Introduction

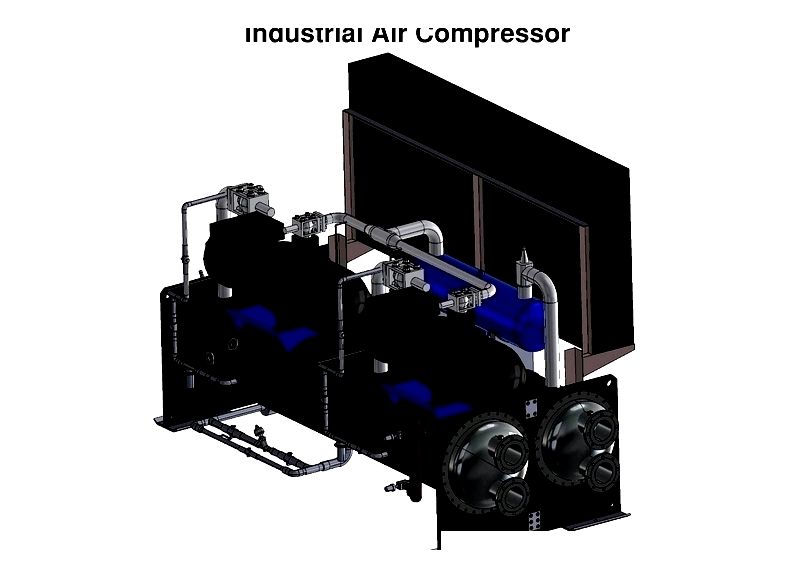

This article provides an in-depth examination of industrial air compressors.

You'll explore key topics including:

- Industrial Air Compressor Fundamentals

- Industrial Air Compressor Varieties

- Control Systems for Air Compressors

- Drive Mechanisms in Air Compressors

- Performance Metrics for Air Compressors

- Selecting the Optimal Industrial Air Compressor

- Industrial Applications of Air Compressors

Industrial Air Compressor Fundamentals

An industrial air compressor is a mechanical device designed to increase gas pressure, primarily focusing on air compression. Different compressor models serve diverse industrial applications, performing functions such as:

- Providing instrument or workshop air supply

- Powering pneumatic tools, sandblasting equipment, and paint sprayers

- Circulating refrigeration and HVAC refrigerants

- Transporting gases through pipeline systems

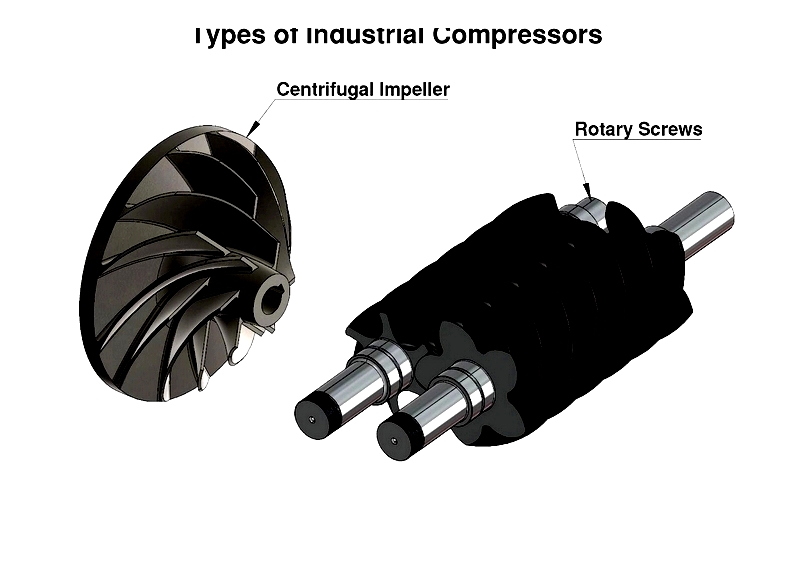

Similar to pumps, compressors fall into two main classifications: positive-displacement and centrifugal (also termed kinetic or dynamic). While most pumps operate centrifugally, the majority of compressors utilize positive-displacement technology.

Industrial compressors exhibit substantial size variation, ranging from compact glovebox units for tire inflation to massive turbo compressors employed in pipeline operations.

Power Generation Through Compressed Air

Air compression requires energy input to create pressures exceeding atmospheric levels. When compressed air returns to ambient pressure, it releases stored energy. Air compressors amplify this effect by increasing air pressure and storing potential energy. Unlike other power transmission methods, compressed air requires no energy conversion at the point of use. Pneumatic tools powered by compressed air demonstrate exceptional power-to-weight and power-to-size ratios.

While compressed air may not match electricity's speed or hydraulics' force, it offers unparalleled versatility. Its cost-effectiveness and operational efficiency make it a preferred choice for many applications.

The primary advantage of compressed air systems lies in their precise control capabilities, eliminating electrical shock and fire hazards associated with hydraulic oils. However, strict adherence to safety protocols remains essential when working with compressed air systems.

Compressed air systems are categorized into two distinct types: active air and energy air.

