Introduction

This article explains the various types of cardboard balers and their applications.

You'll explore topics including:

- What is a Cardboard Baler?

- Types of Cardboard Balers

- How Cardboard Balers Work

- Benefits of Baling Cardboard

- And more...

Chapter One – What is a Cardboard Baler?

A cardboard baler is a powerful machine featuring a hydraulic-powered metal plate that applies tremendous pressure to crush and compact cardboard into dense, transportable bales. These machines transform bulky cardboard packaging into convenient cubes and rectangles for efficient recycling. Retailers and manufacturers rely on cardboard balers to save space and prepare materials for recycling. Growing environmental regulations have significantly increased baler adoption in recent years.

Chapter Two – Types of Cardboard Balers

Cardboard balers are essential recycling equipment that compacts waste while optimizing space. They're categorized by orientation (vertical or horizontal) based on material type, available space, and processing volume. All balers share core components: a hydraulic ram, compaction chamber, and compression platen. Selecting the right baler improves waste management efficiency, supports sustainability goals, and can create revenue through bale sales to recyclers.

Balers come in various configurations to suit different business needs - from small retail stores handling occasional boxes to large factories processing bulk corrugated materials. Compact balers work well for offices with limited waste, while industrial facilities require heavy-duty models capable of producing 1,000+ pound bales with hundreds of tons of pressing force.

Vertical Cardboard Baler

Vertical balers use an upward-moving hydraulic ram to compress cardboard into stackable bales. These space-efficient machines are ideal for moderate waste producers like grocery stores and retail shops. When choosing a vertical baler, consider ceiling height requirements due to the ram's upward motion. Modern models offer single- or multi-ram systems with 10-200 tons of force, providing flexibility in bale density and size. Vertical balers reduce hauling costs and help businesses meet recycling standards.

Horizontal Balers

Horizontal balers handle large-scale recycling with semi- or fully-automatic operation. Their wide hoppers accept manual, conveyor, or forklift-fed materials, processing 1-15 tons per hour. These high-capacity machines are preferred by distribution centers and manufacturing plants. With 20-400 tons of pressure, they produce mill-ready bales. Automatic cycling begins when the chamber reaches capacity, minimizing labor requirements.

Horizontal balers come in two main designs:

Closed-End Horizontal Baler

Closed-end models feature fully enclosed chambers that press material against a rear or side door. These medium-capacity balers produce about one bale per hour with consistent sizing. Ideal for businesses needing reliable throughput with minimal operator involvement, they can process cardboard, paper, and plastics.

Open-End Horizontal Baler

Open-end balers feature rear openings and often include automatic tying systems. Designed for high-volume operations like fulfillment centers, they can produce four times more bales than closed-end models. Many feature programmable controls for integration with automated material handling systems, making them ideal for facilities processing 25+ tons monthly.

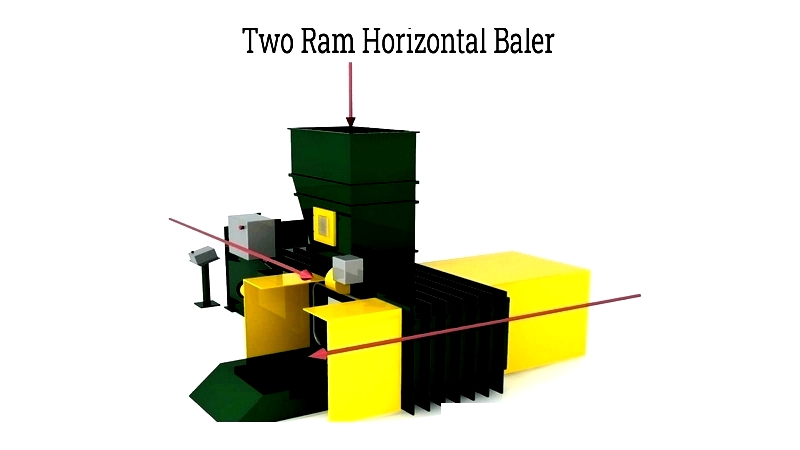

Two Ram Horizontal Baler

These heavy-duty systems use dual rams - one for compaction and another for bale tying/ejection. Perfect for recycling centers handling mixed materials (OCC, paper, plastics, metals), they operate continuously with minimal intervention. Two-ram balers produce uniform bales that optimize truckloads and storage space.

Portable Cardboard Balers

Compact and mobile, these balers create 140-pound bales for small businesses with space constraints. Featuring casters and low-profile designs, they're easily relocated within facilities. Portable balers help shops and offices manage waste without frequent pickups.

Top Loading Cardboard Baler

These space-saving "mini balers" create 90-130 pound bales loaded from above. Perfect for cafes and pharmacies, their compact size allows placement near work areas. Preset programs ensure consistent bale sizes for easy handling.

Cardboard Baler Tonnage

Choosing the right baler depends on daily processing volume:

- Under 2 tons: Manual vertical balers (100-1,500 lb bales) suit small retailers

- 1-4 tons: Semi-automatic horizontal balers for moderate waste

- 3-200 tons: Automated horizontal balers for industrial facilities

- 200+ tons: High-capacity systems with automatic feeding/tying

Consult manufacturers to ensure proper sizing, safety compliance, and after-sale support. Consider compaction force, bale size, automation level, and material compatibility when selecting equipment.