Introduction

This article covers everything you need to know about polyurethane bushings and their applications.

You'll discover:

- What Polyurethane Bushings Are

- How Polyurethane Bushings Are Manufactured

- Different Polyurethane Varieties

- Applications of Polyurethane Bushings

- And much more...

Chapter One: Understanding Polyurethane Bushings

Polyurethane bushings serve as friction-reducing components positioned between stationary and moving parts, offering an alternative to conventional lubricants. Chosen for their exceptional durability, strength, and resistance to wear, these bushings typically outlast those made from rubber or plastic materials.

Polyurethane is a polymer created through a chemical reaction between diisocyanates (organic compounds containing two isocyanate groups) and polyols. The term "polyurethane" encompasses various polymer formulations, each with distinct molecular structures. These variations in hardness and flexibility make polyurethane suitable for diverse applications.

While both rubber and polyurethane serve similar functions, they differ significantly. Polyurethane stands out for its superior strength, durability, and resilience in demanding conditions compared to rubber, which tends to degrade over time.

Chapter Two: Manufacturing Polyurethane Bushings

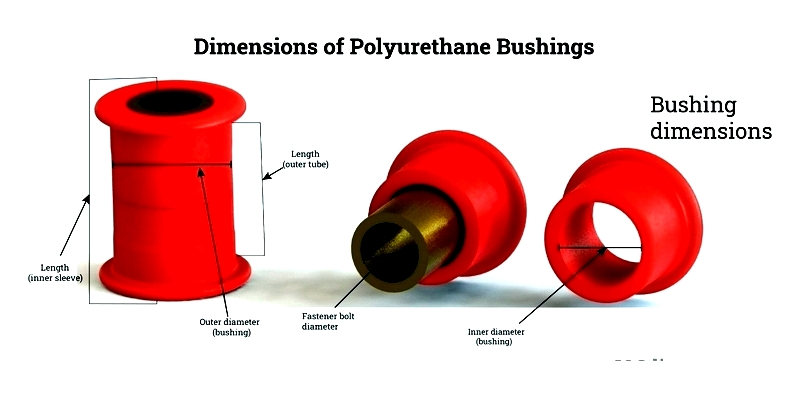

Valued across industries for their durability, resilience, and vibration-dampening properties, polyurethane bushings are widely used in automotive, industrial, and machinery applications. Their production involves several advanced techniques, each offering unique advantages depending on intended use, required properties, and production volume. Common methods include injection molding, casting, compression molding, and emerging options like vacuum molding and CNC machining for custom bushings. The ideal manufacturing method depends on factors like bushing geometry, tolerances, mechanical strength, and cost efficiency.

Injection Molding

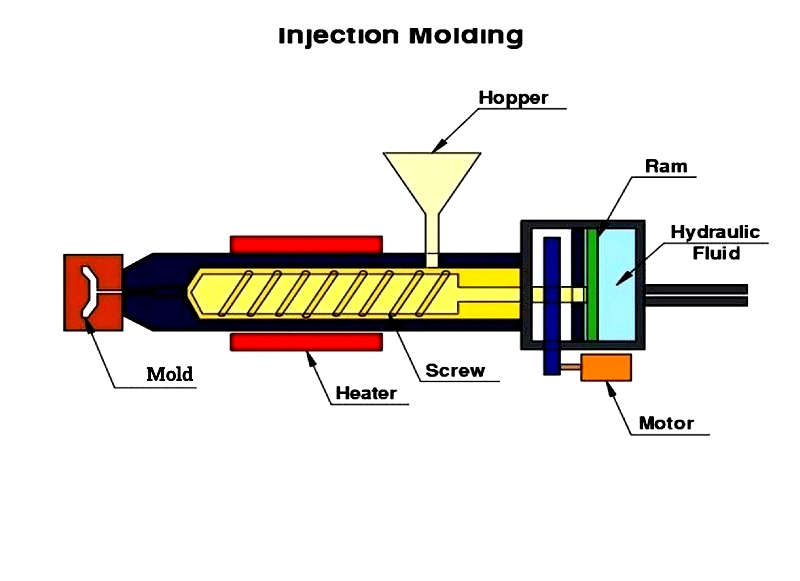

Injection molding forces molten polyurethane under pressure into precision-engineered steel molds, where it cools and solidifies. This method is preferred for high-volume production due to its repeatability, efficiency, and ability to maintain tight tolerances. The process uses a clamping unit and injection unit, with molds positioned between them. The resulting bushings exhibit excellent uniformity, crucial for demanding applications like automotive suspension systems and industrial machinery.

