Introduction

This article provides an in-depth exploration of electric motors.

It covers essential topics including:

- Working Principles of Electric Motors

- Various Types of Electric Motors

- Applications and Advantages of Electric Motors

- And More...

Chapter 1: Understanding Electric Motor Principles

This chapter examines the fundamental concepts behind electric motors, including their construction and operational mechanisms.

What is an Electric Motor?

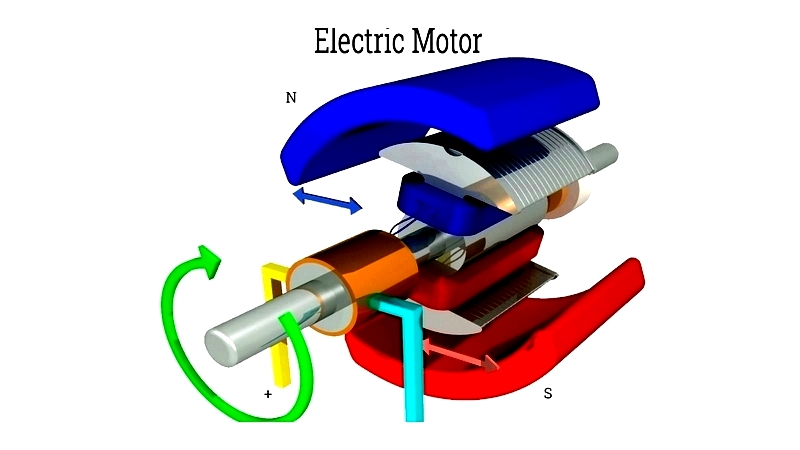

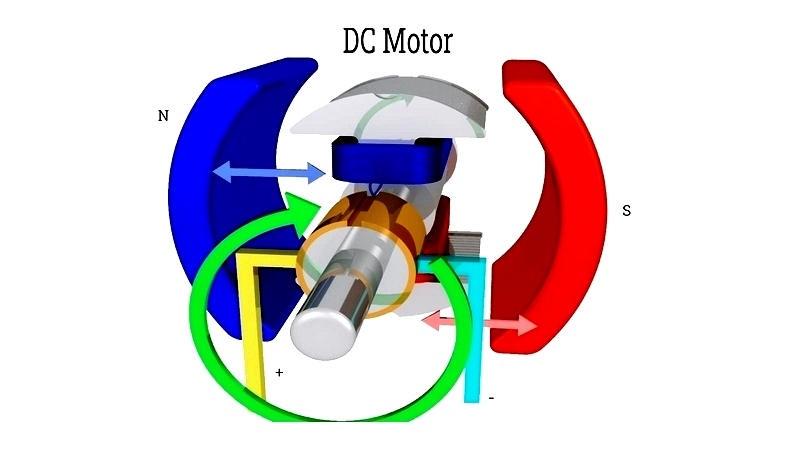

An electric motor converts electrical energy into mechanical energy by generating magnetic fields through current-carrying coils, producing torque on the motor shaft. While similar in construction to electrical generators, motors perform the inverse function by transforming mechanical energy into electrical energy.

Electric motors operate on either direct current (DC) from batteries or alternating current (AC) from power grids. They can be classified by power source, application, construction, and output type, including DC/AC variants, brushless/brushed designs, and single/multi-phase configurations. These motors serve diverse applications from industrial machinery to household appliances.

