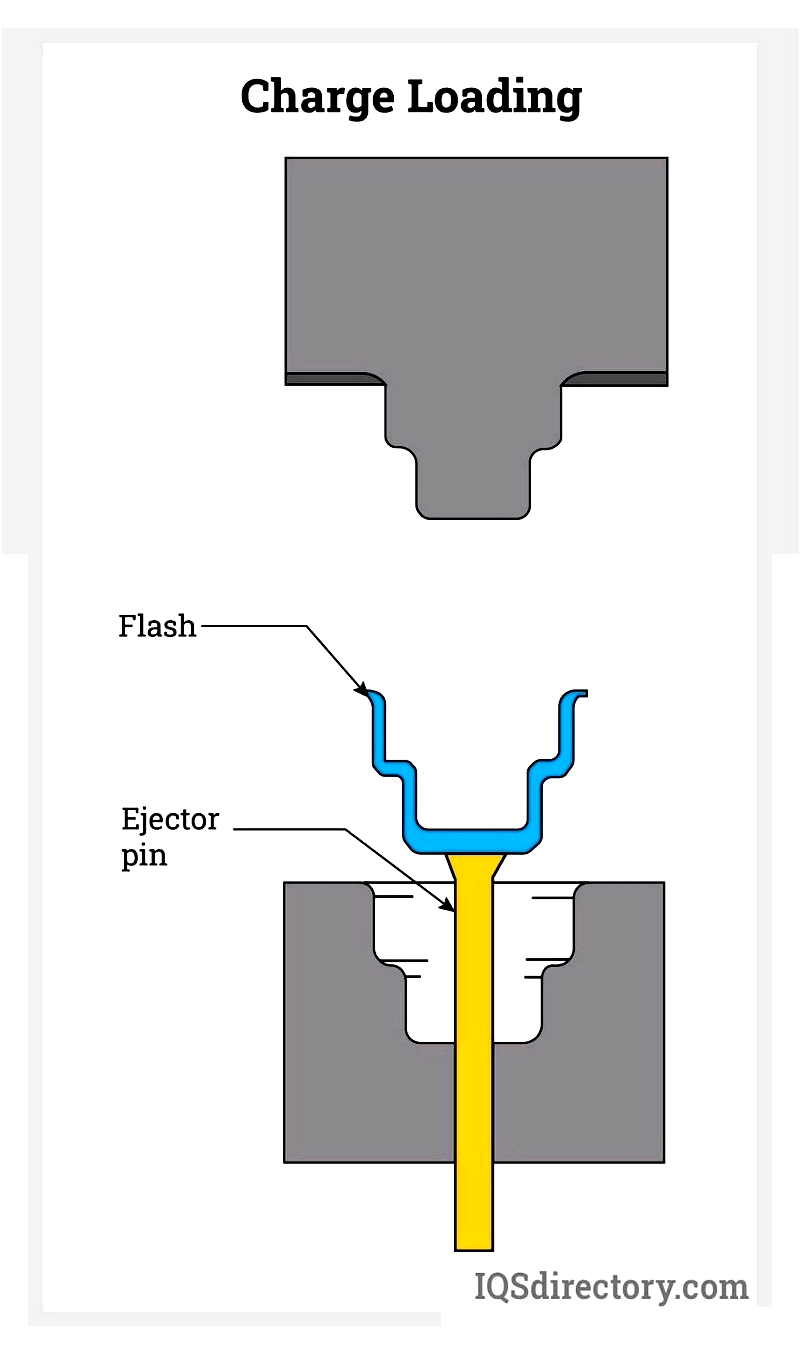

Material Loading

The material is positioned in the mold base to ensure proper compression, considering factors like required thickness and specifications.

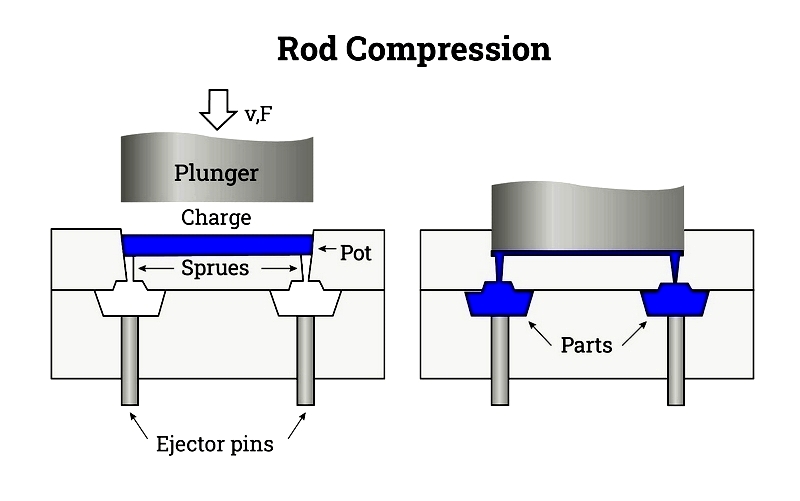

Rod Compression

The mold halves close, compressing material to fill the cavity accurately and achieve proper density before curing.

Curing Process

Curing transforms compressed material into the final product using temperature control or hardening agents.

