Introduction

This article provides an in-depth exploration of scissor lifts.

It covers various aspects including:

- Working Principle of Scissor Lifts

- Different Types of Scissor Lifts

- Applications and Advantages of Scissor Lifts

- And More...

Chapter 1: Understanding the Principle of Scissor Lifts

This section examines scissor lifts in detail, explaining their components and operation.

What is a Scissor Lift?

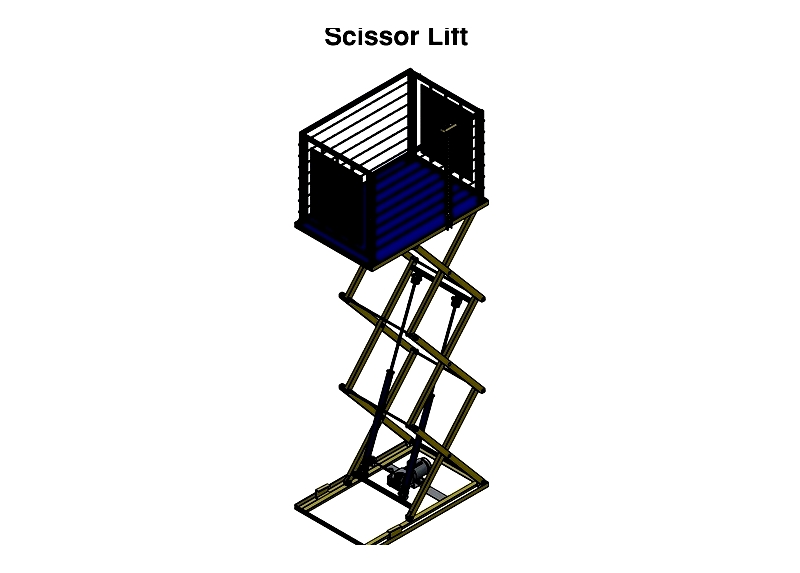

A scissor lift is a mobile platform used in construction and maintenance to elevate workers and equipment to required heights.

Scissor lifts operate through interconnected power systems using electricity, diesel, or compressed air. These systems power a pump that pressurizes hydraulic fluid, extending the cylinder to raise the platform. The lift typically uses 220V or 380V electrical power.

Commonly used in manufacturing, utilities, and logistics, these devices provide safe elevation for high-altitude tasks.

Key Components

Essential parts of a scissor lift include:

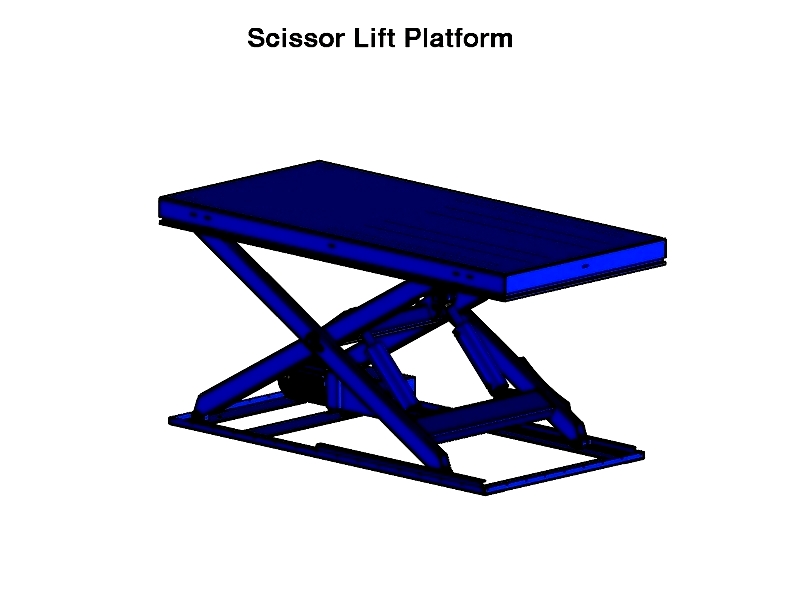

Platform

The working area varies in size and material, often featuring safety rails for personnel. Lift tables without rails are used for material handling.

Scissor Mechanism

X-shaped metal struts connect the platform to the base, determining lift height through their arrangement and quantity.