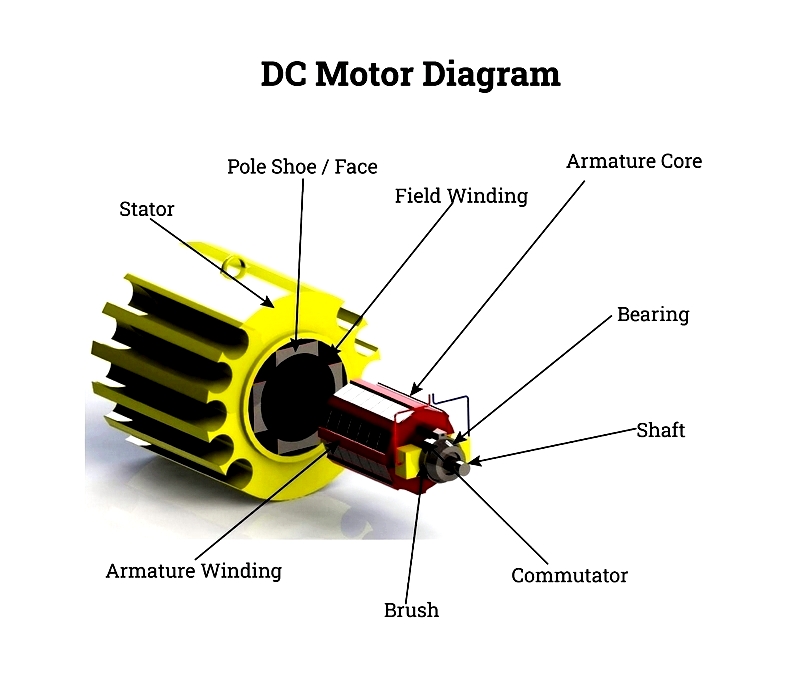

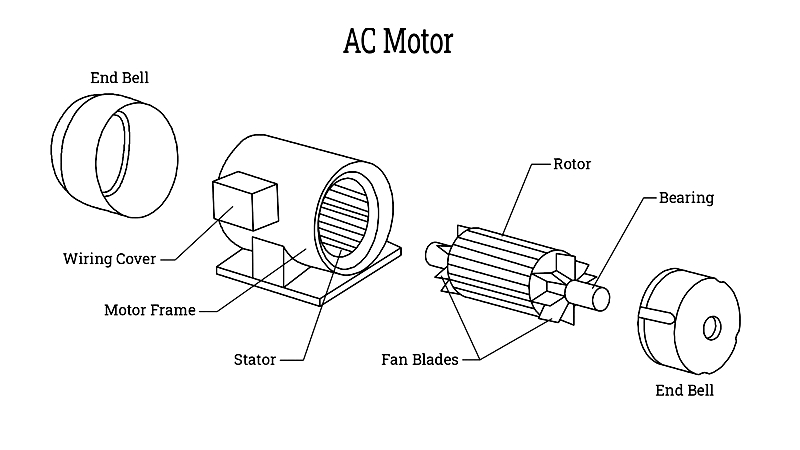

Electric Motor Components

Electric motors consist of two primary mechanical parts: the stationary stator and rotating rotor. Key electrical elements include field magnets and armature windings, which create the motor's magnetic circuit.

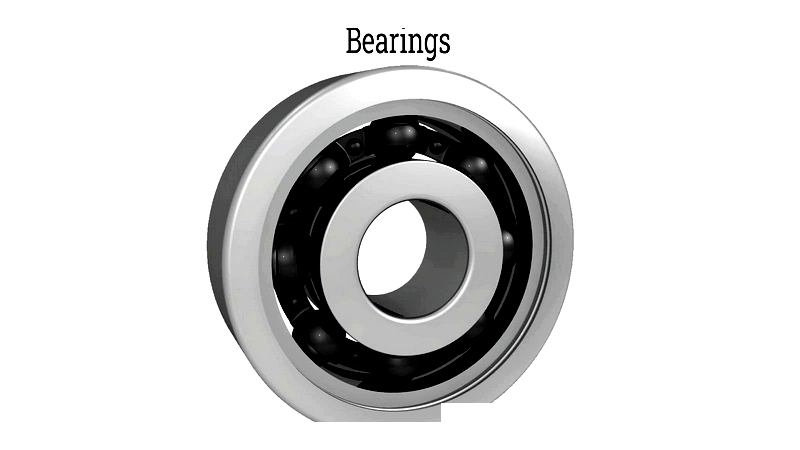

Motor Bearings

Bearings support the rotor, enabling smooth rotation while the motor housing maintains bearing alignment.