Mold Cooling

Cooling prepares the mold for reuse, establishing necessary thermal and mechanical properties for efficient removal and storage.

Graphite Ejection

Automated ejection removes graphite after curing, aided by release agents and using plungers or suction systems to prevent sticking.

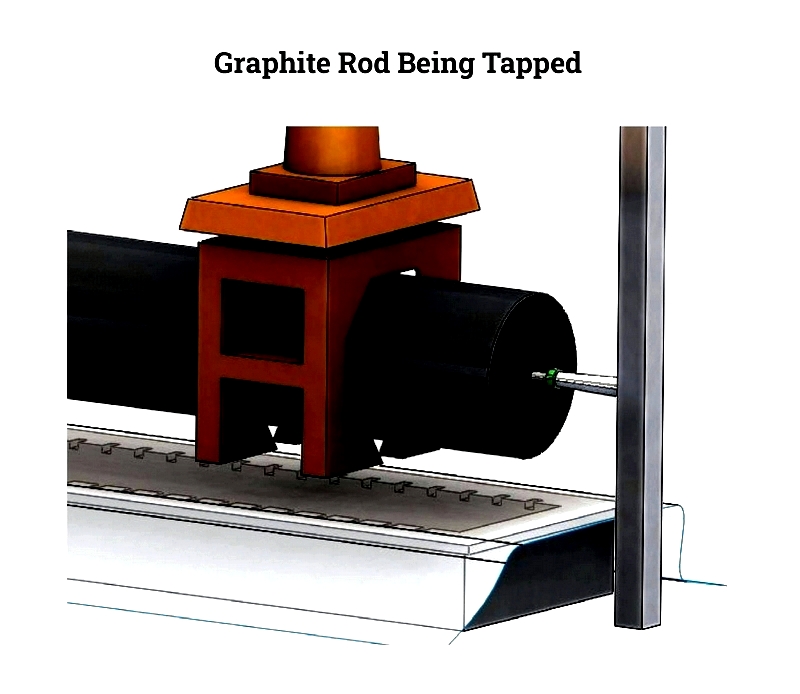

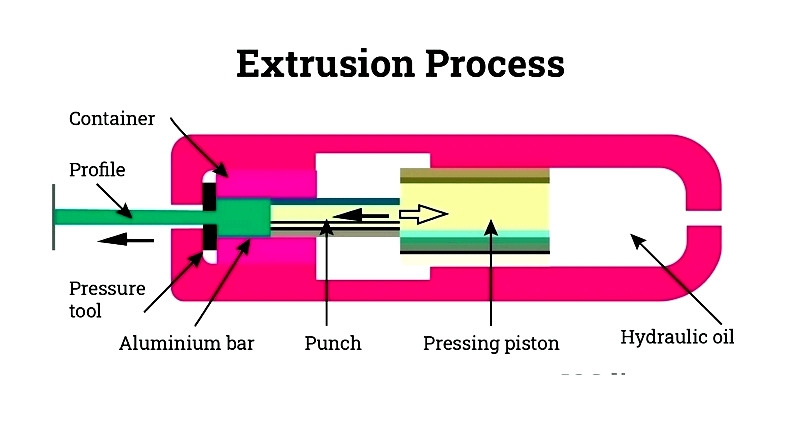

Rod Extrusion

Standard extrusion involves heating graphite stock with additives until molten, then forcing it through a die to form specific shapes upon cooling.

Hot Extrusion

Performed above recrystallization temperature using heavy hydraulic presses. Lubrication varies with temperature, using oil and graphite for lower temperatures and glass for higher temperatures.

Isostatic Pressing

This technique uses uniform gas pressure to shape graphite, with hot and cold variants for consolidation or part formation.

Hot Isostatic Pressing (HIP)

HIP consolidates powder, forms shapes, and refines castings using gases like argon at 1000-2200°C and 100-200 MPa pressures.

Cold Isostatic Pressing

Suitable for complex or large shapes, CIP compacts various powders to specific pressures using elastomeric molds.

CIP produces graphite with excellent densities and granularity, particularly in ESM and CGI series.

Cokes - Produced during oil refining by heating coal between 600-1200°C, offering higher energy than standard coal.

Pulverizing - Raw materials are ground into fine dust using specialized machinery for thorough grinding and size sorting.

Kneading - Pulverized coke mixes with pitch at elevated temperatures for proper blending.

Secondary Pulverizing - Formed carbon balls undergo additional grinding to reduce particle size further.

Pressing - Material is molded under high pressure to achieve consistent grain and structure.

Carbonizing - Controlled high-temperature baking over months produces desired hardness and structure.

Pitch Impregnation - Reduces porosity by filling gaps with low-viscosity pitch.

Graphitizing - Carbon matrix reorganization at 3000°C enhances conductivity, density, and machinability.

Material Preparation - Post-graphitization checks ensure readiness for rod machining according to key parameters.

Materials for Graphite Rod Production

The choice of graphite type and production method depends on application requirements. Fine-grain graphite produces smooth finishes, while coarser types suit varied tasks without needing smooth surfaces.

Graphite Rod Specifications

Specifications like density, compressive strength (11,000-38,000 psi), and modulus of elasticity determine suitability. G purified grades at