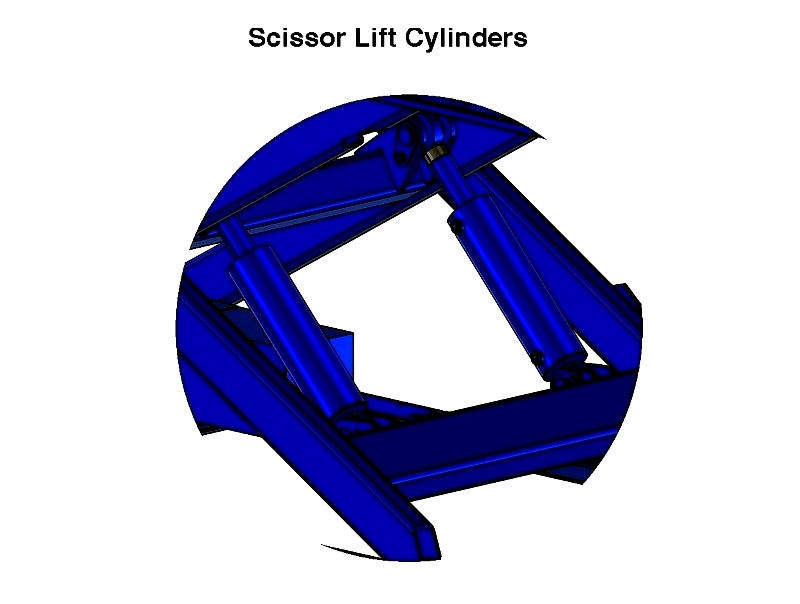

Actuation System

Hydraulic or pneumatic cylinders (1-4 per lift) control platform movement through fluid or air pressure.

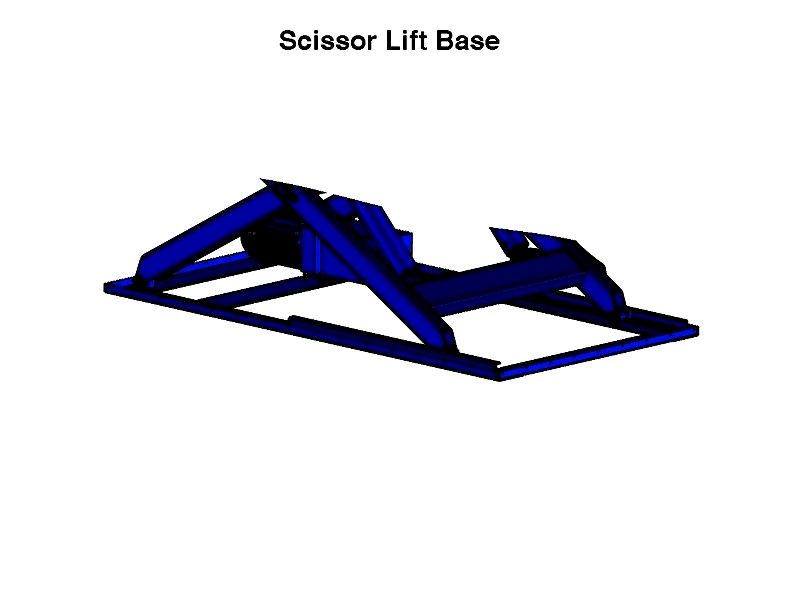

base frame

A sturdy foundation with guide tracks ensures smooth operation during height adjustments.

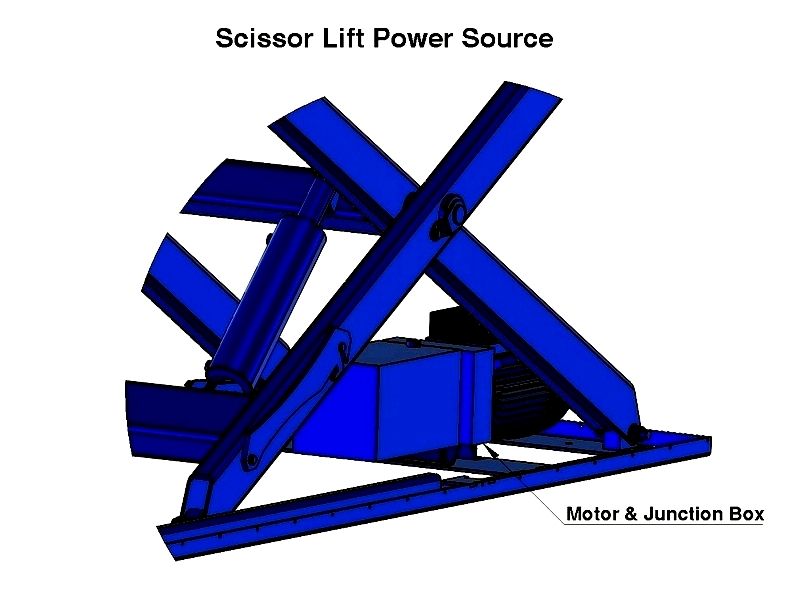

Power Source

Options include internal combustion engines or external power units, selected based on application requirements.

Control Valves

Down valves regulate descent speed while flow control valves manage ascent/descent rates.

Chapter 2: Types of Scissor Lifts

Scissor lifts come in four main configurations suited for different applications:

Hydraulic Models

Versatile lifts using fluid power for precise control in warehouses and construction sites.

Available in stationary or mobile versions with various platform sizes and lift capacities.

Diesel-Powered

Heavy-duty outdoor models with high load capacities for construction and industrial use.

Feature rugged designs for challenging terrain with extended runtime capabilities.