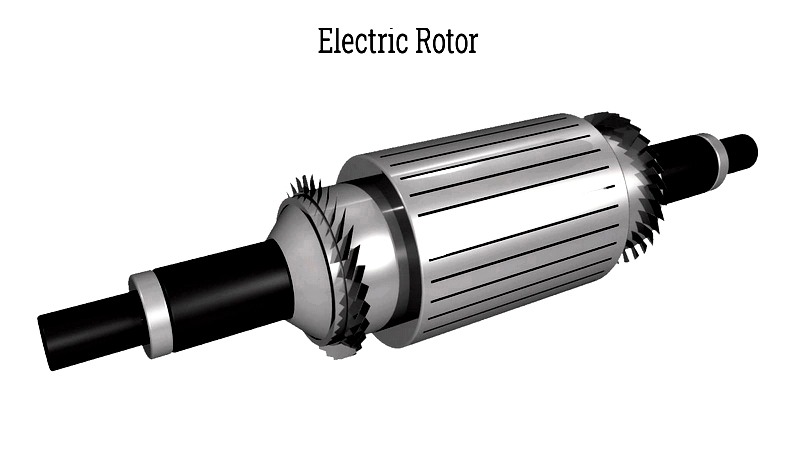

The Rotor Assembly

The rotor delivers mechanical power through conductor interaction with the stator's magnetic field. Modern designs often feature permanent magnets for improved efficiency.

The air gap between rotor and stator affects performance, with narrower gaps typically enhancing efficiency.

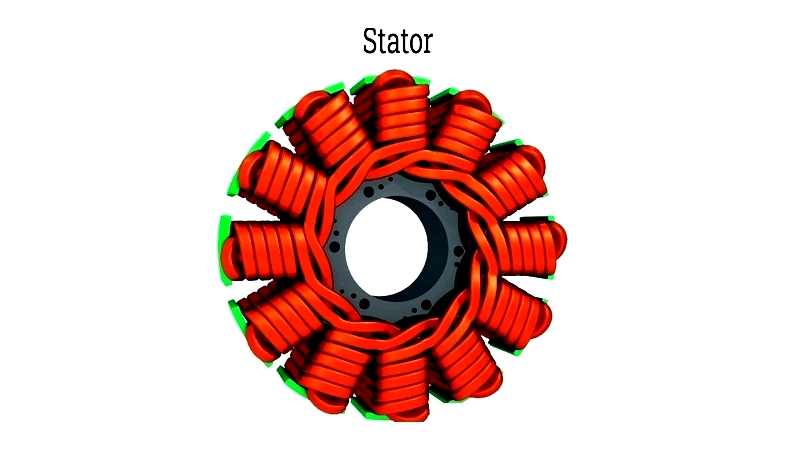

The Stator Structure

The stator houses field magnets (permanent or electromagnetic) that interact with rotor windings. Laminated iron cores minimize energy losses.

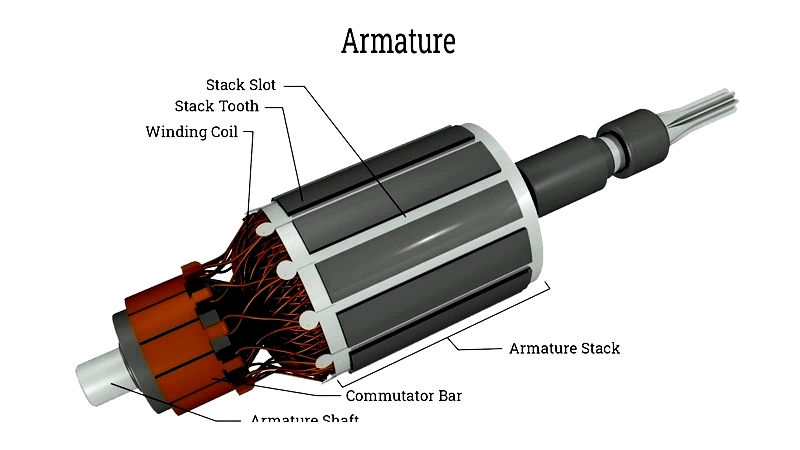

Armature Function

The armature's wound coils create magnetic poles when energized, generating rotational force through Lorentz forces.