Active Air vs. Energy Air Systems

Active air refers to compressed air that directly contacts products, commonly used in food preservation, beverage production, and sensitive industries like electronics, pharmaceuticals, and chemical processing.

Energy air denotes compressed air employed for energy storage and transmission in mechanical operations, typically powering pneumatic equipment.

Due to their differing applications, active air systems demand higher purity standards than energy air systems, requiring filtration of contaminants like particulates, moisture, and lubricants. Similar to how turbine water differs from drinking water in quality requirements, active air systems maintain stricter purity standards than energy air systems.

Industrial Air Compressor Varieties

Industrial air compressors are vital machines that convert power into stored potential energy through air compression. Various compressor types serve manufacturing facilities, automotive repair shops, food processing plants, chemical industries, and numerous other applications. For systems under 30 horsepower, rotary and reciprocating compressors represent the most common options, each employing distinct compression methods tailored to specific industrial requirements.

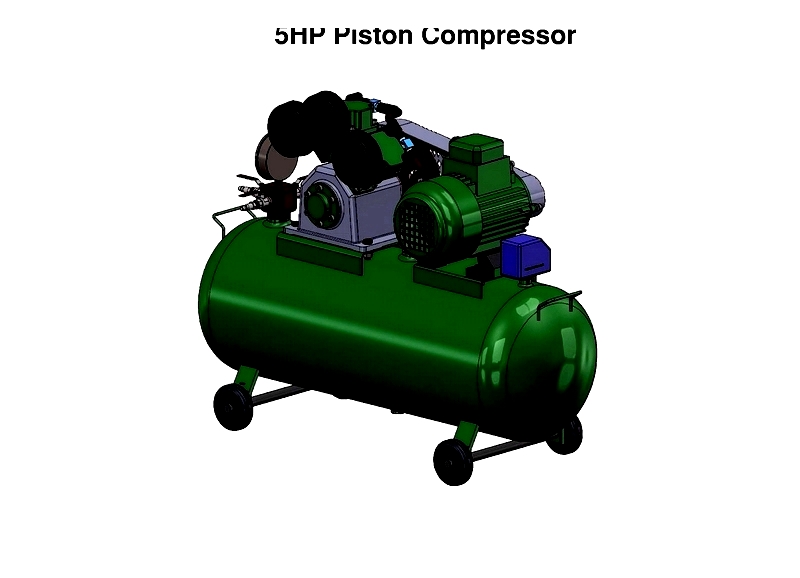

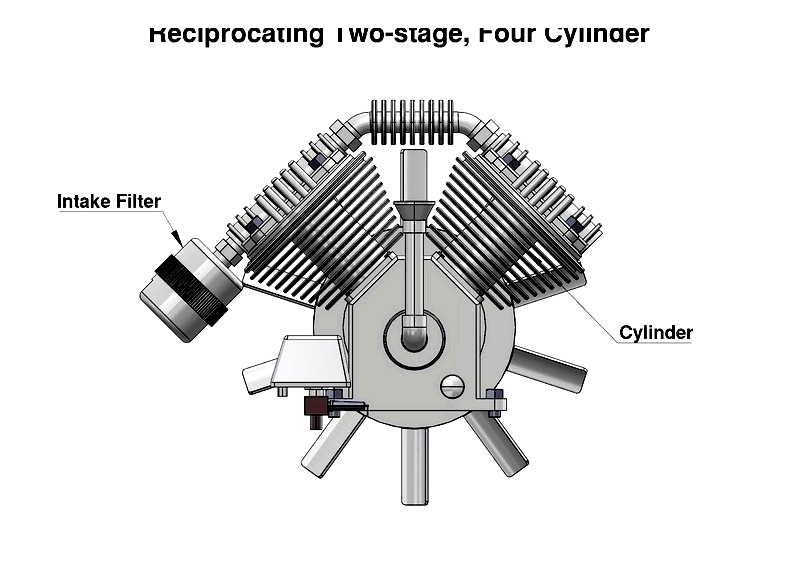

Reciprocating (piston) compressors utilize piston-cylinder arrangements to compress gas through reciprocating motion. The compressed air is then directed through valves into high-pressure storage tanks. Most piston compressors feature integrated compressor-tank assemblies, optimizing energy efficiency and simplifying installation.

Beyond powering pneumatic tools, piston compressors are extensively used in natural gas pipeline operations. Key selection criteria include flow rate (scfm), pressure rating (psi), duty cycle, and lubrication type (oil-lubricated vs. oil-free). Oil-free models are particularly crucial in industries demanding high air purity, such as food processing, pharmaceuticals, and healthcare, ensuring compliance with stringent air quality standards.

