Introduction

This article provides comprehensive information about chemical milling and its applications.

You will learn about:

- The fundamentals of Chemical Milling

- Different Chemical Milling Processes

- Applications of Chemical Milling

- Products created through Chemical Milling

- And additional valuable insights

Chapter 1: What is Chemical Milling?

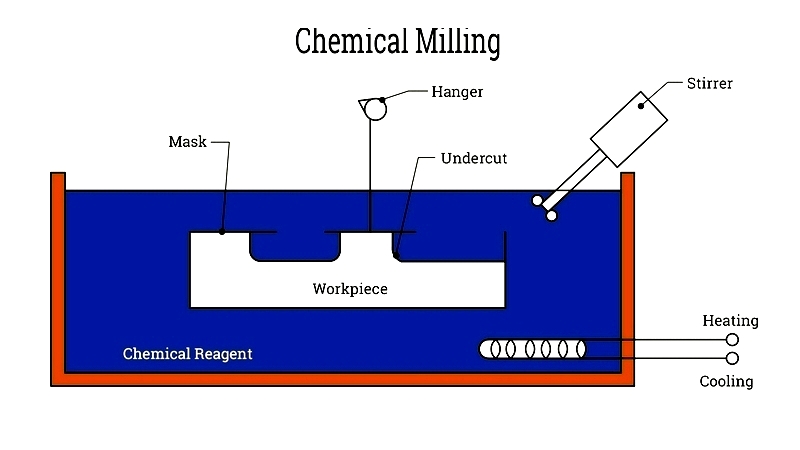

Chemical milling is a precision manufacturing process that selectively removes material from workpieces using controlled chemical reactions. Unlike mechanical milling that relies on cutting tools, this technique employs specialized etching solutions to dissolve targeted metal areas. A protective maskant is applied to shield unaffected regions before immersing the workpiece in the chemical bath.

This method excels at creating contours, cavities, and precise openings while reducing weight. It's particularly effective for surface finishing operations like deburring. Originally developed to address aerospace industry needs for flawless surfaces, chemical milling now serves various sectors requiring exceptional surface quality and dimensional accuracy.

Chapter 2: The Chemical Etching Process

The chemical etching process involves five key stages:

Cleaning

Thorough surface preparation ensures optimal maskant adhesion and consistent etching results. Advanced cleaning methods include ultrasonic treatment and plasma cleaning for precision applications.

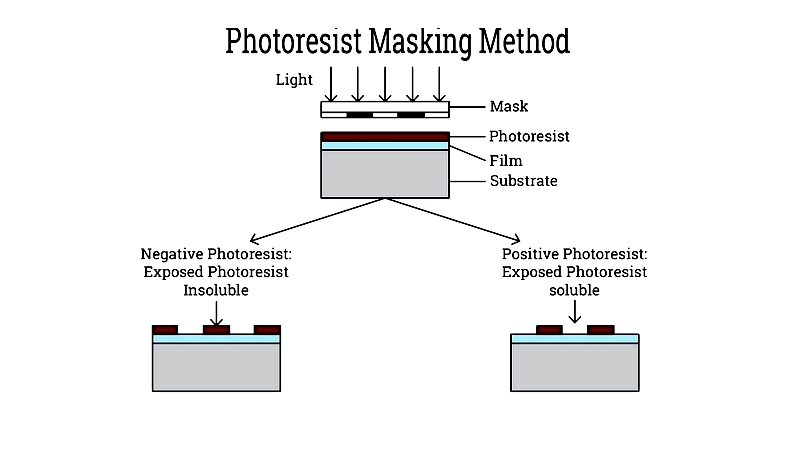

Masking

Various masking techniques protect specific areas from etching:

- Photoresist Method: Uses UV-sensitive polymers for micro-scale precision

- Offset Printing: Cost-effective for large-scale production

- Scribe and Peel: Ideal for custom or low-volume projects

- Mechanical Masking: Suitable for prototyping and simple geometries

Chemical Milling

Specialized etchants dissolve exposed metal areas with precision. Common solutions include:

- Ferric Chloride for stainless steel and copper

- Ferric Nitrate for nickel alloys

- Sodium Hydroxide for aluminum

Demasking

The final stage removes protective masks and cleans the etched components, ensuring feature definition and surface quality.

Chapter 3: Chemical Milling Variations

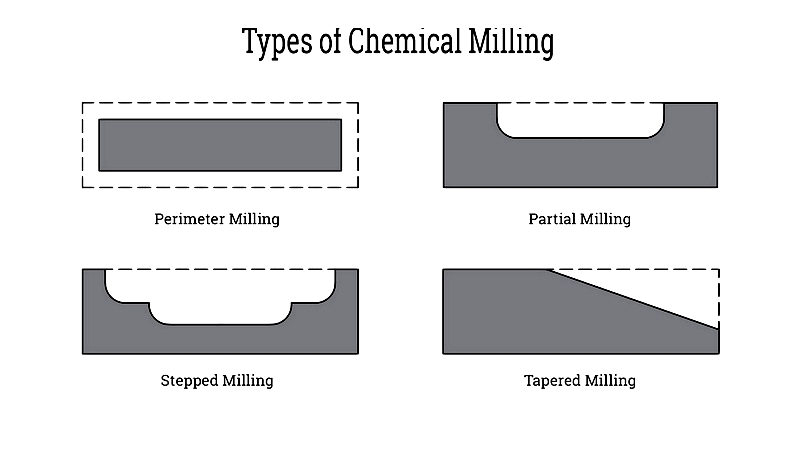

Different techniques address specific manufacturing needs:

Perimeter Chemical Milling

Reduces external dimensions without masking, ideal for refining cast components.

Partial Chemical Milling

Creates specific features like grooves and pockets in targeted areas.

Step Chemical Milling

Uses sequential masking for multi-level contours and cavities.

Tapered Chemical Milling

Produces gradual thickness variations for aerodynamic components.

Structural Chemical Milling

Reduces weight while maintaining structural integrity, crucial for aerospace applications.