Clamping Unit

The clamping unit withstands stresses during the injection process. Polyurethane enters the injection unit via a hopper above the screw mechanism. As the screw rotates, it melts the material and pushes it into the mold, which is secured by the clamping unit to ensure proper alignment and surface finish.

Three main clamping unit types exist:

- Toggle – Used for high-speed production, featuring a toggle link, crosshead, and driving mechanism - ideal for automotive bushings requiring rapid cycles.

- Hydraulic – Uses pressurized hydraulic fluid to push a piston against the clamp, providing precise force distribution for larger or complex designs.

- Magnetic – Generates clamping force through magnetic plates, allowing quick mold changes and increased flexibility.

Injection Unit

The injection unit consists of a hopper, heaters, screw, and motor. Polyurethane pellets enter the hopper and feed into the screw, which advances the material toward the mold while increasing pressure. Heating elements warm the polyurethane as it moves, with the motor ensuring consistent material delivery - critical for producing high-quality bushings.

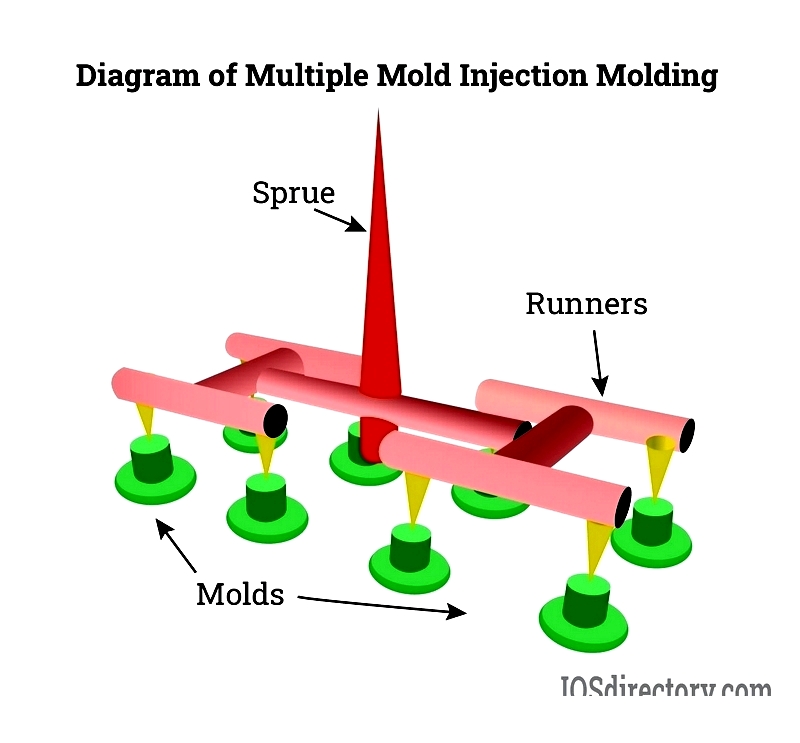

Mold

The steel mold is designed to match the bushing's shape and includes a sprue connecting to the injection unit. Often featuring multiple cavities, the mold uses runners to distribute material evenly, ensuring balanced flow and consistent performance.

Cooling and Ejection

After injection, the polyurethane remains under pressure to prevent defects. The screw then retracts to facilitate cooling before the clamping unit releases and ejects the finished bushing. Modern automation streamlines this process for large-scale production.