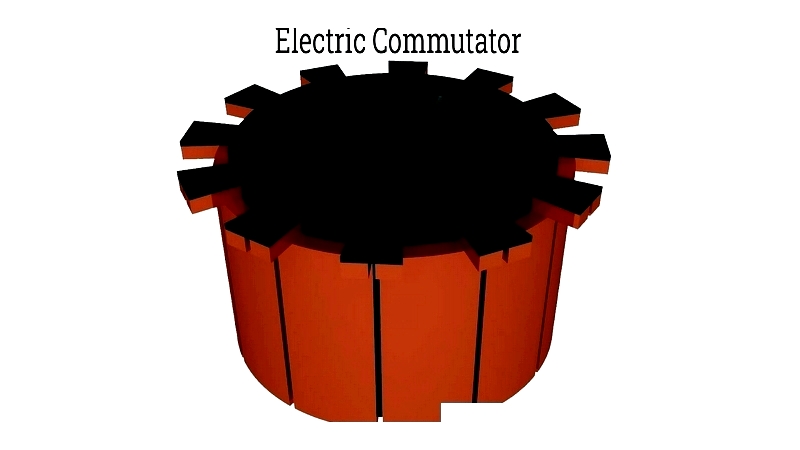

Commutator Operation

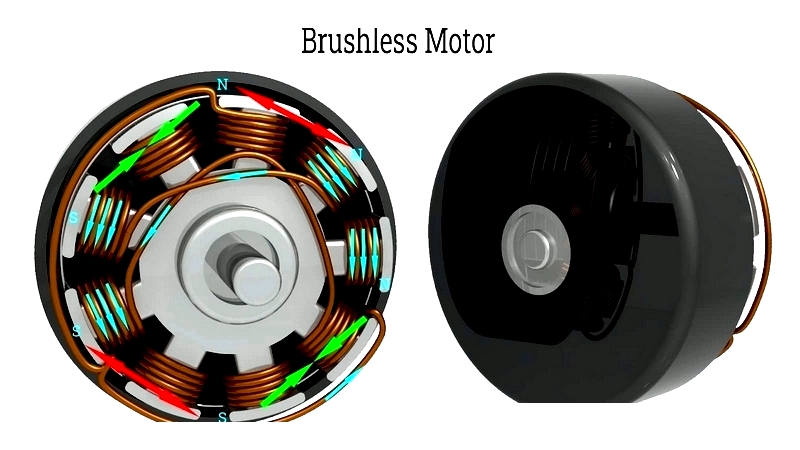

Commutators reverse current direction in rotor windings to maintain consistent torque, though brushless designs are increasingly replacing traditional commutators.

Motor Selection Criteria

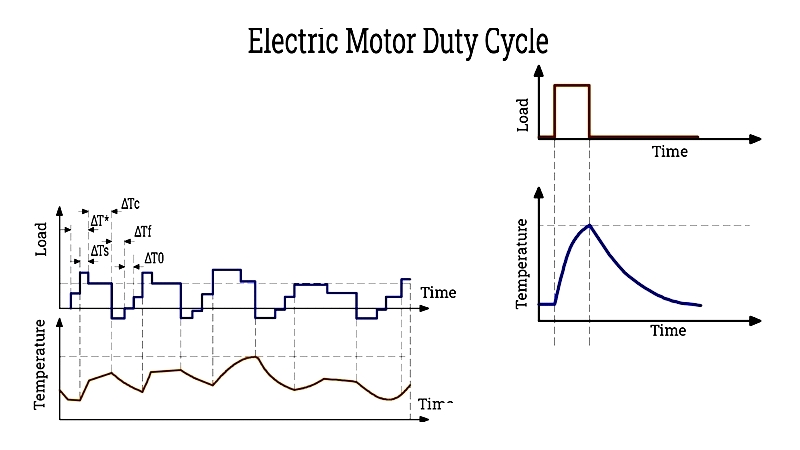

Key considerations include:

- Voltage: Match power source requirements

- Frequency: 50Hz/60Hz compatibility

- Speed/Torque: Application-specific needs

- Duty Cycle: Continuous vs intermittent operation

- Efficiency: Energy consumption optimization

Chapter 2: Electric Motor Varieties

Electric motors serve diverse applications across industrial, commercial, and residential sectors. This chapter examines major motor categories and their characteristics.