Primary reciprocating compressor categories:

- Diaphragm compressors

- Single-acting compressors

- Rocking piston compressors

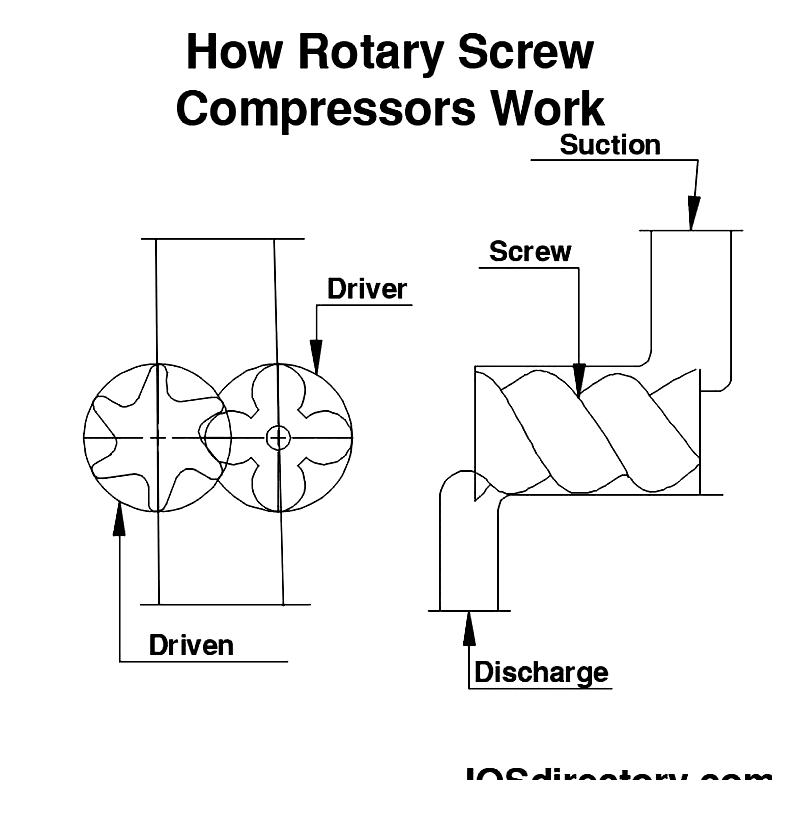

Main rotary compressor types:

- Helical screw compressors

- Sliding vane compressors

- Scroll compressors

These fundamental categories encompass diverse compressor technologies, each offering unique advantages in efficiency, duty cycles, maintenance requirements, operational costs, footprint, and air delivery characteristics for various commercial and industrial applications.

Single-Acting Reciprocating Compressors

Single-acting reciprocating compressors are available in single-stage and two-stage configurations, accommodating low-to-medium pressure requirements. Single-stage units compress atmospheric air to final pressure in one stroke, ideal for applications requiring 70-135 psi, including automotive shops, woodworking facilities, and light industrial operations.

Two-stage compressors are better suited for high-pressure applications like metal fabrication, industrial painting, and heavy equipment repair. These systems compress air to intermediate pressure in the first stage, cool it through an intercooler, then complete compression in the second stage. This design enhances efficiency, reduces condensation, and maintains stable pressure output for demanding operations.

Multi-piston compressors operate cyclically rather than continuously, preventing overheating and extending service life. Effective cooling systems, typically featuring finned heads, dissipate operational heat, lowering energy costs and ensuring consistent performance during prolonged operation.

While most single- and two-stage compressors employ oil lubrication, oil-free alternatives exist for clean air applications, eliminating compressor oil vapor contamination risks.

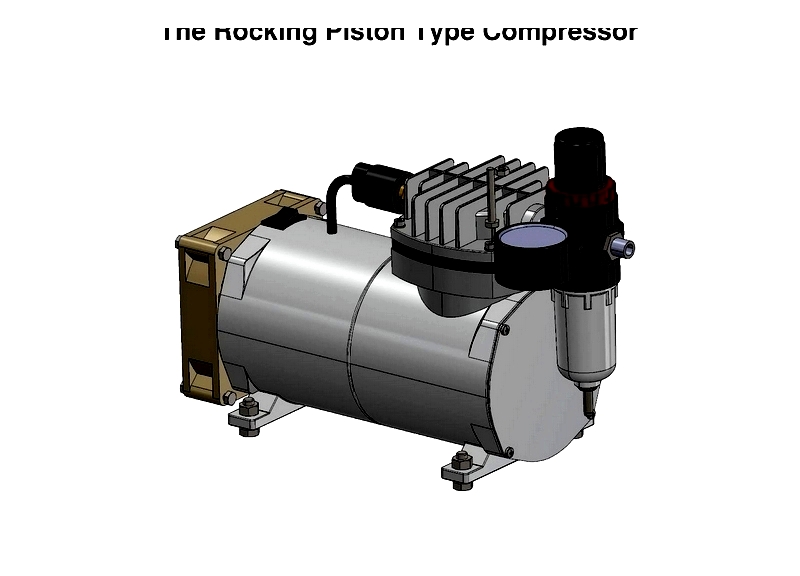

Rocking Piston Compressors

Rocking piston compressors generate pressure through a unique rocking motion of a single-rod piston assembly. Their compact, lightweight design makes them ideal for portable systems. Many models feature non-metallic, low-friction piston rings, enabling oil-free operation that prevents contamination and simplifies maintenance. With moderate pressure capabilities, these compressors excel in medical devices, analytical instruments, off-grid applications, and laboratory environments where compact size and oil-free operation are advantageous.

Diaphragm Compressors

Diaphragm compressors deliver oil-free air