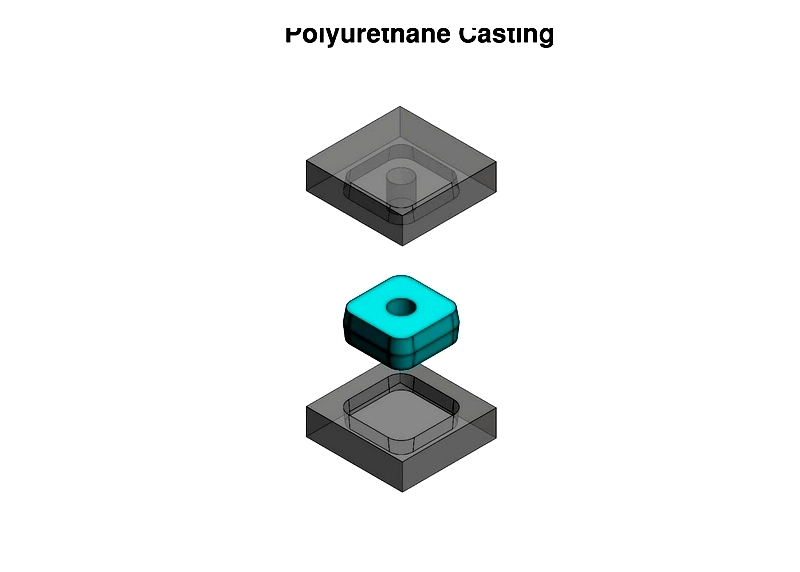

Casting

Similar to injection molding but without clamping and injection units, casting uses molds shaped like the bushing. This cost-effective method suits short to medium production runs and custom designs, allowing for unique geometries and specialized properties.

Polyurethane Compounds

Casting begins with mixing polyols and diisocyanates, along with catalysts and additives. The specific compounds used determine flexibility, chemical resistance, and hardness, enabling customization for various industrial applications.

Casting Mold

Casting molds are made from aluminum, silicone, or steel, either as closed two-part molds or open single-section molds. This flexibility supports manufacturing complex bushing designs.

Heating

After injection, molds move to ovens where high temperatures harden the polyurethane. Proper curing is essential for achieving desired wear resistance and load capacity.