DC Motor Types

DC motors convert direct current into mechanical rotation, offering precise speed control. Modern applications range from small appliances to industrial machinery.

12V DC Motors

Compact 12V motors provide reliable power for robotics, automotive systems, and portable devices, featuring brushless designs for improved longevity.

Brushless DC Motors

BLDC motors offer superior efficiency and reliability through electronic commutation, replacing mechanical brushes in many applications.

Stepper Motors

Stepper motors provide precise positional control through discrete steps, ideal for CNC machines and automation systems.

AC Motor Categories

AC motors dominate industrial applications due to their robustness and grid compatibility.

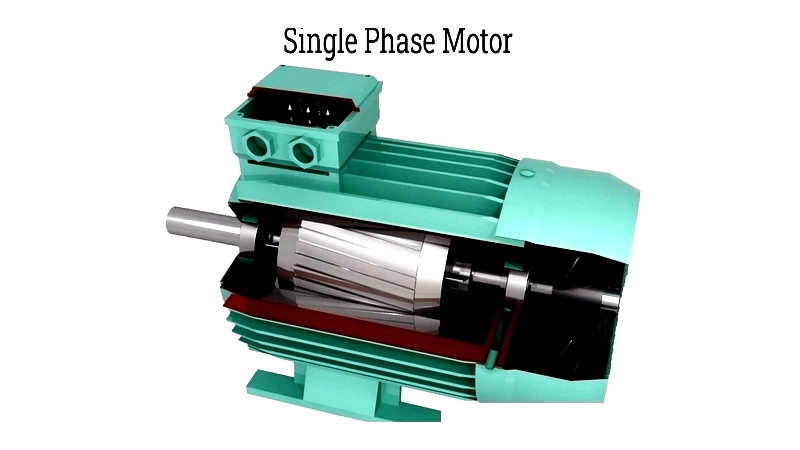

Single-Phase Motors

Common in residential applications, single-phase motors power appliances and small equipment through capacitor-start designs.

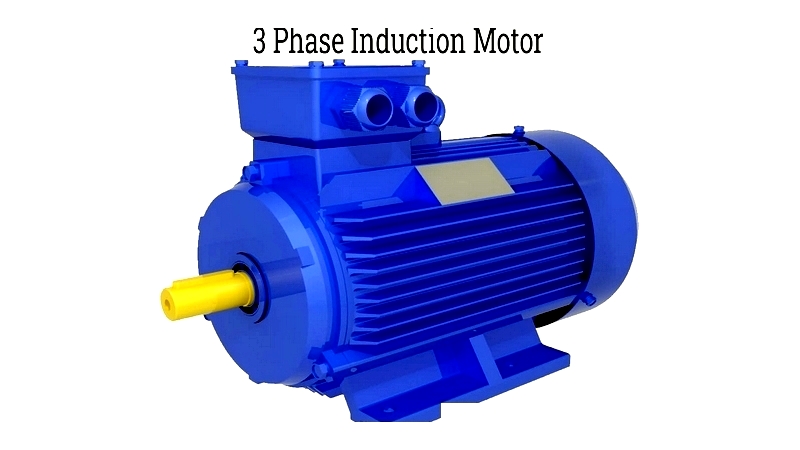

Three-Phase Motors

Industrial workhorses, three-phase motors deliver high efficiency and reliability for heavy-duty applications.

Specialty Motors

Servo Motors

Servo systems provide precise motion control for robotics, CNC equipment, and automation applications.

Industrial Motors

Rugged industrial motors withstand demanding environments while delivering consistent performance.