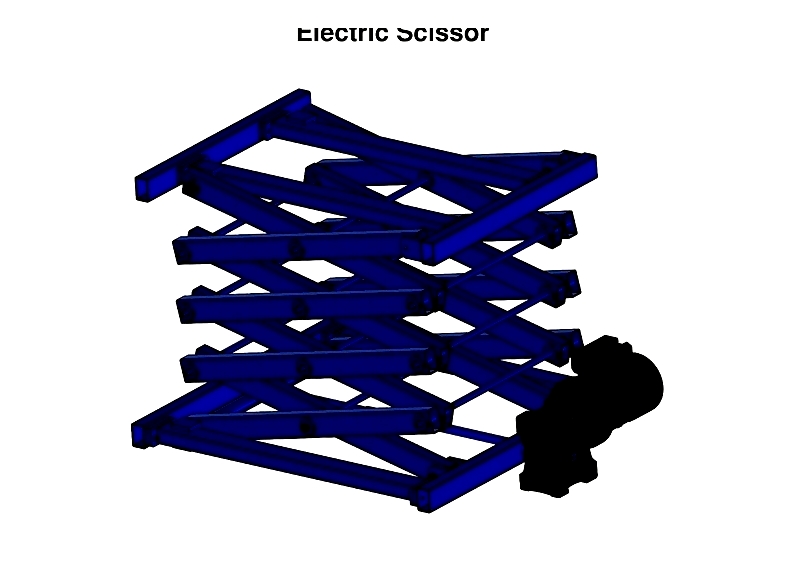

Electric Models

Quiet, emission-free operation ideal for indoor environments like warehouses and hospitals.

Compact designs with advanced safety features for confined spaces.

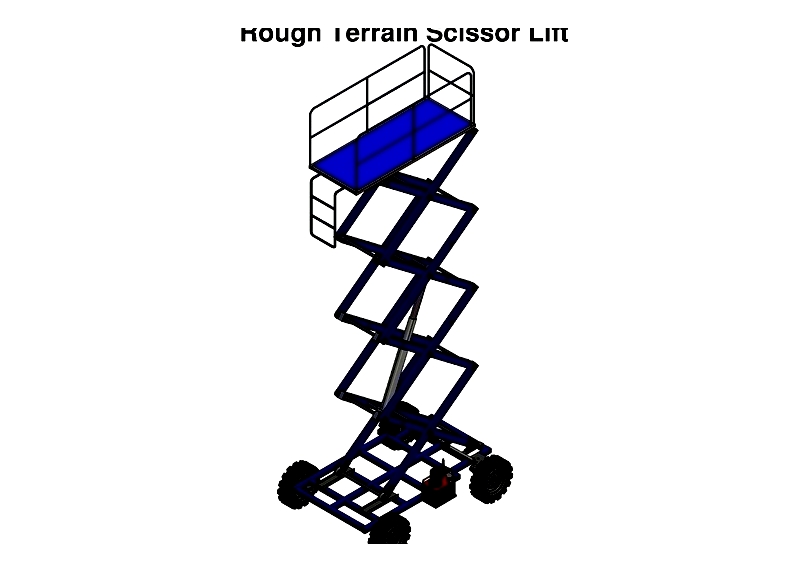

Rough Terrain

Specialized units with enhanced traction for outdoor applications on uneven ground.

Include stability features like outriggers for safe operation on slopes.

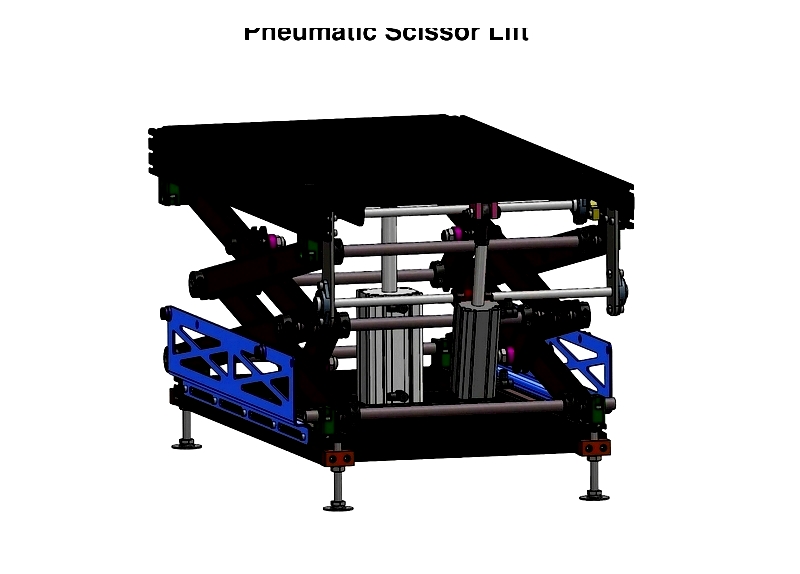

Pneumatic Models

Clean-air alternative using compressed air for sensitive environments.

Low-maintenance solution for light-duty material handling applications.