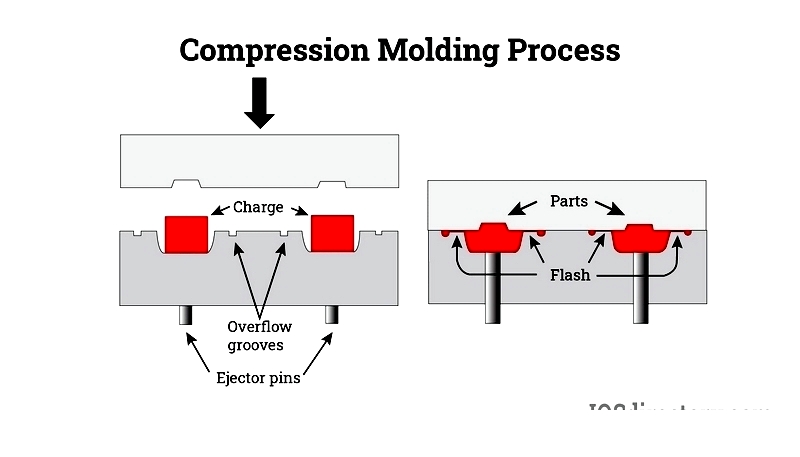

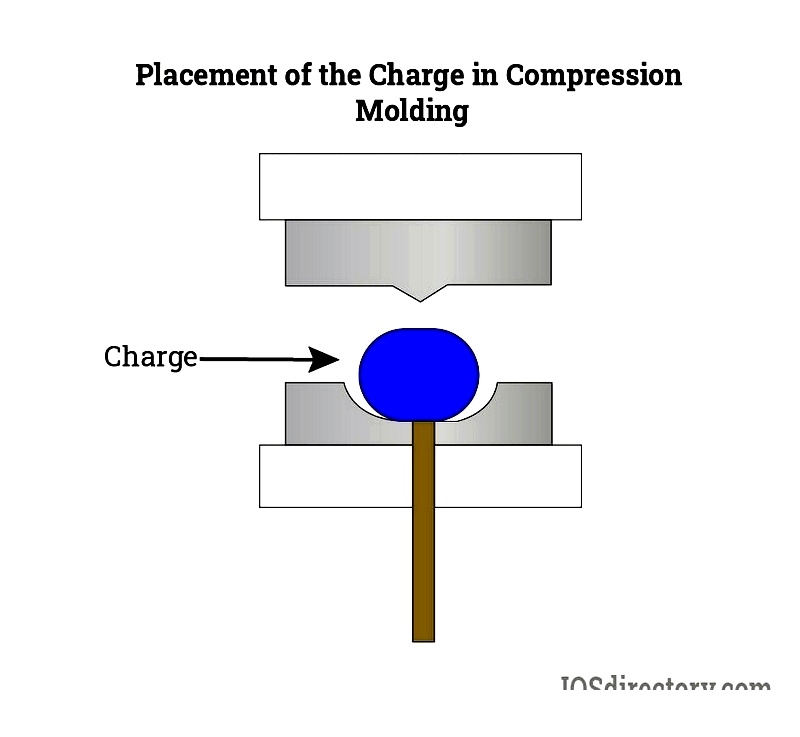

Compression Molding

This high-temperature process compresses measured polyurethane (called a charge) into a mold. Suitable for lower volumes and prototyping, it doesn't require injection or clamping units.

Creating the Mold

Molds are made using CNC machining, 3D printing, or die casting, with durability to withstand high pressures and temperatures.

The Charge

Proper charge preparation ensures dimensional accuracy. Excess material may cause flash that requires trimming.

Compressing

The mold's top section presses down on the charge, with temperature, pressure, and time carefully controlled to ensure quality. Typical conditions include 350°F (176°C) and pressures from 100-2000 psi.

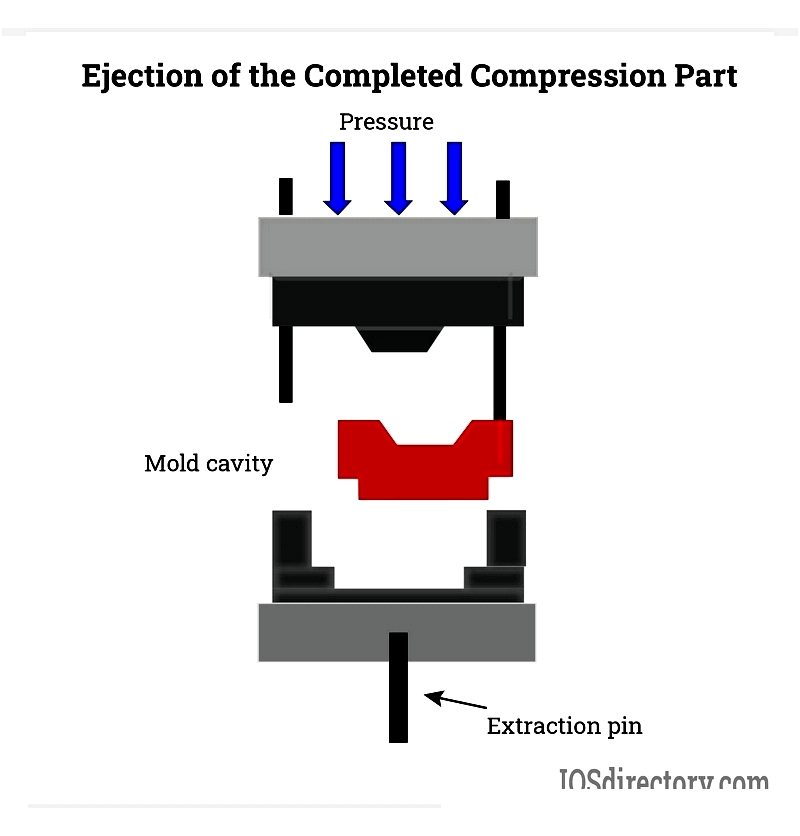

Curing

Curing hardens the part, often taking 8-16 hours at temperatures exceeding 200°F (93.3°C) to enhance impact resistance and longevity.

Ejection

Completed bushings are removed manually or automatically, with release agents sometimes used to prevent sticking.

While casting, injection molding, and compression molding are common, other methods like vacuum molding and CNC machining also produce custom bushings. Each technique offers unique advantages in speed, accuracy, and complexity.

Chapter Three: Polyurethane Varieties

By altering polyols and diisocyanates during polymerization, manufacturers create polyurethanes with unique properties. This versatility makes them suitable for commercial, automotive, industrial, and consumer applications. Unlike traditional rubber or plastic, polyurethane offers an exceptional balance of rigidity, resilience, and elasticity.

Polyurethanes fall into two main categories: